Thermodynamic calculation of precipitation behavior of chromium spinel in the CaO-SiO2-MgO-Al2O3-FeO-Cr2O3 slag system

-

摘要: 不锈钢渣中铬赋存在尖晶石相中,可防止Cr6+浸出。将不锈钢中重金属Cr选择性富集、稳定化,有利于提高不锈钢渣综合利用率。本文基于熔渣非平衡凝固理论,研究了碱度、MgO及FeO含量对CaO-SiO2-MgO-Al2O3-FeO-Cr2O3不锈钢渣体系凝固过程中尖晶石相析出温度、析出量及化学组成的影响。计算结果表明:CaO-SiO2-MgO-Al2O3-FeO-Cr2O3渣析出相主要有Ca2SiO4、Ca2MgSi2O7、Ca2Al2SiO7、尖晶石相等。MgCr2O4尖晶石析出量随碱度增加而逐渐增大,提高碱度可抑制FeCr2O4析出。当温度降低至1 000 ℃,MgO含量为8%~12%时,渣中MgCr2O4尖晶石析出量最大,FeCr2O4尖晶石析出量随MgO含量的增加而降低。随着FeO含量升高,MgCr2O4尖晶石析出量降低,FeCr2O4尖晶石析出量增加,FeO不利于Cr在MgCr2O4尖晶石相中的富集。不锈钢渣中含铬尖晶石相析出的实验结果验证了热力学计算结果,碱度为1.5时,不锈钢渣中铬在尖晶石相中的富集率约为93%。Abstract: Chromium existing as a spinel phase in stainless steel slag can prevent the leaching of Cr6+ into the environment. Chromium in stainless steel is selectively enriched and stabilized, which is beneficial to improve the comprehensive utilization rate of stainless steel slag. Based on slag non-equilibrium solidification theory, the effects of basicity, MgO and FeO contents on the precipitation temperature, precipitation amount and chemical composition of the spinel phase during the solidification process of the CaO-SiO2-MgO-Al2O3-FeO-Cr2O3 stainless steel slag system were studied, respectively. The results show that the precipitated phases of CaO-SiO2-MgO-Al2O3-FeO-Cr2O3 are mainly Ca2SiO4, Ca2MgSi2O7, Ca2Al2SiO7 and spinel phase. The precipitation amount of MgCr2O4 spinel gradually increases with increasing basicity, which can inhibite FeCr2O4 precipitation. When the temperature is reduced to 1 000 ℃ and MgO content ranges from 8% to 12%, the precipitation amount of MgCr2O4 is maximum. The precipitation amount of FeCr2O4 spinel decreases with the increase of MgO. With the increase of FeO content, the precipitation amount of MgCr2O4 spinel decreases and the amount of FeCr2O4 spinel increases. FeO is not conducive to the enrichment of chromium in MgCr2O4 spinel phase. The experimental results of chromium spinel phase precipitation in stainless steel slag have verified the thermodynamic calculation results. At a basicity of 1.5, the enrichment rate of chromium in the spinel phase of the stainless steel slag is approximately 93%.

-

Keywords:

- stainless steel slag /

- chrome spinel /

- precipitated phase /

- thermodynamics analysis

-

不锈钢渣主要分为EAF渣和AOD渣,分别来自不锈钢冶炼的2个步骤:EAF冶炼和AOD炉精炼。不锈钢冶炼过程中,大量Cr元素被氧化而进入钢渣中。通常,不锈钢渣的主要成分有CaO、SiO2、MgO,以及一定量的Cr2O3(3.3%~12%)。目前,我国不锈钢渣年排放量已达1 000万吨[1-3]。不锈钢渣虽可用作建筑材料、水泥、微晶玻璃、多孔陶瓷材料等[4-8],但是目前仍有大量不锈钢渣以填埋的方式处理。在长期环境暴露下,不锈钢渣中的Cr3+可能会被氧化成毒性剧烈的Cr6+而浸出至环境中,不仅污染水和土壤,还会影响人体健康[9-11]。对不锈钢渣进行无害化处理[12],提高钢渣综合利用率,是冶金行业亟待解决的问题。不锈钢渣处理过程中,将其中重金属元素富集、固化、去除,能有效降低炉渣中重金属离子的浸出[13]。

在不锈钢渣中,Cr主要以Cr2O3、MgCr2O4、FeCr2O4、CaCr2O4、CaCrO4等形式存在。当Cr元素赋存在AB2O4形式的尖晶石中,具有很强的抗氧化能力,并且不易受酸碱侵蚀,可有效抑制铬的浸出。CAO等[14]发现不锈钢渣中的Al2O3可与MgO和Cr2O3反应生成Mg(CrxAl1-x)O4固溶体,添加Al2O3有利于降低Cr2O3在熔渣中的含量,对不锈钢渣中铬的富集和稳定有积极作用。CABRARA-REAL等[15]分析了碱度及MgO含量对CaO-MgO-SiO2-Cr2O3-CaF2渣矿物相稳定性的影响,发现碱度由1增至2时,炉渣中含Cr化合物为MgCr2O4及络合物Ca5(CrO4)3F,并且析出相中MgCr2O4尖晶石随着MgO含量增加而逐渐增多。LIN等[16]研究B2O3对不锈钢渣的改性作用时发现,随着B2O3含量增加,尖晶石相尺寸增大且大部分Cr富集在尖晶石相中。ENGSTROM等[17]研究表明,不锈钢渣中铬尖晶石析出量与炉渣中MgO、Fe2O3含量有关,MgO、Fe2O3质量的增加有利于炉渣中铬尖晶石相析出。操龙虎等[18]研究了碱度对不锈钢渣中Cr富集行为的影响,发现碱度为1.5时有利于不锈钢渣中的Cr富集于尖晶石相中,1 300 ℃条件下Cr在尖晶石相中的富集度接近100%。

由此可见,通过适当的处理使不锈钢渣中Cr元素在尖晶石相中选择性富集、稳定,对于提高不锈钢渣资源化利用率,推动冶金行业绿色制造具有重要意义。因此,本文基于EAF不锈钢渣成分及热力学原理,利用热力学软件Factsage7.3模拟CaO-SiO2-MgO-Al2O3-FeO-Cr2O3渣系凝固过程,分析碱度、MgO及FeO含量对尖晶石相析出行为的影响,为不锈钢渣中Cr元素富集及钢渣综合利用提供理论依据。

1 热力学模拟计算

1.1 不锈钢渣成分设计

根据工业冶炼不锈钢的EAF渣成分,设计本实验模拟计算渣系的基础配料方案,各组分质量分数分别为:w(CaO)=48%,w(SiO2)=32%,w(MgO)=5%,w(Al2O3)=5%,w(FeO)=5%,w(MgO)=5%,二元碱度R =w(CaO)/w(SiO2)=1.5。设计基础渣料质量为100 g,在此基础上分别改变钢渣碱度、MgO及FeO含量,研究不同组分对含铬尖晶石相析出行为的影响。模拟计算渣样配方如表 1所列。

表 1 设计渣样配方Table 1. Design slag sample formula

1.2 Factsage模拟计算条件

Sheil-Gulliver凝固模型是对熔体复杂凝固过程的一种近似模型,假设液相中的元素扩散无限快,而固相中的扩散速率为0,在冷却过程中,固液界面总是保持区域平衡状态。界面处的液相成分和固相成分可根据系统相平衡计算得到,并且固相形成后其成分保持不变,同时液相总保持均匀成分。

基于熔体的非平衡凝固理论,即Sheil-Gulliver方程,利用热力学软件Factsage 7.3,调用相应的数据库模拟CaO-SiO2-MgO-Al2O3-FeO-Cr2O3渣系凝固过程中相平衡计算,考察碱度、MgO及FeO含量对熔渣冷却过程中尖晶石相析出行为的影响。

模拟计算采用的数据库、化合物及析出相设置条件如下[16]:①数据库:FToxide,FactPS;②化合物设置:idea gas,pure solid;③液相设置:FToxide-SLAGA,FToxide-SPINA,FToxide-MeO_A,FToxide-aC2SA,FToxide-bC2SA,FToxide-Mel_A,其中设置FToxide-SLAGA中Cooling calculation为Sheil-Gulliver cooling。

设置计算凝固温度范围为1 000~2 000 ℃,凝固步长为10 ℃,设置系统计算压力为1.013 × 105 Pa。模拟计算结果以数据方式导出并进一步分析。

为验证热力学计算结果,对比不锈钢渣中含铬尖晶石相生成的实验结果,验证不锈钢渣的碱度对Cr富集行为的影响。

2 计算结果与讨论

2.1 不锈钢渣中尖晶石析出行为

利用Sheil-Gulliver凝固模型模拟计算S0基础渣系w(CaO)= 48%,w(SiO2)= 32%,w(MgO)= 5%,w(Al2O3)= 5%,w(FeO)= 5%,w(MgO)= 5%的非平衡凝固过程,结果如图 1所示,熔渣凝固过程中,主要析出相有尖晶石相、Ca2SiO4、Ca2MgSi2O7、Ca2Al2SiO7等。尖晶石相属于高温析出相[19],基础渣系S0凝固过程中,尖晶石相开始析出温度为1 800 ℃,随着温度降低,尖晶石析出量逐渐增加,在1 230 ℃时,析出量达到最大。渣中Ca2SiO4开始析出温度为1 710 ℃,温度低至1 403 ℃时,析出量不再增加,最大析出分数为43.5%。Ca2MgSi2O7、Ca2Al2SiO7约在1 360 ℃时开始析出,析出分数由0分别增至0.44%、0.40%;当温度降至1 180 ℃时,Ca2Al2SiO7析出分数达到最大,约为10.00%;当温度降至1 160 ℃时,Ca2MgSi2O7析出分数达到最大,约为12.03%。

模拟计算出的S0渣中尖晶石相成分及其析出分数如图 2所示,尖晶石相为固溶体相,主要成分为镁铬尖晶石(MgCr2O4)、铁铬尖晶石(FeCr2O4)、铝铬尖晶石(AlCr2O4),此外还有少量镁铝尖晶石(MgAl2O4)、铁铝尖晶石(FeAl2O4)等。凝固完成后,尖晶石相析出总分数为7.13%,其中,MgCr2O4含量为4.45%,FeCr2O4含量为1.53%,AlCr2O4含量为0.41%,而MgAl2O4、FeAl2O4含量仅为0.21%、0.09%。此外,尖晶石相中还包括尖晶石型CrO∙Cr2O3铬酸盐0.05%,Fe3O4反式尖晶石0.15%,以及少量MgFe2O4、CrFe2O4、CrAl2O4尖晶石相等,由于设计渣系中Al2O3含量不变,并且本文主要考察碱度、MgO及FeO含量对渣系中含铬尖晶石相的析出影响,因此将重点分析MgCr2O4、FeCr2O4尖晶石相的析出分数及开始析出温度的变化。

基础渣系S0凝固过程渣中及尖晶石相中Cr含量的变化如图 3所示,温度降至1 800 ℃时,尖晶石相中Cr含量开始增加;温度降至1 000 ℃时,S0基础渣完全凝固后,尖晶石相中Cr质量分数为3.415%。此时计算得出基础渣为5%,Cr2O3中Cr质量分数为3.421%,尖晶石相中Cr含量占总铬量99.82%,氧化物(CrOx)中Cr质量分数为0.006%,因此可认为在理论上铬元素均赋存于尖晶石相中。

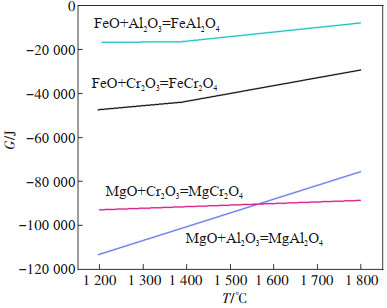

4种尖晶石相形成的标准吉布森自由能[20]如图 4所示,在一定温度下,MgCr2O4、MgAl2O4是最稳定的相。有研究表明,碱度、Al2O3含量都能影响FeCr2O4尖晶石相在渣中的溶解度[21-22]。为了使不锈钢渣中Cr元素富集在稳定的尖晶石相中,防止Cr6+浸出至环境中,通过改变渣中组元含量,使得Cr元素更多地以MgCr2O4尖晶石相析出。

2.2 碱度对尖晶石析出的影响

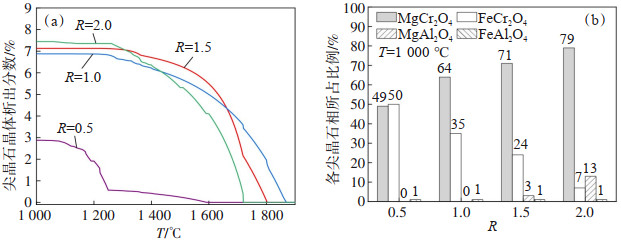

不同碱度对体系中总尖晶石析出行为及凝固完成后各尖晶石相所占比例的影响如图 5所示。由图 5(a)可见,碱度由1.0增至2.0时,尖晶石相的开始析出温度分别为1 870、1 800、1 720 ℃,随着碱度增加,尖晶石开始析出温度不断降低。碱度R=0.5时,尖晶石相的析出温度为1 590 ℃。随着不锈钢渣碱度增加,尖晶石相的析出量呈上升趋势,当碱度R = 1.0、1.5、2.0时,渣中总尖晶石相的析出分数分别为6.88%、7.13%、7.44%,其值变化不大。当碱度R=0.5时,尖晶石相的析出分数仅为2.88%。黄兵等[23]研究发现,1 300 ℃时,CaO-SiO2-FeO-Cr2O3-MgO-MnO渣系碱度从1.2增至2.0,渣系中尖晶石相的质量分数由11.5%增至26.3%,表明增加碱度可促进尖晶石相的形成,因此,可通过适当提高钢渣碱度促进尖晶石相的形成。由图 5(b)可知,当碱度增加时,尖晶石中MgCr2O4比例从49%增至79%,而FeCr2O4比例由50%降至7%,说明提高碱度有利于Cr元素以MgCr2O4尖晶石形式富集,这与CABRARA-REAL等[15]的研究结果一致。WEI等[20]开展了FeCr2O4在CaO-MgO-Al2O3-SiO2渣系中的溶解实验,研究表明高碱度有利于FeCr2O4在渣中溶解,随着炉渣碱度从0.54增至1.0,FeCr2O4尖晶石溶解度由0.33%提高至0.54%,并且温度升高,FeCr2O4溶解度逐渐增大。综上可知,提高碱度可促进MgCr2O4析出而抑制FeCr2O4析出。

碱度对渣中镁铬尖晶石、铁铬尖晶石析出行为的影响如图 6所示。由图 6(a)可知,随着碱度由0.5增至2.0,MgCr2O4尖晶石析出分数由1.37%增至5.08%;由图 6(b)可知,碱度R > 1.0时,FeCr2O4尖晶石析出量随碱度增加而降低,碱度R = 1.0、1.5、2.0时,FeCr2O4析出分数分别为2.22%、1.53%、0.43%;碱度R = 0.5时,FeCr2O4析出分数为1.36%。

2.3 MgO含量对尖晶石析出的影响

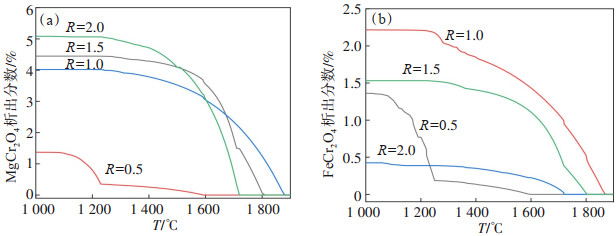

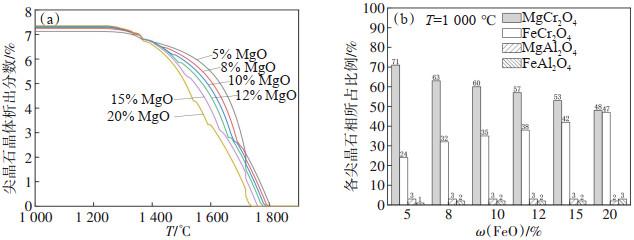

MgO含量对不锈钢渣中总尖晶石析出行为及凝固完成后各尖晶石相所占比例的影响如图 7所示。由图 7(a)可见,MgO含量由5%增至20%时,尖晶石相的开始析出温度范围为1 750~1 810 ℃,尖晶石总析出量先增加后减小。MgO含量为5%、8%、10%、12%时,所对应尖晶石析出总分数分别为7.13%、8.93%、10.80%、10.50%;MgO含量继续增加,尖晶石析出量逐渐降为8.95%,说明渣中MgO含量大于12%后,再添加MgO不能提高尖晶石析出总量,因此,在研究不锈钢中尖晶石析出实验中,控制MgO质量分数为10%~12%即可取得较好的效果。由图 7(b)可知,随着MgO含量增加,凝固结束后,不锈钢渣总尖晶石相中MgCr2O4析出量比例从71%缓慢降至56%,FeCr2O4析出比例量由24%降至3%;与此同时,MgAl2O4及FeAl2O4尖晶石比例都有所增加,当MgO含量大于10%时,尖晶石相中MgAl2O4比例大于27%,这是因为MgO与Al2O3结合能力极强(图 4),低温阶段MgAl2O4优先于MgCr2O4生成。

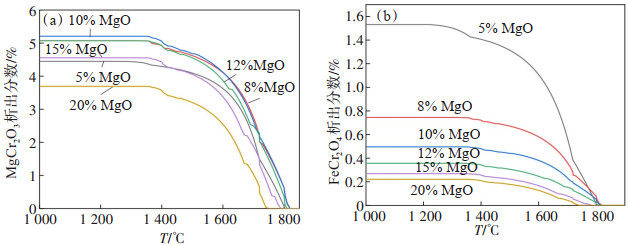

MgO含量对渣中MgCr2O4尖晶石、FeCr2O4尖晶石析出行为的影响如图 8所示。由图 8(a)可知,MgO含量为8%~12%时,渣中MgCr2O4尖晶石析出分数均大于5%;MgO含量为10%时,MgCr2O4析出分数达到最大值5.21%。MgO含量由10%增至20%时,MgCr2O4析出量逐渐降低,M5渣中MgCr2O4析出分数为3.69%,这是因为渣中大量MgO与Al2O3反应生成MgAl2O4。随着渣中MgO含量增加,MgAl2O4尖晶石析出量增大,M5渣中MgAl2O4析出量占总尖晶石析出量的35%(图 7(b))。由图 8(b)可知,不锈钢渣中FeCr2O4尖晶石析出量随MgO质量分数增加而减小。当MgO含量由5%增至20%时,FeCr2O4析出分数由1.53%降至0.21%,说明添加MgO能抑制FeCr2O4尖晶石析出。因此,控制渣中MgO质量分数范围为8%~12%时,有利于MgCr2O4尖晶石析出。

2.4 FeO含量尖晶石析出的影响

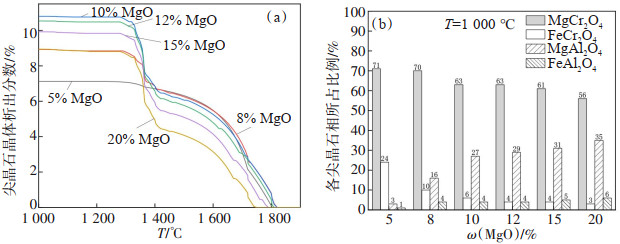

不锈钢渣中FeO含量对体系中总尖晶石析出行为及凝固完成后各尖晶石相所占比例的影响如图 9所示。由图 9(a)可知,随着FeO含量由5%增至20%,尖晶石的开始析出温度逐渐降低,析出温度为1 730~1 800 ℃。熔渣凝固过程中,随FeO含量增加,尖晶石总析出量呈现先减小再增大的趋势,在1 370 ℃达到拐点,总析出分数为7.13%~7.35%,这说明FeO含量对不锈钢渣中尖晶石的总析出量影响不大。如图 9(b)所示,随着FeO含量增加,凝固结束后,不锈钢渣中MgCr2O4尖晶石析出量比例从71%降至48%,同时FeCr2O4析出量比例由24%增至47%。MgAl2O4及FeAl2O4尖晶石比例范围均在1%~3%之间。综上可知,一定温度下,MgCr2O4比FeCr2O4稳定,MgCr2O4尖晶石是最好的固Cr相。因此,增加FeO含量不利于Cr元素以MgCr2O4尖晶石相析出。

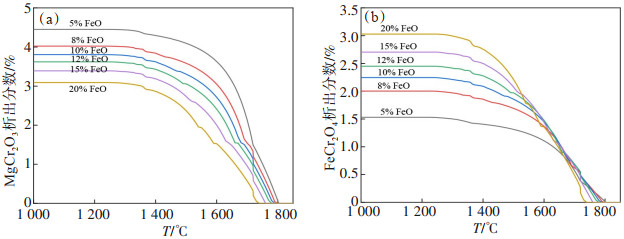

FeO含量对渣中MgCr2O4尖晶石、FeCr2O4析出量比例由24%增至47%。MgAl2O4及FeAl2O4尖晶石的析出行为的影响如图 10所示。由图 10(a)可知,随着FeO质量分数由5%增至20%,渣中MgCr2O4尖晶石析出量逐渐降低,在1 000 ℃时,S0渣中MgCr2O4析出分数最大(4.45%),F5渣中MgCr2O4析出分数为3.09%,因此,提高FeO含量可抑制MgCr2O4析出。由图 10(b)可知,随着FeO含量增加,FeCr2O4尖晶石开始析出温度不断降低;渣中FeCr2O4尖晶石析出量随着FeO质量分数增加而增大,析出量为1.53%~3.03%,增幅较大。这与佟志芳等[24]的研究结果相一致。因此,在研究Cr元素固定、富集实验中,应控制FeO含量在较低范围,才能使得Cr主要以MgCr2O4尖晶石相析出。

2.5 尖晶石析出热力学讨论

熔渣中MgO、FeO与Cr2O3反应生成尖晶石相的反应如式(1)和式(2)所示:

(1)

(2) 其反应平衡常数分别为:

根据化学反应平衡原理[25],令固相反应产物的活度为1,则式(1)反应的平衡常数为:

K1=1/(α(MgO)×α(Cr2O3));同理,式(2)反应的平衡常数为:K2=1/(α(FeO)×α(Cr2O3))。其中,反应的平衡常数K1和K2只与温度有关,当温度不变时,反应的平衡常数为定值。

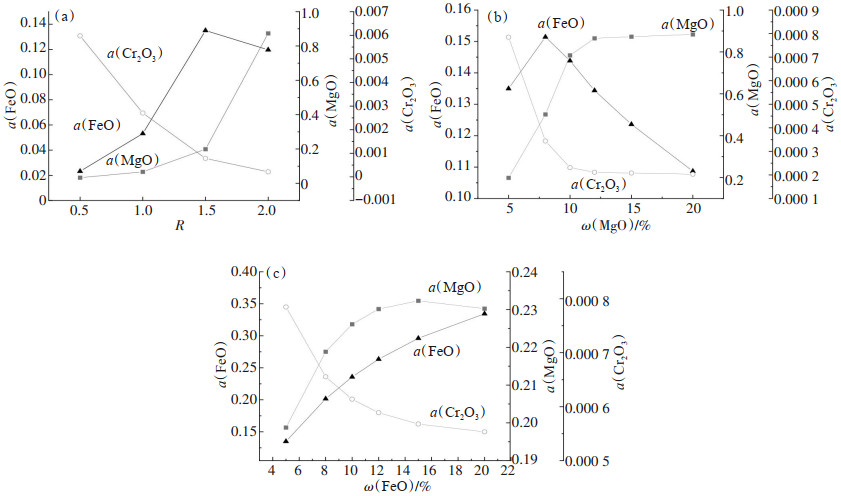

利用Factsage软件分别计算1 500 ℃温度下不同碱度、MgO及FeO含量对熔渣中MgO、FeO、Cr2O3活度的影响,如图 11所示。由图 11(a)可知,T = 1 500 ℃时,随着碱度增加,熔渣中MgO和FeO的活度均增大,MgO活度由0.034增至0.869;FeO活度先由0.024增至0.143,在碱度为2.0时稍微下降;MgO活度增幅大于FeO。在反应式(1)中,当α(MgO)升高,反应正向发生时,MgCr2O4生成量增多,渣中Cr2O3含量降低;对于反应式(2),α(Cr2O3)降低促使反应(2)逆向反应,因此提高碱度可促进MgCr2O4尖晶石的形成,抑制FeCr2O4生成。由图 11(b)可知,随着MgO含量增加,熔渣中MgO活度不断升高,在MgO含量大于12%后,再增加MgO量,其活度变化不大。利用Factsage软件Equilib模块计算出MgO含量由5%增至20%时,1 500 ℃下液态渣中MgO含量分别为3.17%、5.81%、7.60%、7.53%、7.51%、7.49%。随着MgO含量增加,平衡渣中MgO饱和溶解度保持约为7.5%,不再增加,因此,过量的MgO对渣中MgO活度影响不大。随着MgO含量增加,FeO活度先增大再减小,MgO含量为8%时达最大值;Cr2O3活度随着MgO量增加而降低。因此,不锈钢渣中FeO与Cr2O3反应能力降低,FeCr2O4尖晶石析出减少。由图 11(c)可知,FeO含量增加,MgO和FeO活度增加,而Cr2O3活度降低,并且FeO活度增幅大于MgO。对于反应式(2),当α(FeO)升高时,反应正向发生,FeCr2O4尖晶石生成量增加,渣中Cr2O3含量降低;对于反应式(1),α(Cr2O3)使得反应式(1)逆向发生,MgCr2O4尖晶石生成量减少。因此,增加FeO含量有利于FeCr2O4尖晶石析出,而抑制MgCr2O4尖晶石析出。

2.6 不锈钢渣中铬尖晶石相析出的试验对比验证

为验证不锈钢渣中铬尖晶石相析出行为,本文模拟计算了CaO-SiO2-MgO-Al2O3-FeO-Cr2O3六元渣系冷却过程,对比文献[26]中CaO-SiO2-9%MgO-4%Al2O3-3%FeO-5%Cr2O3不锈钢渣中含铬尖晶石相生成的实验结果,通过热力学分析和高温实验模拟,探讨碱度对铬富集行为的影响。实验结果如图 12所示,当不锈钢钢渣在1 300 ℃水冷时,碱度对尖晶石的析出行为影响显著。当碱度为1.0时,尖晶石相析出量约为4.2%,此时铬主要富集于尖晶石相中;当碱度提高到1.5时,尖晶石相析出量明显提高(约为8.4%),Cr的富集度也明显提高;当碱度进一步提高至2.0时,由于部分Cr赋存于方镁石相中析出,导致尖晶石相析出量略有下降(约为7.8%),同时Cr在尖晶石相中的富集度也略有下降。热力学模拟计算的尖晶石析出量也如图 12所示,尖晶石析出量随不锈钢渣碱度的变化趋势与实验结果保持一致。由于实验过程中部分Cr固溶在硅酸二钙相中[26],导致热力学计算出的尖晶石相析出量与实验结果存在少许差异。模拟计算得出钢渣碱度为1.5时,有利于不锈钢渣中含铬尖晶石相的形成,1 300 ℃下Cr的富集率约为93%。

3 结论

1)不锈钢渣凝固过程中主要析出相包括Ca2SiO4、Ca2MgSi2O7、Ca2Al2SiO7、尖晶石相等,尖晶石相主要由MgCr2O4及FeCr2O4构成。

2)碱度增加时,尖晶石开始析出温度降低,总尖晶石析出量减少。在1 000 ℃时,尖晶石中MgCr2O4比例从49%增至79%,而FeCr2O4比例由50%降至7%。MgCr2O4尖晶石析出量随碱度增加而逐渐增大,提高碱度可抑制FeCr2O4析出。

3)MgO含量为8%~12%时,凝固终点渣中MgCr2O4尖晶石析出量最大,FeCr2O4尖晶石析出量随着MgO含量增加而降低。MgCr2O4尖晶石析出量随着FeO含量升高而降低,FeCr2O4尖晶石析出量随着FeO含量升高而增加,添加FeO不利于Cr在MgCr2O4尖晶石相中富集。

4)不锈钢渣中含铬尖晶石相析出的热力学计算结果与高温实验模拟结果保持一致。碱度为1.5时,不锈钢渣中铬在尖晶石相中的富集率约为93%。

-

表 1 设计渣样配方

Table 1 Design slag sample formula

-

[1] 汪正洁, 杨健, 潘德安, 等. 不锈钢渣资源化利用技术研究现状[J]. 钢铁研究学报, 2015, 27(2): 1-6. https://www.cnki.com.cn/Article/CJFDTOTAL-IRON201502001.htm [2] 邵立志. 不锈钢渣处理现状及未来展望[J]. 铸造技术, 2021, 42(3): 234-238. doi: 10.16410/j.issn1000-8365.2021.03.018 [3] 李建立, 徐安军, 贺东风, 等. 不锈钢渣的无害化处理和综合利用技术研究[J]. 炼钢, 2010, 26(6): 74-77. https://www.cnki.com.cn/Article/CJFDTOTAL-LGZZ201006023.htm [4] MATSUURA H, YANG X, LI G Q, et al. Recycling of ironmaking and steelmaking slags in Japan and China[J]. International Journal of Minerals, Metallurgy and Materials, 2022, 29(4): 739-749. doi: 10.1007/s12613-021-2400-5

[5] SHEN H T, FORSSBERG E. An overview of recovery of metals from slags[J]. Waste Management, 2003, 23(10): 933-949. doi: 10.1016/S0956-053X(02)00164-2

[6] 武绍文, 张延玲, 张帅, 等. 铬元素固化机理及利用不锈钢工业含铬固废制备无机材料研究进展[J]. 工程科学学报, 2021, 43(12): 1725-1736. https://www.cnki.com.cn/Article/CJFDTOTAL-BJKD202112013.htm [7] 佟志芳, 范佳乐, 曾庆钋, 等. 利用金属尾矿制备泡沫微晶玻璃的研究现状及展望[J]. 有色金属科学与工程, 2020, 11(2): 34-41. doi: 10.13264/j.cnki.ysjskx.2020.02.005 [8] LI Y, TANG W T, SHENG H J, et al. Generation of pyroxene-based porous ceramics from steel refining slag[J]. ISIJ International, 2021, 61(7): 2041-2047.

[9] 甄常亮, 那贤昭, 齐渊洪, 等. 不锈钢渣毒性浸出特征及无害化处置现状[J]. 钢铁研究学报, 2012, 24(10): 1-5. https://www.cnki.com.cn/Article/CJFDTOTAL-IRON201210000.htm [10] SAMADA Y, MIKI T, HINO M. Prevention of chromium elution from stainless steel slag into seawater[J]. ISIJ International, 2011, 51(5): 728-732.

[11] PILLAYK, VON BLOTTNITZ H, PETERSENJ. Ageing of chromium(Ⅲ)-bearing slag and its relation to the atmospheric oxidation of solid chromium(Ⅲ)-oxide in the presence of calcium oxide[J]. Chemosphere, 2003, 52(10): 1771-1779.

[12] 佟志芳, 曾庆钋, 王佳兴, 等. 利用尾矿制备地聚物研究现状及展望[J]. 有色金属科学与工程, 2021, 12(4): 96-103. doi: 10.13264/j.cnki.ysjskx.2021.04.013 [13] 何哲祥, 张亚星, 李雷. 基于高炉渣的重金属废水净化材料的研制[J]. 有色金属科学与工程, 2019, 10(2): 47-51. doi: 10.13264/j.cnki.ysjskx.2019.02.007 [14] CAO L H, LIU C J, ZHAO Q, et al. Effect of Al2O3 modification on enrichment and stabilization of chromium in stainless steel slag[J]. Journal of Iron and Steel Research, International, 2017, 24(3): 258-265.

[15] CABRERA-REAL H, ROMERO-SERRANO A, ZEIFERT B, et al. Effect of MgO and CaO/SiO2 on the immobilization of chromium in synthetic slags[J]. Journal of Material Cycles and Waste Management, 2012, 14(4): 317-324.

[16] LIN Y, LUO Q Y, YAN B J, et al. Effect of B2O3 addition on mineralogical phases and leaching behavior of synthetic CaO-SiO2-MgO-Al2O3-CrOx slag[J]. Journal of Material Cycles and Waste Management, 2020, 22: 1208-1217.

[17] ENGSTROM F, ADOLFSSON D, YANG Q, et al. Crystallization behaviour of some steelmaking slags[J]. Steel Research International, 2010, 81(5): 362-371.

[18] 操龙虎, 刘承军, 赵青, 等. 碱度对不锈钢渣中铬的迁移及富集行为的影响[C]//第十九届(2016年)全国炼钢学术会议大会报告及论文摘要集. 长沙, 2016: 183. [19] 卢嘉枫, 李晶, 史成斌, 等. 304不锈钢AOD冶炼过程脱碳保铬和铬烧损的研究[J]. 江西冶金, 2021, 41(1): 12-18. https://www.cnki.com.cn/Article/CJFDTOTAL-JXYE202101003.htm [20] WEI K J, WANG L J, LIU S Y, et al. Dissolution kinetics of synthetic FeCr2O4 in CaO-MgO-Al2O3-SiO2 slag[J]. ISIJ International, 2022, 62(4): 617-625.

[21] 刘岩, 姜茂发, 许力贤. 铬矿在CaO-SiO2-MgO-Al2O3渣系中的熔解行为[J]. 过程工程学报, 2007, 7(2): 322-326. https://www.cnki.com.cn/Article/CJFDTOTAL-HGYJ200702022.htm [22] LI Z, KATO C, KOBAYASHI Y. Determination of solubility of chromium oxide in the CaO-SiO2-Cr2O3 slag system at 1873 K under moderately reducing conditions[J]. ISIJ International, 2021, 61(9): 2340-2344.

[23] 黄兵, 祝明妹, 钟勇, 等. CaO-SiO2-FeO-Cr2O3-MgO-MnO渣系物相组成的热力学计算[J]. 钢铁研究学报, 2019, 31(8): 718-725. https://www.cnki.com.cn/Article/CJFDTOTAL-IRON201908004.htm [24] 佟志芳, 贾志恒, 曾庆钋, 等. 炉渣组分对CaO-MgO-Al2O3-SiO2-Cr2O3-FeO-TiO2渣系中铬尖晶石相析出影响的热力学[J]. 有色金属科学与工程, 2020, 11(3): 1-10. doi: 10.13264/j.cnki.ysjskx.2020.03.001 [25] 黄希祜. 钢铁冶金原理[M]. 4版. 北京: 冶金工业出版社, 2013: 22-25. [26] 操龙虎, 刘承军, 赵青, 等. 不同碱度下不锈钢渣中铬的迁移及富集行为[J]. 炼钢, 2016, 32(6): 73-78. https://www.cnki.com.cn/Article/CJFDTOTAL-LGZZ201606015.htm -

期刊类型引用(3)

1. 佟志芳,王佳兴,许聪聪,谢肇勋. TiO_2和碱度对CaO-MgO-Al_2O_3-SiO_2-Cr_2O_3-Fe_2O_3-TiO_2渣系黏度和结构及氧化铬溶解度的影响. 有色金属科学与工程. 2024(03): 332-341 .  本站查看

本站查看

2. 陈均优,张庆猛,周敏,赵艳芸. 不同TiO_2和Nb_2O_5含量对BaO-SrO-PbO-TiO_2-Nb_2O_5-SiO_2玻璃陶瓷介电性能的影响. 稀有金属. 2024(10): 1502-1509 .  百度学术

百度学术

3. 马行娟,徐昌华. 纳米材料制备的气体传感器对装饰环境中乳胶漆化学检测试验. 粘接. 2023(11): 87-90 .  百度学术

百度学术

其他类型引用(1)

下载:

下载: