Research on pipeline transportation design of tailings slurry from a tin mine in Yunnan Province based on ANSYS-FLUENT

-

摘要:

以云南某锡矿井下充填管道为对象,经流变实验获得了该矿山全尾砂流变参数,并采用布金汉方程对尾砂料浆阻力损失进行了初步计算,最后运用ANSYS-FLUENT软件进行了模拟计算,并对模拟结果进行了深入分析。结果表明,较优方案为C1,即水泥量为300 kg/m3,质量浓度为72%的尾砂料浆能够在管道内安全输送2 600余米,充填流量可达110 m3/h,满足了矿山井下充填制备站至各采场空区的充填需求,确保了充填系统的安全、可靠和高效运行。进一步研究分析发现,在管道内输送的尾砂料浆速度和压力存在边界层效应;管输阻力损失随尾砂料浆的屈服应力及黏度的增加而增加,并得出了阻力损失与屈服应力及黏度之间的关系表达式。本文针对充填采矿法中矿山尾砂料浆合理、安全地管道输送,制定了简便高效的计算、模拟和分析方法,为充填采矿法的实际应用提供了有益指导。

-

关键词:

- 充填采矿 /

- 布金汉方程 /

- ANSYS-FLUENT模拟 /

- 尾砂料浆管道输送 /

- 阻力损失

Abstract:Taking the filling pipeline under a tin mine in Yunnan Province as the object, this article obtained the rheological parameters of the entire tailings of the mine through rheological experiments, and preliminarily calculated the resistance loss of the tailings slurry using the Buckingham equation. Finally, simulation calculations were conducted using ANSYS FLUENT software, and the simulation results were analyzed in depth. The research results indicate that the optimal solution is the C1 scheme, which means that the tailings slurry with a cement content of 300 kg/m3 and a mass concentration of 72% can be safely transported within the pipeline for over 2 600 meters, and the filling flow rate can reach 110 m3/h, which meets the filling requirements from the underground filling preparation station to various goaves in the mine and ensures the safe, reliable, and efficient operation of the filling system. Further research and analysis have found that the velocity and pressure of the tailings slurry transported in the pipeline have a boundary layer effect. The resistance loss of pipeline transportation increases with the increase of yield stress and viscosity of tailings slurry, and the relationship expression between resistance loss and yield stress and viscosity is obtained. This article develops a simple and efficient calculation, simulation, and analysis method for the reasonable and safe pipeline transportation of tailings slurry in the filling mining method, providing technical guidance for the practical application of the filling mining method.

-

0 引言

W-Cu 复合材料是由热膨胀系数低、硬度高的钨和导热导电性高的铜组成的一种复合材料[1-2].近年来,随着现代科学技术的发展,使得大功率微波器件不断向小型化发展,要求W-Cu 复合材料具有更优异性能.为了适应发展的需要,要求对W-Cu 复合材料新型生产工艺和新型W-Cu 复合材料进行研究[3-6].由于W-20 %Cu 复合材料中W 相具有低的膨胀系数,同时又能保证材料具有好的导热导电性,在封装材料和触头材料中应用比较广泛[7-9].碳纳米管独特的空间结构使其具有良好的力学性能和高导热导电等特性,是复合材料理想的强化相[10-15];使用碳纳米管作为强化相能对复合材料起到细化颗粒粒度的作用,并利用它优良的力学性能,以提高复合材料的致密度和硬度,高致密度是保证材料具有高性能的前提,而在W-Cu 复合材料中较高硬度可以延长器件的使用寿命和提高器件的可靠性,从而进一步提高它在电触头和封装材料应用中的机械性能.因此,文中主要研究在W-20 %Cu 复合材料中添加碳纳米管后对其致密度和硬度的影响.

1 试验材料及方法

试验采用粒度为2.63 μm 的W 粉和3 μm 的Cu 粉、0.1 μm 的碳纳米管.试验先利用QM-BP 行星式球磨机对W 粉和Cu 粉、碳纳米管粉末进行真空球磨30 h, 制得碳纳米管质量分数分别为1 %、2 %、3 %、8 %的W-20 %Cu 复合粉末,为了避免在机械合金化过程中产生成分偏析,选择球料比为15∶1,纯酒精作为球磨介质,纯氮气作为保护气体;再把复合粉末在压力机上压制成直径为20 mm×50 mm柱坯,压制时先缓慢加压5 min, 以便排除行腔内的气体,加压到650 MPa 并保压2 min.最后把压坯在ZSJ-20/20/24-160 型真空烧结炉中进行1200 ℃×30 min烧结,对烧结样品进行性能检测.试验使用欧美克激光粒度测试仪检测复合粉末粒度,采用阿基米德排水法计算复合材料的密度,使用HV1-10A 型低负荷维氏硬度测试仪对复合材料的硬度进行测试.

2 分析与讨论

2.1 碳纳米管对W-20 %Cu 复合粒度的影响

在球磨过程中添加无水乙醇作为球磨介质,无水乙醇不但可以防止粉末的团聚和结块现象使粉末的粒度分布均匀,而且能够缩短粉末的细化时间[16].图 1 是球磨30 h 添加相含量不同的粒径分布图.

由图 1(a) 粒度分布图可知,粉末粒度(D50=1.06 μm),并且复合粉末粒度已经达到了纳米级,其主要原因是由于粉末在球磨过程中反复与磨球和罐壁产生碰撞、挤压,导致复合粉末不断变形,由于Cu颗粒的延展性比较好,球磨初期变成片状,W 颗粒脆性很大,被撞击后发生脆断,并会被片层状的Cu 颗粒包裹;随着球磨时间的增加,复合粉末会发生断裂、破碎,使复合粉末的粒度逐渐减小.球磨时间长,可以使复合粉末的粒度达到纳米级,图 1(b)粒度分布图中可看出,粉末粒度(D50=0.84 μm),复合粉末明显得到了细化;由此可知,碳纳米管能细化复合粉末,并随着质量分数的增加,细化程度提高.由于采用机械合金化制备复合材料过程中,使碳纳米管能弥散均匀分布在基体中,可以保证碳纳米管与基体有足够的接触面积,增强碳纳米管与基体的结合力,结合力越强,可改善基体与碳纳米管的湿润性,使碳纳米管质量分数增加,增强效果越明显,复合粉末的细化程度提高.

2.2 碳纳米管质量分数对W-Cu 复合材料致密度的影响

表 1是球磨30 h 及添加相含量不同的W-20 %Cu 复合材料的3 项密度.由表 1 可知,随着碳纳米管质量分数的增加,复合材料的理论密度不断减小.W-20 %Cu/C 复合材料理论密度不断减小,主要是因为碳纳米管的密度仅为1.8 g/cm3,比钨和铜的密度要小得多,所以随着碳纳米管质量分数的增加,W-20 %Cu/C复合材料理论密度不断减小.不过试验样品的实际密度较低的原因并不仅仅是因为碳纳米管的密度低而造成的,而是因为复合粉末是采用冷压成型.在冷压成型过程中,压坯内存在一些闭孔,即使烧结过程可以消除一些闭孔,但是并不能完全清除,残留的闭孔直接影响烧结体的密度,所以实测密度较低;从每种W-20 %Cu/C 复合材料的相对密度的结果可以得出,复合材料的致密度并没有达到全致密,最高的只有94 %.

表 1 W-20 %Cu/C 复合材料的各项密度

另外,从表 1 可以看出,随着碳纳米管质量分数的增加,W-20 %Cu 复合材料的致密度提高,主要有2 个原因:第1,由于W-Cu 复合材料在烧结致密化过程中主要是靠W 颗粒的重排,而碳纳米管有一定的润湿性,在一定程度上能帮助W 颗粒的重排,可影响复合材料的致密化程度.碳纳米管质量分数越高,W 颗粒的重排越容易,孔隙也越容易填充.第2,碳纳米管在高温时与铜的润湿性很好,甚至要比W、Cu之间的润湿性好得多,说明碳纳米管的加入,能够有效地提高复合材料的致密度.同时通过随后的分析可知,碳纳米管加入对提高W-20 %Cu 复合材料的硬度也发挥较大的作用.

2.3 碳纳米管质量分数对W-Cu 复合材料硬度的影响

图 2是碳纳米管质量分数不同的W-20 %Cu 复合材料,从图 2 中可以看出,随着碳纳米管质量分数的增加,W-20 %Cu 复合材料的硬度提高,最高硬度达到483 HV.一方面,采用高能球磨工艺制备的W-20 %Cu/C 复合粉末可得到纳米级晶粒且成分分布均匀,一定程度上扩展W、Cu 间的固溶度.当烧结温度高于Cu 熔点时,Cu 相完全溶化并逐渐向颗粒外流动,填充压坯中孔隙,并促使W 颗粒产生适应性的变形,从而使烧结体获得较高的致密度.另一方面,由于碳纳米管的加入能促进复合粉末细化,加强W-W 之间的连接,而且碳纳米管在高温条件下发挥润滑作用,促进W 颗粒能够在Cu 液相中分布更加均匀,对致密度的提高发挥较大作用.因此,W-20 %Cu 复合粉末粒度越小,晶格畸变增加,提高了复合粉末烧结活性,烧结活性越大,复合材料的致密度提高,材料硬度也随之增加.

3 结论

(1) 在机械合金化过程中,添加碳纳米管对WCu复合粉末有细化晶粒作用,并且复合粉末粒度达到纳米级.

(2)在W-20 %Cu 复合材料中添加碳纳米管,提高了复合材料的致密度和硬度,随着碳纳米管质量分数的增加,材料的密度和硬度不断提高.

赵中波 -

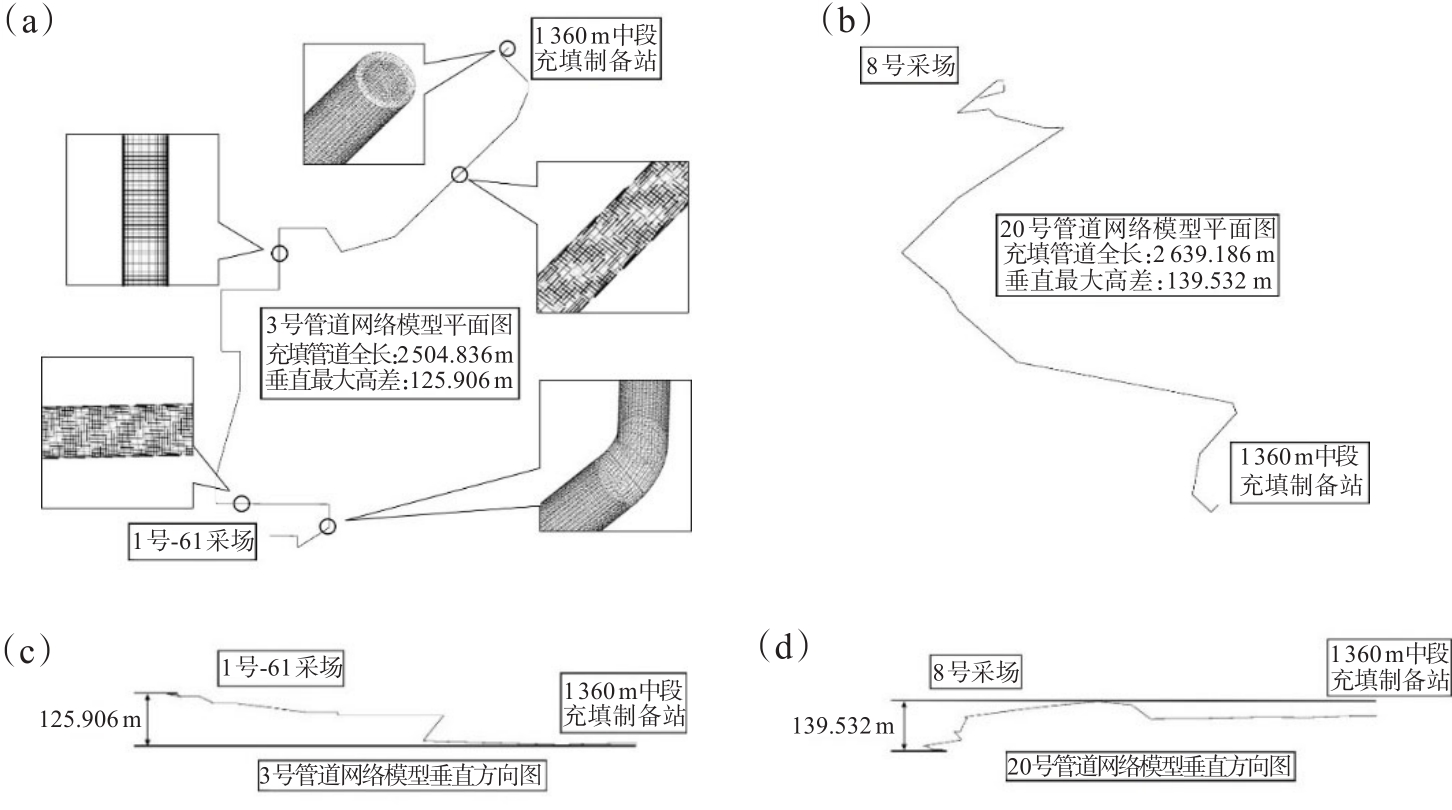

图 3 充填管道网格模型图及部分网格划分放大:(a) L3管道网格平面;(b) L20管道网格平面;(c) L3管道网格垂面图示;(d) L20管道网格垂面图示

Fig 3. Grid model of filling pipeline and enlarged view of partial grid division:(a) plan view of L3 pipeline grid;(b) plan view of L20 pipeline grid;(c) vertical view of L3 pipeline grid;(d) vertical view of L20 pipeline grid

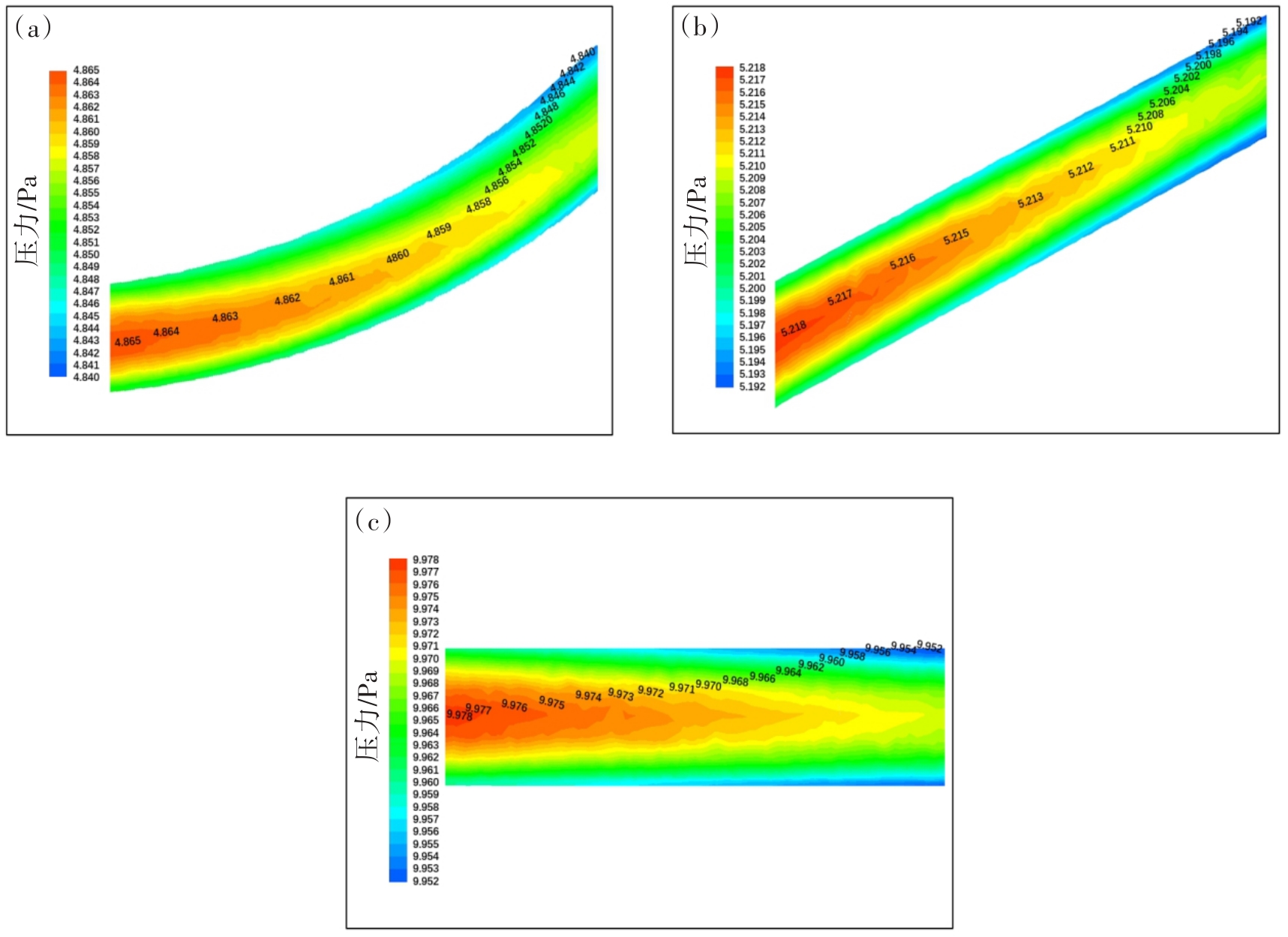

图 6 C1方案部分管道速度分布图和速度矢量图示:(a) 弯管速度分布图示;(b) 弯管速度矢量图示;(c) 斜管速度分布图示;(d) 斜管速度矢量图示;(e) 水平管速度分布图示;(f) 水平管速度矢量图示

Fig 6. Velocity distribution map and velocity vector map of partial pipeline from C1 scheme:(a) velocity distribution diagram of the curved pipeline;(b) velocity vector diagram of the curved pipeline;(c) velocity distribution diagram of the inclined pipeline;(d) velocity vector diagram of the inclined pipeline;(e) velocity distribution diagram of the horizontal pipeline;(f) velocity vector diagram of the horizontal pipeline

图 7 水平管断面速度分布图和速度折线图示:(a) 水平管1断面速度分布图示;(b) 水平管2断面速度分布图示;(c) 不同速度水平管断面速度折线图示;(d) 1.73 m/s速度水平管断面速度折线图示

Fig 7. Horizontal pipe cross-section velocity distribution diagram and velocity line diagram:(a) cross section velocity distribution diagram of the horizontal pipeline 1;(b) cross section velocity distribution diagram of the horizontal pipeline 2;(c) line chart of cross-sectional velocity of horizontal pipelines at different speeds;(d) line chart of cross-sectional velocity of horizontal pipelines at 1.73 m/s

表 1 井下充填制备站至二工区各采场充填管道实际情况

Table 1 Actual situation of filling pipelines from underground filling preparation station to various stopes in second work area

管道编号 充填终点工区 充填终点采场 总长度/m 最大高差/m 充填管道参数变化描述 L1 二工区 6号采场 1 813 71 管道全程管径分2部分:初始部分为143 mm或150 mm大管径;在变径点处分流,向各采场管径缩小为125 mm小管径。 L2 二工区 6号-3采场1 1 721 89 L3 二工区 1号-61采场 2 505 126 L4 二工区 1号-6采场1 1 745 101 L5 二工区 1号-6采场2 1 752 129 L6 二工区 6号-3采场2 1 771 160 L7 二工区 5号-3采场 1 911 156 L8 二工区 7号采场 1 904 140 表 2 井下充填制备站至三工区各采场充填管道实际情况

Table 2 Actual situation of filling pipelines from underground filling preparation station to various stopes in third work area

管道编号 充填终点工区 充填终点采场 总长度/m 最大高差/m 充填管道参数变化描述 L9 三工区 2号采场正二 1 771 83 管道全程管径相同:均为143 mm或150 mm大管径。 L10 三工区 2-6号采场 1 884 114 L11 三工区 2号采场西六 2 163 111 L12 三工区 5号采场 2 347 115 L13 三工区 2号采场正八 1 617 77 L14 三工区 24号采场 1 081 86 L15 三工区 1号采场 1 561 73 L16 三工区 2号采场 1 493 74 L17 三工区 0号采场 1 830 60 L18 三工区 3号采场 2 169 52 L19 三工区 6号采场 2 461 85 L20 三工区 8号采场 2 639 140 L21 三工区 3-7号采场 1 977 63 表 3 实验结果记录

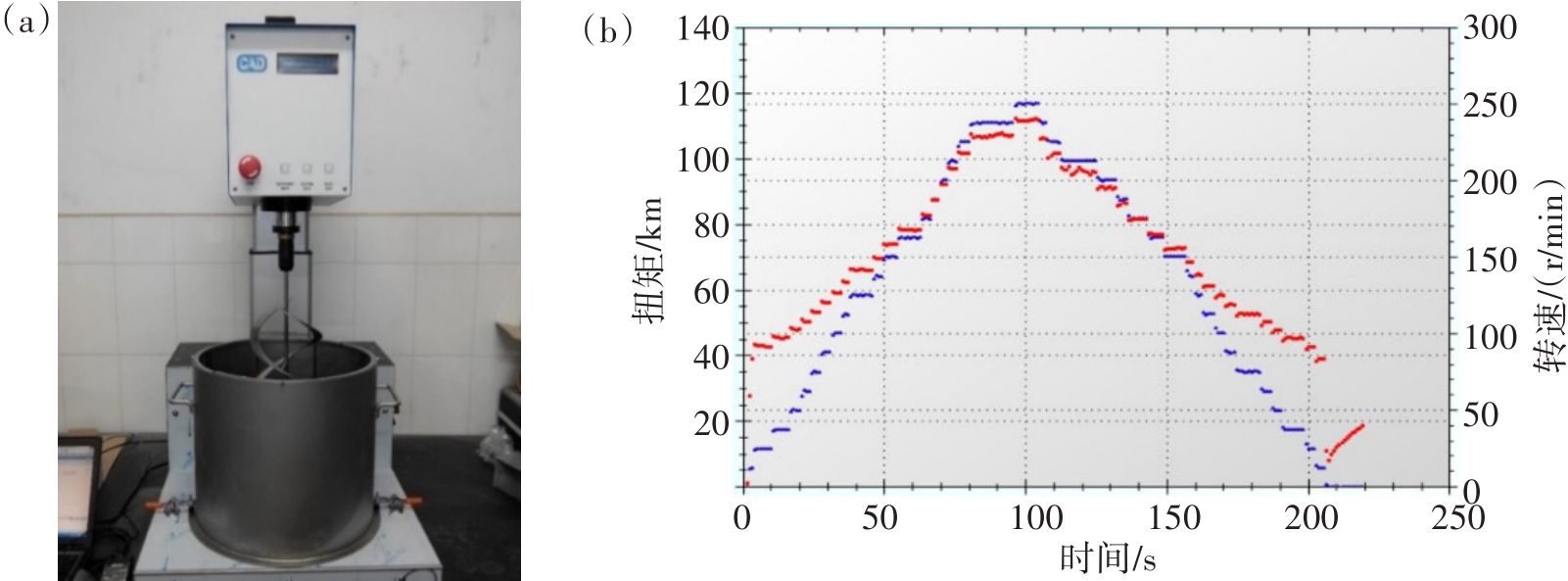

Table 3 Record of experimental results

实验编号 材料 水泥用量/ (kg/m3) 质量浓度/% 浆体密度/ (kg/m3) 屈服应力/Pa 黏度/(Pa·s) T1 全尾砂 300 72 1 939 30.08 0.87 T2 全尾砂 300 73 1 964 37.41 0.98 T3 全尾砂 300 74 1 991 46.10 1.17 表 4 阻力损失计算

Table 4 Resistance loss calculation

实验编号 浆体密度/(kg/m3) 屈服应力/Pa 黏度/(Pa·s) 沿程阻力损失/(Pa/m) 阻力损失差值/MPa T1 1 939 30.08 0.87 3 210.10 1.71 T2 1 964 37.41 0.98 3 741.37 2.09 T3 1 991 46.10 1.17 4 517.83 2.65 表 5 L3管道(初始管径150 mm,分流变径125 mm)模拟方案及流变参数

Table 5 Simulation plan and rheological parameters for pipeline L3 (Initial pipe diameter 150 mm, diversion variable diameter 125 mm)

方案编号 材料 水泥用量/(kg/m3) 质量浓度/% 管径/mm 进料流量/(m3/h) 进料流速/(m/s) 屈服应力/Pa 黏度/(Pa·s) 浆体密度/(kg/m3) A1 全尾砂 300 72 150转125 110 1.73 30.08 0.87 1 939 A2 全尾砂 300 73 150转125 110 1.73 37.41 0.98 1 964 A3 全尾砂 300 74 150转125 110 1.73 46.10 1.17 1 991 A4 全尾砂 300 72 150转125 100 1.57 30.08 0.87 1 939 A5 全尾砂 300 73 150转125 100 1.57 37.41 0.98 1 964 A6 全尾砂 300 74 150转125 100 1.57 46.10 1.17 1 991 A7 全尾砂 300 73 150转125 80 1.26 37.41 0.98 1 964 A8 全尾砂 300 73 150转125 60 0.93 37.41 0.98 1 964 表 6 L3管道(初始管径143 mm,分流变径125 mm)模拟方案及流变参数

Table 6 Simulation plan and rheological parameters for pipeline L3 (Initial pipe diameter 143 mm, diversion variable diameter 125 mm)

方案编号 材料 水泥用量/(kg/m3) 质量浓度/% 管径/mm 进料流量/(m3/h) 进料流速/(m/s) 屈服应力/Pa 黏度/(Pa·s) 浆体密度/(kg/m3) B1 全尾砂 300 72 143转125 100 1.73 30.08 0.87 1 939 B2 全尾砂 300 73 143转125 100 1.73 37.41 0.98 1 964 B3 全尾砂 300 74 143转125 100 1.73 46.10 1.17 1 991 B4 全尾砂 300 72 143转125 90 1.56 30.08 0.87 1 939 B5 全尾砂 300 73 143转125 90 1.56 37.41 0.98 1 964 B6 全尾砂 300 74 143转125 90 1.56 46.10 1.17 1 991 表 7 L20管道(全长管径150 mm)模拟方案及流变参数

Table 7 Simulation plan and rheological parameters for pipeline L20 (Full length pipe diameter 150 mm)

方案编号 材料 水泥用量/(kg/m3) 质量浓度/% 管径/mm 进料流量/(m3/h) 进料流速/(m/s) 屈服应力/Pa 黏度/(Pa·s) 浆体密度/(kg/m3) C1 全尾砂 300 72 150 110 1.73 30.08 0.87 1 939 C2 全尾砂 300 73 150 110 1.73 37.41 0.98 1 964 C3 全尾砂 300 74 150 110 1.73 46.10 1.17 1 991 C4 全尾砂 300 72 150 100 1.57 30.08 0.87 1 939 C5 全尾砂 300 73 150 100 1.57 37.41 0.98 1 964 C6 全尾砂 300 74 150 100 1.57 46.10 1.17 1 991 C7 全尾砂 300 72 150 90 1.42 30.08 0.87 1 939 表 8 L20管道(全长管径143 mm)模拟方案及流变参数

Table 8 Simulation plan and rheological parameters for pipeline L20 (Full length pipe diameter 143 mm)

方案编号 材料 水泥用量/(kg/m3) 质量浓度/% 管径/mm 进料流量/(m3/h) 进料流速/(m/s) 屈服应力/Pa 黏度/(Pa·s) 浆体密度/(kg/m3) D1 全尾砂 300 72 143 100 1.73 30.08 0.87 1 939 D2 全尾砂 300 73 143 100 1.73 37.41 0.98 1 964 D3 全尾砂 300 74 143 100 1.73 46.10 1.17 1 991 D4 全尾砂 300 72 143 90 1.56 30.08 0.87 1 939 D5 全尾砂 300 73 143 90 1.56 37.41 0.98 1 964 D6 全尾砂 300 74 143 90 1.56 46.10 1.17 1 991 表 9 L3管道(初始管径150 mm,分流变径125 mm)模拟方案总阻力损失

Table 9 Total resistance loss of pipeline L3 (Initial pipe diameter 150 mm, diversion variable diameter 125 mm) simulation scheme

方案编号 管长/m 管径/mm 进料流量/ (m3/s) 进料流速/ (m/s) 总损失/MPa A1 2 505 150转125 110 1.73 11.55 A2 2 505 150转125 110 1.73 12.59 A3 2 505 150转125 110 1.73 15.59 A4 2 505 150转125 100 1.57 7.79 A5 2 505 150转125 100 1.57 9.20 A6 2 505 150转125 100 1.57 12.78 A7 2 505 150转125 80 1.26 9.90 A8 2 505 150转125 60 0.93 7.93 表 10 L3管道(初始管径143 mm,分流变径125 mm)模拟方案总阻力损失

Table 10 Total resistance loss of pipeline L3 (Initial pipe diameter 143 mm, diversion variable diameter 125 mm) simulation scheme

方案编号 管长/m 管径/mm 进料流量/ (m3/s) 进料流速/ (m/s) 总损失/MPa B1 2 505 143转125 100 1.73 12.58 B2 2 505 143转125 100 1.73 13.67 B3 2 505 143转125 100 1.73 16.96 B4 2 505 143转125 90 1.56 11.35 B5 2 505 143转125 90 1.56 12.21 B6 2 505 143转125 90 1.56 15.10 表 11 L20管道(全长管径150 mm)模拟方案总阻力损失

Table 11 Total resistance loss of simulation scheme for pipeline L20 (Full length pipe diameter 150 mm)

方案编号 管长/ m 管径/mm 进料流量/ (m3/s) 进料流速/ (m/s) 总损失/MPa C1 2 639 150 110 1.73 9.21 C2 2 639 150 110 1.73 10.59 C3 2 639 150 110 1.73 14.17 C4 2 639 150 100 1.57 6.22 C5 2 639 150 100 1.57 7.72 C6 2 639 150 100 1.57 11.62 C7 2 639 150 90 1.42 7.64 表 12 L20管道(全长管径143 mm)模拟方案总阻力损失

Table 12 Total resistance loss of simulation scheme for pipeline L20 (Full length pipe diameter 143 mm)

方案编号 管长/m 管径/mm 进料流量/ (m3/s) 进料流速/ (m/s) 总损失/MPa D1 2 639 143 100 1.73 9.96 D2 2 639 143 100 1.73 11.46 D3 2 639 143 100 1.73 15.23 D4 2 639 143 90 1.56 8.87 D5 2 639 143 90 1.56 10.26 D6 2 639 143 90 1.56 14.13 表 13 符合生产要求模拟方案汇总

Table 13 Summary of simulation plans that meet production requirements

方案编号 材料 水泥用量/(kg/m3) 质量浓度/% 管长/m 管径/mm 进料流量/(m3/s) 进料流速/(m/s) 总损失/MPa A4 全尾砂 300 72 2 505 150转125 100 1.57 7.79 A5 全尾砂 300 73 2 505 150转125 100 1.57 9.20 C1 全尾砂 300 72 2 639 150 110 1.73 9.21 D1 全尾砂 300 72 2 639 143 100 1.73 9.96 D4 全尾砂 300 72 2 639 143 90 1.56 8.87 D5 全尾砂 300 73 2 639 143 90 1.56 10.26 表 14 阻力损失Δp与尾砂料浆屈服应力τ0之间的关系表达式

Table 14 Expression for relationship between resistance loss Δp and yield stress τ0 of tailings slurry

方案编号 管长/m 管径/mm 进料流量/(m3/s) 进料流速/(m/s) 关系表达式 A1-A3 2 505 150转125 110 1.73 A4-A6 2 505 150转125 100 1.57 B1-B3 2 505 143转125 100 1.57 B4-B6 2 505 143转125 90 1.42 C1-C3 2 639 150 110 1.73 C4-C6 2 639 150 100 1.57 D1-D3 2 639 143 100 1.57 D4-D6 2 639 143 90 1.42 表 15 阻力损失Δp与尾砂料浆黏度η之间的关系表达式

Table 15 Expression for relationship between resistance loss Δp and viscosity η of tailings slurry

方案编号 管长/m 管径/mm 进料流量/(m3/s) 进料流速/(m/s) 关系表达式 A1-A3 2 505 150转125 110 1.73 A4-A6 2 505 150转125 100 1.57 B1-B3 2 505 143转125 100 1.57 B4-B6 2 505 143转125 90 1.42 C1-C3 2 639 150 110 1.73 C4-C6 2 639 150 100 1.57 D1-D3 2 639 143 100 1.57 D4-D6 2 639 143 90 1.42 -

[1] 乔登攀,程伟华,张磊等.现代采矿理念与充填采矿[J].有色金属科学与工程,2011,2(2):7-14. [2] WANG X L, YAO W X, WANG H, et al. The directions of R&D on backfill with waste rock and total tailings in underground mine[J].China Mining Magazine, 2011,20(9):76-77.

[3] YIN S H, SHAO Y J, WU A X, et al. A systematic review of paste technology in metal mines for cleaner production in China[J].Journal of Cleaner Production, 2020,247(11):9590.

[4] DONG H Z, NURAINI A A, HELMI S M Z, et al. Computational fluid dynamics study on cemented paste backfill slurry: Review[J]. Construction and Building Materials,2023,369(13):558.

[5] DONG H Z, ABDUL N A, MOHD Z H S, et al. Numerical study on transportation of cemented paste backfill slurry in bend pipe[J]. Processes,2022,10(8):1454.

[6] 黄永刚,饶运章,李勇.充填系统稳定性的在线监测及评价[J].有色金属科学与工程,2016,7(4):121-126. [7] 吴爱祥,杨莹,程海勇,等.中国膏体技术发展现状与趋势[J].工程科学学报,2018,40(5):517-525. [8] WANG Y, WANG Z Q, WU A X, et al. Experimental research and numerical simulation of the multi-field performance of cemented paste backfill: Review and future perspectives[J]. International Journal of Minerals, Metallurgy and Materials,2023,30(2):193-208.

[9] 程海勇,吴爱祥,吴顺川,等.金属矿山固废充填研究现状与发展趋势[J].工程科学学报,2022,44(1):11-25. [10] 邱晓伟.膏体管道输送现状分析与技术研究[J].中国矿山工程,2019,48(1):51-53. [11] 石宏伟,黄吉荣,滕高礼,等.高浓度分级尾砂充填料浆管输阻力影响因素研究与分析[J].有色金属(矿山部分),2019,71(6):89-94. [12] 吴爱祥,刘晓辉,王洪江,等.结构流充填料浆管道输送阻力特性[J].中南大学学报(自然科学版),2014,45(12):4325-4330. [13] 张修香,乔登攀,孙宏生.废石-尾砂高浓度料浆管道输送特性模拟[J].中国有色金属学报,2019,29(5):1092-1101. [14] 杨天雨,乔登攀,王俊,等.废石-风砂高浓度料浆管道输送数值模拟及管输阻力新模型[J].中国有色金属学报,2021,31(1):234-244. [15] WU A X, RUAN Z E, WANG Y M, et al. Simulation of long-distance pipeline transportation properties of whole-tailings paste with high sliming[J].Journal of Central South University, 2018,25(1):141-150.

[16] 石宏伟,黄吉荣,乔登攀,等.基于ANSYS FLUENT的超深井长距离膏体充填管道输送模拟研究[J].有色金属(矿山部分),2020,72(2):5-12. [17] 张善硕.全尾矿砂充填体室内配比试验及管输数值模拟研究[D].广州:广州大学,2019. [18] 侯俊,程文文,张小瑞,等.基于FLUENT的磷石膏膏体充填料浆管道输送模拟[J].现代矿业,2018,34(4):148-152. [19] 罗涛,张亮,姜亮亮,等.高浓度全尾砂料浆流变特性参数试验及管道输送研究[J].有色金属科学与工程,2015,6(4):86-90. [20] 陈建宏,陈峤曦,张钦礼,等.基于Fluent的充填料浆管道输送阻力模拟[J].科技导报,2015,33(9):64-68. [21] DOS SANTOS J D B,ANJOS G R,SAVI M A. An investigation of fluid-structure interaction in pipe conveying flow using reduced-order models[J]. Meccanica,2022,57(10):2473-2491.

[22] 陈寅,郭利杰,邵亚平,等.粗骨料膏体充填料浆流变特性与管道输送阻力计算[J].中国矿业,2018,27(12):178-182. [23] 杨纪光,王义海,吴再海等.某金矿全尾砂高浓度充填流变特性与微观结构的分析[J].有色金属科学与工程,2023,14(2):249-256. [24] 张钦礼,刘奇,赵建文,等.深井似膏体充填管道的输送特性[J].中国有色金属学报,2015,25(11):3190-3195. [25] 熊庭,张梦达,危卫,等.泥浆管道输送特性的CFD模拟[J].人民黄河,2018,40(4):19-23. [26] 王新民,贺严,陈秋松.基于Fluent的分级尾砂料浆满管流输送技术[J].科技导报,2014,32(1):53-58. -

期刊类型引用(7)

1. 邱小英,蓝桥发,邱小兵,黄金. 熔盐电解法制备Y-Ni合金工艺研究. 稀土. 2024(02): 105-112 .  百度学术

百度学术

2. 彭军军,王旭,蔡伯清,石忠宁,任如山. LiF-[CaF_2/YbF_3]-Yb_2O_3熔盐及Yb-Ni合金密度特性研究. 有色金属科学与工程. 2024(02): 189-194 .  本站查看

本站查看

3. 曾露雪,边子俊,宁周神,陈明,董伟. 稀土铽对斑马鱼急性毒性及抗氧化酶活性的影响. 有色金属科学与工程. 2024(04): 623-632 .  本站查看

本站查看

4. 李琳穗,徐明钟,苏严. 原料物理性能对稀土氟盐电解影响的研究. 广州化工. 2024(20): 53-56+88 .  百度学术

百度学术

5. 刘雯雯,赖华生,王玉香,周有池. La/Y比对A_2B_7型La-Y-Ni储氢合金性能的影响. 矿冶工程. 2023(02): 149-153 .  百度学术

百度学术

6. 张永健,蔡伯清,王旭,王瑞祥,石忠宁. LiF-CaF_2-Yb_2O_3熔盐及Ni-Yb合金表面张力研究. 有色金属科学与工程. 2023(06): 802-807 .  本站查看

本站查看

7. 刘力,杨天辉,周曦,孟冉浩. 氢化物对Mg_2Ni基合金储氢性能的影响. 有色金属科学与工程. 2023(06): 825-832 .  本站查看

本站查看

其他类型引用(2)

下载:

下载: