Preparation and Performance of Nano-crystalline (Nd, Ce)-Fe-B/(Nd, R)-Fe-B (R=Pr, La) Hot-pressed Magnets

-

摘要:

基于双合金技术,采用放电等离子体烧结制备了不同比例的各向同性纳米晶 (Nd, Ce)-Fe-B/(Nd, R)-Fe-B (R = Pr, La) 热压磁体,并探究了不同热压磁体的磁性能和微观结构。结果表明,随着(Pr, Nd)-Fe-B合金的添加,剩磁和矫顽力均有所提升。背散射图像(结果)表明,团聚的块状富稀土相逐渐消失,晶界相变得更为均匀且薄,从而提升了矫顽力。此外,磁体中(Pr, Nd)-Fe-B主相比例的增加,也有效地提升了热压磁体的磁性能。当添加量(质量分数,下同)为60 %时,磁体剩磁Jr为8.58 ×0.1 (T),矫顽力Hcj为12.65 ×79.6 (kA/m),最大磁能积(BH)max为15.79 ×7.96 (kJ/m3)。

Abstract:Based on the dual-alloy technology, isotropic nanocrystalline (Nd, Ce) -Fe-B/(Nd, R)-Fe-B (R = Pr, La ) hot-pressed magnets with different proportions were prepared by spark plasma sintering, and the magnetic properties and microstructure of the hot-pressed magnets were investigated. The results show that the remanence and coercivity are improved with the addition of (Pr, Nd)-Fe-B alloy. BSE images(results) shows that the agglomerated block rare earth-rich phase gradually disappears, and the grain boundary phase becomes more uniform and thin, thereby increasing the coercivity. In addition, the increase of the proportion of (Pr, Nd)-Fe-B main phase also effectively improves the magnetic properties of hot-pressed magnets. When the addition amount is 60 %, the magnetic properties of Jr=8.58 ×0.1 (T), Hcj=12.65 ×79.6 (kA/m), (BH)max=15.79 ×7.96 (kJ/m3) were obtained.

-

Keywords:

- double alloy /

- magnetic properties /

- microstructure /

- spark plasma sintering

-

钕铁硼自1983年被发明以来,由于其优异的综合磁性能,享有“磁王”的美誉,被应用在各个领域[1-7]。在一定体积下,Nd2Fe14B型磁体可以获得更大的磁能积,这对于实现相关器件的小型化、轻量化和集成化具有重要意义[8-9]。然而,Nd2Fe14B型磁体的广泛应用导致了昂贵稀土 (如Tb、Dy和Nd) 的大量消耗,为此,Ce、La等低成本、高丰度的稀土元素备受关注[10-19]。由于Ce2Fe14B相 (饱和磁化强度Js =1.17 T,各向异性场HA = 26 ×79.6 (kA/m) 的内禀磁性不如Nd2Fe14B相 (饱和磁化强度Js =1.60 T,各向异性场HA = 73 ×79.6 kA/m) [20], Ce取代Nd会导致较强的磁稀释效应,从而导致Nd-Fe-B磁体的磁性显著降低。因此,研究人员目前的重点是利用高丰度元素,如La和Ce,部分取代Dy/Tb/Nd元素,从而实现稀土资源使用的平衡[21-24]。

TANG等[25-27]的研究改善了Ce取代Nd-Fe-B基各向异性永磁体的硬磁性能,结果表明,20% Ce取代Nd-Fe-B的热变形磁体矫顽力为1.69 T、剩磁为1.32 T,与Nd-Fe-B烧结永磁体相当。PATHAK等[28-29]通过熔体快淬、热压和变形成功地获得了一系列 (Nd1-xCex)2Fe14B和 (Nd1-xCex)2Fe14-yCoyB合金,证明了Ce和Co的引入可以作为一些基于Dy的Nd-Fe-B磁体的优秀替代品,并表现出卓越的磁性。此外,La对合金的室温磁性能也有着积极的影响。HUSSAIN等[30]研究表明,La取代 (Nd1-xLax)10Fe84B6 合金中10%的Nd后,晶粒得到了细化,从而提高了合金的内禀矫顽力,弥补了其由于低各向异性场造成的矫顽力降低。CHANG等[31]发现,5%的La取代Nd后,会产生细小晶粒的微观结构,从而提高合金的内禀矫顽力。因此,通过部分La或Ce取代Nd,合金磁性能得到有效提升。

为了进一步提升磁性能,在含La、Ce的热压磁体中,胡宇霆[32]通过双合金工艺添加低熔点合金NdAl,改善了磁体的致密度,磁性能提升为:Hcj = 9.14 ×79.6 kA/m,Jr = 6.32 ×0.1 T,(BH)max = 8.51×7.96 kJ/m3。CUI等[33]通过双合金技术研究了PrCu合金对Nd-Ce-Fe-B基磁体磁特性的影响,当添加量均为 2%时,磁体的矫顽力分别从13.2 ×79.6 kA/m 增加至14.2 ×79.6 kA/m。此外,通过双合金工艺制备的多主相 (MMP) 磁体,由于RE在2:14:1相中的分布不均匀,MMP磁体可以有效降低Ce的磁稀释效应[34]。研究表明,这种化学非均质性对MMP Nd-Ce-Fe-B磁体的磁性有重要贡献[35]。在烧结磁体中,ZHU等[36]采用双主相合金法,获得烧结磁体的最大磁能积(BH)max = 43.0 ×7.96 kJ/m3,Ce取代30%的Nd。在黏结磁体或热压磁体中,如何利用双合金多主相技术来制备出高性能的高丰度稀土永磁体需要进一步探索和实践。

为了更好地利用高丰度稀土元素 (如La、Ce等),平衡稀土资源的使用,降低稀土永磁体的成本,本文首先探究了不同烧结温度下(Nd, Ce)-Fe-B热压磁体的磁性能,优化了放电等离子烧结温度,随后通过双合金法制备了纳米晶MMP RE-Fe-B热压磁体,并探究了在不同 (Nd, Ce)-Fe-B/(Nd, R)-Fe-B (R = Pr, La) 比例下热压磁体磁性能和微观结构。

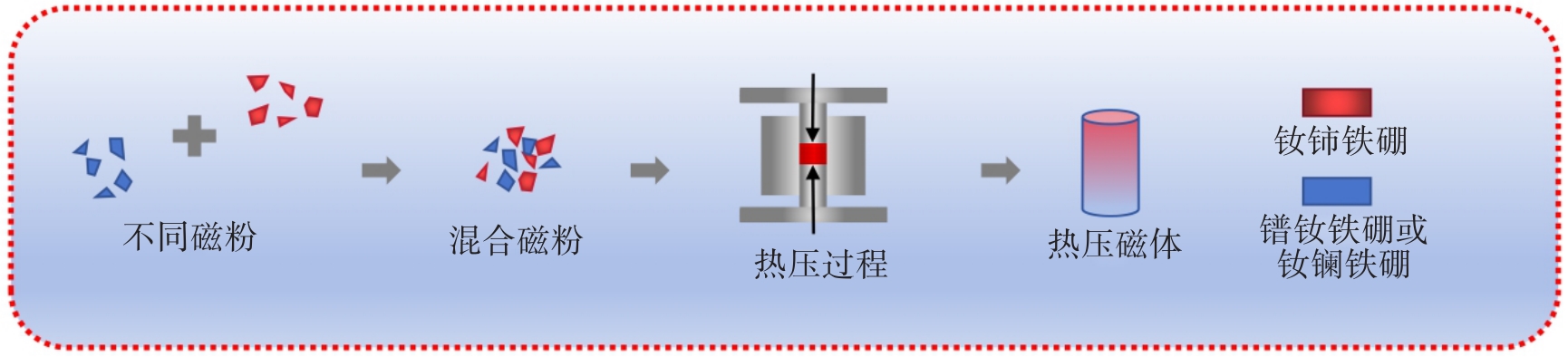

1 实验部分

本实验材料采用购于江西江钨稀有金属新材料股份有限公司的3种商业磁粉,其主要成分分别是(Nd, Ce)-Fe-B、(Pr, Nd)-Fe-B和(Nd, La)-Fe-B(简称:NC、PN和NL)。具体成分为:NC (Nd18.18Pr5.95Ce5.77Fe68.81·Co0.02Mn0.03Cu0.01Al0.17Bbal ,%),PN (Nd29.8Pr0.1Fe64.7Si0.1·Co3.0Al0.1Ga0.5Bbal ,%),NL(Nd19.04Pr6.66La4.18Fe68.26Co0.02·Mn0.03Cu0.01Al0.67Bbal ,%)。 如图1所示,通过双合金法,将NC磁粉分别与PN/NL磁粉按不同的比例混合,混合均匀后,倒入内孔径为13 mm的圆形合金模具中。在模具内侧,铺上一层0.1 mm的石墨纸,以增加其导电导热性能。随后,通过放电等离子烧结 (SPS) 进行加热,使磁体致密。加热前真空度需达到8×10-3 Pa,在加热结束后,随炉自然冷却至120 ℃,关闭真空后取样脱模。将脱模后的热压磁体打磨干净,以进行磁性能的测试和表征。

使用永磁测量仪 (NIM-500C) 测试了不同工艺下热压磁体的常温磁性能。磁体的密度基于阿基米德原理,通过排水法测试。通过Cu Kα辐射的X射线衍射仪获得了磁体的XRD图谱,并使用Jade软件进行分析。采用扫描电子显微镜 (SEM, MLA650F) 对不同热压磁体的微观结构和元素分布等进行表征分析。

2 结果与讨论

2.1 物相分析

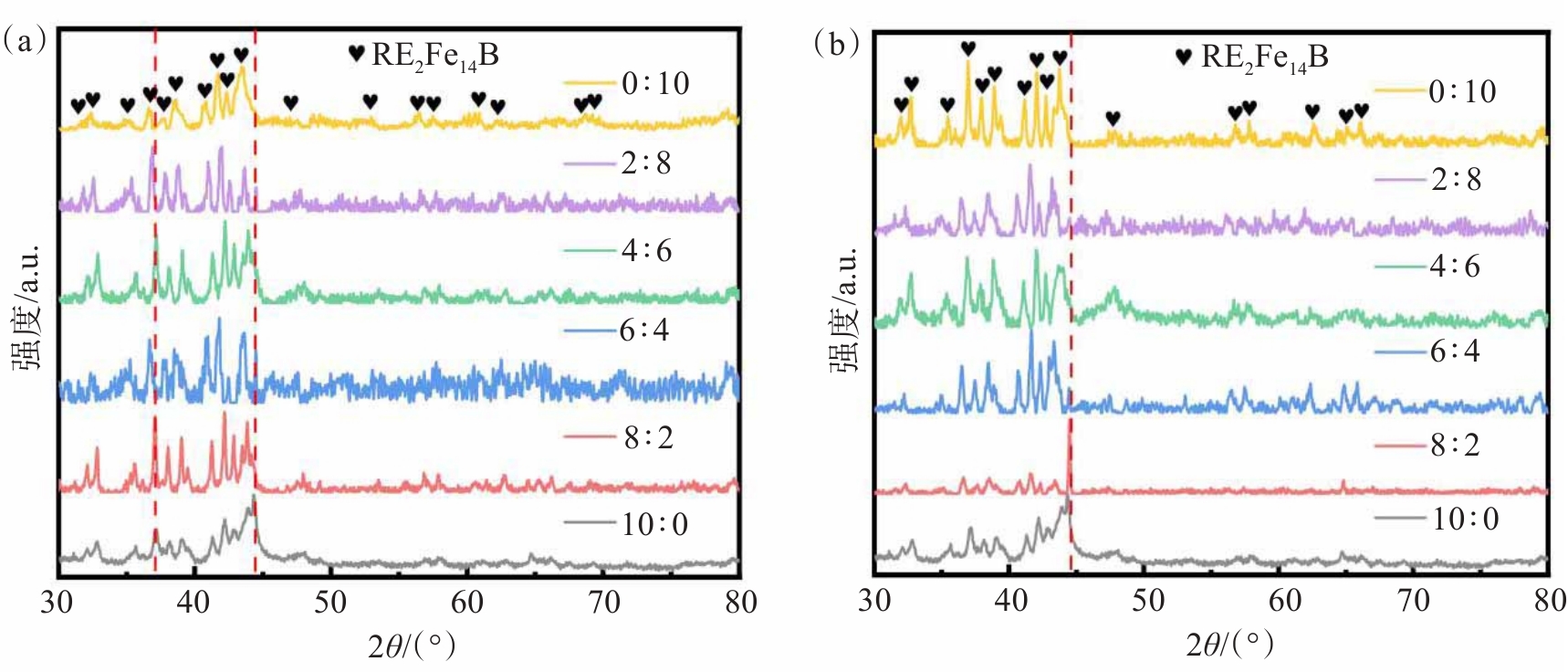

本文研究分析了不同混合比例下热压磁体中物相的组成,如图2所示为不同热压磁体的XRD图谱。如图2 (a) 可知,在掺杂一定比例的PN磁粉后,图2中衍射峰均为2∶14∶1主相,无明显杂相。在原Nd-Ce-Fe-B磁体中,成分测试结果表明,Ce约占稀土总量的20%,可能形成少量的CeFe2相,但由于含量较低,XRD很难检测出明显的衍射峰。此外,由图2中虚线标记处可知,随着PN磁粉比例的增加,主相的衍射峰向低角度偏移,表明主相晶粒的晶格常数变大,这与文献[37]报道的结果一致。在掺杂一定比例的NL磁粉后,如图2 (b) 所示,也观察到了衍射峰的偏移。这主要是由于在磁体中,Pr-Fe-B或La-Fe-B主相的比例增加,而Pr2Fe14B化合物的晶格常数 (a = 8.81 Å,c = 12.27 Å)、La2Fe14B 化合物的晶格常数(a = 8.82 Å,c = 12.34 Å) 均大于Ce2Fe14B化合物的晶格常数 (a = 8.76 Å,c = 12.11 Å) [38]。

2.2 磁性能分析

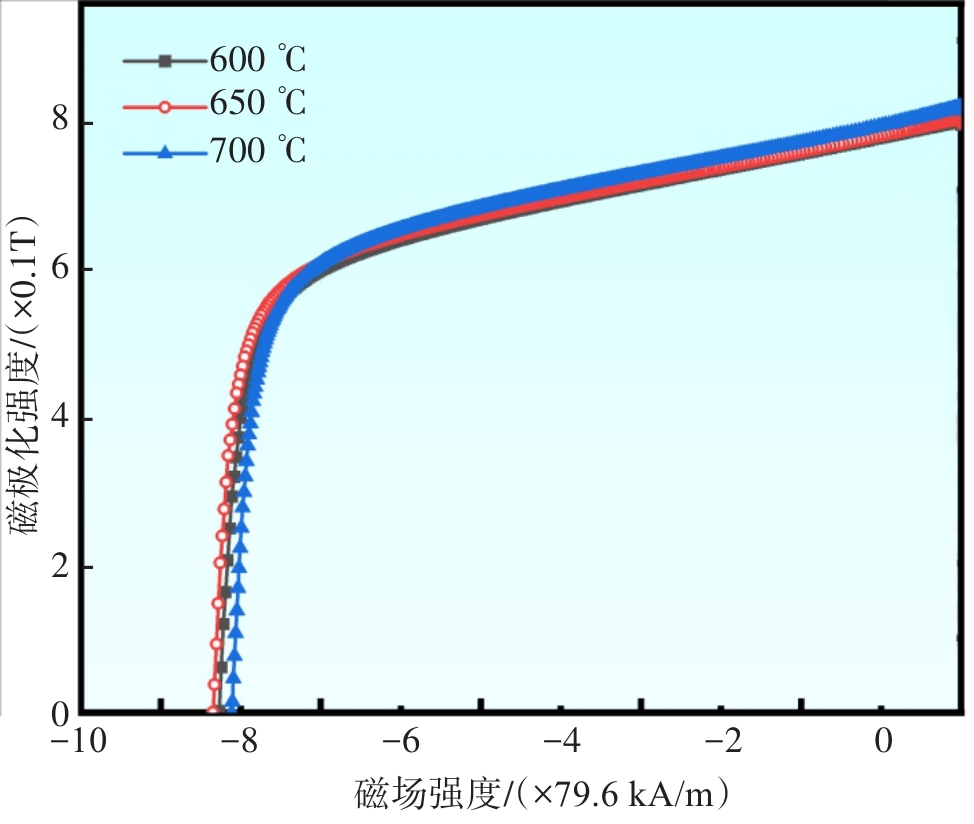

在热压热变形钕铁硼中,烧结温度直接影响了磁体的微观结构,从而对磁性能产生重大影响。与传统烧结相比,放电等离子烧结 (SPS) 具有温度低、时间短等优势[39]。它可以保持化学非均质性的多主相结构,同时实现超细主相晶粒结构,有望获得更高的性能。烧结温度是影响磁体致密化、晶粒尺寸和MMP Nd-Ce-Fe-B磁体中Nd/Ce互扩散的最重要因素[40-41]。如图3所示,采用NC磁粉探究了不同的烧结温度,在250 MPa/5 min条件下,热压磁体的磁性能退磁曲线。由图3可知,随着温度的升高,磁体的剩磁逐步增大,而矫顽力先增大后减小。随着烧结温度的逐步提高,增大了磁体的密度,从而提高了剩磁。然而,烧结温度过高,也会促进晶粒的过度生长,增加了晶粒表面缺陷的数量,从而促进了反转畴的成核,使得磁体矫顽力减小[42]。磁体具体磁性能如表1所列,综合考虑,确定650 ℃为较优烧结工艺。

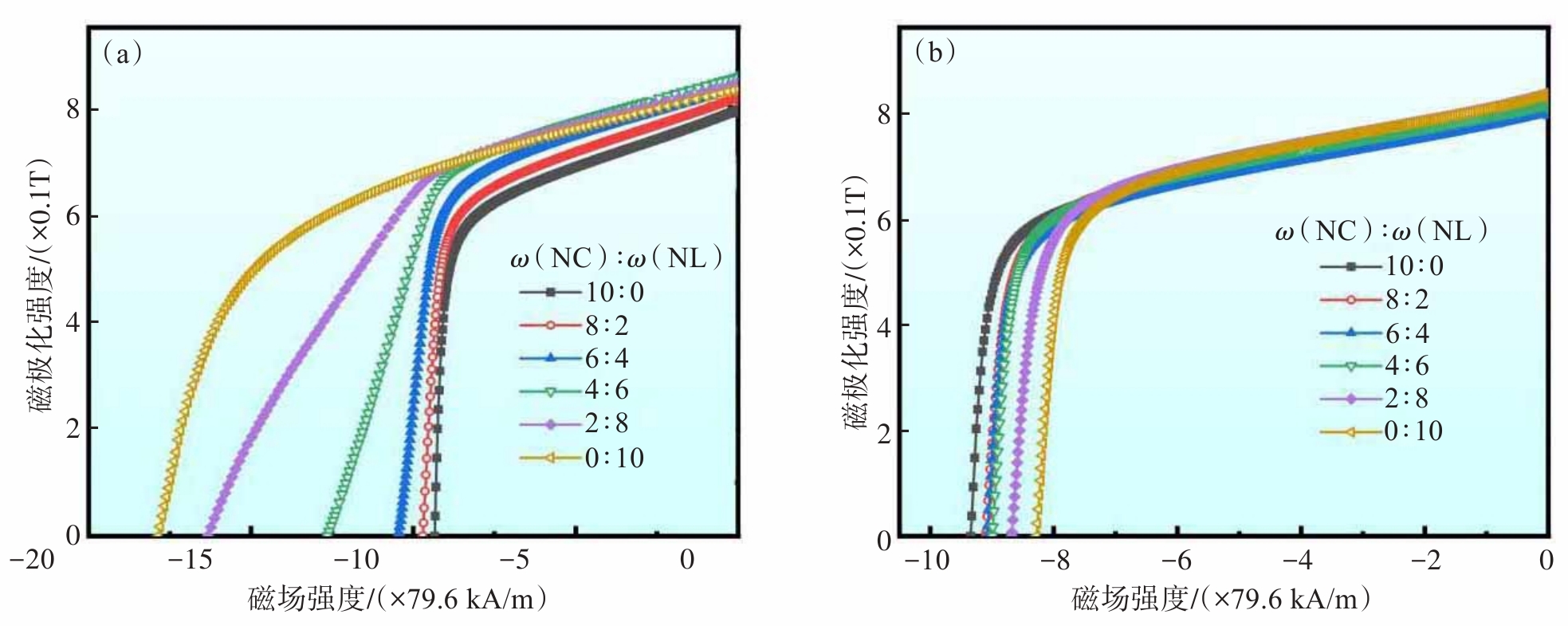

表 1 不同烧结温度Nd-Ce-Fe-B热压磁体的磁性能Table 1. Magnetic properties of Nd-Ce-Fe-B hot-pressed magnets sintered at different temperatures烧结温度/保温时间/压力 剩磁 /(×0.1 T) 矫顽力 /(×79.6 kA/m) 最大磁能积 /(×7.96 kJ/m3) 密度 /(g/cm³) 600 ℃/5 min/250 MPa 7.92 9.27 12.91 7.632 650 ℃/5 min/250 MPa 7.96 9.35 13.02 7.662 700 ℃/5 min/250 MPa 8.07 9.21 12.99 7.721 为了提高 (Nd, Ce)-Fe-B热压磁体的磁性能,将NC磁粉分别与PN/NL磁粉按不同的比例进行混合,退磁曲线如图4所示。磁体的烧结工艺为:650 ℃/250 MPa/5 min。当掺入不同比例的PN磁粉后发现,热压磁体的剩磁先增大后减小,当掺杂量为60%时,达到最优为8.58 ×0.1 (T),而矫顽力则持续增大,具体磁性能如表2所列。然而,随着掺杂量的增加,磁体的密度有所下降。这主要是由于磁体中Pr-Nd-Fe-B相的增加,富Ce稀土相和CeFe2相的质量分数相对减少,而Ce2Fe14B化合物的理论密度 (7.67 g/cm3) 和CeFe2化合物的理论密度 (8.60 g/cm3) 均大于Nd2Fe14B化合物的理论密度 (7.60 g/cm3) 和Pr2Fe14B化合物的理论密度 (7.54 g/cm3),这在文献[43]中也发现了类似的现象。

表 2 不同混合比例NC/PN热压磁体的磁性能Table 2. Magnetic properties of NC / PN hot-pressed magnets with different mixing ratiosω(NC)/ω(PN) 剩磁 /(×0.1 T) 矫顽力 /(×79.6 kA/m) 最大磁能积 /(×7.96kJ/m3) 密度 /(g/cm³) 10∶0 7.96 9.35 13.02 7.662 8∶2 8.19 9.71 13.92 7.660 6∶4 8.40 10.46 14.93 7.643 4∶6 8.58 12.65 15.79 7.638 2∶8 8.44 16.33 15.49 7.634 0∶10 8.35 17.86 15.15 7.601 当掺入不同比例的NL磁粉后,可以得知,磁体的剩磁呈现总体上升的趋势,而矫顽力则逐步下降,具体磁性能如表3所列。同样,随着磁体中Nd-La-Fe-B相增加,由于其理论密度 (7.40 g/cm3) 相对较低,使得磁体的密度下降。

表 3 不同混合比例NC/NL热压磁体的磁性能Table 3. Magnetic properties of NC / NL hot-pressed magnets with different mixing ratiosω(NC)/ω(NL) 剩磁 /(×0.1 T) 矫顽力 /(×79.6 kA/m) 最大磁能积 /(×7.96 kJ/m3) 密度 /(g/cm³) 10∶0 7.96 9.35 13.02 7.662 8∶2 8.11 9.10 13.41 7.620 6∶4 7.92 9.08 12.76 7.583 4∶6 8.07 8.99 13.34 7.552 2∶8 8.26 8.68 13.82 7.496 0∶10 8.25 8.26 13.80 7.483 2.3 微观结构分析

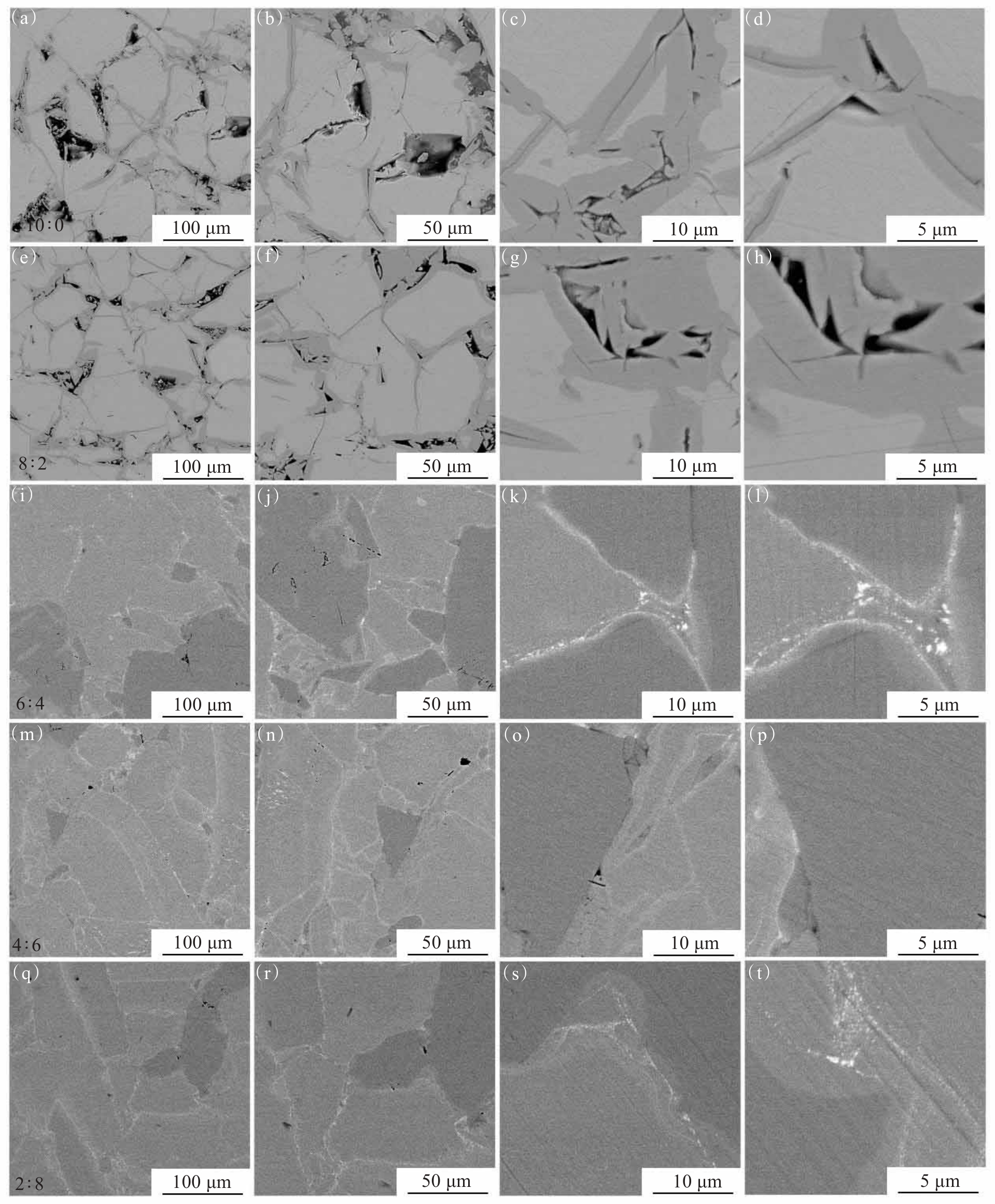

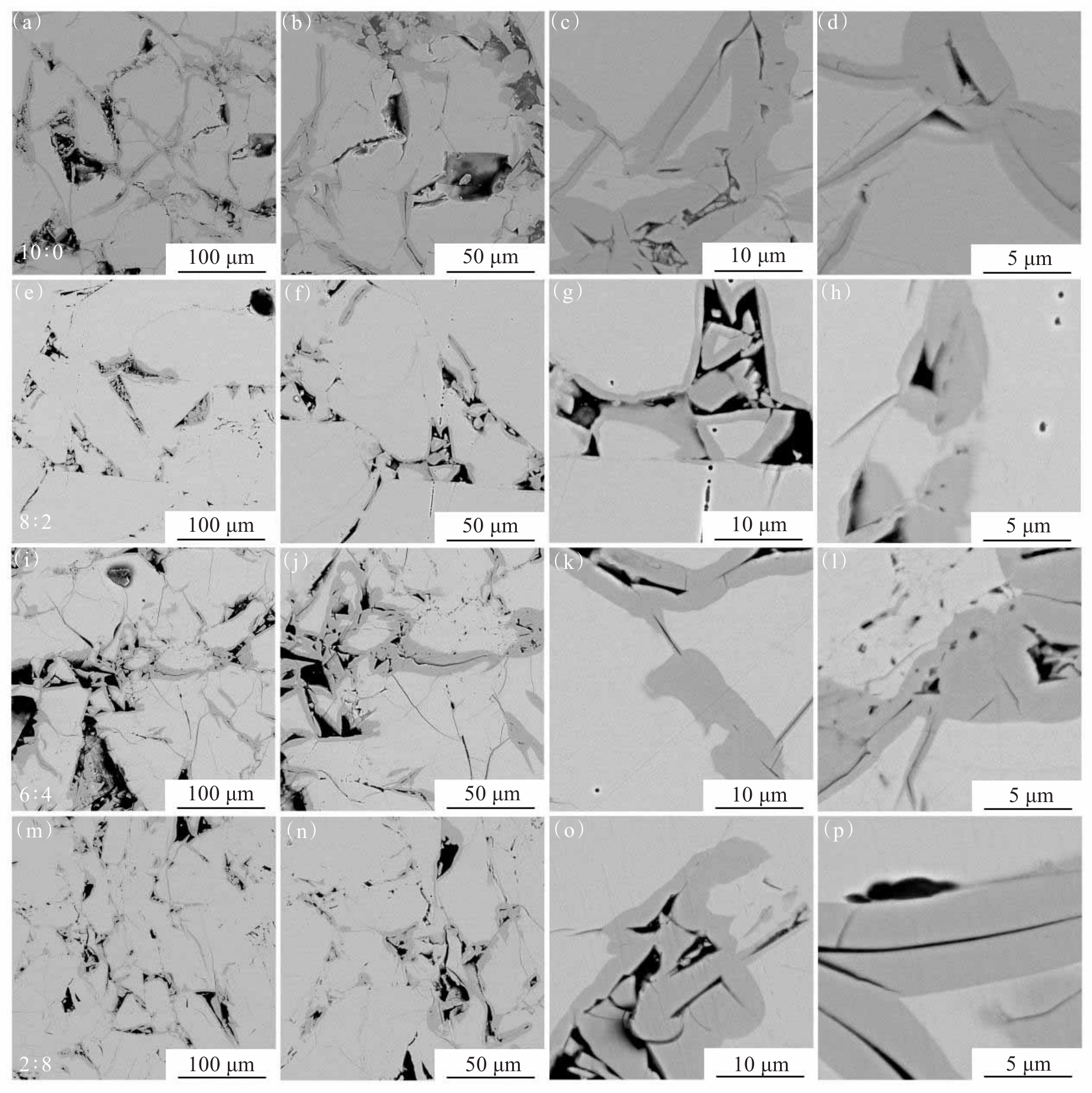

在不同的混合比例下,热压磁体的微观结构直接影响了磁体的磁性能。如图5所示为不同混合比例下NC/PN热压磁体表面的背散射 (BSE)像。图 5(a)—图5(d) 为原 (Nd, Ce)-Fe-B热压磁体不同倍率下的BSE像,可以观察到,浅灰色块状区域即为2∶14∶1主相,深灰色条纹状区域为富稀土相,黑色区域为样品抛光时脱落的富稀土相。由此可知,在该热压磁体中,富稀土相团聚严重,不利于隔绝主相晶粒之间的交换耦合作用。随着PN磁粉掺杂量的增加,可以发现,富稀土相的团聚减少,晶界相变得更为连续且薄,有利于矫顽力的增加,这与磁性能的结果一致。此外,富稀土相的衬度变白,这主要是晶界相中Pr和Nd含量增加导致的。

如图6所示,为不同混合比例下ω(NC)/ω(NL)热压磁体的BSE像。可以观察到,随着NL磁粉掺杂量的增加,富稀土相的团聚现象并没有改善,反而在局部区域存在着更为严重的团聚,不利于隔绝主相晶粒之间的交换耦合作用,导致矫顽力下降。

此外,针对ω(NC)/ω(NL)热压磁体进行了扫描电镜能谱 (BSE-EDS) 分析,如图7所示,其中,EDS面扫区域对应于BSE区域。由于富稀土相在抛光过程中脱落,使得EDS像中稀土元素在晶界的富集现象并不明显,但Fe元素在主相晶粒和晶界中存在明显的浓度梯度。当NL的掺杂量为20%时,在主相粉末中,Nd和Ce的分布较为均匀,而La元素则存在着局部的富集。当掺杂量增加到40%时,Nd、Ce和La的分布相对均匀;持续增加到80%时,能够明显地观察到在主相晶粒中存在着富Ce的主相和富La的主相。这表明在不同的掺杂量下,形成了不同比例的(Nd, Ce)-Fe-B主相和(Nd, La)-Fe-B主相晶粒。

2.4 讨 论

在掺杂不同比例的PN合金后,随着掺杂量的增加,(Pr, Nd)-Fe-B主相的比例逐步增加,增大了主相晶粒的晶格常数,使得XRD中衍射峰向低角度偏移。BSE结果表明,随着掺杂量的增加,富稀土相的团聚减少,晶界相变得连续且薄,隔绝了主相晶粒的磁交换耦合作用,从而增加了矫顽力。此外,Pr-Fe-B和Nd-Fe-B主相的内禀性质均优于Ce-Fe-B主相,使剩磁和矫顽力增大[38]。另外,当磁体中Ce含量较高时,由于富Ce相熔点较低,促进了磁体的致密化程度。而当掺杂量达到80%时,磁体中Ce含量较低,从而导致磁体密度相对降低,使得剩磁略微下降。

在掺杂不同比例的NL合金后,同样增大了主相晶粒的晶格常数。BSE结果表明,随着掺杂量的增加,富稀土相的团聚现象并没有有效提升,反而在局部区域存在恶化现象,导致矫顽力的下降。EDS结果表明,在不同的掺杂量下,形成了不同比例的(Nd, Ce)-Fe-B和(Nd, La)-Fe-B主相。另外,La-Fe-B主相的饱和磁化强度高于Ce-Fe-B主相,但各向异性场低于Ce-Fe-B主相,这也导致了剩磁的增大和矫顽力的减小[38]。

CUI等[44]的研究表明,微观结构和化学非均质性对磁性能起着至关重要的影响。在SPS过程中,(Nd, Ce)-Fe-B磁体中粉末之间的成分差异自然产生Nd/Ce互扩散,能够减小Ce的磁稀释效应。Ce元素从富Ce粉末沿晶界相扩散到富Nd 粉末中,再通过晶格扩散到富Nd晶粒中。同样,Nd元素沿相反方向扩散到富Ce粉末内的富Ce晶粒中。随着PN合金的添加,形成了不同比例的(Nd, Ce)-Fe-B主相和(Pr, Nd)-Fe-B主相,主相粉末间仍存在着不同程度的互扩散,进一步减小了Ce的磁稀释效应,从而增强了磁体的磁性能。同样,随着NL合金的添加,形成了不同比例的(Nd, Ce)-Fe-B主相和(Nd, La)-Fe-B主相,虽然仍存在着主相粉末间的互扩散,但La和Ce均存在着类似的磁稀释效应,并未明显改善磁性能。

3 结 论

本研究通过双合金法,采用SPS制备了不同比例的各向同性纳米晶 (Nd, Ce)-Fe-B/(Nd, R)-Fe-B (R = Pr, La) 热压磁体,并探究了不同热压磁体的磁性能和微观结构。在添加60% (Pr, Nd)-Fe-B合金后,优化了晶界相的分布,增加了(Pr, Nd)-Fe-B主相的比例,有效地提升了热压磁体的磁性能,剩磁达8.58 ×0.1 T,矫顽力达12.65 ×79.6 kA/m,最高磁能积为15.79 ×7.96 kJ/m3。在添加不同比例的 (Nd,La)-Fe-B合金后,剩磁略有增大,但矫顽力有所降低,局部微观结构有所恶化。

王庆龙 -

表 1 不同烧结温度Nd-Ce-Fe-B热压磁体的磁性能

Table 1 Magnetic properties of Nd-Ce-Fe-B hot-pressed magnets sintered at different temperatures

烧结温度/保温时间/压力 剩磁 /(×0.1 T) 矫顽力 /(×79.6 kA/m) 最大磁能积 /(×7.96 kJ/m3) 密度 /(g/cm³) 600 ℃/5 min/250 MPa 7.92 9.27 12.91 7.632 650 ℃/5 min/250 MPa 7.96 9.35 13.02 7.662 700 ℃/5 min/250 MPa 8.07 9.21 12.99 7.721 表 2 不同混合比例NC/PN热压磁体的磁性能

Table 2 Magnetic properties of NC / PN hot-pressed magnets with different mixing ratios

ω(NC)/ω(PN) 剩磁 /(×0.1 T) 矫顽力 /(×79.6 kA/m) 最大磁能积 /(×7.96kJ/m3) 密度 /(g/cm³) 10∶0 7.96 9.35 13.02 7.662 8∶2 8.19 9.71 13.92 7.660 6∶4 8.40 10.46 14.93 7.643 4∶6 8.58 12.65 15.79 7.638 2∶8 8.44 16.33 15.49 7.634 0∶10 8.35 17.86 15.15 7.601 表 3 不同混合比例NC/NL热压磁体的磁性能

Table 3 Magnetic properties of NC / NL hot-pressed magnets with different mixing ratios

ω(NC)/ω(NL) 剩磁 /(×0.1 T) 矫顽力 /(×79.6 kA/m) 最大磁能积 /(×7.96 kJ/m3) 密度 /(g/cm³) 10∶0 7.96 9.35 13.02 7.662 8∶2 8.11 9.10 13.41 7.620 6∶4 7.92 9.08 12.76 7.583 4∶6 8.07 8.99 13.34 7.552 2∶8 8.26 8.68 13.82 7.496 0∶10 8.25 8.26 13.80 7.483 -

[1] 刘庆生, 肖浩, 邱廷省.钕铁硼废料浸出前后物相转变行为研究[J]. 有色金属科学与工程, 2022, 13(6): 127-133. [2] LIAO X F, ZHAO L Z, ZHANG J S, et al. Textured (Ce,La,Y)-Fe-B permanent magnets by hot deformation[J]. Journal of Materials Research and Technology, 2022, 17: 1459-1468.

[3] 钟震晨, 曾庆文, 江庆政, 等. Y取代对Pr-Nd-Fe-B合金微观结构和磁性能的影响[J]. 有色金属科学与工程, 2019, 10(3): 99-103. [4] SAGAWA M, FUJIMURA S, TOGAWA N, et al. New material for permanent magnets on a base of Nd and Fe[J]. Journal of Applied Physics, 1984, 55(6): 2083-2208.

[5] NAKAMURA H. The current and future status of rare earth permanent magnets[J]. Scripta Materialia, 2018, 154: 273-276.

[6] CUI X G, WANG X H, YIN G C, et al. Magnetic properties and microstructure of sintered NdFeB magnets with intergranular addition of Ni powders[J]. Journal of Alloys and Compounds, 2017, 726: 846-851.

[7] MASSARI S, RUBERTI M. Rare earth elements as critical raw materials: focus on international markets and future strategies[J]. Resources Policy, 2013, 38(1): 36-43.

[8] LUO Y. Development of NdFeB magnet industry in new century[J]. Journal of Iron and Steel Research International, 2006, 13(1): 1-11.

[9] QIAO Z Q , DONG S Z, LI Q, et al. Performance prediction models for sintered NdFeB using machine learning methods and interpretable studies[J]. Journal of Alloys and Compounds, 2023, 963: 171250.

[10] YOO J G, CHA H R, KIM T H, et al. Coercivity improvement in Nd-Cu infiltrated Nd-Fe-B hot-deformed magnets by controlling microstructure of initial HDDR powders[J]. Journal of Materials Research and Technology, 2021, 14: 340-347.

[11] LIAO X F, ZHANG J S, HE J Y, et al. Development of cost-effective nanocrystalline multi-component (Ce,La,Y)-Fe-B permanent magnetic alloys containing no critical rare earth elements of Dy, Tb, Pr and Nd[J]. Journal of Materials Science & Technology, 2021, 76(17): 215-221.

[12] 雷伟凯, 曾庆文, 胡贤君, 等. 高丰度稀土永磁材料的研究现状与展望[J]. 有色金属科学与工程, 2017, 8(5): 1-13. [13] 何伦可, 权其琛, 胡贤君, 等. Nb添加对Nd-Ce-Fe-B合金的磁性能及晶间交换耦合作用的影响[J]. 有色金属科学与工程, 2018, 9(5): 103-108. [14] KIM G Y, KIM T H, CHA H R, et al. Highperformance Ce-substituted (Nd0.7Ce0.3)-Fe-B hot-deformed magnets fabricated from amorphous melt-spun powders[J]. Scripta Materialia, 2022, 214: 114676.

[15] TANG X, SEPEHRI-AMIN H, BOLYACHKIN A, et al. (Nd, La, Ce)-Fe-B hot-deformed magnets for application of variable-magnetic-force motors[J]. Acta Materialia, 2022, 228: 117747.

[16] LI Z B, SHEN B G, ZHANG M, et al. Substitution of Ce for Nd in preparing R2Fe14B nanocrystalline magnets[J]. Journal of Alloys and Compounds, 2015, 628: 325-328.

[17] LIN X, LUO Y, PENG H J, et al. Phase structure evolution and magnetic properties of La/Ce doped melt-spun NdFeB alloys[J]. Journal of Magnetism and Magnetic Materials, 2019, 490: 165454.

[18] SKOKOV K P, GUTFLEISCH O. Heavy rare earth free, free rare earth and rare earth free magnets-Vision and reality[J]. Scripta Materialia, 2018, 154: 289-294.

[19] ZHA L, WU R, LIU Z, et al. Efficiently controlling crystallization and magnetic properties of nanostructured Nd-Ce-Fe-B ribbons via electron beam exposure[J]. Journal of Alloys and Compounds, 2019, 807: 151669.

[20] HERBST J F, MEREY M S, PINKERTON F E. Magnetic hardening of Ce2Fe14B[J]. Journal of Applied Physics, 2012, 111: 07A718.

[21] HUSSAIN M, LIAO X F, AKRAM R, et al. Elevated temperature behavior of rapidly quenched La/Ce substituted nanocrystalline NdFeB alloys with various compositions[J]. Journal of Alloys and Compounds, 2020, 845: 15629.

[22] LIAO X F, ZHANG J S, LI W, et al. Performance improvement and element segregation behavior in Y substituted nanocrystalline (La, Ce)-Fe-B permanent magnetic alloys without critical RE elements[J]. Journal of Alloys and Compounds, 2020, 834: 155226.

[23] KIM G Y, KIM T H, CHA H R, et al. Texture development and grain boundary phase formation in Ce and Ce-La-substituted Nd-Fe-B magnets during hot-deformation process[J]. Journal of Materials Science & Technology, 2022, 126(31): 71-79.

[24] ZHANG M, LI Z B, SHEN B G, et al. Permanent magnetic properties of rapidly quenched (La, Ce)2Fe14B nanomaterials based on La-Ce mischmetal[J]. Journal of Alloys and Compounds, 2015, 651: 144-148.

[25] TANG X, SEPEHRI-AMIN H, Matsumoto M, et al. Role of Co on the magnetic properties of Ce-substituted Nd-Fe-B hot-deformed magnets[J]. Acta Materialia, 2019, 175: 1-10.

[26] TANG X, SONG S Y, LI J, et al. Thermally-stable high coercivity Ce-substituted hot-deformed magnets with 20% Nd reduction[J]. Acta Materialia, 2020, 190: 8-15.

[27] TANG X, LAI J W, SEPEHRI-AMIN H, et al. (Pr0.75Ce0.25)-Fe-B hot-deformed magnets for cryogenic applications[J]. Scripta Materialia, 2021, 194: 113648.

[28] PATHAK A K, KHAN M, GSCHNEIDNER K A, et al. Cerium: an unlikely replacement of dysprosium in high performance Nd-Fe-B permanent magnets[J]. Advanced Materialia, 2015, 27(16): 2663-2667.

[29] PATHAK A K, KHAN M, GSCHNEIDNER K A, et al. Magnetic properties of bulk, and rapidly solidified nanostructured (Nd1-xCex)2Fe14-yCoyB ribbons[J]. Acta Materialia, 2016, 103: 211-216.

[30] HUSSAIN M, ZHAO L Z, ZHANG C, et al. Composition-dependent magnetic properties of melt-spun La or/and Ce substituted nanocomposite NdFeB alloys[J]. Physical B:Condensed Matter, 2016, 483(1): 69-74.

[31] CHANG W C, CHIOU DY, WU S H, et al. High performance α-Fe/Nd2Fe14B-type nanocomposites[J]. Applied Physics Letters, 1998, 72(1): 121-123.

[32] 胡宇霆. 纳米晶混合稀土磁体微结构与磁性能研究[D]. 赣州:江西理工大学,2022. [33] CUI X G, ZHANG H J, PAN J X, et al. Magnetic properties, thermal stability, and microstructure of spark plasma sintered multi-main-phase Nd-Ce-Fe-B magnet with PrCu addition[J]. Journal of Alloys and Compounds, 2020, 822: 153612.

[34] JIN J Y, YAN M, LIU Y S, et al. Attaining high magnetic performance in as-sintered multi-main-phase Nd-La-Ce-Fe-B magnets: toward skipping the post-sinter annealing treatment[J]. Acta Materialia, 2019, 169: 248-259.

[35] JIN J Y, MA T Y, ZHANG Y J, et al. Chemically Inhomogeneous RE-Fe-B permanent magnets with high figure of merit: solution to global rare earth criticality[J]. Scientific Reports, 2016, 6(1): 32200.

[36] ZHU M, LI W, WANG J, et al. Influence of Ce content on the rectangularity of demagnetization curves and magnetic properties of Re-Fe-B magnets sintered by double main phase alloy method[J]. IEEE Transactions on Magnetics, 2014, 50(1): 1-4.

[37] LI X, JIANG Q Z, REHMAN S U, et al. Structural evolution and improvement of magnetic properties of hot-deformed CeFeB magnets with Nd70Cu30 addition[J]. Intermetallics, 2022, 143: 107475.

[38] HERBST J F. R2Fe14B materials: intrinsic properties and technological aspects[J]. Reviews of Modern Physics, 1991, 63(4): 819-898.

[39] SAITO T, SAJIMA Y, NISHIO-HAMANE D. Enhancement of magnetic properties by Zn addition in Nd-Fe-B hot-deformed magnets produced by spark plasma sintering method[J]. Journal of Alloys and Compounds, 2016, 687: 662-666.

[40] WANG G P, LIU W Q, HUANG Y L, et al. Effects of sintering temperature on the mechanical properties of sintered NdFeB permanent magnets prepared by spark plasma sintering[J]. Journal of Magnetism and Magnetic Materials, 2014, 349: 1-4.

[41] MO W J, ZHANG L T, SHAN A D, CAO L J, et al. Microstructure and magnetic properties of NdFeB magnet prepared by spark plasma sintering[J]. Intermetallics, 2007, 15: 1483-1488.

[42] RAMESH R, THOMAS G, MA B M, Magnetization reversal in nucleation controlled magnets Ⅱ. Effect of grain size and size distribution on intrinsic coercivity of Fe-Nd-B magnets[J]. Journal of Applied Physics, 1988, 64(11): 6416-6423.

[43] 江庆政. 纳米晶Ce-Fe-B基磁体的制备、结构和性能调控[D]. 赣州:江西理工大学,2018. [44] CUI X G, LIANG W J, ZHANG H J, et al. Synergistically tailoring the microstructure and chemical heterogeneity of nanocrystalline multi-main-phase Nd-Ce-Fe-B magnet: Critical role in magnetic performance[J]. Journal of Alloys and Compounds, 2023, 941: 168939.

下载:

下载: