High temperature deformation behavior and hot processing map of Cu-Ni-Ti alloy

-

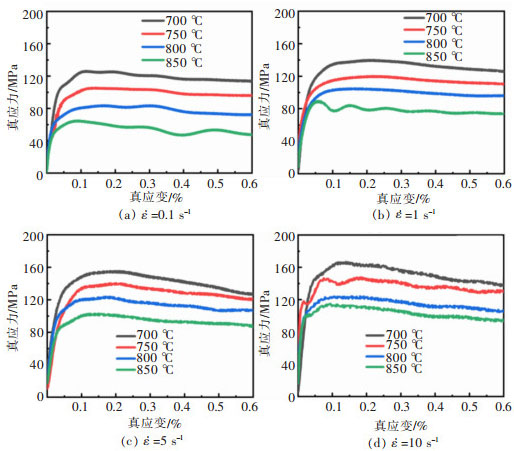

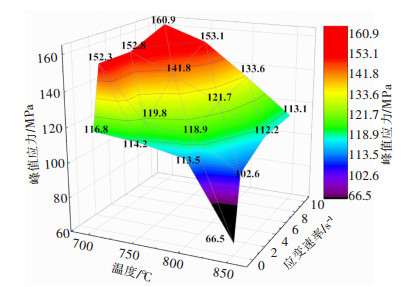

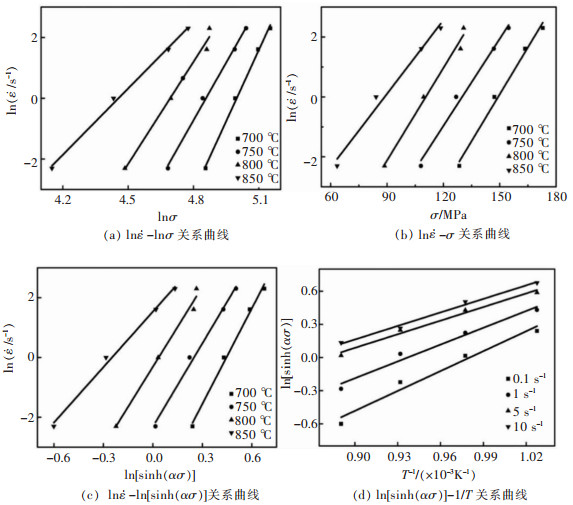

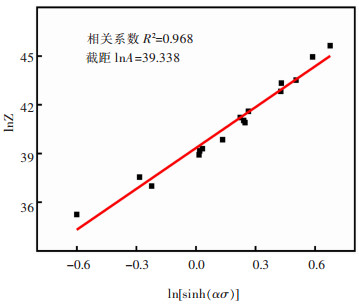

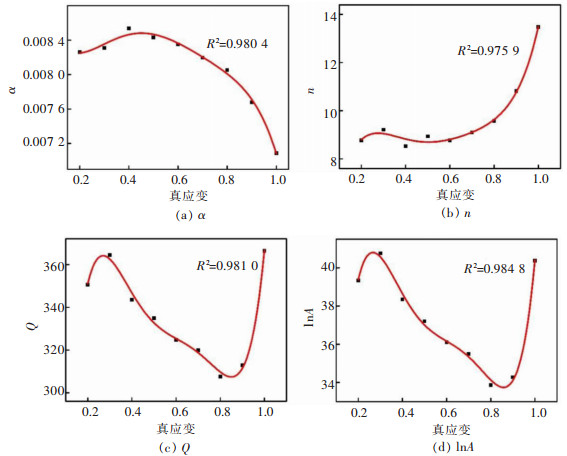

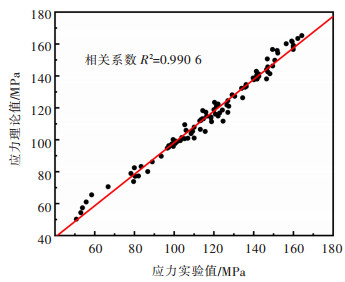

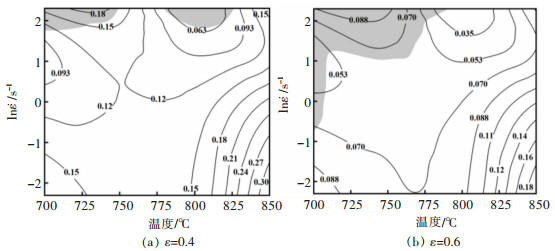

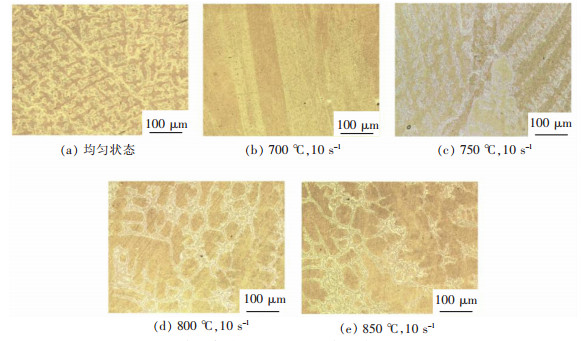

摘要: 采用MMS-100热力模拟机对Cu-Ni-Ti合金进行了温度为700~850 ℃、变形速率为0.01~10 s-1的等温压缩试验。研究表明,流变应力随应变程度增加快速上升至极限值后逐渐转变为平缓曲线,随温度增加而降低,随应变速率增加而上升。基于应力与变形速率和应变温度之间的关系,构建了Cu-Ni-Ti合金的本构方程和热加工图。得到了Cu-Ni-Ti合金较优热加工工艺:温度为840~850 ℃,应变速率为0.1~1 s-1。较优工艺条件下,组织为动态回复、再结晶的晶粒,失稳区组织多为细长的纤维组织。

-

关键词:

- Cu-Ni-Ti合金 /

- 等温压缩 /

- 流变应力 /

- 本构方程 /

- 热加工图

Abstract: The Cu-Ni-Ti alloy was subjected to isothermal compression tests at temperatures ranging from 700 to 850 ℃ with deformation rates ranging from 0.01 to 10 s-1 using MMS-100 thermal simulator. The results showed that with the increase of strain, the flow stress rapidly rose to the limit value and then gradually turned into an easy curve. The flow stress decreased with the increase of temperature and increased with the increase of strain rate. Based on the relationship between stress, deformation rate and strain temperature, the constitutive equation and hot processing map of Cu-Ni-Ti alloy were constructed. The optimal processing conditions of Cu-Ni-Ti alloys were in the range of temperature 840~850 ℃ and strain rate 0.1~1 s-1. Under the optimal process conditions, the microstructure was an equiaxed crystal with dynamic recovery and recrystallization grain, and slender fibrous structure could be mostly found in the instability zone.-

Keywords:

- Cu-Ni-Ti alloy /

- isothermal compression /

- flow stress /

- constitutive equation /

- hot processing map

-

目前,金属锌的生产90%以上通过湿法冶金实现[1-3]。湿法冶金流程主要包括焙烧、浸出、净化和电积等过程[4-7]。锌精矿浸出液中包含的金属元素除了锌之外,还含有铁、砷、锑、铜、镉、钴、镍等杂质[8]。溶液中杂质离子不仅影响电积锌的电流效率[9-11],而且还严重影响电积锌的质量[12]。因此,锌浸出液在进入电积工序之前需要经过严格的净化处理,去除其中的杂质,才能保证电积过程顺利进行,得到优质的电锌产品。溶液中的 Fe、As、Sb、Ge 等杂质大部分会由于浸出过程的中和水解作用除去,铜、镉、钴、镍等杂质通常采用锌粉置换法去除[13-15]。锌粉置换法也称为锌粉胶结法,是利用锌的电化学势较负的特性,加入锌粉置换电化学势较正的杂质金属离子,使后者沉淀脱除的方法[16]。该方法不会在锌电解液中增加额外的杂质元素,且操作相对简单、容易实现,在锌湿法冶金工业中得到广泛的应用[17-19]。但是,锌粉置换法用于锌电解液除杂净化过程中仍然存在锌粉投放量远远超出理论用量、净化深度低以及净化渣中含锌量高等问题[20-23]。破解这些难题的关键是强化锌粉在溶液中的分散,且保持锌粉表面活化状态,使锌粉得到充分利用[24]。国内外学者在加速液相扩散和破坏锌粉包覆层等开展了许多研究工作。ZHANG等[25]发现引入超声波能够加速溶液中的离子传输,对于化学反应速率有显著贡献。PHAM等[26]发现超声波产生的撞击能够破坏反应表面上的沉积物。KRUU等[27]发现超声波的声空化作用可以将固体产物从Zn表面剥离,从而保持锌的活性。

近年来超声波强化技术不断被应用于湿法冶金过程,使湿法冶金过程时间更短、效率更高并且有效降低试剂用量[28]。研究发现超声强化在溶液中形成机械作用,使溶液发生强烈震动,提高溶液的传质效率[29-30];其次是超声产生的热效应,来源于溶液吸收声能转化产生热量以及超声空化产生的局部高温[31]。研究也发现超声波造成的溶液剧烈震动和瞬时高温高压也会造成固体反应物和反应产物之间的崩裂和剥离,增加了固液接触面积,加快反应速度[29, 32-33]。然而,截至目前很少有研究涉及超声波对于固液反应的新生固相产物微观形态和分布的影响。在锌粉置换法进行锌电解液净化中,杂质金属置换产物的形貌、分布状态等直接影响溶液在其中内扩散速度,进而影响反应速度[24, 34]。显然,弄清超声波对于溶液中新生固相微观形貌的影响将提升对超声波强化固液反应机理的认知,有助于发现进一步促进超声强化作用的手段。

本文研究了不同输出功率超声波对于锌粉置换法去除硫酸锌溶液中铜杂质效率的影响,同时系统表征了不同输出功率超声波作用下铜置换产物微观形貌和分布状态,探究超声对于新生固相晶体生长的作用机理,进而为超声强化置换法进行溶液除杂净化提供理论支持。

1 实验材料和方法

1.1 实验材料

本实验采用的化学试剂皆为分析纯,购自国药集团化学试剂有限公司(中国上海)。所有溶液配制采用去离子水,配制的硫酸铜和硫酸锌混合溶液浓度为:Zn2+为150 g/L 和 Cu2+为500 mg/L。采用2种规格的锌进行锌置换反应,锌粒(直径约5 mm, 99.8%(质量分数))和锌粉(325~350目(46~43 μm),99.9%(质量分数))。

1.2 实验方法

实验采用500 mL烧杯,放入配制溶液450 mL。烧杯放置在恒温水浴锅中,锌粉置换法除铜反应设置温度60 ℃,经测量溶液初始pH为4.1,反应时间均为1 h。通过钛合金超声探头放入反应溶液中将超声波引入反应过程,超声发生器(YTS-2000-20)20 kHz频率,输出功率0~2 000 W。反应装置见图1。

为分析超声波辅助锌粉置换除铜的实际效果,采用锌粉作为除杂剂。锌粉投放即开始计时,每隔一定时间用液体取样器在反应烧杯中取样,留待分析。作为对比的实验条件分别采用无搅动硫酸锌溶液(静态)和低转速搅拌(50 r/min)硫酸锌溶液。对反应后的溶液进行过滤,收集固体产物,通过XRD分析其物相组成。

为分析超声波辅助置换过程中固-液界面上产物的形貌分布、结构状态,以及和锌基底的结合情况,采用锌粒做除杂剂。将锌粒嵌入树脂中,并经过打磨和抛光制样(见图2),放入待净化的硫酸锌溶液中;反应结束后,锌粒样品经过去离子水洗涤、干燥,留样待测。

1.3 分析表征与计算

利用X射线衍射仪(XRD, a Bruker-AXS D8 Advance)对反应产物进行物相分析;采用等离子体发射光谱仪(ICP-AES, Perkin-Elmer 7 300DV)测定锌粉置换反应不同时间取样溶液的铜离子浓度;采用扫描电子显微镜(SEM, FEI Nova Nano 450)和金相显微镜(OM, Leica, DM4 000M)进行置换产物形貌观察。利用Image J软件对置换产物的SEM图进行处理分析,测量一定数量产物的尺寸,用计算的平均粒径来表征相应参数下的产物大小。用式(1)计算相应时间下硫酸锌溶液杂质铜的去除率X:

% (1) 式(1)中:X为铜离子去除率;C0为硫酸锌溶液中的初始杂质铜离子浓度;C为一定反应时间下的铜离子浓度。

2 结果与讨论

2.1 超声波对杂质铜去除率的影响

图3中分析了加入锌粉后,不同外场条件下铜离子去除效率与时间的关系。结果显示溶液无搅动时,铜离子去除率仅23.9%,置换反应缓慢,最终反应程度较低。这主要是由于溶液只有伴生的析氢反应提供少量液体扰动,溶液体扩散比较缓慢,不利于反应进行。采用低转速搅拌(50 r/min)进行置换反应时,反应速度较无搅动条件明显加快,铜离子去除率约64.2%。搅拌能够减少锌粉聚集,增加反应比表面积;还能促进在液相中的离子传质,从而促进锌与溶液中铜离子的置换反应。将超声波引入反应溶液时,发现不同超声波输出功率下的铜离子去除速率和最终去除率差别很大。当输入超声功率在500 W和1 000 W时,对锌置换反应的强化作用与机械搅拌50 r/min作用类似,主要加速了离子的液相扩散,有利于反应的进行。实验结果还表明锌置换反应在开始的20 min铜离子去除速率较快,之后明显减缓,这很可能是由于锌表面形成的固体产物层阻碍了溶液扩散至反应活性表面,使置换反应速率减缓。当输入超声功率在1 500 W和2 000 W时,明显提高了反应1 h后铜的最终去除率;特别是超声功率在2 000 W时,铜离子去除速率明显提升,反应10 min后铜离子去除率就已经高于90%。这表明超声波功率足够大时,不仅可以强化溶液中传质扩散,也可以强化溶液在固体产物层中的扩散。

2.2 不同功率超声波对溶液温度的影响

图4所示为在不同超声波功率下加入锌粉进行置换反应时,溶液温度随时间的变化。观察发现随着反应的进行,溶液温度经过约20 min的升高后出现“平台期”。这是由于溶液散热和超声波的能量输入达到动态平衡,使得溶液温度保持稳定。随超声波功率的增大,溶液在1 h置换过程中的升温幅度增高。当硫酸锌溶液中引入2 000 W超声波时,1 h置换过程中溶液最大升温达7.0 ℃。超声波诱导的空化气泡破裂会释放能量并产生局部高温热点,这在溶液中体现在整体温度升高。而高强度超声波导致的气泡内爆更密集,单位时间内对溶液的输入能量更多,所以液相热效应更大。这在一定程度上增大了反应热力学,强化了置换反应。

2.3 超声波强度对于置换反应固体产物层形貌的影响

图5展示了在含杂质Cu(Ⅱ)的硫酸锌溶液中引入超声波后,不同超声波输出功率下,锌粒表面置换产物的形貌和分布。观察发现置换产物由固体小颗粒有序排列构成,产物的生长方式和形态尺寸受颗粒的空间排布直接影响。当超声功率较小时(500 W),置换产物多呈棒状且尺寸较大。产物表面由树叶颗粒叠加构成且凹凸不平,无序分布在反应界面上。超声功率增大后(1 000 W),叠加生长的树叶状晶粒尺寸明显变小。当超声波的输出功率增大到1 500 W时,晶粒生长的择优取向趋势减弱,产物形貌转变为小尺寸棒状和颗粒状。足够大的超声波(2 000 W)下,产物的生长方式完全由择优取向转变为均匀生长,呈颗粒状且尺寸进一步减小。小颗粒产物在锌面上聚集分布,并且已经不能对锌基底形成全覆盖,有部分锌基底露出。不同强度超声波对于固体颗粒排布的破坏能力不同,进而显著影响产物的生长方式和分布。低功率超声波对固体颗粒的排布影响较小,强化传质的作用还有利于晶粒的生长。而大功率超声波会严重破坏固体颗粒的排列,使得沉积产物为零散颗粒。超声波对产物颗粒的结构破坏作用主要是基于超声波的液相效应。首先超声波能够对液体赋能,液相传播时压力失衡而产生空间搅动,从而对固相质点有机械剪切力。其次超声波会产生空化效应,在液体压力不均处出现液体断裂。由此产生的声空穴或空化气泡受声波压缩后急剧膨胀,空化气泡内爆产生强大的冲击波,破坏固体不溶相。据报道超声波效应对固体不溶物的作用甚至比研磨更强[35]。表面SEM图显示不同超声波输出功率时,产物的微观形态发生改变,但具体的生长方式和尺寸变化规律需进一步分析。

图6所示为利用Image J测量不同功率下锌粒表面多个置换产物长度,计算平均颗粒尺寸,进一步具体量化超声波功率增大后产物颗粒尺寸减小的趋势。由Image J测量结果可知,500 W低功率下产物平均尺寸约为8.82 μm,且颗粒尺寸分布范围较大。这可能是因为低能量超声输入对晶体长大影响较小,低能量的超声波冲击不足以破坏新生固体颗粒。当超声波输出功率增大至2 000 W时,晶体颗粒的平均尺寸减小至1.57 μm,且尺寸分布范围相对较窄。推断强超声可以有效抑制锌置换生成的铜晶粒长大,并且可能使得固体小颗粒有序排布。

图7中分析了锌粒表面产物颗粒的尺寸和铜离子去除率之间的关系。结果显示固体产物层中颗粒尺寸越小,铜离子去除率越高。均匀生长的类球形颗粒与具有择优取向的树叶状产物相比,对硫酸锌溶液的阻挡能力更弱。产物固体颗粒尺寸越小,且对锌基底遮蔽不完整,两相反应面积就越大,因此铜离子的去除率越高。由于产物颗粒尺寸受超声波输出功率严重影响,因此高强度超声波对铜离子去除率有重要影响。

图8所示是锌粒样品的截面SEM图,展示了锌基底的状态以及与置换固体产物的结合情况。结果显示由锌置换产生的固体产物层具有一定厚度,这说明置换产物在界面上叠加分布。产物层整体松散的“漂浮”在锌基底上,与反应面的结合力较弱。置换产物的生长趋势在空间中存在分形维数,且具有空间选择性,这导致了界面产物表面的高致密性。当施加低功率500 W超声时,固体产物呈现树叶状,且树叶分支发达,可能对锌基底连续覆盖,锌基底也相对较平整。随着施加超声波功率增大,产物颗粒变小且分支欠发达,难以形成对锌基底的全覆盖。此时产物层中间出现较大空隙,与500 W下的情况相比,“漂浮”情况更明显。锌基底出现较多“沟壑”,这个现象在大功率(2 000 W)超声输入时更为明显。这是因为大功率下固体产物层的松散程度更大,且对于硫酸锌溶液和锌粒的遮蔽作用有限,硫酸锌溶液通过产物层中的间隙渗透至被包裹锌面,造成锌与硫酸锌溶液更多接触机会。固-液接触保证了两相间的离子交换,使得锌基底发生持续置换反应而溶解。

图9所示为不同超声波功率下置换反应后锌粒样品的截面OM照片,给出了较大范围锌发生置换反应后的溶损情况和锌基底上固体产物层的分布状态。结果显示,当施加低功率500 W超声波时,基底锌的溶损几乎是均匀的,基底相对平整;此时置换反应进程有限,固体产物层较薄且分布不均匀;并且发现产物层在超声波作用下似乎有“漂移”现象。低功率时固体产物层致密性较好,硫酸锌溶液渗透困难,锌基底很难被侵蚀。此时超声波的热效应和强化传质的作用都比较小,置换产物数量有限,使得堆叠形成的产物层较薄。而反应界面的局部浓度梯度使得产物的生长和分布不均匀,因此整体产物层厚薄不一。随着施加超声场强度的增加,置换反应进程明显加快,固体产物层明显增厚。密集的声波传播促进了杂质离子均匀化分布,所以产物层的厚度趋于均匀。而此时锌基底溶损变得不均匀,基底表面不平整,出现大面积“沟壑”。2 000 W超声场条件下,固体反应层虽然最厚,但是产物层中间隙很大,存在较大的贯通孔。结合图8中结果,可以得出结论,2 000 W超声场形成的产物层固体颗粒小且分支不发达,易于形成大的贯通孔。这有助于溶液在其中的扩散,促进置换反应的进行,强化了溶液中的除铜效率,还能够提高锌的利用效率。

2.4 固体产物的物相组成分析及超声强化机理

图10显示了在不同超声波能量密度下,反应后回收的锌粉置换产物的物相组成。在500 W和1 000 W的输出功率下,置换产物主要由Cu0和合金产物Cu5Zn8组成;而在1 500 W和2 000 W时,置换产物中还存在Cu2O。Cu2O主要是由置换出的单质氧化,或硫酸锌溶液中的氧化还原反应生成。铜锌合金相的生成说明了置换产物中会裹挟着部分锌,这部分的锌不具有置换反应活性,会降低锌的除杂利用率。

图11所示为锌置换除铜过程中界面处形成的锌-铜微电池机理分析。杂质Cu(Ⅱ)从体溶液中扩散至锌附近,穿过液相扩散层后靠近反应锌面。锌在硫酸锌溶液中持续失去电子,溶解Zn(Ⅱ)进入溶液中。Cu(Ⅱ)在锌面上的活性位点获电子沉积,形成的置换产物包裹在锌面上。由于生成的产物中裹挟着铜锌合金,仍然与锌存在电位差,具有反应活性。因此沉积产物会持续消耗溶解Zn(Ⅱ)释放的自由电子,这会减缓置换反应速率。致密的沉积产物还会阻挡溶液中Cu(Ⅱ)与锌面的接触,严重阻碍置换反应进程,因此需要引入高强度超声破坏锌面沉积物,保证反应的进行。

图12中结合了不同超声波输出功率时的置换产物微观形貌,分析了超声场强度对于置换反应固体产物颗粒尺寸和形貌影响。由于置换产物中含硬脆的Cu5Zn8和Cu2O,对超声波的传播具有良好的反射能力;固体颗粒的有序排布使得产物表面粗糙度较大,超声波在固相硬质表面间会持续反射,这有利于减缓声波衰弱,产生局部应力集中。当密集的声波冲击超过产物的应力极限,声空化效应和局部涡流的机械剪切力使得粗壮枝晶断裂。当超声波输出功率逐渐增大时,置换产物由分支发达的树叶状转变为树叶变小且分支欠发达的颗粒。1 500 W的超声波在折断的枝晶间的剪切力更大,持续研磨硬度较大的固相质点。由于输出功率较大,超声波对于产物颗粒冲击的次数多,声波在破碎化产物间的反射更加均衡,使破碎枝晶被声波均匀研磨,产物趋于颗粒状且尺寸进一步减小(约为2.33 μm)。当超声波能量最大化(2 000 W)时,超声波将产物颗粒研磨成尺寸极小的固体颗粒(约为1.57 μm),并可能造成部分产物脱落。

图13所示为基于产物层的微观形貌对于置换反应的影响,并对超声波辅助锌置换除铜的机理进行了整体分析。超声波通过液体介质向反应溶液输入不同能量密度的机械波,这些声波之间的相互作用力能够增大溶液搅动。超声波对溶液持续输入能量使得超声源周围液体赋能,裹挟离子的赋能溶液在声波的助推下传播,有力促进了溶液的体扩散。

随着锌置换除铜反应的进行,超声波的热效应加速了锌表面固体产物层的生成;固体产物层的存在严重阻碍了溶液扩散至锌表面,导致了置换反应减缓甚至阻断反应。在反应体系中施加强超声可以打断堆叠严密的粗壮枝晶、减小固体产物层中颗粒尺寸、形成较大贯通孔,减小溶液在产物层中传输的空间阻力,促进溶液在固体产物层中的内扩散;超声波的空化效应和声流作用还能使置换产物层破碎化,进一步增大产物的孔隙。声波在贯通孔中的传递继续强化离子传输,不仅加速杂质Cu(Ⅱ)扩散至反应面,还能推动溶解Zn(Ⅱ)远离锌面,降低了扩散通道中的离子浓度,进一步减小传质阻力。总的来说,超声波促进了硫酸锌溶液在产物层中的内扩散使得锌持续溶解,增大两相反应面积,加速锌置换除铜反应。超声波在硫酸锌溶液的净化中能够对钝化层造成结构破坏,改善除杂剂的包覆问题,从而提高锌粉利用效率。

3 结论

1)超声波对于置换法进行硫酸锌溶液净化除铜过程的强化作用受其强度的影响,低强度输入超声波(500 W)强化作用与机械搅拌作用相似,对沉积产物的形貌分布影响较弱,主要强化离子在溶液中的体扩散;高强度输入(2 000 W)超声波破坏了固体产物层的连续性,进而强化多孔固体产物层中的内扩散,超声波热效应还能提高置换反应速率,最终可以将1 h置换反应铜的去除率由37.3%提高至99.4%。

2)超声波输入功率由500 W增至2 000 W,锌粉置换反应的固体产物形貌和分布状态发生明显改变:低功率超声波条件下,固体产物层由分支发达树叶状产物组成,这些产物由固体颗粒按生长优势方向有序排列构成,且连续分布在锌表面;功率增加至2000 W,固体产物层由类球形的小颗粒组成,在锌表面分布不连续,很多锌表面暴露于溶液;强超声还能在固体产物层中形成贯通孔,减少溶液在固体产物层中扩散的结构阻力,强化离子在产物层中的内扩散。

-

表 1 Cu-Ni-Ti合金化学成分

Table 1 Chemical composition of Cu-Ni-Ti alloy

表 2 α、n、Q和A多项式系数

Table 2 Coefficients of α, n, Q and A polynomials

-

[1] ZHAO Z, ZHANG Y, TIAN B, et al. Co effects on Cu-Ni-Si alloys microstructure and physical properties[J]. Journal of Alloys and Compounds, 2019, 797: 1327-1337. doi: 10.1016/j.jallcom.2019.05.135

[2] LEI Q, LI Z, WANG M P, et al. The evolution of microstructure in Cu-8.0Ni-1.8Si-0.15Mg alloy during aging[J]. Materials Science and Engineering: A, 2010, 527: 24-25.

[3] XIA C, JIA Y, WAN Z, et al. Study of deformation and aging behaviors of a hot rolled-quenched Cu-Cr-Zr-Mg-Si alloy during thermomechanical treatments[J]. Materials & Design, 2012, 39: 404-409.

[4] PANG Y, XIA C, WANG M, et al. Effects of Zr and (Ni, Si) additions on properties and microstructure of Cu-Cr alloy[J]. Journal of Alloys & Compounds, 2014, 582: 786-792.

[5] 冯颖, 李益民, 曾昭易, 等. 注射成形和模压成形Cu-10Ni合金的烧结行为[J]. 粉末冶金材料科学与工程, 2009, 14(1): 42-47. doi: 10.3969/j.issn.1673-0224.2009.01.009 [6] 马艳霞, 苑伟, 梁晨, 等. CuNi10Fe1.6Mn铜镍合金热压缩流变应力行为研究[J]. 锻压装备与制造技术, 2018, 53(6): 130-133. https://www.cnki.com.cn/Article/CJFDTOTAL-DYJX201806047.htm [7] ZHANG H, HE Y, YANG F, et al. Thermodynamic assessment of Cu-Ni-Ti ternary system assisted with key measurements[J]. Thermochimica Acta, 2013, 574: 121-132. doi: 10.1016/j.tca.2013.08.012

[8] ZHU W J, DUARTE L I, LEINENBACH C. Experimental study and thermodynamic assessment of the Cu-Ni-Ti system[J]. Calphad, 2014, 47: 9-22. doi: 10.1016/j.calphad.2014.06.002

[9] ZHANG P, LI Y, LEI Q, et al. Microstructure and mechanical properties of a Cu-Ni-Ti alloy with a large product of strength and elongation[J]. Journal of Materials Research and Technology, 2020, 9(2): 2299-2307. doi: 10.1016/j.jmrt.2019.12.061

[10] LIU J, WANG X H, GUO T T, et al. Microstructure and properties of Cu-Ti-Ni alloys[J]. International Journal of Minerals Metallurgy and Materials, 2015, 11: 1199-1204.

[11] LIU J, WANG X H, GUO T T, et al. Microstructural evolution and properties of aged Cu-3Ti-3Ni alloy[J]. Rare Metal Materials & Engineering, 2016, 45(5): 1162-1167.

[12] CHALON J, GUÉRIN J D, DUBAR L, et al. Characterization of the hot-working behavior of a Cu-Ni-Si alloy[J]. Materials Science & Engineering A, 2016, 667: 77-86.

[13] LIU J, WANG X H, LIU J T, et al. Hot deformation and dynamic recrystallization behavior of Cu-3Ti-3Ni-0.5Si alloy[J]. Journal of Alloys & Compounds, 2019, 782: 224-234.

[14] LEI Q, LI Z, WANG J, et al. Hot working behavior of a super high strength Cu-Ni-Si alloy[J]. Materials and Design, 2013, 51: 1104-1109. doi: 10.1016/j.matdes.2013.05.001

[15] 吴文博, 崔书辉, 郑学清, 等. 某发动机用Cu-Ni-Si生产工艺的确定[J]. 有色金属科学与工程, 2020, 11(2): 76-81. https://www.cnki.com.cn/Article/CJFDTOTAL-JXYS202002011.htm [16] 周家林, 史密, 张陪毅, 等. 45钢低温区热变形行为研究[J]. 钢铁, 2014, 49(10): 62-65. https://www.cnki.com.cn/Article/CJFDTOTAL-GANT201410012.htm [17] 王桂花, 杨秋月, 吴珊珊, 等. GH2132高温合金热变形行为研究[J]. 塑性工程学报, 2021, 28(3): 137-145. doi: 10.3969/j.issn.1007-2012.2021.03.018 [18] 权国政, 王阳, 余春堂, 等. 基于DMM加工图的7050铝合金热塑性变形参数优化识别[J]. 材料热处理学报, 2013, (6): 169-173. https://www.cnki.com.cn/Article/CJFDTOTAL-JSCL201306034.htm [19] 蔡薇, 高鹏哲, 陈辉明, 等. Cu-Cr-Zr-Ti合金高温热变形行为及热加工图[J]. 金属热处理, 2019, 44(8): 147-154. https://www.cnki.com.cn/Article/CJFDTOTAL-JSRC201908032.htm [20] LIANG Q, LIU X, LI P, et al. Hot deformation behavior and processing map of high-strength nickel brass[J]. Metals, 2020, 10(6): 782. doi: 10.3390/met10060782

[21] 孙军伟, 张荣伟, 李升燕, 等. 5812铝合金热变形行为研究[J]. 有色金属科学与工程, 2018, 9(5): 49-53. https://www.cnki.com.cn/Article/CJFDTOTAL-JXYS201805008.htm [22] SELLARS C M, MCTEGART W J. On the mechanism of hot deformation[J]. Acta Metallurgica, 1966, 14: 1136-1138. doi: 10.1016/0001-6160(66)90207-0

[23] LIN Y C, CHEN M S, ZHONG J. Constitutive modeling for elevated temperature flow behavior of 42CrMo steel[J]. Computational Materials Science, 2008, 42: 470-477. doi: 10.1016/j.commatsci.2007.08.011

[24] PRASAD Y V R K, RAO K P. Processing maps for hot deformation of rolled AZ31 magnesium alloy plate: Anisotropy of hot workability[J]. Materials Science and Engineering: A, 2008, 487: 316-327. doi: 10.1016/j.msea.2007.10.038

[25] PRASAD Y V R K, SESHACHARYULU T. Processing maps for hot working of titanium alloys[J]. Materials Science and Engineering: A, 1998, 243: 82-88. doi: 10.1016/S0921-5093(97)00782-X

[26] MURTY S, RAO B N. On the flow localization concepts in the processing maps of titanium alloy Ti-24Al-20Nb[J]. Journal of Materials Processing Technology, 2000, 104(1/2): 103-109.

下载:

下载: