Effects of Ni on structure and mechanical properties of Al-Cu-Mn alloy

-

摘要: 为研究添加Ni元素对Al-5.0Cu-0.6Mn合金组织及力学性能的影响,通过硬度试验、拉伸力学试验及摩擦磨损试验对合金力学性能进行研究;采用扫描电子显微镜、激光共聚焦显微镜及透射电子显微镜对合金微观组织进行检测分析。结果表明:向Al-5.0Cu-0.6Mn合金中添加Ni元素后,由于Al3CuNi相析出的强化作用,并且与基体结合良好的增强相颗粒能均匀分布于合金中,使得合金硬度和强度大幅提高,摩擦磨损深度显著降低,综合力学性能得到有效的提升。当Ni元素的添加量为0.3%(质量分数)时,由于T相(Al20Cu2Mn3)和Al3CuNi相分布比较均匀,合金综合性能较为理想,其HV硬度、抗拉强度、摩擦磨损系数分别为126.4 MPa、395.2 MPa、0.12。

-

关键词:

- Al-Cu-Mn合金 /

- Ni元素 /

- 力学性能 /

- 显微组织

Abstract: To study the effects of adding Ni on the tissues and mechanical properties of Al-5.0Cu-0.6Mn alloy, the mechanical properties of the alloy were studied by hardness tests, tensile mechanical tests and friction and wear tests, and the alloy microtissues were detected and analyzed by scanning electron microscope, laser confocal microscope and transmission electron microscopy. The results show that after adding Ni to Al-5.0Cu-0.6Mn alloy, the hardness and strength of the alloy are greatly improved, the frictional wear depth significantly reduced, and the comprehensive mechanical properties effectively improved, due to the reinforcement of Al3CuNi phase precipitation and the enhanced phase particles well combined with the matrix being uniformly distributed in the alloy. When the added quantity of Ni is 0.3% (referring to the mass fraction), due to rather evenly distributed T phase (Al20Cu2Mn3) and Al3CuNi phase, the comprehensive performance of the alloy is relatively ideal, with HV hardness of 126.4 MPa, tensile strength 395.2 MPa, and friction and wear coefficient 0.12, respectively.-

Keywords:

- Al-Cu-Mn alloy /

- Ni element /

- mechanical properties /

- microtissue

-

Al-Cu-Mn合金由于具有密度低、比强度高、价格低廉、工艺性能好等特点,同时具有良好的力学性能与耐蚀性能,是轻质结构材料的首选之一,在航空航天、汽车制造等领域得到广泛的应用[1-4]。目前全球绿色经济的发展要求和工业材料的工作环境越来越严格,传统Al-Cu-Mn合金的应用受到了一定程度的限制。因此,提高Al-Cu-Mn合金的综合性能是亟待解决的问题[5-7]。

国内外部分学者通过添加微量元素来改善Al-Cu系合金的综合性能,这种工艺方法是发展和开发新型的高综合性能铝合金的有效途径[8-11]。铝合金的力学性能、抗腐蚀性能等在很大程度上都取决于其组织及相的特征,尤其是各析出相的类型、尺寸及分布状态等[12]。在Al-Cu-Mn定向凝固合金中,合金共晶组织由θ相(Al2Cu)和T相(Al20Cu2Mn3)2相组成,2相位于铝基体(α-Al)中。Al和Al2Cu相有规律地生长,而Al20Cu2Mn3相则在Al-Al2Cu共晶相之间随机生长。Cu/Mn含量和比例对Al-Cu-Mn合金的凝固有较大影响。在较低Cu/Mn含量和比例的合金中,合金凝固过程中仅在枝晶间区域形成少量的θ相(Al2Cu)和呈棒状的T相(Al20Cu2Mn3)。在较高Cu/Mn含量和比例的合金中,除上述相外,在枝晶间区域还出现大量的骨状和圆形多相组织,由α-Al、θ相(Al2Cu)和T相(Al13Cu4Mn3)组成,多相组织中的Al13Cu4Mn3相呈现大颗粒状[13-14]。

对于铸造Al-Cu系合金而言,合金还需要具有较好的流动性。因此,选择合适的元素控制析出相的特征是获得铝合金优良性能的关键。WU等[15]经系统地研究后发现微量Sc的添加促进了Al-Cu系合金中θ相(Al2Cu)的析出,添加Sc后的Al-Cu系合金力学性能得以提升。MANDAL等[16]研究Ag元素对Al-Cu系合金力学性能的影响,发现当Ag元素添加量为0.07%(质量分数)时,合金在具有较高的强度与硬度的同时也具有较好的延展性。MENG等[17]研究了V元素对Al-Cu-Mn合金组织、析出行为和力学性能的影响。结果发现V的添加促进了α-Al基体中θ相(Al2Cu)的生长速度,同时延缓了T相(Al20Cu2Mn3)的析出,从而达到力学性能的优化。SUN等[18]发现在Al-Cu系合金中添加Sc和Zr能抑制再结晶,细化晶粒,阻止Cu元素沿晶界偏析,增加晶界析出物间距,从而有效提升合金综合性能。ZUO等[19]在铸态Al-Si-Cu-Ni合金中观察到条状和鱼骨状的δ-Al3CuNi相,鱼骨状δ-Al3CuNi相由许多独立的短棒组成。随着δ-Al3CuNi相数量的增加,合金的抗拉、屈服强度提高,综合性能得以提升,这对优化Al-Cu-Mn合金的成分和改善其性能具有重要意义。

本文沿此方向进一步深入探索。采用扫描电镜(SEM)和透射电镜(TEM)对不同Ni元素添加量的Al-Cu-Mn合金进行显微组织观察,通过硬度试验、拉伸力学试验及摩擦磨损试验对合金力学性能进行研究。

1 试验材料及方法

在Al-Cu系合金中,随着Cu含量的增加,Al-Cu系合金的伸长率降低。超出最大固溶极限的铝中过量的Cu以金属间颗粒的形式在晶界析出,这些颗粒的尺寸和体积分数随Cu含量的增加而增大,从而影响合金的力学性能。因此,Al-Cu系合金中的Cu含量最好在5.6%以下。Mn含量会对Al-Cu系合金力学性能产生一定程度的影响,合金的强度和硬度与Mn含量呈相同趋势变化,但韧性与Mn含量呈相反趋势变化。当合金中Mn含量超过1.6%时,铸造合金中会形成粗大的Al6Mn析出相,对合金的力学性能产生消极影响。

本实验采用真空熔炼制备的铸造Al-Cu-Mn合金,所设计的合金化学成分:Cu为5.0%(质量分数,下同),Mn为0.6%,余量为Al。向Al-Cu-Mn合金中分别添加0.1%、0.2%、0.3%、0.4%的Ni,并与未添加Ni的Al-Cu-Mn合金进行空白对照,制备出5组不同Ni含量的合金试样。本实验所用合金的实际成分如表 1所列。

表 1 Al-Cu-Mn-Ni合金成分表Table 1. Al-Cu-Mn-Ni alloy composition table

硬度试验采用UH250型数显维氏硬度测试仪,每个试样测试5次,取平均值。拉伸试验采用MTS型万能拉伸试验机,拉伸试样厚度为3 mm、标距长度为20 mm,拉伸速率为2 mm/min。摩擦磨损试验采用MMU-5G材料端面高温摩擦磨损试验机,常温下采用销盘式进行实验,转速为60 r/min,时间为10 min,载荷为200 N,摩擦磨损试样为边长为10 mm的正方体。测试结束后,采用TM-3030扫描电子显微镜观察各组合金试样的摩擦磨损表面形貌;采用激光共聚焦显微镜观察各组合金试样摩擦磨损表面的三维形貌;采用JEM-2100透射电子显微镜对合金试样进行显微组织观察、高分辨成像、电子衍射分析。与能谱仪结合,在观察组织的同时进行材料的微区成分的点成分分析。透射试样需要进行预处理,将合金冲压成直径3 mm的圆片,将其手动研磨至厚度低于50 μm的圆片。然后使用电解双喷的制备方法,设置好电解液、电压、温度将样品减薄至出现足够薄区。

2 结果与讨论

2.1 硬度、拉伸性能

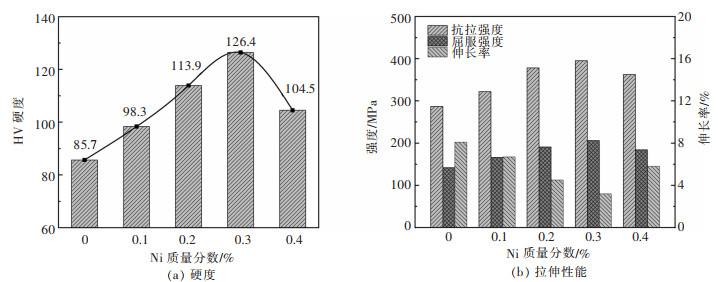

添加不同Ni含量的Al-5.0Cu-0.6Mn合金的力学性能如图 1所示。从图 1(a)中可以看出,未添加Ni的Al-5.0Cu-0.6Mn合金HV硬度值为85.7。当添加0.1%、0.2%、0.3%、0.4%(质量分数)Ni元素时,合金HV硬度值分别为98.3、113.9、126.4、104.5。随着Ni添加量的增加,合金硬度值呈现逐渐上升的趋势。当添加0.4% Ni时,合金硬度值反而下降。由此可见,由于Ni的添加,合金硬度发生显著变化。当Ni的添加量为0.3%时,合金HV硬度值为126.4,较其他含量制备的合金最高,其硬度值较为理想。

从图 1(b)中可以看出,未添加Ni的Al-5.0Cu-0.6Mn合金抗拉强度、屈服强度和伸长率分别为286.9 MPa、142.1 MPa、8.1%。随着Ni添加量的增加,合金抗拉强度、屈服强度值呈现先大幅度上升后略微下降的趋势,伸长率呈现先下降后上升的趋势。当添加0.3% Ni时,合金的抗拉强度由286.9 MPa增加到395.2 MPa,增幅为27.4%;合金的屈服强度强度由142.1 MPa增加到206.5 MPa,增幅为31.1%;合金的伸长率由8.1%下降到3.2%,降幅为60.0%。当添加0.4% Ni时,合金的抗拉强度由395.2 MPa下降到362.7 MPa,降幅为8.2%;合金的屈服强度由206.5 MPa下降为184.2 MPa,降幅为10.8%;合金的伸长率由3.2%增加到5.8%,增幅为41.3%。由此可见,由于Ni的添加,合金的拉伸性能发生显著提升。当Ni的添加量为0.3%时,合金的抗拉强度、屈服强度值较其他含量制备的合金高,其拉伸性能较好。

2.2 摩擦磨损性能

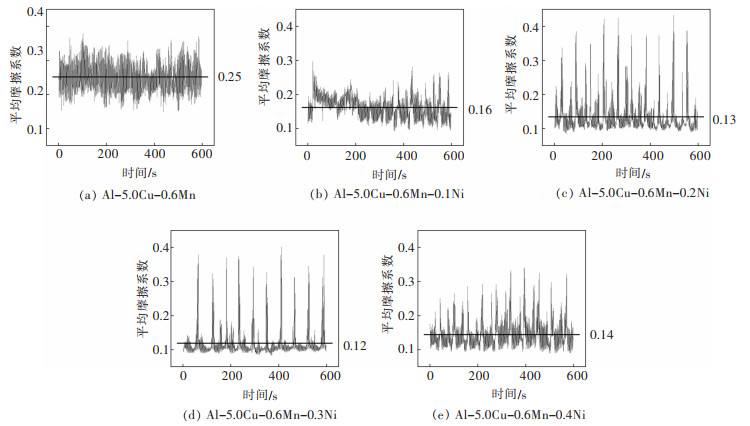

图 2所示为不同Ni含量Al-5.0Cu-0.6Mn合金摩擦磨损试验过程中摩擦系数随时间变化的关系曲线。如图 2(a)所示,未添加Ni的Al-5.0Cu-0.6Mn合金的摩擦系数波动趋势较大,平均摩擦系数为0.25。如图 2(b)—图 2(e)所示,当添加0.1%、0.2%、0.3%、0.4% Ni时,合金平均系数值分别为0.16、0.13、0.12、0.14。随着Ni添加量的增加,合金的摩擦系数随时间波动趋势减小,平均摩擦系数逐渐减小。但当添加0.4% Ni时,合金的摩擦系数波动趋势略微增大,平均摩擦系数反而增大。由此可见,当Ni的添加量为0.3%时,合金的摩擦系数随时间变化虽偶尔出现波动,但总体上较其他含量制备的合金更平稳。此时合金在摩擦磨损试验过程中表现出相对较平稳的振幅与相对较低的摩擦系数,合金表面磨损程度较轻,耐磨性能较理想。

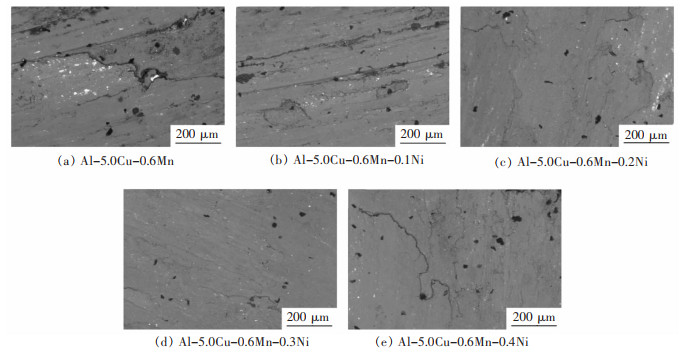

图 3所示为不同Ni含量Al-5.0Cu-0.6Mn合金摩擦磨损的表面形貌。如图 3(a)所示,未添加Ni的Al-5.0Cu-0.6Mn合金的磨损表面有较深的磨损痕迹,合金表面磨损程度比较严重。在摩擦磨损过程中,由于合金磨损表面上存在硬颗粒或粗糙峰,从而引起犁沟作用导致合金表面上留下沟槽,即在合金磨损表面上由于微观切削作用产生了沿摩擦方向的擦伤或沟痕。从图 3(b)、图 3(c)可以看出,添加Ni元素后的合金磨损表面上的磨痕明显减轻,并出现波浪纹状磨损图案,合金摩擦磨损情况得到缓解。当添加0.3% Ni时,如图 3(d)所示,合金磨损表面仅出现一小部分波纹状磨损图案,其他大多数为平行于滑动方向的轻微磨痕,较明显的粗大磨痕基本消失且磨痕较为均匀,合金的耐磨性能较好。当添加0.4% Ni时,如图 3(e)所示,合金磨损表面上再次出现较明显的磨痕,波纹状磨损图案增多,合金耐磨性能受到影响。由于Ni的添加,合金摩擦磨损情况得到有效改善。当Ni的添加量为0.3%时,合金表面磨损程度较其他含量制备的合金更轻,其耐磨性能较好。

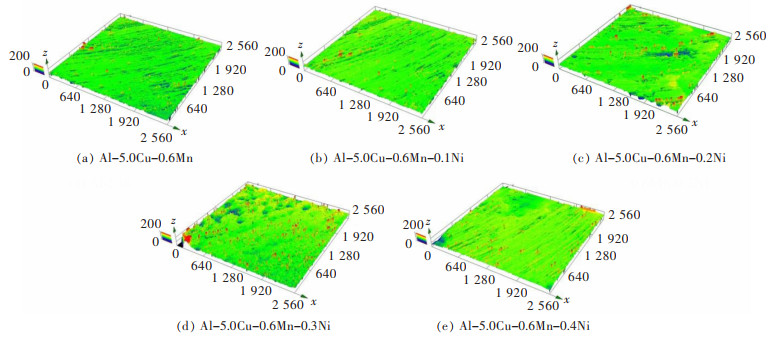

对摩擦磨损试验后的合金试样进行三维轮廓表征,以便更清晰地观察试样表面的磨损程度和研究磨损机制。图 4所示为不同Ni含量Al-5.0Cu-0.6Mn合金磨损表面的三维形貌。图 4中颜色趋近于红色的区域越多代表磨损量越小,颜色趋近于蓝色的区域越多代表磨损量越大。如图 4(a)所示,未添加Ni的Al-5.0Cu-0.6Mn合金磨损表面的三维形貌中绿色区域占主体部分,并出现部分蓝色区域,红色区域极少。此时合金磨损面积较大,磨痕深度较深,磨损量较大。从图 4(b)、图 4(c)可以看出,当添加0.1%、0.2% Ni时,合金磨损表面的三维形貌中绿色区域依旧占主体部分,蓝色区域减少,红色区域略微增多。合金磨损表面的磨痕深度逐渐减小,磨损量逐渐减少,合金摩擦磨损情况得到改善。如图 4(d)所示,当添加0.3% Ni时,合金磨损表面的三维形貌中呈现大面积的红色区域,蓝色区域极少。此时合金磨损表面的粗大磨痕基本消失,磨损量较少,合金的耐磨性能较好。当添加0.4% Ni时,如图 4(e)所示,合金磨损表面的三维形貌中红色区域减少。此时合金磨损表面上再次出现明显的磨痕,磨损量增加,合金耐磨性能有所下降。由此可见,由于Ni的添加,合金磨损量逐渐减少,耐磨性能得到提升。当Ni的添加量为0.3% 时,合金在摩擦磨损试验过程中产生的磨损量较小,其耐磨性能较好。

2.3 显微组织

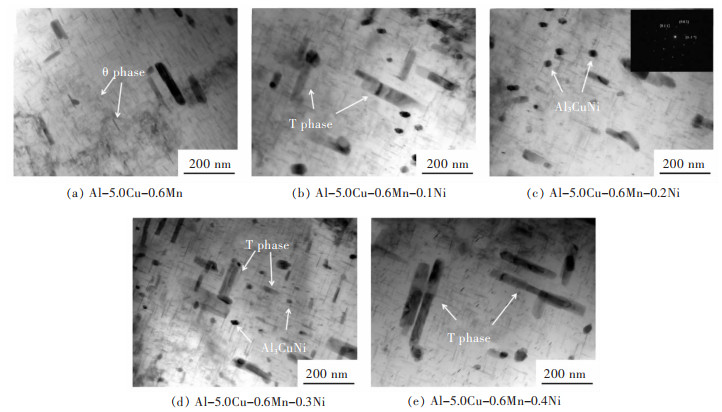

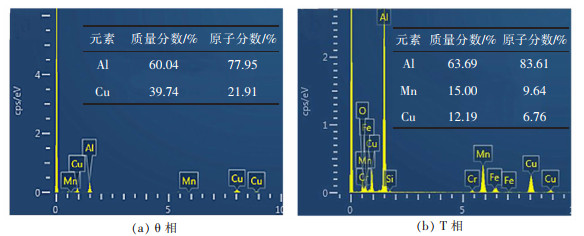

图 5所示为添加不同Ni含量的Al-5.0Cu-0.6Mn合金的微观组织形貌。Al-Cu-Mn合金的析出顺序为:SSS(过饱和固溶体)→GP区→θ′′→θ′→θ(Al2Cu)[20]。当未添加Ni时,如图 5(a)所示,合金中主要析出相为细针状θ相(Al2Cu),数量较多且分布均匀,相组成如图 6(a)所示。此时合金基体力学性能较差,强度较低且易发生塑性变形。在摩擦磨损实验中,对磨材料可以较深地压入基体,导致合金磨损表面的磨损深度及磨损量都有所增加。在滑动磨损试验条件下使得合金表面形成较深的磨损痕迹,呈现为如图 3(a)所示的磨损形貌特点。

当添加0.1% Ni时,如图 5(b)所示,合金中θ相数量减少,出现少量棒状T相(Al20Cu2Mn3),相组成如图 6(b)所示。对于Al-Cu系合金而言,棒状T相(Al20Cu2Mn3)是较常见的金属间化合物[21-22]。随着Ni元素的添加,合金中同时出现富Ni相(Al3CuNi),电子衍射分析如图 5(c)所示,呈块状分布[23]。如图 5(c)、图 5(d)所示,随着Ni添加量的增加,合金中棒状T相与细针状θ相的数量减少,同时Al3CuNi相的数量显著增加。此过程消耗了合金中大量的Cu溶质,从而降低了凝固铝合金溶液中Cu溶质的过饱和度。因此合金中棒状T相(Al20Cu2Mn3)析出量呈一定幅度降低[24]。当添加0.3% Ni元素时,合金中T相数量较少且尺寸较小,Al3CuNi相数量较多且分布情况较好。如图 5(e)所示,当添加0.4% Ni时,T相的尺寸反而变得粗大,Al3CuNi相数量有所减少。微量元素的过量添加会通过形成粗大金属间化合物相而对合金力学性能产生消极作用[17]。由此可见,当Ni的添加量为0.3%时,各类析出相的尺寸细小,其比例与数量较其他添加含量制备的合金更好。

金属材料的性能主要由其内部组织所决定,合金中形成的金属间化合物总量随着Ni的添加而增加。由于Ni的添加,合金中绝大多数T相和Al3CuNi相均溶解到α-Al相基体中,形成过饱和固溶体起固溶强化作用。同时添加Ni后合金中T相和Al3CuNi相尺寸变小、形状变得更加圆整、更加规则,有效减小了拉伸变形过程中的应力集中。当Ni的添加量为0.3%时,合金晶粒更为细小,第二相尺寸较小且均匀分布,合金强度和硬度显著提高。未添加Ni的Al-5.0Cu-0.6Mn合金中虽产生稳定的增强相,但在摩擦磨损过程中,由于较大的磨损深度和磨损量,部分增强相颗粒会随基体合金一起被切削而发生剥离,因此在未添加Ni的Al-5.0Cu-0.6Mn合金中,增强相阻碍对磨材料对摩擦件磨损的能力较弱,导致合金磨损程度较严重。向Al-5.0Cu-0.6Mn合金中添加Ni后,合金中出现分布情况良好的富Ni相(Al3CuNi),金属材料中第二相粒子从过饱和固溶体里析出而引起应变,从而引起金属点阵的强化。由于块状Al3CuNi相析出的强化作用,合金基体硬度与强度得到大幅度提升,摩擦件表面的磨痕深度显著降低,合金摩擦磨损情况明显改善。同时合金中析出的增强相颗粒均匀分布于合金中,更加有效地阻碍对磨材料对摩擦件的磨损,并且能充分发挥增强相支撑对磨材料以阻碍其磨损基体的积极作用,因此合金抗摩擦磨损的能力得到提高。当添加0.3% Ni时,合金中析出的Al3CuNi相较其他添加含量制备的合金数量多,Al3CuNi析出相的强化效果较为理想。此时合金中析出的增强相颗粒均匀分布于合金中,且稳定性较好,阻碍对磨材料对摩擦件的磨损效果较好,因此添加0.3% Ni的Al-5.0Cu-0.6Mn合金硬度、强度及耐磨性能较为理想。

如上述实验结果所示,合金试样的硬度、强度与耐磨程度均随Ni添加量的增加而增加。这表明合金中形成的金属间化合物对力学性能强化有一定的作用,这与Al-Si-Cu-Ni合金的结果一致[25-26]。

3 结论

1)通过添加Ni元素可有效改善Al-5.0Cu-0.6Mn合金的微观组织形貌,棒状T相与细针状θ相的数量减少,同时Al3CuNi相的数量显著增加。添加Ni元素后的合金组织致密,析出相分布情况良好。

2)添加Ni元素后的Al-5.0Cu-0.6Mn合金中形成的金属间化合物对耐磨性能强化有明显作用。合金磨损表面的磨痕深度显著降低,合金中Al3CuNi增强相颗粒可充分发挥其支撑作用以阻碍对受磨材料的磨损,合金耐磨性能明显改善。

3)随着Ni元素添加量的增加,合金力学性能得到提升,通过添加Ni元素可制备综合性能优异的Al-5.0Cu-0.6Mn合金。添加0.3% Ni元素的Al-5.0Cu-0.6Mn合金综合性能较理想,HV硬度、抗拉强度、摩擦磨损系数分别为126.4 MPa、395.2 MPa、0.12。

-

表 1 Al-Cu-Mn-Ni合金成分表

Table 1 Al-Cu-Mn-Ni alloy composition table

-

[1] CHENG W J, LIU W, FAN X B, et al. Cooperative enhancements in ductility and strain hardening of a solution-treated Al-Cu-Mn alloy at cryogenic temperatures[J]. Materials Science and Engineering A, 2020, 790: 1-14. https://www.sciencedirect.com/science/article/pii/S0924013615301680

[2] WANG J, LU Y L, ZHOU D S, et al. Influence of homogenization on microstructural response and mechanical property of Al-Cu-Mn alloy[J]. Materials, 2018, 11(6): 1-17. https://www.mdpi.com/1996-1944/11/6/914

[3] 林波, 张卫文. Fe含量对挤压铸造Al-Cu合金组织演变及高温力学性能的影响[J]. 中国有色金属学报, 2017, 27(5): 885-893. doi: 10.19476/j.ysxb.1004.0609.2017.05.002 [4] DONG F, YI Y P, HUANG C, et al. Influence of cryogenic deformation on second-phase particles, grain structure, and mechanical properties of Al-Cu-Mn alloy[J]. Journal of Alloys and Compounds, 2020, 827: 1-33.

[5] GUO T B, ZHANG F, DING W W, et al. Effect of micro-scale Y addition on the fracture properties of Al-Cu-Mn alloy[J]. Chinese Journal of Mechanical Engineering, 2018, 31(6): 217-227. doi: 10.1186/s10033-018-0282-x

[6] 余芳, 徐道芬, 陈送义, 等. Cu含量对Al-Cu-Mn合金力学性能各向异性的影响[J]. 材料研究学报, 2018, 32(11): 853-860. doi: 10.11901/1005.3093.2017.766 [7] 赵愈亮, 孟凡生, 张杨, 等. Si含量对挤压铸造Al-5.0Cu-0.6Mn-0.7Fe合金显微组织和力学性能的影响[J]. 中国有色金属学报, 2015, 25(11): 3040-3050. doi: 10.19476/j.ysxb.1004.0609.2015.11.011 [8] 李作为, 刘晓腾, 郝海. Gd对ZL205A合金显微组织和力学性能的影响[J]. 铸造技术, 2013, 62(6): 549-553. https://www.cnki.com.cn/Article/CJFDTOTAL-ZZZZ201306019.htm [9] TOSCHI S, BALDUCCI E, CESCHINI L, et al. Effect of Zr addition on overaging and tensile behavior of 2618 aluminum alloy[J]. Metals - Open Access Metallurgy Journal, 2019, 9(2): 1-10.

[10] TIAN W, HU M N, CHEN X H, et al. Effect of Ce addition on microstructure, mechanical properties and corrosion behavior of Al-Cu-Mn-Mg-Fe alloy[J]. Mater Res Express, 2020, 7(3): 1-13.

[11] KAIRY S K, ROUXEL B, DUMBRE J, et al. Simultaneous improvement in corrosion resistance and hardness of a model 2xxx series Al-Cu alloy with the microstructural variation caused by Sc and Zr additions[J]. Corrosion Science, 2019, 158(9): 1-40.

[12] 付俊伟, 崔凯, 王江春. Al-Cu系耐热铝合金的研究进展[J]. 中国有色金属学报, 2021, 31(7): 1827-1841. https://www.cnki.com.cn/Article/CJFDTOTAL-ZYXZ202107014.htm [13] KAYGLSLZ Y. Microstructure characterization and hardness of Al-Cu-Mn eutectic alloy[J]. China Foundry, 2018, 15(5): 390-396. doi: 10.1007/s41230-018-7225-0

[14] DAR S M, LIAO H, XU A. Effect of Cu and Mn content on solidification microstructure, T-phase formation and mechanical property of Al-Cu-Mn alloys[J]. Journal of Alloys and Compounds, 2019, 774: 758-767. doi: 10.1016/j.jallcom.2018.09.362

[15] WU S H, ZHANG P, SHAO D, et al. Grain size-dependent Sc microalloying effect on the yield strength-pitting corrosion correlation in Al-Cu alloys[J]. Materials Science and Engineering A, 2018, 721(4): 200-214. https://www.sciencedirect.com/science/article/pii/S0921509318303083

[16] MANDAL P K, ROBI P S. Influence of micro-alloying with silver on microstructure and mechanical properties of Al-Cu alloy[J]. Materials Science and Engineering A, 2018, 722(11): 99-111. https://www.sciencedirect.com/science/article/pii/S0921509318303472

[17] MENG F S, WANG Z, ZHAO Y L, et al. Microstructures and properties evolution of Al-Cu-Mn alloy with addition of Vanadium[J]. Metals, 2016, 7(1): 1-12. doi: 10.3390/met7010001

[18] SUN F F, LIU G R, LI Q Y, et al. Effect of Sc and Zr additions on microstructures and corrosion behavior of Al-Cu-Mg-Sc-Zr alloys[J]. Journal of Materials Science and Technology, 2017, 33(9): 1015-1022. doi: 10.1016/j.jmst.2016.12.003

[19] ZUO L J, YE B, FENG J, et al. Effect of δ-Al3CuNi phase and thermal exposure on microstructure and mechanical properties of Al-Si-Cu-Ni alloys[J]. Journal of Alloys and Compounds, 2019, 791: 1015-1024. doi: 10.1016/j.jallcom.2019.03.412

[20] SU R M, WANG K N, YANG Y P, et al. Effect of Mg content on the microstructure and corrosion properties of Al-Cu-Mn alloy[J]. Journal of Materials Engineering and Performance, 2020, 29(3): 1622-1629. doi: 10.1007/s11665-020-04684-2

[21] FENG Z Q, YANG Y Q, HUANG B, et al. Crystal substructures of the rotation-twinned T (Al20Cu2Mn3) phase in 2024 aluminum alloy[J]. Journal of Alloys and Compounds, 2014, 583: 445-451. doi: 10.1016/j.jallcom.2013.08.200

[22] CHEN Z, CHEN P, LI S. Effect of Ce addition on microstructure of Al20Cu2Mn3 twin phase in an Al-Cu-Mn casting alloy[J]. Materials Science and Engineering A, 2012, 532(15): 606-609. https://www.sciencedirect.com/science/article/pii/S0921509311012640

[23] LIN B, ZHANG W, ZHENG X, et al. Developing high performance mechanical properties at elevated temperature in squeeze cast Al-Cu-Mn-Fe-Ni alloys[J]. Materials Characterization, 2019, 150: 128-137. doi: 10.1016/j.matchar.2019.01.022

[24] CHEN J L, LIAO H C, WU Y N, et al. Contributions to high temperature strengthening from three types of heat-resistant phases formed during solidification, solution treatment and ageing treatment of Al-Cu-Mn-Ni alloys respectively[J]. Materials Science and Engineering A, 2020, 772(20): 1-15.

[25] LI Y G, YANG Y, WU Y Y, et al. Quantitative comparison of three Ni-containing phases to the elevated-temperature properties of Al-Si piston alloys[J]. Materials Science and Engineering A, 2010, 527(26): 7132-7137. doi: 10.1016/j.msea.2010.07.073

[26] YANG Y, YU K L, LI Y G, et al. Evolution of nickel-rich phases in Al-Si-Cu-Ni-Mg piston alloys with different Cu additions[J]. Materials and Design, 2012, 33: 220-225. doi: 10.1016/j.matdes.2011.06.058

-

期刊类型引用(4)

1. 邱小云,王冀恒. 挤压铸造铝铜合金的组织与力学性能研究. 铸造. 2024(03): 364-370 .  百度学术

百度学术

2. 潘丽飞,罗伟强,罗云丽,罗世阳. 改善金属材料摩擦磨损性能的有效途径. 装备制造技术. 2024(07): 147-151 .  百度学术

百度学术

3. 陈子健,林业佳,李传强,邓仁昡,董勇,章争荣. 微合金化调控7075铝合金的微观组织与力学性能. 金属热处理. 2024(09): 58-63 .  百度学术

百度学术

4. 毛鹏燕,赵晖,李宏达. Al含量对AlxCoCrFeNi高熵合金组织和力学性能的影响. 有色金属科学与工程. 2024(06): 867-876 .  本站查看

本站查看

其他类型引用(3)

下载:

下载: