Study on preparation of MoSx@ZVI composite by carbothermal reduction synthesis and its treatment of acid orange G wastewater

-

摘要: 以辉钼矿(MoS2)、褐铁矿和无烟煤为原料,通过碳热还原法制备了MoSx@ZVI复合材料。研究了MoS2用量、焙烧温度、无烟煤用量和焙烧时间对MoSx@ZVI去除酸性橙G(OG)的影响,并确定了制备MoSx@ZVI的较优制备条件为焙烧温度1 000 ℃、MoS2用量6%、焙烧时间60 min和无烟煤用量25%。通过X射线衍射、扫描电子显微镜和能谱仪对较优条件制备的MoSx@ZVI进行表征,结果表明,材料中生成了大量核壳结构的硫化零价铁,内核为Fe-Mo-C合金,外壳可能由硫化钼、FeS、C、钼氧化物和铁氧化物组成。降解实验结果表明,将较优条件制备的MoSx@ZVI碎磨至粒径 < 0.1 mm,用0.6 g MoSx@ZVI处理400 mL 200 mg/L OG模拟废水,在初始pH = 3.0~10.0范围处理150 min,OG的去除率均在90%以上。

-

关键词:

- 碳热还原 /

- MoSx@ZVI复合材料 /

- 酸性橙G废水 /

- pH

Abstract: MoSx@ZVI composite was synthesized with molybdenite (MoS2), limonite and anthracite by carbothermal reduction. Effects of molybdenite dosage, roasting temperature, anthracite content, and roasting time on the performance of the prepared MoSx@ZVI for removing orange G (OG) were investigated. MoSx@ZVI with the best performance was prepared by roasting at 1 000 ℃ for 60 min with 6% of molybdenum and 25% anthracite. MoSx@ZVI prepared under the best conditions was analyzed by X-ray diffraction, scanning electron microscopy and energy dispersive spectrometry. The results show that a large amount of sulfide zero-valent iron with a core-shell structure is formed in the material, the core is Fe-Mo-C alloy, and the shell may be composed of molybdenum sulfide, FeS, C, molybdenum oxide and iron oxide. The degradation experiment results show that the removal rate of OG is above 90% when MoSx@ZVI prepared under the optimal conditions is crushed to particle size smaller than 0.1 mm, and 400 mL OG simulated wastewater with a concentration of 200 mg/L is treated with 0.6 g of MoSx@ZVI for 150 min within the initial pH range of 3.0-10.0.-

Keywords:

- carbothermal reduction /

- MoSx@ZVI compound material /

- orange G wastewater /

- pH

-

目前,零价铁(ZVI,Fe0)作为一种低成本和环境友好的废水处理剂被认为是有前途的废水处理材料[1-2]。众所周知,ZVI是一种具有负标准还原电位(E0(Fe2+/Fe0) = ‒0.44 V)的优良电子供体[3]。由于ZVI具有活性强和还原性强等特点,被用于去除地下水中的重金属、有机化合物和染料等[4-6]。然而,ZVI的强还原性使其表面与水发生析氢反应(HER)或与溶液中存在的其他具有氧化性物质发生界面反应[7-8];此外,ZVI的强磁性会引起其表面腐蚀和颗粒聚集,从而导致其反应性和迁移率降低[9]。另外,ZVI与废水中的天然氧化剂(如溶解氧、硝酸盐)发生副反应,导致其对目标污染物的选择性较差,而且ZVI表面的铁氧化物阻碍电子迁移,导致利用效率和寿命降低。可通过减小粒径、负载、修饰和表面改性等方式提升ZVI在水溶液中的性能,包括双金属改性ZVI、聚合物改性ZVI和硫化物改性ZVI等改性方法[10-12]。

在众多改性方法中,硫化改性被认为是一种更有效的方法,可显著提高ZVI的反应性和选择性[13-14]。目前,硫化零价铁(S-ZVI)的制备方法主要包括液相还原法和球磨法[15-17]。但是,液相还原法需要大量硼氢化物作为还原剂,其价格不仅昂贵且还原过程产生大量的氢气,给环境造成二次污染,该方法难以规模化[18]。球磨法制备S-ZVI的过程是直接将零价铁和硫化改性剂进行球磨,通常还需要通入氮气或在真空条件下操作,所以该制备方法成本较高,而且在合成过程中形成硫化层(FeS、FeS2)或ZVI易被氧化[17]。最近,碳热还原法在制备ZVI-生物碳复合材料方面备受关注。SUN等[19]和ZHOU等[20]在惰性气氛下热解预载铁的再循环碳前体,同时还原高价铁物种形成ZVI-生物碳材料;YANG等[21]用玉米秸秆和氯化铁通过碳热还原制备了ZVI-生物炭复合材料,并证实碳热还原可以避免ZVI在生物炭上的团聚;张小毛等[22]对比研究了液相化学还原法和碳热还原法制备的ZVI/活性炭复合材料,发现碳热还原合成的复合材料对六氯苯的去除能力、反应速率和脱氯能力均高于液相还原法。辉钼矿(MoS2)是一种富含硫的二维过渡金属硫化物,已被证明具有强疏水性和良好的导电性[23-26]。因此,本研究采用褐铁矿、MoS2和无烟煤为原材料通过碳热还原法制备MoSx@ZVI复合材料,并将其用于处理酸性橙G(OG)模拟废水,为染料废水治理提供了一种环境友好型复合材料。

1 实验部分

1.1 材料和试剂

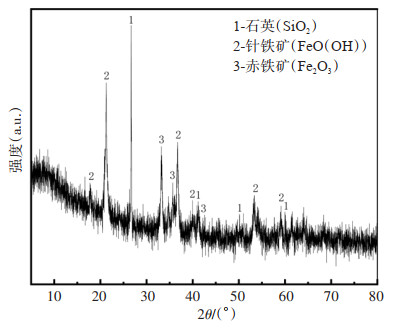

本研究采用的褐铁矿产自江西省江西铁坑铁矿,其化学分析结果见表 1,X射线衍射(XRD)物相分析结果如图 1所示。所用还原剂为无烟煤,其工业分析结果见表 2。辉钼矿产自江西,纯度为99.50%。本研究中使用的所有其他试剂均来自国药集团(上海),均为分析级试剂。

表 1 褐铁矿的X荧光分析结果Table 1. Results of X-ray fluorescence analysis of limonite 表 2 无烟煤工业分析结果Table 2. Industrial analysis results of anthracite

表 2 无烟煤工业分析结果Table 2. Industrial analysis results of anthracite

由表 1可知,褐铁矿中含71.68%(质量比,下同)Fe2O3、0.60% MnO、0.24% CuO、0.21% SO3和0.10% ZnO,其中,脉石的主要组成为SiO2、CaO和Al2O3。

由图 1可知,褐铁矿的主要物相为针铁矿、赤铁矿和石英。

由表 2可知,无烟煤灰分和硫含量分别仅为10.91%和0.39%,挥发分及固定碳总含量达88.29%,属优质还原剂。

1.2 实验方法

1.2.1 MoSx@ZVI的制备

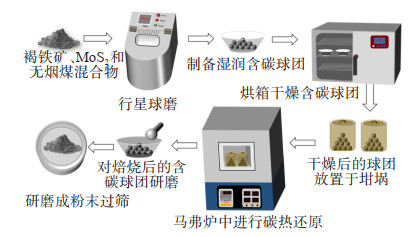

MoSx@ZVI制备步骤如图 2所示,在50 g褐铁矿中加入适量粒度小于0.1 mm的无烟煤和MoS2,放入行星磨机中以400 r/min混合2 h,向混合后的粉末中加少许去离子水,制成直径约为10 mm的小球。在焙烧之前,将刚制好的湿小球放入105 ℃烘箱中干燥2 h,干燥后装入石墨坩埚中,再放入已经达到目标温度的马弗炉中焙烧一定时间后取出,在空气中冷却,得到MoSx@ZVI,将其研磨至粒度小于0.1 mm,备用。

1.2.2 OG废水的处理

用分析纯OG试剂配制200 mg/L模拟废水,在500 mL烧杯中装入400 mL OG溶液,研究MoS2用量、焙烧温度、无烟煤用量、焙烧时间对MoSx@ZVI去除OG的影响。配制100、200、300、400、500 mg/L的OG溶液,研究OG初始浓度对MoSx@ZVI去除OG的影响;采用稀H2SO4或NaOH调节溶液所需的初始pH值,研究初始pH值对MoSx@ZVI去除OG的影响。此外,所有实验均在空气中进行,用水浴锅保持复合材料在溶液中的反应温度为28 ℃,并使用机械搅拌器(400 r/min)搅拌溶液,反应时间为150 min。反应一定时间后,用注射器取样,并通过0.45 μm过滤头过滤后收集。

1.3 分析方法

采用X荧光元素分析仪(XRF)(Axios Max,荷兰帕纳科公司)测定褐铁矿的化学成分;试样中存在的物相通过XRD(DX-2700,丹东浩元仪器有限公司)进行检测,检测条件:Cu-Kα辐射,步长为0.02°,扫描速率为4.8(°)/min;使用HSC 6.0软件计算铁氧化物和MoS2的吉布斯自由能(ΔrGmɵ)随温度变化之间的关系;使用扫描电子显微镜(SEM)和能谱分析仪(EDS)(MLA650F,美国FEI公司)对较优条件下制备的MoSx@ZVI进行表征;使用Perkin Elmer Spectrum Two N型傅立叶变换近红外光谱仪(FTIR)分析MoSx@ZVI的官能团反应前后的变化;采用数字pH计(pHS-3G,上海市仪千仪器店)测定溶液pH的变化;采用紫外-可见分光光度计(T6新世纪,北京普析通用仪器有限责任公司)分析溶液中目标污染物的残留浓度,OG的检测波长为478 nm[27],测试前均先稀释10倍。OG去除率计算公式如式(1):

(1) 式(1)中:R是OG去除率,%;C0是溶液中OG的初始浓度,mg/L;Ct是时间t(min)时溶液中OG的浓度,mg/L。

2 结果与讨论

2.1 MoS2用量对MoSx@ZVI去除OG的影响

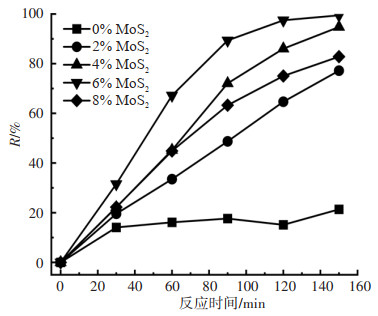

Fe/S比是影响ZVI颗粒表面形成硫化层的一个重要变量,因此,MoS2用量可能对MoSx@ZVI去除OG有影响。本试验是在焙烧温度为1 000 ℃、25%的无烟煤和60 min的焙烧时间,同时添加不同MoS2用量(0%、2%、4%、6%和8%)条件下进行。降解条件为1.0 g/L MoSx@ZVI、溶液温度保持28 ℃、OG初始浓度为200 mg/L和溶液初始pH值为6.2(原溶液)。如图 3所示,当MoS2用量从0增到2%时,反应150 min后,MoSx@ZVI对OG的去除率从21.35%增至77.17%。当MoS2用量增至4%和6%时,均反应150 min后,OG的去除率分别为94.76%和99.46%,脱色效果显著。然而,当MoS2用量进一步增至8%时,OG的去除率降至82.82%,其原因可能是MoS2过量会导致ZVI颗粒表面形成一层厚且致密的包裹物,阻碍Fe0释放电子转移至目标污染物[28]。实验结果表明,MoS2用量为6%时OG去除率约是MoS2用量为0时的5倍,说明添加MoS2合成的MoSx@ZVI对OG去除效果比不添加时更好,并且在MoS2用量6%条件下制备的MoSx@ZVI对OG去除效果较佳。因此,确定较优的MoS2用量为6%。

2.2 焙烧温度对MoSx@ZVI去除OG的影响

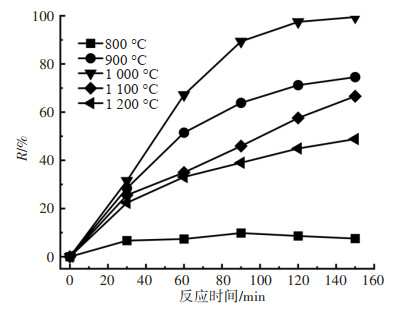

在MoS2用量为6%、焙烧时间为60 min和无烟煤用量为25%的条件下,研究焙烧温度对MoSx@ZVI去除OG的影响。如图 4所示,当焙烧温度从800 ℃升至900 ℃时,OG的去除率从7.54%增至74.54%;当焙烧温度升至1 000℃时,OG的去除率达到最高为99.46%;进一步将焙烧温度升至1 100 ℃和1 200 ℃时,反应150 min后,OG去除率显著下降,分别降至66.61%和48.84%。这可能是因为在焙烧前期提高焙烧温度有利于将铁矿物还原为ZVI[29], 从而有利于去除OG,但是,当铁矿物被完全还原后,进一步提高焙烧温度不能促进形成更多的ZVI,甚至引起ZVI颗粒聚集,导致ZVI与OG碰撞接触的几率下降,从而降低了MoSx@ZVI的反应活性。因此,确定较优焙烧温度为1 000 ℃。

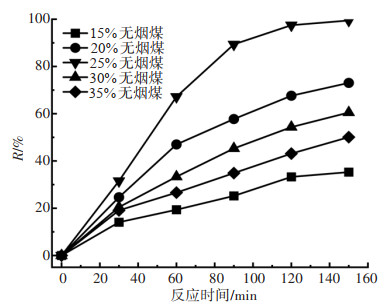

2.3 无烟煤用量对MoSx@ZVI去除OG的影响

在MoS2用量为6%、焙烧温度为1 000 ℃和焙烧时间为60 min条件下,考察无烟煤用量对OG去除率的影响。如图 5所示,随着无烟煤用量从15%增加到25%,OG的去除率逐渐增加。当无烟煤用量从15%增至20%时,反应150 min后,OG去除率从35.28%增至73.06%。当无烟煤用量增至25%时,相同反应时间,OG的去除率最高,达到99.46%。然而,随着无烟煤用量进一步增加,OG的去除率显著下降。当无烟煤的用量增至35%时,OG去除率仅为50.09%。无烟煤用量过少,不能完全还原氧化铁,适当增加无烟煤可以促进更多ZVI的形成[30],从而增加OG的去除率;但是,当无烟煤过量时,MoSx@ZVI中会存在更多尺寸相似的碳颗粒,无烟煤中的碳在MoSx@ZVI中占比增加,相同质量的MoSx@ZVI中ZVI含量减少,导致OG的去除率下降。因此,无烟煤较优用量为25%。

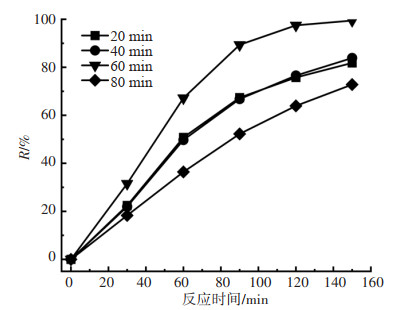

2.4 焙烧时间对MoSx@ZVI去除OG的影响

在无烟煤与褐铁矿质量比为25%,MoS2用量为6%和焙烧温度为1 000 ℃条件下,探究焙烧时间对MoSx@ZVI去除OG的影响。如图 6所示,当焙烧时间从20 min延长至40 min和60 min,MoSx@ZVI在OG溶液中反应150 min后,OG的去除率从81.82%分别增至83.87%和99.46%。进一步延长焙烧时间至80 min,OG去除率却下降至72.82%。延长焙烧时间有利于氧化铁的还原[31-32];但是,焙烧时间延长至80 min,脱色效率与焙烧时间20 min相比约降低11.00%,可能是由于铁氧化物已经被彻底还原,过度延长焙烧时间并不会有更多的ZVI生成,反而会使已生成的ZVI颗粒黏结在一起,导致颗粒长大,ZVI颗粒数量减少,提供的反应活性位点减少,进而引起复合材料对OG去除率下降。过度延长焙烧时间不仅会降低MoSx@ZVI对OG的去除率,而且还会造成能源浪费。因此,较优焙烧时间为60 min。

综上,MoSx@ZVI的较优制备条件为:MoS2用量6%,焙烧温度1 000 ℃,无烟煤用量25%,焙烧时间60 min。

2.5 较优条件制备的MoSx@ZVI表征分析

2.5.1 MoSx@ZVI的制备机理

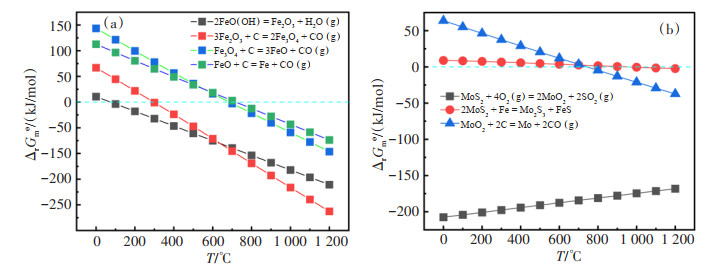

褐铁矿碳热还原过程中的热力学反应主要是针对铁矿的分解和铁氧化物的还原,同时添加的MoS2也有部分被空气氧化及其产生的氧化物被还原,反应方程式如下:

(2)

(3)

(4)

(5)

(6)

(7)

(8) 通过热力学数据库计算反应的ΔrGmɵ与焙烧温度(T)之间的关系。如图 7(a)所示,当焙烧温度约100 ℃时,针铁矿分解成赤铁矿(Fe2O3),随着焙烧温度升高,铁氧化物被逐级还原的过程为Fe2O3→Fe3O4→FeO→Fe。较优制备条件中的焙烧温度为1 000 ℃,MoSx@ZVI中6%的MoS2可能有部分在焙烧前期被空气氧化。如图 7(b)所示,MoS2的氧化反应在高温条件下极易发生,生成MoO2;MoO2在1 000 ℃的碳热还原过程被碳还原生成Mo和CO;MoS2在1 000 ℃高温条件下与Fe发生反应生成Mo2S3和FeS。

2.5.2 MoSx@ZVI的表征

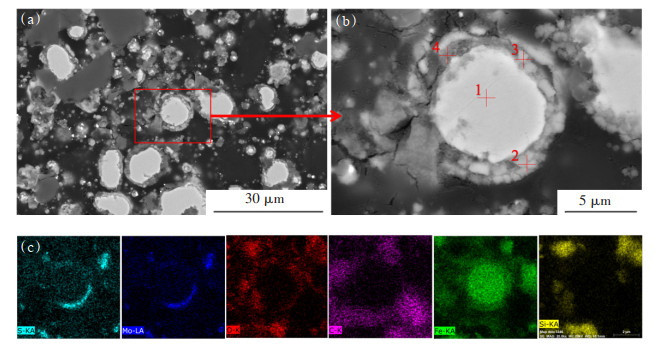

在较优条件下制备的MoSx@ZVI经SEM-EDS表征的结果见图 8。在整个焙烧过程中,无烟煤作为铁氧化物还原剂,将铁氧化为ZVI,此结果与先前对铁氧化物转化为ZVI的研究结果基本一致[33-34]。许多微小的ZVI(白色)颗粒的外层被壳包裹,通过EDS分析核壳结构中的点1—点4,其中,Fe、Mo、S、C、Si和O元素的质量占比见表 3。采用EDS分析对内核中的点1,结果表明,内核中主要有Fe、Mo和C元素,质量占比分别为88.58%、4.47%和6.8%,3种元素均可能以单质形式存在。其中,Mo单质可能是在焙烧过程中由MoS2被空气氧化后形成的MoO2被C还原形成,然后进入ZVI中。另外,焙烧过程中少量C进入ZVI,说明内核是Fe-Mo-C合金。由图 8(c)的能谱图中可以观察到Mo元素和S元素分布相似,基本在ZVI表面,呈开环状包裹。对外壳中的点2、点3和点4进行分析发现,S和Mo的平均摩尔比约为3.3(大于MoS2中的S/Mo摩尔比2.0),可能是另一部分MoS2在焙烧过程中被分解。如图 7(b)所示,由于MoS2在1 000 ℃高温条件下可与Fe发生反应并生成Mo2S3和FeS,通过热力学数据库计算可得该反应的ΔrGmɵ < 0,为自发反应,所以该反应在焙烧过程中可能发生。在外壳中可能形成了硫化钼和FeS的混合物,而外壳中被检测到O元素可能是因为硫化物容易被氧化造成的。综合上述分析,MoSx@ZVI的内核主要是Fe-Mo-C合金,而外壳可能由硫化钼、FeS、C、钼氧化物和铁氧化物组成。形成核壳结构,有利于提升ZVI对目标污染物的选择性,以及促进内核ZVI释放的电子向污染物迁移[35-36]。

表 3 MoSx@ZVI核壳结构的点扫结果Table 3. Point scan results of core-shell structure of MoSx@ZVI

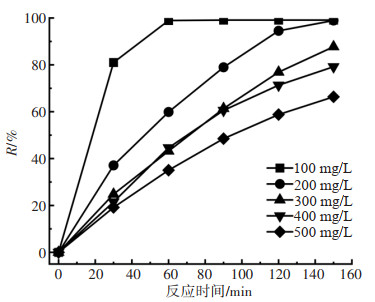

2.6 溶液初始浓度对MoSx@ZVI去除OG的影响

进行了不同初始OG浓度(100、200、300、400、500 mg/L)的分批实验,降解条件:MoSx@ZVI用量为1.5 g/L、溶液温度始终保持28 ℃、溶液初始pH为6.2(原溶液)。如图 9所示,当OG溶液的初始浓度从100 mg/L增至200 mg/L,反应速率明显下降,对溶液高效脱色所需时间从60 min延长至120 min。当初始浓度增至300 mg/L和400 mg/L时,OG去除率显著下降,反应150 min后,去除率分别降至87.73%和79.21%。进一步增加初始浓度至500 mg/L,反应150 min后,OG去除率降至66.38%,OG初始浓度过高,活性位点减少,导致反应速率逐渐降低[37-38]。此外,OG分解产生的中间产物将参与活性物种的竞争[25],也会导致OG的脱色速率下降。

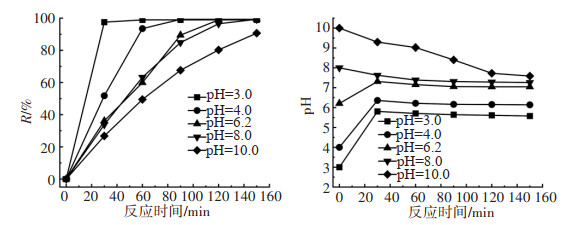

2.7 溶液初始pH值对MoSx@ZVI去除OG的影响

实际排放的染料废水的pH值通常不同[39]。因此,研究溶液初始pH对MoSx@ZVI去除OG的影响。设置3种不同的初始pH值:酸性条件(pH=3.0和pH=4.0)、原始溶液(pH 6.2)和碱性条件(pH 8.0和10.0);其他降解条件为溶液温度28 ℃,MoSx@ZVI用量1.5 g/L,OG初始浓度200 mg/L。OG在不同初始pH下的降解效率如图 10所示。在酸性条件下,MoSx@ZVI均能快速完全去除OG,初始pH越低,脱色效率越快,然而反应30 min后,pH从酸性变成弱酸性,可能是由于ZVI发生非均相类芬顿反应时消耗了大量H+[40-42]。在原溶液(pH=6.2)中,反应120 min,MoSx@ZVI对OG的去除率达到98.93%,反应过程中pH在中性范围内波动。进一步提高初始溶液pH至8.0时,MoSx@ZVI对OG去除率与原溶液环境中基本一致,而pH在反应30 min后降至中性范围内。当溶液初始pH提高至10.0时,反应150 min后,MoSx@ZVI对OG的去除率为90.67%,pH随反应时间延长而逐渐减低至中性。因此,MoSx@ZVI可适用于初始溶液pH范围为3.0~10.0,在此条件下对200 mg/L OG的去除率均在90%以上。

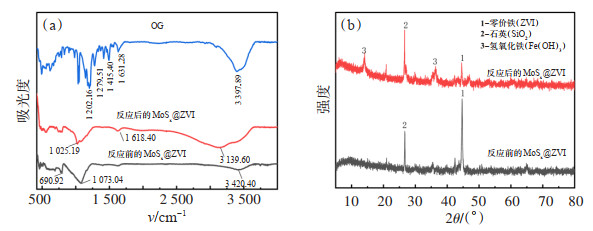

2.8 反应前后的MoSx@ZVI经FTIR和XRD的分析

FTIR光谱通常用于表征固体表面上的官能团。通过FTIR研究了MoSx@ZVI在OG溶液中反应前后固体表面官能团的变化,结果见图 11(a)。OG最主要的官能团是氮氮双键(‒N=N‒),双键拉伸区域在1 630~1 575 cm‒1范围内,峰值强度可变。通过FTIR分析,OG含有多种官能团,主要在1 631~1 035 cm‒1范围内的特征峰由OG分子结构中的‒N=N‒拉伸振动引起,而3 700~3 200 cm‒1范围的特征峰主要由OG分子中的O‒H拉伸振动引起[43]。比较反应前应后的MoSx@ZVI在FTIR光谱上出现了特征吸收峰为1 025 cm‒1和3 139 cm‒1,特征峰基本相似。MoSx@ZVI对OG的降解反应前后XRD谱图见图 11(b),对比反应前的MoSx@ZVI,以1.5 g/L用量加入200 mg/L OG溶液(水浴温度为28 ℃,pH=6.2)中反应150 min后,清晰地发现ZVI峰显著下降,并且有氢氧化铁生成,说明该反应过程消耗大量的ZVI,并且有部分Fe0转化为Fe3+,但是ZVI的还原性不能直接还原去除OG,所以ZVI释放电子转化成Fe3+同时可能伴有活性物质产生,从而氧化降解OG。因此,ZVI峰下降说明了MoSx@ZVI去除OG的方式是氧化还原机制。

3 结论

1)通过优化焙烧条件对MoSx@ZVI去除OG的影响进行研究,确定了MoSx@ZVI的较优制备条件是以50 g褐铁矿,加入其质量比6%的MoS2和25%无烟煤,在1 000 ℃下焙烧60 min。

2)通过SEM-EDS分析,清楚地观察到许多微小的ZVI(白色)颗粒的外层被壳包裹,形成核壳结构,MoSx@ZVI的内核主要是ZVI-Mo-C合金,而外壳可能由硫化钼、FeS、C、钼氧化物和铁氧化物组成。

3)将较优条件制备的MoSx@ZVI碎磨粒径小于0.1 mm,取0.6 g MoSx@ZVI处理400 mL 200 mg/L OG模拟废水,在初始pH = 3.0~10.0范围处理150 min,OG的去除率均在90%以上。

4)在较优条件下合成的MoSx@ZVI在初始pH =6.2、400 mL 200 mg/L OG溶液中反应前后状态经FTIR和XRD分析,其结果表明此反应是通过氧化还原的方式去除OG。

-

表 1 褐铁矿的X荧光分析结果

Table 1 Results of X-ray fluorescence analysis of limonite

表 2 无烟煤工业分析结果

Table 2 Industrial analysis results of anthracite

表 3 MoSx@ZVI核壳结构的点扫结果

Table 3 Point scan results of core-shell structure of MoSx@ZVI

-

[1] FERREIRA M B, MUÑOZ-MORALES M, SÁEZ C, et al. Improving biotreatability of hazardous effluents combining ZVI, electrolysis and photolysis[J]. Science of the Total Environment, 2020, 713: 136647. doi: 10.1016/j.scitotenv.2020.136647

[2] WANG Q, SONG X, WEI C L, et al. In situ remediation ofCr(Ⅵ) contaminated groundwater by ZVI-PRB and the corresponding indigenous microbial community responses: a field-scale study[J]. Science of the Total Environment, 2022, 805: 150260-150260. doi: 10.1016/j.scitotenv.2021.150260

[3] WANG M Q, YANG S Y, LIU J Q, et al. Enteromorpha prolifera biochar as a novel ball milling aid for enhancing the interfacial reaction activity of microscale zero-valent iron (mZVI) forCr(Ⅵ) removal from water[J]. Journal of Water Process Engineering, 2022, 48: 102844. doi: 10.1016/j.jwpe.2022.102844

[4] 刘学, 李小燕, 陈玉洁, 等. 石墨负载纳米零价铁去除溶液中U(Ⅵ)[J]. 中国有色金属学报, 2020, 30(8): 1967-1973. https://www.cnki.com.cn/Article/CJFDTOTAL-ZYXZ202008024.htm [5] MOLLA A, KIM A Y, WOO J C, et al. Study on preparation methodology of zero-valent iron decorated on graphene oxide for highly efficient sonocatalytic dye degradation[J]. Journal of Environmental Chemical Engineering, 2022, 10(2): 107214. doi: 10.1016/j.jece.2022.107214

[6] 何桂春, 陈健, 丁军, 等. 活性炭负载纳米零价铁去除矿山废水中的Cu2+[J]. 有色金属科学与工程, 2016, 7(5): 119-124. doi: 10.13264/j.cnki.ysjskx.2016.05.021 [7] CHENG Y J, DONG H R, LU Y, et al. Toxicity of sulfide-modified nanoscale zero-valent iron to escherichia coli in aqueous solutions[J]. Chemosphere, 2019, 220: 523-530. doi: 10.1016/j.chemosphere.2018.12.159

[8] XU J, WANG Y, WENG C, et al. Reactivity, selectivity, and long-term performance of sulfidized nanoscale zerovalent iron with different properties[J]. Environmental Science & Technology, 2019, 53(10): 5936-5945.

[9] SUN Y, GU M B, LYU S G, et al. Efficient removal of trichloroethene in oxidative environment by anchoring nano FeS on reduced graphene oxide supported nZVI catalyst: the role of FeS on oxidant decomposition and iron leakage[J]. Journal of Hazardous Materials, 2020, 392: 122328. doi: 10.1016/j.jhazmat.2020.122328

[10] KIM E J, KIM J H, AZAD A M, et al. Facile synthesis and characterization of Fe/FeS nanoparticles for environmental applications[J]. ACS Applied Materials & Interfaces, 2011, 3(5): 1457-62.

[11] WANG B, DONG H R, LI L, et al. Influence of different co-contaminants on trichloroethylene removal by sulfide-modified nanoscale zero-valent iron[J]. Chemical Engineering Journal, 2020, 381(C): 122773.

[12] PANG H W, LIU L J, BAI Z A, et al. Fabrication of sulfide nanoscale zero-valent iron and heterogeneous fenton-like degradation of 2, 4-dichlorophenol[J]. Separation and Purification Technology, 2022, 285: 120408. doi: 10.1016/j.seppur.2021.120408

[13] FAN D M, JOHNSON G O, TRATNYEK P G, et al. Sulfidation of nano zerovalent iron (nZVI) for improved selectivity during in-situ chemical reduction (ISCR)[J]. Environmental Science & Technology, 2016, 50(17): 9558-65.

[14] CHEN J, DONG H R, TIAN R, et al. Remediation of trichloroethylene-contaminated groundwater by sulfide-modified nanoscale zero-valent iron supported on biochar: investigation of critical factors[J]. Water, Air, & Soil Pollution, 2020, 231(8): 536-544.

[15] DAI Y S, DUAN L F, DONG Y M, et al. Elemental sulfur generated in situ from Fe(Ⅲ) and sulfide promotes sulfidation of microscale zero-valent iron for superiorCr(Ⅵ) removal[J]. Journal of Hazardous Materials, 2022, 436: 129256. doi: 10.1016/j.jhazmat.2022.129256

[16] PANG H W, ZHANG E Y, ZHANG D, et al. Precursor impact and mechanism analysis of uranium elimination by biochar supported sulfurized nanoscale zero-valent iron[J]. Journal of Environmental Chemical Engineering, 2022, 10(2): 107288. doi: 10.1016/j.jece.2022.107288

[17] ZHANG P, SONG D B, HAO Y L, et al. Sulfidated zero valent iron as a persulfate activator for oxidizing organophosphorus pesticides (OPPs) in aqueous solution and aged contaminated soil columns[J]. Chemosphere, 2021, 281: 130760. doi: 10.1016/j.chemosphere.2021.130760

[18] LI J X, ZHANG X Y, SUN Y K, et al. Advances in sulfidation of zerovalent iron for water decontamination[J]. Environmental Science & Technology, 2017, 51(23): 13533-13544.

[19] SUN Y Q, YU I K M, TSANG D C W, et al. Multifunctional iron-biochar composites for the removal of potentially toxic elements, inherent cations, and hetero-chloride from hydraulic fracturing wastewater[J]. Environment International, 2019, 124: 521-532. doi: 10.1016/j.envint.2019.01.047

[20] ZHOU H, WU S K, ZHOU Y Y, et al. Insights into the oxidation of organic contaminants by iron nanoparticles encapsulated within boron and nitrogen co-doped carbon nanoshell: catalyzed fenton-like reaction at natural pH[J]. Environment International, 2019, 128: 77-88. doi: 10.1016/j.envint.2019.04.006

[21] YANG M, ZHANG X L, YANG Y C, et al. Effective destruction of perfluorooctanoic acid by zero-valent iron laden biochar obtained from carbothermal reduction: experimental and simulation study[J]. Science of the Total Environment, 2022, 805: 150326. doi: 10.1016/j.scitotenv.2021.150326

[22] 张小毛, 陈维芳, 晏长成, 等. 液相还原和碳热法制备纳米零价铁/活性炭复合材料的比较研究[J]. 水资源与水工程学报, 2015, 26(3): 129-135. https://www.cnki.com.cn/Article/CJFDTOTAL-XBSZ201503027.htm [23] KOH E, LEE Y T. Hybrid nanocomposites of a molybdenum disulfide (MoS2) based hydrophobic filler for a robust self-cleaning effect[J]. Journal of Industrial and Engineering Chemistry, 2021, 96: 294-306. doi: 10.1016/j.jiec.2021.01.033

[24] LI Z, FAN R, HU Z, et al. Ethanol introduced synthesis of ultrastable 1T-MoS2 for removal ofCr(Ⅵ)[J]. Journal of Hazardous Materials, 2020, 394: 122525. doi: 10.1016/j.jhazmat.2020.122525

[25] DALILA R N, MD ARSHAD M K, GOPINATH S C B, et al. Current and future envision on developing biosensors aided by 2D molybdenum disulfide (MoS2) productions[J]. Biosensors and Bioelectronics, 2019, 132: 248-264. doi: 10.1016/j.bios.2019.03.005

[26] WANG K, CHEN P P, NIE W Y, et al. Improved photocatalytic reduction ofCr(Ⅵ) by molybdenum disulfide modified with conjugated polyvinyl alcohol[J]. Chemical Engineering Journal, 2019, 359: 1205-1214. doi: 10.1016/j.cej.2018.11.057

[27] LU W, SANG W J, JIA D N, et al. Improvement of degradation of orange G in aqueous solution by Fe2+ added in dielectric barrier discharge plasma system[J]. Journal of Water Process Engineering, 2022, 47: 102707. doi: 10.1016/j.jwpe.2022.102707

[28] ZHANG L, SHAO Q Q, XU C H. Enhanced azo dye removal from wastewater by coupling sulfidated zero-valent iron with a chelator[J]. Journal of Cleaner Production, 2019, 213: 753-761. doi: 10.1016/j.jclepro.2018.12.183

[29] DU Y F, DAI M, NAZ I, et al. Carbothermal reduction synthesis of zero-valent iron and its application as a persulfate activator for ciprofloxacin degradation[J]. Separation and Purification Technology, 2021, 275: 119201. doi: 10.1016/j.seppur.2021.119201

[30] ZHOU X L, ZHU D Q, PAN J, et al. Utilization of waste copper slag to produce directly reduced iron for weathering resistant steel[J]. ISIJ International, 2015, 55(7): 1347-1352. doi: 10.2355/isijinternational.55.1347

[31] SARFO P, DAS A, WYSS G, et al. Recovery of metal values from copper slag and reuse of residual secondary slag[J]. Waste Management, 2017, 70: 272-281. doi: 10.1016/j.wasman.2017.09.024

[32] 李中臣, 王亲猛, 田庆华, 等. 铜熔炼渣制备铁精矿研究[J]. 有色金属科学与工程, 2022, 13(4): 1-9. doi: 10.13264/j.cnki.ysjskx.2022.04.001 [33] 谭晓恒, 郭少毓, 喻相标, 等. 焙烧铜渣中磁铁矿的物性转变研究[J]. 有色金属科学与工程, 2020, 11(5): 83-89. doi: 10.13264/j.cnki.ysjskx.2020.05.012 [34] 姜平国, 闫永播, 刘金生, 等. 铜渣在CO2-CO混合气体中焙烧实验研究[J]. 有色金属科学与工程, 2018, 9(1): 28-33. doi: 10.13264/j.cnki.ysjskx.2018.01.005 [35] WU N N, QU R J, LI C G, et al. Enhanced oxidative degradation of decabromodiphenyl ether in soil by coupling Fenton-persulfate processes: insights into degradation products and reaction mechanisms[J]. Science of the Total Environment, 2020, 737: 139777. doi: 10.1016/j.scitotenv.2020.139777

[36] WU Z L, WANG Y P, XIONG Z K, et al. Core-shell magnetic Fe3O4@Zn/Co-ZIFs to activate peroxymonosulfate for highly efficient degradation of carbamazepine[J]. Applied Catalysis B: Environmental, 2020, 277: 119136. doi: 10.1016/j.apcatb.2020.119136

[37] 郑春莉, 林子深, 王辉, 等. 凹凸棒负载非晶态零价铁去除水体中的Cr(Ⅵ)[J]. 中国有色金属学报, 2022, 32(11): 3434-3447. https://www.cnki.com.cn/Article/CJFDTOTAL-ZYXZ202211017.htm [38] ZHOU T, ZOU X, WU X, et al. Synergistic degradation of antibiotic norfloxacin in a novel heterogeneous sonochemical Fe0/tetraphosphate Fenton-like system[J]. Ultrasonics Sonochemistry, 2017, 37: 320-327. doi: 10.1016/j.ultsonch.2017.01.015

[39] WU L, XIE Q, LV Y, et al. Degradation of methylene blue via dielectric barrier discharge plasma treatment[J]. Water, 2019, 11(9): 1818. doi: 10.3390/w11091818

[40] 李小燕, 张明, 刘义保, 等. 离子强度、阴阳离子和腐殖酸对纳米零价铁去除溶液中U(Ⅵ)的影响[J]. 中国有色金属学报, 2015, 25(12): 3505-3512. https://www.cnki.com.cn/Article/CJFDTOTAL-ZYXZ201512029.htm [41] MASSIMA MOUELE E S, TIJANI J O, MASIKINI M, et al. Spectroscopic measurements of dissolved O3, H2O2 and OH radicals in double cylindrical dielectric barrier discharge technology: treatment of methylene blue dye simulated wastewater[J]. Plasma, 2020, 3(2): 59-91.

[42] 揭诗琪, 邵继莹, 吴雨桐, 等. 生物淋滤结合类芬顿反应去除底泥中重金属[J]. 有色金属科学与工程, 2016, 7(1): 108-113. doi: 10.13264/j.cnki.ysjskx.2016.01.020 [43] DEV V V, WILSON B, NAIR K K, et al. Response surface modeling of orange-G adsorption onto surface tuned ragi husk[J]. Colloid and Interface Science Communications, 2021, 41: 100363.

-

期刊类型引用(2)

1. 荆晓生,郭思远,李昕圆,王雪,徐浩,延卫. Ti_4O_7阳极材料制备改性及其在电化学水处理中的应用研究进展. 稀有金属. 2024(08): 1163-1176 .  百度学术

百度学术

2. 胡杨,何沐阳. MoS_2掺杂DLC薄膜对力学性能及摩擦学行为的影响. 陶瓷学报. 2023(05): 958-964 .  百度学术

百度学术

其他类型引用(0)

下载:

下载: