Preparation technology and properties of modified single-crystalline LiNi0.83Co0.12Mn0.05O2 cathode materials by doping and coating

-

摘要: 高镍三元正极材料以其能量密度高的特性成为目前动力型锂离子电池主流正极材料之一,但目前高镍三元材料存在循环稳定性较差、大倍率充放电性能较差等问题,限制了其规模化应用。三元材料的单晶化可以有效降低循环过程中的颗粒间微裂纹产生,结合表面包覆可有效提高高镍三元正极材料的循环稳定性。同时,高价阳离子掺杂可有效提高锂离子传输速率,提高高镍三元材料的倍率充放电性能。本文采用高温固相法制备W6+、Zr4+共掺杂和H3BO3、Al2O3双包覆的高镍单晶LiNi0.83Co0.12Mn0.05O2材料,并探究其电化学性能的变化。在3.0~4.3 V电压范围内,与未掺杂材料相比,W-Zr共掺杂的LiNi0.83Co0.12Mn0.05O2在不同放电倍率下具有更好的电化学性能;采用H3BO3和Al2O3表面双包覆的LiNi0.83Co0.12Mn0.05O2正极材料在1 C倍率下循环100圈后容量保持率为96.7%。Abstract: Ni-rich ternary positive materials have become one of the most preferred cathode materials for application in power lithium-ion batteries owing to their high energy density. However, these cathode materials suffer from inferior cycling performance and poor rate capability, seriously impeding their practical application to scale. The single crystallization of ternary materials can effectively mitigate the generation of particle cracking and improve the cycling stability of Ni-rich cathode materials. At the same time, high-valence cationic doping can effectively improve the transmission rate of lithium ions, and the charge-discharge performance of high-nickel ternary materials. In this paper, nickel-rich single crystal LiNi0.83Co0.12Mn0.05O2 materials doped with W6+ and Zr4+, combined with H3BO3 and Al2O3 double coating was prepared by high-temperature solid phase method, and their changes in electrochemical properties was explored. It is found that LiNi0.83Co0.12Mn0.05O2 doped with W-Zr displays better electrochemical performance compared with the un-doped cathode under the different magnifications specific discharge capacity in 3.0-4.3 V. The capacity retention rate of LiNi0.83Co0.12Mn0.05O2 materials with H3BO3 and Al2O3 double coating was 96.7% after 100 cycles at 1.0 C.

-

镍钴锰酸锂(NCM)三元正极材料因其高能量密度的特点成为动力型锂离子电池主流正极材料之一[1-2]。目前动力型锂离子电池三元正极材料主要为中镍系NCM和中高镍系NCM,如LiNi0.5Co0.2Mn0.3O2和LiNi0.6Co0.2Mn0.2O2。但随着市场的进一步发展,对电动汽车的续航里程和成本提出了更高的要求,这也就对锂离子电池的能量密度和循环使用寿命提出了更高的要求[3]。目前,提高锂离子电池能量密度主要有采用单晶化NCM和高镍型NCM的方式[4-5],但随着NCM正极材料中的Ni含量增加,NCM的能量密度逐渐增加,其体相结构稳定性和表面化学稳定性逐渐降低,特别是球状多晶高镍NCM在循环过程中会产生体相微裂纹,严重阻碍锂离子的传输和电子传导,从而使高镍NCM特别是多晶球状NCM的循环寿命大大降低[6-8]。具有微米级一次颗粒尺寸的单晶NCM可有效降低充放电过程的晶间应力,降低微裂纹的产生,从而提高材料的电化学稳定性。单晶NCM在烧结过程中,一般采用较高温度(≥900 ℃),但高温状态会加剧材料Li/Ni混排程度,并且单晶NCM因具有较大的一次颗粒,其倍率性能较多晶差,从而限制了其大规模产业化应用。目前通常采用离子掺杂以改善单晶NCM的上述问题[9-19]。若制备高镍单晶NCM,通常还需进行表面包覆,以进一步提升其循环稳定性[20-30]。

基于此,本文拟采用Zr-W共掺杂同时结合H3BO3、Al2O3双包覆工艺以制备电化学性能优异的高镍单晶LiNi0.83Co0.12Mn0.05O2。通过一系列测试方法研究并讨论了掺杂、包覆对LiNi0.83Co0.12Mn0.05O2正极材料物理性能和电化学性能的影响。

1 实验部分

1.1 材料制备

采用高温固相法合成所需高镍单晶NCM。采用工业级纳米ZrO2、WO3作为掺杂剂,以微米级H3BO3和纳米级Al2O3作为包覆剂,以电池级LiOH·H2O和自制Ni0.83Co0.12Mn0.05(OH)2作为锂源和前驱体。具体制备过程为:①按照n(Li)/ n(M )= 1.05称取D50约为4 μm的Ni0.83Co0.12Mn0.05(OH)2和LiOH·H2O,分别称取纳米WO3(W掺杂量0.1%)和纳米ZrO2(Zr掺杂量0.15%),将上述4种物料投入10 L高速混合机中,在500 r/min转速下混合30 min,制备均匀的混合物;②将所得混合物装入刚玉坩埚中,利用箱式气氛电阻炉,在氧气气氛下以2 ℃/min的升温速率升温至880 ℃,恒温16 h后自然降温,以制备出W-Zr共掺杂的LiNi0.83Co0.12Mn0.05O2高镍单晶正极材料(Single-Ni83-W-Zr,标记为样品NCM-B);③将烧结后的物料利用小型气流粉碎机粉碎至D50约为4 μm的物料;④将1 000 g粉碎后的NCM-B与3.4 g的纳米级Al2O3(Al包覆量0.18%)和11.1 g的H3BO3(B包覆量0.195%)共同投入10 L高速混合机中,在550 r/min转速下混合50 min,使包覆剂在基材颗粒表面充分包裹均匀;⑤将混合物装入刚玉坩埚中,利用箱式气氛电阻炉,在氧气气氛下以420 ℃煅烧7 h,制备出B-Al双包覆的LiNi0.83Co0.12Mn0.05O2高镍单晶正极材料(Single-Ni83-W-Zr-B-Al,标记为样品NCM-C)。采用相同制备工艺及工艺参数,制备出未添加掺杂剂及包覆剂的LiNi0.83Co0.12Mn0.05O2(标记为样品NCM-A)。每个样品对应简称如表1所列。

表 1 样品编号对应表Table 1. Sample number mapping table序号 样品简称 Zr-W共掺杂 B-Al双包覆 1 NCM-A 无 无 2 NCM-B 0.150%~0.100% 无 3 NCM-C 0.150%~0.100% 0.195%~0.180% 1.2 材料结构和性能分析

用X射线衍射仪(德国Bruker公司)对样品晶体结构进行分析,Cu Kα1= 0.154 060 nm,Kα2= 0.154 439 nm,波长λ= 0.154 06 nm,管流10 mA、管压30 kV,扫描速度为0.083(°)/s(0.24 s/0.02 °),步长为0.02°;用配有X射线能量色散光谱仪(EDS)的扫描电子显微镜(荷兰Phenom公司)对样品进行形貌观察和成分分析;采用电感耦合等离子体发射光谱仪(ICP-AES)对测试样品中所含元素的种类及含量进行定量分析;采用酸碱滴定法对样品的表面残余Li含量进行测定;采用Land充放电测试仪和电化学工作站测试样品的电化学性能。

1.3 电化学性能测试

将正极材料、SP、PVDF按照质量比95∶3∶2称量并混合均匀,加入适量的N-甲基吡咯烷酮(NMP)作为混合溶剂,用磁力搅拌器将上述物料搅拌成均匀浆料,将浆液均匀涂覆在20 μm厚的铝箔上,在120 ℃温度、-0.1 MPa真空条件下干燥16 h后,以20 MPa的压力辊压极片。采用金属锂片为负极、Celgard2300膜为隔膜、1 mol/L LiPF6/EC+DMC(体积比1∶1)为电解液,在手套箱中装配成CR2032型扣式电池。在电压为3.0~4.3 V范围下,用LAND电池测试系统(武汉蓝电公司)进行充放电测试,用电化学工作站(CS310, Contest, 武汉科斯特公司)对循环100圈后的扣式电池进行交流阻抗测试。

2 结果与讨论

2.1 掺杂及包覆后对样品晶体结构的影响分析

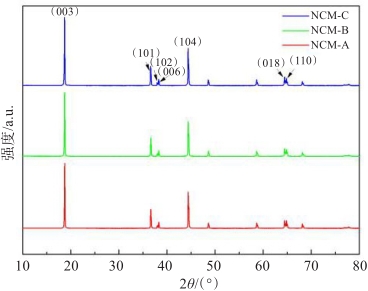

从图1可知,经过Zr-W共掺杂改性样品和经过H3BO3-Al2O3双包覆的样品的衍射峰与未掺杂、未包覆的样品基本一致,均具有R3m空间群的六方α-NaFeO2(PDF:87-1561)结构。每个样品的衍射峰尖锐且均无其他杂峰存在,特征峰(006)/(102)和(018)/(110)的分裂明显,表明3个样品均为结晶度较高的层状结构。表2所列为3种样品的晶胞参数计算结果。从表2中可知,Zr-W共掺杂的样品NCM-B的c值和c/a值均高于未掺杂样品NCM-A,这可能与掺杂离子W6+(离子半径0.06 nm)、Zr4+(离子半径0.072 nm)的离子半径大于Mn4+(离子半径0.053 nm)、Ni3+(离子半径0.056 nm)和Co3+(离子半径0.055 nm)的离子半径有关,当W6+和Zr4+进入晶格取代部分过渡金属离子时,会使晶格间距增加[30]。晶格间距的增加,使Li+更加容易嵌入和脱出,从而提高材料的大倍率充放电性能。从表2中还可以看出,经过Zr-W共掺杂的NCM-B的I(003)/I(104)的值比未掺杂的NCM-A的高,说明经过Zr-W共掺杂,可以有效降低NCM的Li/Ni混排,从而降低由阳离子混排导致的Li+扩散阻力和不可逆容量损失,从而提高材料的电化学性能。经过Zr-W共掺杂和H3BO3-Al2O3共包覆的NCM-C的c值和c/a值与NCM-B的基本一致,并且I(003)/I(104)值也基本一致,说明采用H3BO3和Al2O3包覆后的材料,在较低的热处理温度下,对材料的晶体结构和Li/Ni混排基本不产生影响。

表 2 3种样品的晶胞参数表Table 2. Crystal cell parameters of the three samples样品 a/nm c/nm c/a I(003)/I(104) NCM-A 0.287 22 1.421 77 4.950 1 1.535 8 NCM-B 0.287 697 1.425 73 4.955 7 1.645 9 NCM-C 0.287 698 1.426 00 4.956 6 1.656 3 2.2 掺杂及包覆后对样品形貌的影响分析

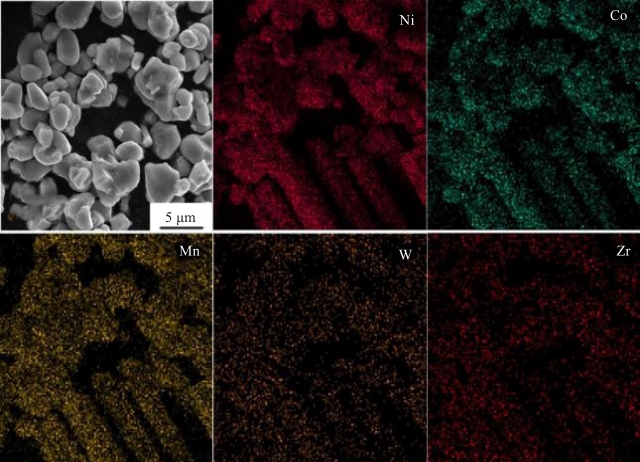

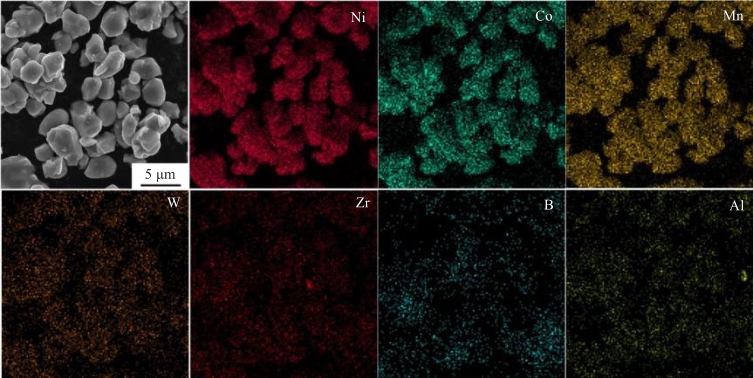

图2、图3和图4所示分别是NCM-A、NCM-B和NCM-C 3个样品的SEM-EDS图。从图2—图4的SEM图可以看出,3个样品均具有典型的单晶颗粒形貌,一次颗粒粒径均约为2 μm。从图3中可以看出,经过ZrO2和WO3掺杂后的NCM-B表面均匀分布W、Zr元素,结合XRD的晶胞参数数据,可说明Zr、W已经进入NCM体相。表3所列为利用ICP-AES测试NCM-A、NCM-B和NCM-C的掺杂、包覆元素含量。从表3中可以看出,掺杂后的NCM-B样品中W和Zr的含量基本与理论计算掺入量(见表1)一致,结合表4对样品的表面残余锂含量测试值可以看出,W-Zr共掺杂后的样品表面残锂降低,这也说明掺杂元素进入体相内部。从图4中可以看出,经过H3BO3和Al2O3包覆后NCM-C的表面均匀分布W、Zr、B和Al,并且ICP结果显示,NCM-C的W、Zr、B、Al元素含量与理论掺入和包覆量相当。同时从表4中可以看出,经过包覆后的样品的表面残余锂含量大大降低。这可能是因为H3BO3在较低的热处理温度下,可以与表面残余的LiOH反应,生成Li3BO3。Li3BO3为一种快离子导体,相比于氧化物的包覆剂,其具有较高的锂离子迁移率和电子电导率,可提升材料的循环稳定性。

表 3 NCM-A、NCM-B和NCM-C的ICP-AES测试结果Table 3. ICP-AES test results of NCM-A, NCM-B and NCM-C samples样品 W Zr B Al NCM-A 0 0 0 0 NCM-B 0.096 4 0.142 0 0 0 NCM-C 0.098 4 0.144 7 0.189 5 0.175 2 表 4 NCM-A、NCM-B和NCM-C的表面残锂含量测试结果Table 4. Test results of surface residual lithium contents of NCM-A, NCM-B and NCM-C samples样品 Li2CO3 LiOH NCM-A 0.431 2 0.495 9 NCM-B 0.423 2 0.301 2 NCM-C 0.205 0 0.135 0 2.3 掺杂及包覆后对样品电化学性能的影响分析

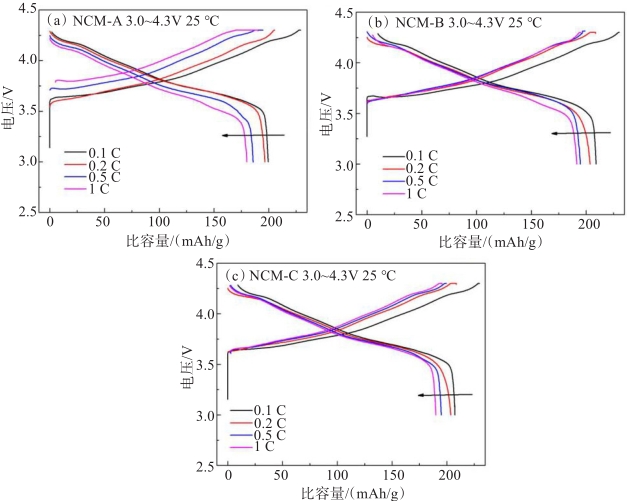

为了验证W-Zr共掺杂和H3BO3-Al2O3包覆对样品电化学性能的影响。利用LAND测试系统,以Celgard2032扣式电池为载体,对NCM-A、NCM-B和NCM-C不同倍率条件下的充放电比容量和首次库仑效率进行了测试。从图5中可知,NCM-A和NCM-B的0.1 C放电比容量分别为199.2 mAh/g和207.3 mAh/g,首次充放电效率分别为86.7%和90.0%。表明W-Zr共掺杂可提升高镍单晶NCM在较高电压条件下的放电比容量和首次充放电效率。并且NCM-B在0.2 C、0.5 C和1 C条件的放电比容量明显高于NCM-A,这说明W-Zr共掺杂可有效改善高镍单晶NCM的倍率放电性能。这可能是因为如前所述,Zr、W的离子半径大于Ni、Co、Mn的离子半径,当Zr、W掺入体相后,可使层间距增加,从而使Li迁移通道扩宽,从而提高倍率充放电容量。并且,Zr、W的掺入使得Li/Ni混排降低,并且在Li的脱嵌过程中化合价不改变,从而使结构更加稳定,因此一定程度上提高了首次库仑效率。从图5和表5中还可知,掺杂后的样品经过H3BO3和Al2O3包覆后,在不同倍率下的放电比容量与未包覆前的近似,说明利用H3BO3和Al2O3对单晶NCM表面进行包覆,并不会增加材料表面的Li+扩散阻力,不会影响材料的倍率性能。

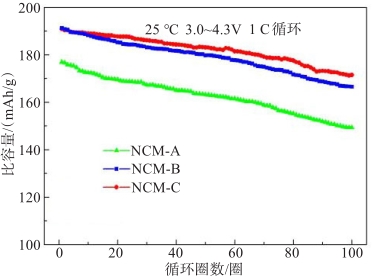

表 5 NCM-A、NCM-B和NCM-C不同倍率条件下的放电比容量、库仑效率Table 5. The discharge capacity and coulombic efficiency data of NCM-A, NCM-B, and NCM-C samples with different charge-discharge rates样品 0.1 C放电比容量/(mAh/g) 0.1 C首次充放电效率/% 0.2 C放电比容量/(mAh/g) 0.5 C放电比容量/(mAh/g) 1 C放电比容量/(mAh/g) 1 C充放电循环100圈容量保持率/% NCM-A 199.2 86.7 195.1 186.3 180.2 90.1 NCM-B 207.3 90.0 205.0 199.4 195.1 92.5 NCM-C 209.4 91.4 204.3 198.8 194.5 96.7 为进一步验证掺杂和包覆对材料电化学性能的提升。测试了NCM-A、NCM-B和NCM-C的循环性能。从图6可知,在25 ℃条件下,在3.0~4.3 V电压范围内,在1 C充放电倍率下循环100圈后,NCM-A、NCM-B和NCM-C的容量保持率分别为90.1%、92.5%和96.7%,说明H3BO3和Al2O3双包覆可有效改善高镍单晶NCM的循环性能。表面包覆可有效阻隔在充放电过程中电解液对NCM颗粒表面的腐蚀,提高材料的循环稳定性。这可能是因为H3BO3在较低热处理温度下可与高镍NCM表面的残余锂反应,生成Li3BO3快离子导体,从而避免了纯Al2O3包覆导致的比容量降低和库仑效率下降。

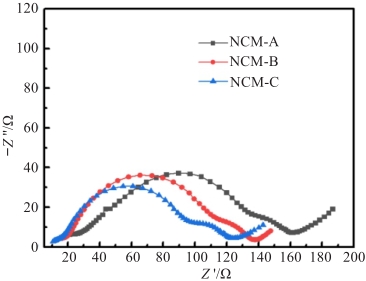

图7中,所有曲线均由半圆和斜线构成,高频部分半圆为锂离子通过SEI膜的阻抗(Rsei),中低频半圆为电荷转移阻抗(Rct),低频部分为锂离子扩散阻抗(Rw)。由图7可以看出,NCM-C样品(Rsei)和电化学阻抗较NCM-A、NCM-B小,NCM-B样品(Rsei)和电化学阻抗较NCM-A小,表明NCM-C形成的致密SEI膜较NCM-A、NCM-B薄,且Li+迁移更容易。这可能是因为NCM-B掺杂Zr、W提高了晶胞参数,拓宽了Li+迁移通道,并且W掺杂能有效降低H2-H3相变稳定材料结构[31],能有效降低可逆相变的形成,致使在负极表面形成较薄的致密均匀的SEI膜。NCM-C样品表面包覆的H3BO3会与表面残锂反应生成Li3BO3,减少表面残锂与电解液之间的反应,减少可逆相变的形成,也能形成较薄的致密均匀的SEI膜。

3 结论

采用高温固相法合成单晶LiNi0.83Co0.12Mn0.05O2材料,并添加W-Zr元素进行共掺杂改性及H3BO3-Al2O3双包覆改性。研究了上述改性手段对高镍材料电化学性能的影响。研究结果表明:

1)W-Zr掺杂可有效进入材料结构,扩宽Li+迁移通道,提高高镍单晶NCM的倍率充放电性能,使经过W-Zr共掺杂改性后的样品在1 C倍率下放电比容量达195.1 mAh/g。

2)H3BO3和Al2O3表面双包覆NCM,可以在样品材料表面形成一层均匀的膜,降低在循环过程中电解液对材料的侵蚀,提高材料循环稳定性。

3)经过掺杂和包覆后的样品,明显改善了循环稳定性,在1 C条件下,循环100圈后容量保持率为96.7%,显示了其潜在的应用价值。

-

表 1 样品编号对应表

Table 1 Sample number mapping table

序号 样品简称 Zr-W共掺杂 B-Al双包覆 1 NCM-A 无 无 2 NCM-B 0.150%~0.100% 无 3 NCM-C 0.150%~0.100% 0.195%~0.180% 表 2 3种样品的晶胞参数表

Table 2 Crystal cell parameters of the three samples

样品 a/nm c/nm c/a I(003)/I(104) NCM-A 0.287 22 1.421 77 4.950 1 1.535 8 NCM-B 0.287 697 1.425 73 4.955 7 1.645 9 NCM-C 0.287 698 1.426 00 4.956 6 1.656 3 表 3 NCM-A、NCM-B和NCM-C的ICP-AES测试结果

Table 3 ICP-AES test results of NCM-A, NCM-B and NCM-C samples

样品 W Zr B Al NCM-A 0 0 0 0 NCM-B 0.096 4 0.142 0 0 0 NCM-C 0.098 4 0.144 7 0.189 5 0.175 2 表 4 NCM-A、NCM-B和NCM-C的表面残锂含量测试结果

Table 4 Test results of surface residual lithium contents of NCM-A, NCM-B and NCM-C samples

样品 Li2CO3 LiOH NCM-A 0.431 2 0.495 9 NCM-B 0.423 2 0.301 2 NCM-C 0.205 0 0.135 0 表 5 NCM-A、NCM-B和NCM-C不同倍率条件下的放电比容量、库仑效率

Table 5 The discharge capacity and coulombic efficiency data of NCM-A, NCM-B, and NCM-C samples with different charge-discharge rates

样品 0.1 C放电比容量/(mAh/g) 0.1 C首次充放电效率/% 0.2 C放电比容量/(mAh/g) 0.5 C放电比容量/(mAh/g) 1 C放电比容量/(mAh/g) 1 C充放电循环100圈容量保持率/% NCM-A 199.2 86.7 195.1 186.3 180.2 90.1 NCM-B 207.3 90.0 205.0 199.4 195.1 92.5 NCM-C 209.4 91.4 204.3 198.8 194.5 96.7 -

[1] HANG Y, TANG Y, YUAN W, et al. Challenges and recent progress in thermal management with heat pipes for lithium-ion power batteries in electric vehicles[J]. Science China Technological Science, 2021, 64(5):1-38.

[2] JUNG C H, SHIM H, EUM D, et al. Challenges and recent progress in LiNixCoyMn1-x-yO2 (NCM) cathodes for lithium ion batteries[J]. Journal of the Korean Ceramic Society, 2021, 58(1):1-27.

[3] XIE Q, LI W D, DOLOCAN A, et al. Insights into boron-based polyanion-tuned high-nickel cathodes for ligh-energy-density lithium-ion batteries[J]. Chemistry of Materials, 2019, 31(21):8886-8897.

[4] GUO Q K, HUANG J L, ZHONG S W. The use of a single-crystal nickel-rich layered NCM cathode for excellent cycle performance of lithium-ion batteries[J]. New Journal of Chemistry, 2021, 45(7):3652-3659.

[5] 姜子昂,王宇杰,陈轩锋,等. 铁基氟化物锂电池正极材料研究进展[J]. 稀有金属,2022,46(6):724-735. [6] CSERNICA P M, KALIRAI S S, GENT W E, et al. Persistent and partially moblie oxygen vacancies in Li-rich layered oxides[J]. Nature Energy, 2021, 6(6):642-652.

[7] 孙媛媛,李思卿,王成儒,等. 钠离子电池层状过渡金属氧化物正极材料的研究进展[J]. 稀有金属,2022,46(6):776-795. [8] LANGDON J, MANTHIRAM A. A Perspective on single-crystallayered oxide cathodes for lithium-ion batteries[J]. Energy Storage Material, 2021, 37:143-160.

[9] JO S J, HWANG D Y, et al. Use of zirconium dual-modification on the LiNi0.8Co0.1Mn0.1O2 cathode for Improved electrochemical performances of lithium-ion batteries[J]. ACS Applied Energy Materials, 2021, 4(4):3693-3700.

[10] RYU H H, PARK N Y, et al. New class of Ni-Rich cathode materials Li[NixCoyB1-x-y]O2 for next lithium batteries[J]. Advanced energy Materials, 2020, 10(25):2000495.1-2000495.8.

[11] KIM J M, KUMAGAI N, KADOMA Y, et al. Synthesis and Electrochemical properties of lithium non-stoichiometric Li1+x(Ni1/3Co1/3Mn1/3)O2+δ prepared by a spray drying method[J]. Journal of Power Sources, 2007, 174(2):473-479.

[12] KIM J M, KUMAGAI N, KOMABA S. Improved electrochemical properties of Li1+x(Ni0.3Co0.4Mn0.3)O2-δ(x=0.0.03 and 0.06) with lithium excess composition prepared by a spray drying method[J]. Electrochimica Acta, 2006, 52(4):1483-1490.

[13] LIU D, WANG Z, CHEN L. Comparison of structure and electrochemistry of Al- and Fe-doped LiNi1/3Co1/3Mn1/3O2[J]. Electrochimica Acta, 2006, 51(20):4199-4203.

[14] FU Z, ZHAO X, LU Z, et al. The effect of Al substitution on the reactivity of delithiated LiNi1/3Mn1/3Co(1/3-z)AlzO2 with non-aqueous electrolyte[J]. Electrochemistry Communications, 2008, 10(8):1168-1171.

[15] WANG Z H, ZHU H W, YU H F. et al. Complementary dual-doping of LiNi0.8Co0.1Mn0.1O2 cathode enhances ion-diffusion and stability for Li-ion batteries[J]. Chinese Chemical Letters, 2023, 34:107718-107723.

[16] ZHONG S, YOU W, LIU J, et al. Synthesis and electrochemical properties of Ce-doped LiNi1/3Mn1/3Co1/3O2 cathode material for li-ion batteries[J]. Journal of Rare Earths, 2011, 29(9):891-895.

[17] WANG S, JIANG S, LI Y J, et al. Interface dual-engineering strategy boosting the excellent high-temperature electrochemical properties of LiMn2O4[J]. Journal of Power Sources, 2023, 579(30):233292.1-233292.10.

[18] SHIN H S, SHIN D, SUN Y K. Improvement of electrocheical properties of Li[Ni0.4Co0.2Mn(0.4-x)Mgx]O2-yFy cathode materials at high voltage region[J]. Electrochimica Acta, 2006, 52(4):1477-1482.

[19] DING Y H, ZHANG P. Synthesis and electrochemical properties of layered Li[Ni1/3Co1/3Mn1/3]0.96Ti0.04O1.96F0.04 as cathode material for lithium-ion batteries[J]. Journal of Alloys and Compounds, 2008, 456(1/2):344-347.

[20] 李西安, 冯彦彦. LiTi2(PO4)3修饰高镍单晶三元正极材料增强结构稳定性[J]. 电源技术, 2023, 47(5):618-622. [21] ZHENG J C, YANG Z, HE Z J, et al. In situ formed LiNi0.8Co0.15Al0.05O2@Li4SiO4 composite cathode material with high rate capability and long cycling stability for lithium-ion batteries[J]. Nano Energy, 2018, 53:613-621.

[22] CHEN J Y, SU B T, FAN J, et al. A low-temperature coating method with H3BO3 for enhanced electrochemical performance of Ni-rich LiNi0.82Co0.12Mn0.06O2 cathode[J]. Electrochimica Acta, 2022, 422:140564-140571.

[23] ZHI Y, LI X, WANG Z, et al. Surface modification of spherical LiNi1/3Co1/3Mn1/3O2 with A12O3 using heterogeneous nucleation process[J]. Transactions of Nonferrous Metals Society of China, 2007, 17(6):1319-1323.

[24] KIM Y, KIM H S, MARTIN S W. Synthesis and electrochemical characteristics of Al2O3-coated LiNi1/3Co1/3Mn1/3O2 cathode materials for lithium ion batteries[J]. Electrochimica Acta, 2006, 52(3):1316-1322.

[25] 饶先发, 李宝宝, 楼轶韬, 等. 单晶型LiNi0.8Co0.1Mn0.1O2正极材料的制备及性能对比[J]. 有色金属科学与工程, 2021, 12(4):42-50. [26] MACHIDA N, KASHIWAGI J, NAITO M, et al. Electrochemical properties of all-solid-state batteries with ZrO2-coated LiNi1/3Co1/3Mn1/3O2 as cathode materials[J]. Solid State Ionics, 2012, 225:354-358.

[27] HU S K, CHENG G H, CHENG M Y, et al. Cycle life improvement of ZrO2-coated spherical LiNi1/3Co1/3Mn1/3O2 cathode material for lithium ion batteries[J]. Journal of Power Sources, 2009, 188(2):564-569.

[28] 彭弯弯, 饶先发, 王春香, 等. Na、Zr复合改性提高LiNi0.8Co0.1Mn0.1O2正极材料理化性能[J]. 有色金属科学与工程, 2022, 13(5):60-67. [29] YOU L Z, CHU B B, LI G X, et al. H3BO3 washed LiNi0.8Co0.1Mn0.1O2 with enhanced electrochemical performance and storage characteristics[J]. Journal of Power Sources, 2021, 482:228940-228948.

[30] LI J B, XU Y L, LI X F, et al. Li2MnO3 stabilized LiNi1/3Co1/3Mn1/3O2 cathode with improved performance for lithium ion batteries[J]. Applied Surface Science, 2013, 285(11):235-240.

[31] PARK G T, RYU H H, PARK N Y, et al. Tungsten doping for stabilization of Li[Ni0.90Co0.05Mn0.05]O2 cathode for Li-ion battery at high voltage[J]. Journal of Power Sources, 2019, 442:227242.1-227242.9.

-

期刊类型引用(2)

1. 匡玲瑶,乔双,王倩,王星敏,代金航,古兴兴. 原位构筑聚糠醇SEI膜用于稳定锌负极的机制研究. 稀有金属. 2024(07): 965-975 .  百度学术

百度学术

2. 周兴杰,王家伟,王海峰,裴正清,马德华,郑可欣,鲁菊. 新生二氧化锰的制备及其吸附硫酸锰溶液中钼的行为. 有色金属科学与工程. 2024(06): 792-800 .  本站查看

本站查看

其他类型引用(2)

下载:

下载: