Inclusions in IF steel continuous casting slab and hot rolled sheet

-

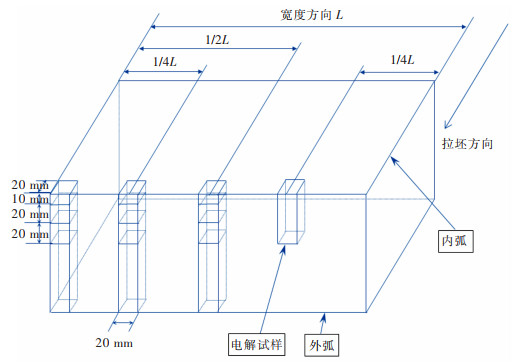

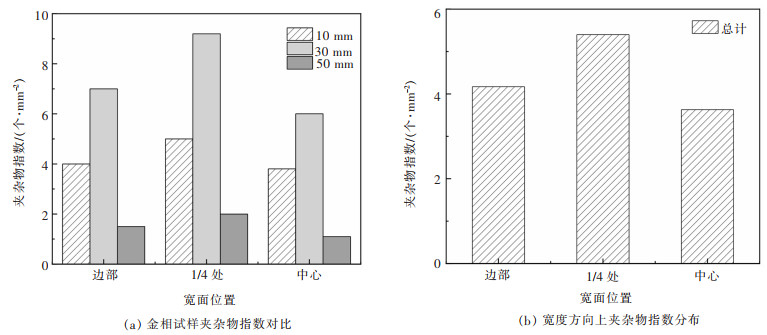

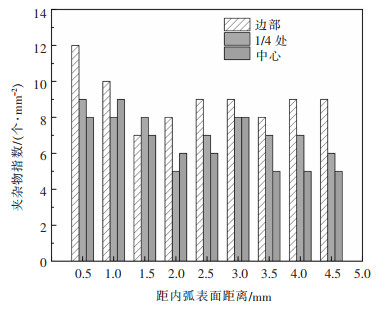

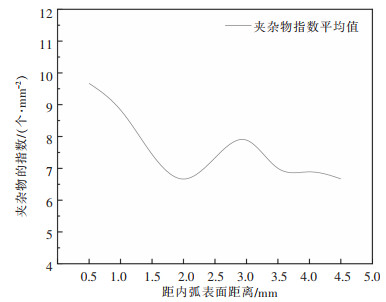

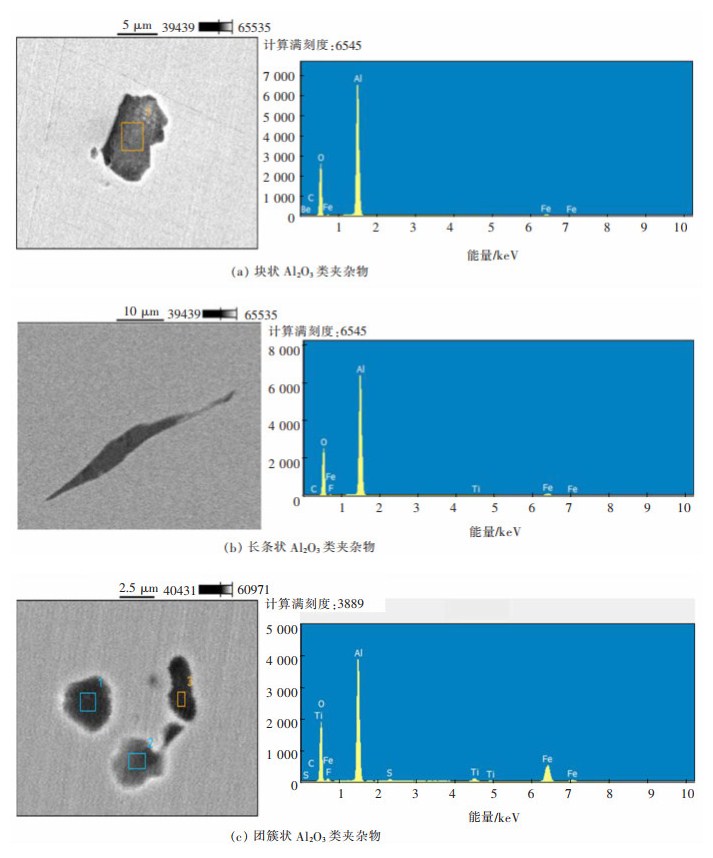

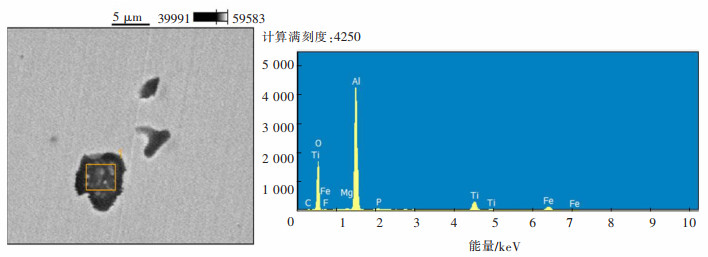

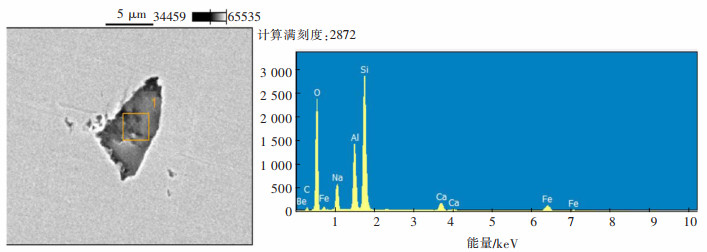

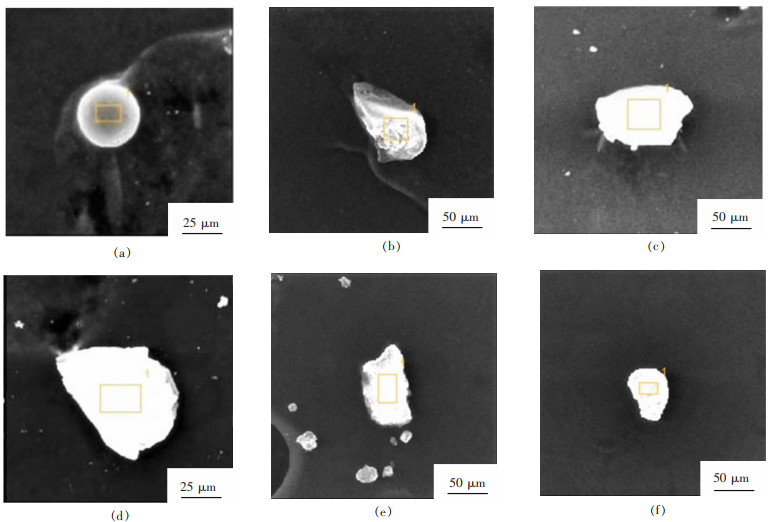

摘要: 夹杂物是影响IF钢表面质量的重要因素。对某厂生产的IF钢连铸坯和热轧板取样, 采用光学显微镜、扫描电镜、能谱、大样电解等多种检测分析方法, 分析了夹杂物的形貌、尺寸、数量、分布以及成分等。研究发现, 热轧工艺的轧制作用使连铸坯宽度方向1/4处聚集的夹杂物向边部迁移, 最终造成热轧板边部夹杂物指数最高, 说明夹杂物聚集带在轧制过程中具有遗传性。热轧板中20 μm以下夹杂所占百分比与连铸坯中夹杂相比稍有增大, 50 μm以上夹杂所占百分比稍有降低。热轧工艺的轧制作用将连铸坯中大颗粒氧化铝夹杂挤压变形为热轧板中的长条状, 容易形成表面条状缺陷。夹杂物在连铸坯距内弧侧30 mm处存在聚集现象, 热轧板中距内弧侧0.5 mm处夹杂物指数最高, 这是由于等效应变不同使夹杂物聚集带向表层迁移。IF钢连铸坯和热轧板中主要有4类显微夹杂, 分别为Al2O3类、TiN、Al2O3-TiOx和SiO2类复合夹杂, 且两者中各类夹杂物所占百分比差别不大。Abstract: Inclusions are important factors affecting the surface quality of IF steel. This paper studied the IF steel slab and hot-rolled plate produced by a domestic factory. The two-dimensional morphology, size, quantity, distribution and composition of inclusions were analyzed by optical microscope, scanning electron microscope and energy spectrum. The results show that the rolling action of hot rolling process makes the inclusion gathered at 1/4 of the width of continuous casting billet migrate to the edge. This results in the highest inclusion index at the edge of the hot rolled plate, indicating that the inclusion accumulation zone is hereditary during the rolling process. Compared with the constant casting billet, the inclusion percentage under 20 meters in the hot-rolled plate increases slightly, while the inclusion percentage above 50 meters decreases slightly. During the hot rolling process, the inclusion of large alumina particles in the continuous casting slab is extruded and deformed into long strip in the hot rolling plate, which is easy to form surface strip defects. The inclusion aggregation was found at 30 mm from the inner arc side of the casting billet, and the inclusion index was highest at 0.5 mm from the inner arc side of the hot rolled plate. The difference in equivalent strain caused the inclusion aggregation to migrate to the surface. There are mainly four kinds of microscopic inclusions in IF steel continuous casting slab and hot rolled plate, which are Al2O3, TiN, Al2O3-TiOx and SiO2 composite inclusions respectively, and there is little difference in the percentage of each kind of inclusions between them.

-

Keywords:

- IF steel /

- hot-rolled plate /

- inclusion /

- continuous cast slab

-

0 前言

在岩石力学室内试验研究中, 一般都是将现场取到的不规则大块试样, 在室内加工成一定形状的规则试件, 应用各种测量仪器和加载设备, 按试验设计的要求进行试验, 最后得到各种不同的强度指标和弹性指标。在这些试验中, 一般都是把岩石假设成均质的、各向同性的座续介质, 而且是变形很小的弹性体, 然后应用弹性理论或弹塑性理论进行分析。然而这些假设条件, 对大多数岩体来说是不符合实际情况的。因为岩体是地质体的一部分, 它在长期的地质作用下, 使岩体存在有断层、裂隙、节理、片理等各种结构构造, 所以, 它是非均质、各向异性、存在着许多弱面的不连续介质, 特别是对于片岩、板岩等结构面发育的岩体来说, 在各个不同的结构面上有非常明显的强度指标和弹性指标的差异。因此, 本文在研究片岩的强度特征、变形特征和破坏机制的同时, 着重研究它们之间的相互关系和一般规律。

1 试验方法

将试样按施压轴平行片理面、垂直片理面和斜交片理面成45°角三种情况加工成标准试件, 在每块试件的四个对称侧面上分别贴上纵向电阻应变片和横向电阻应变片, 进行变形试验和抗压强度试验。用E⊥、μ⊥和6⊥, 表示施压轴与片理面垂直时的弹性模量、泊桑比和抗压强度, 如图 1(a)所示。用σ⊥表示施压轴与片理面平行时的抗压强度, 用E‖、μ‖表示xy平面上的弹性模量、泊桑比, 用E'‖、μ'‖表示yz平面上的弹性模量、泊桑比, 如图 1(b)。用己σa表示施压轴与片理面成45°。角时的抗压强度, 用Ea、μa表示xy平面上的弹性模量、泊桑比, 用E'a、μ'a表示yz平面上的弹性模量、泊桑比, 如图 1(c)。最后用横观各向同性的异性岩休计算出五个独立弹性常数, 分别用E、E'、μ、μ'和G'产表示施压轴平行片理面、垂直片理面加压时的弹性模量、泊桑比和剪切模量。

抗拉强度是按施压轴平行片理面和垂直片理面两种情况对试件进行劈力法试验, 求得施压轴平行片理面的抗拉弧度R‖和垂直片理面的抗拉强度R⊥。

抗剪断强度试验用倾斜压模法进行。同样采用施压轴与片理面平行和与片理面垂直两种清况加压试验, 剪切角分别为44°、51°、58°、63°、68°、75°和85°, 并将试验绪果作出岩石强度曲线, 求得内聚力C和内摩擦角ϕ。

变形试验采用电阻应变仪法测量变形, 逐级循环法加压, 每次循环级差为4MPa, 加压至试件完全破坏, 求得岩石的弹性参数和极限应力。

2 试验结果

2.1 抗压强度与抗拉强度试验结果

表 1 抗压强度试验结果 表 2 抗拉强度试验结果

表 2 抗拉强度试验结果

2.2 抗剪断强度试验结果

利用倾斜压模法分别进行施压轴平行片理面和垂直片理面加压剪断试验(图 2), 得出不同剪切角的正应力σi和剪立力τi值, 然后用抗拉强度R、正应力σi、剪应力τi及抗压张度σ作出强度曲线。

由图 2之1得出施压轴垂直片理面加压的内聚力C⊥=17.0MPa, 内摩擦角ϕ⊥= 30°~35°; 由图 2之2得出施压轴平行片理面加压的内聚力C‖=9.5MPa, 内摩擦角ϕ‖=40°~45°。

2.3 变形试验结果

变形试验结果示于表 3。

表 3 变形试验结果

3 试验结果分析

3.1 岩石强度与片理面的关系

试验结果证明, 岩石强度与加压方向有关, 当施压轴与片理面垂直时强度最大, 施压轴与片理面平行时次之, 与片理面成45°角时最小。由抗压强度可以看出:垂直加压的抗压强交为平行加压强度的2倍左右, 为45°角加压强度的3倍左右, 同样垂直加压的抗拉强度为平行加压抗拉强度的3倍左右, 内凝结力为2倍左右。从岩石试验的偏差系数来看, 垂直加压的偏差系数最小, 平行加压的火之, 而45°角加压的最大。这些情况表明:影响当石强度的主耍因素是片理面的结构形式与受力状态。在采矿过程中, 改变岩石的受力伏态, 对提高岩石的强度是极为有利的。

3.2 应力-应变(σ-ε)与岩石片理面关系

表 3说明, 当岩石受压时, 由于施压轴与片理面之问存在一个角度关系, 使得弹性参数有物明显的差异, 并符合E‖>Ea> E⊥, μ‖>μ⊥, μ'‖>μ‖, E‖>E'‖, Ea>E'a的变化规律。同时将试块视为横观各向同性的异性体进行平差计算, 得出5个独立参数如下:E、E'、μ、μ'和G'分别表示施压轴平行片理面和垂直片理面加压的弹性模量、泊桑比和剪切模量。

E=8.73×104MPa, E'=6.18×104MPa, μ=0.235, μ'=0.212, G'=1.75×104 MPa, E'/E=0.707, μ'/μ=0.903

应力-应变与岩石片理面的关系曲线如图 3、图 4、图 5所示。

从三付应力一应变关系曲线图中, 可以发现岩石的变形特征主要受作用力和结构面控制, 变形曲线特征主要反映在以下三个方面, 即力的作用阶段, 应力循坏回滞圈和作用应力与结构而的关系。

力的作用阶段:当岩石试件开始受力直至试件完全破坏, 应力-应变关系曲线可以分为五个阶段, 即微裂隙压密闭合阶段, 似线弹性阶役, 破坏稳定发展阶段, 破坏不稳定发展阶段以及急剧破坏阶段。

a. 微裂隙压密闭合阶段。它出现在低应力区, 一般在破坏载荷的3%以内。在这一阶段中, 呈现出应力增加较小时, 纵向应变增加较大, 而且有较大的残余变形, 变形模量较小, 随着应力的增长, 变形模量逐渐增大, 变形逐渐减少。而横向应变变化狡小, 由线较陡, 说明变形主要是由于微裂隙和孔隙的压密闭合所致。

b. 似线弹性阶没。在微裂隙压密闭合后, 就出现一段线性关系很好的斜直线, 弹性参数基本上是一个常数。这段直线约占整条曲线长的15%~20%。

c. 破坏稳定发展阶段。在线弹性阶段后面出现一段线性关系仍较好的直线, 有一定的残余变形, 这种残余变形随着应力的增加而增加, 曲线斜率逐渐增大, 横向应变变化较剧烈。这一区段较大, 约占曲线长度的30%~40%。

d. 破坏不稳定发展阶段。一般占曲线长度的25%~30%左右, 在这一区段内, 当应力逐渐增加时, σ-ε曲线无一定的变化规律, 有时甚至出现纵向应变量减少而横向应变量突然增大, 或电阻片突然被拉断, 同时发出破裂声, 片理面明显张开, 纵向压缩应变量有时小于横向膨胀应变量。

e. 急剧破坏阶段。这段应力占曲线长度的20%以内, 应力和应变剧烈变化, 破裂声频繁, 裂隙明显增大, 横向应变片基本都被拉断, 最后并有应力下降的现象, 试件突然破坏。

由于应力-应变曲线受到作用应力和结构面的控制, 所以在垂直片理面加压时, 线弹性阶段和破坏稳定发展阶段比较大, 斜交片理面次之, 平行片理面的最小; 而破坏不稳定发展阶段和急剧破坏阶段刚好相反, 平行片理面加压时较大, 斜交片理面的次之, 垂直片理面的最小。另外我们还发现垂直片理面加压时, 破坏稳定发展阶段很大, 为破坏不稳定阶段的1倍左右。而平行片理面加压的破坏稳定发展阶段小于破坏不稳定发展阶段, 45°时的破坏稳定阶段略大于破坏不稳定发展阶段。以上情况说明岩石在片理面与受压轴垂直时, 受力情况较好, 虽然岩石受力后开始破坏, 但因有较大的破坏稳定发展阶段, 能充分利用它的安全抗压强度; 然而急剧破坏阶段小, 应注意防止突然性破坏。平行片理面加压时, 在破坏稳定发展阶段后面有较大的不稳定发展阶段和较大的急剧破坏阶段, 这对于防止岩石突然性破坏而采取安全措施是有利的。

岩石应力-应变曲线的另一个特征是应力循环的回滞圈。在弹性应力范围内, 通过逐级循环加压后, 基木上都有回滞圈出现, 但是当垂直片理面加压时, 纵向应变片的回滞圈较大, 而横向回滞圈则很小; 在平行片理面加压时, 平行片理面上的纵向和横向应变片的回滞圈均很小, 而在另一对称侧面上即电阻片与片理面垂直的情况下, 横向片的回滞圈很大, 纵向片的回滞圈仍很小。这些情况说明, 层面与层面之间有较大的塑性变形。此外, 说明岩石的变形恢复需要一个时间过程。

应力-应变曲线的第三个特征是作用应力与片理面的关系。在垂直片理面加压时, σ-ε曲线的线性关系均较好, 斜率变化小。当平行片理面或斜交片理面45°加压时, 在破坏稳定发展阶段以内, 平行片理面或斜交45°的曲线斜率变化小, 曲线较陡, 电阻片和片理面垂直或斜交的曲线斜率较缓, 也就是说E‖>E'‖, μ‖ < μ'‖当作用力超过稳定发展阶段后, 平行片理面和斜交片理面上的纵向应变片的变化不大, 而横向应变片的应变量突然增大或被拉断, 这是片理面间的粘结力突然受破坏的结果, 纵向应变片则因两对称侧面的张拉应力均等, 电阻片主要受压应力作用。

4 岩石破坏机制的探讨

试验研究表明, 由于岩石具有较大的抗压强度和较高的弹性模量, 片理面间的粘结性较好, 因此在单轴压应力作用下, 呈现出脆性破坏特征。由于结构面的影响, 当载荷与片理面平行时, 主要表现为张拉破坏, 试件破坏不象其他脆性均质岩石那样成x型或y型破坏, 它基本上分裂成3~5mm厚的薄片沿片理面平行裂开, 粉碎性大, 由于上下承压板阻力与张拉应力方向相反, 在试件中部薄片被张拉折断, 呈现出六角形的破坏; 当施加载荷与片理面垂直时, 主要表现为剪切破坏, 试件破坏后多呈不规则的三棱体, 粉碎程度小, 它不沿片理面破裂, 同样x型或y型破坏不明显; 斜交片理面45°时的情况介于以上二者之间, 它的破坏特点是:在结构面上沿片理面剪切和滑移成45。的斜楔体, 剪切滑移现象明显, 片理面间由于错动滑移, 形成一层很细的粉末, 除去粉末后即可发现层面间很光滑, 且略带很细的摩擦痕迹。

通过以上三种破坏现象可以清楚地看到, 由于岩体的不均质性, 结构面和作用应力所引起的破坏机制也是不泪同的, 在同一应力状态下, 不同的岩体结构面可以反映出张拉破坏或剪切破坏, 而这些破坏机制主要是受应力状态和结构面的控制。

5 结论

通过对片岩的岩石力学试验研究, 得出在单轴应力作用下, 片岩的强度特征、变形特征和破坏机制的一般规律, 强度大小、应力-应变关系是受应力状态和结构面所控制。研究证明:

a. 片岩岩石的强度指标直接受结构面控制, 并得出σ⊥>σ‖>σa, R⊥>R‖, C⊥>C‖, ϕ⊥ < ϕ‖的结论。

b. 岩石从开始受力到破坏可以分为五个阶段:即微裂隙的压密闭合阶段, 似线弹性阶段, 破坏稳定发展阶段, 破坏不稳定发展阶段和破坏急剧阶段。这符合岩石破坏的一般规律。

c. 提出反映岩石应力-应变关系的三个特征, 即力的作用阶段, 结构面与回滞圈的关系及作用应力、结构面与弹性参数的关系, 得出:E‖>Ea>E⊥, μ‖>μ⊥>μ'‖>μ‖, E‖>E'‖。

d. 岩石的破坏机制受应力状态与结构面所控制。它的破坏不象x型, 也不象y型破坏。当作用应力与片理面平行时, 主要表现为张拉破坏; 作用应力与片理面垂直时, 主要表现为剪切破坏; 作用应力与片理面成45°时, 主要表现为沿结构弱面剪切滑移成斜楔形体。

-

表 1 IF钢化学成分

Table 1 Chemical composition of IF steel

-

[1] 陈俊杰, 刘建华, 刘建飞, 等. IF钢连铸坯表层夹杂物[J].北京科技大学学报, 2011, 18(增刊1):173-178. https://www.cnki.com.cn/Article/CJFDTOTAL-BJKD2011S1036.htm [2] 岳峰, 崔衡, 包燕平, 等. Ti-IF钢中夹杂物的行为[J].炼钢, 2009, 25(4):9-12. https://www.cnki.com.cn/Article/CJFDTOTAL-LGZZ200904004.htm [3] 刘延强, 杨敬铭, 单伟, 等.热轧卷表面线状缺陷分析[J].中国冶金, 2016, 26(7):48-53. https://www.cnki.com.cn/Article/CJFDTOTAL-ZGYE201607011.htm [4] 刘启龙, 王志政, 臧红臣. IF钢板坯连铸工艺优化[J].钢铁, 2011, 46(8):36-39. https://www.cnki.com.cn/Article/CJFDTOTAL-GANT201108009.htm [5] 苑鹏, 宋丽娜, 李海波, 等. IF钢铸坯皮下夹杂物与钩状坯壳的特征分布[J].钢铁研究学报, 2016, 28(12):27-34. https://www.cnki.com.cn/Article/CJFDTOTAL-IRON201612006.htm [6] 吴国荣, 张敏, 谢鑫, 等. IF钢铸坯皮下夹杂分布规律研究[J].铸造技术, 2018, 39(11):2572-2574. https://www.cnki.com.cn/Article/CJFDTOTAL-ZZJS201811044.htm [7] 周力, 王新华, 姜敏, 等. IF钢连铸过程洁净度分析[J].炼钢, 2016, 32(2):53-59. https://www.cnki.com.cn/Article/CJFDTOTAL-LGZZ201602012.htm [8] 肖鹏程, 朱立光, 刘海春, 等. IF钢非稳态连铸坯洁净度定量分析[J].钢铁钒钛, 2017, 38(3):111-117. https://www.cnki.com.cn/Article/CJFDTOTAL-GTFT201703022.htm [9] 田恩华, 崔衡, 尤大利, 等. IF钢铸坯表层洁净度研究[J].炼钢, 2014, 30(1):59-62. https://www.cnki.com.cn/Article/CJFDTOTAL-LGZZ201401017.htm [10] 尹延斌. IF钢板坯表面缺陷形成机理的数值模拟研究[D].北京: 北京科技大学, 2020: 120-123. [11] 丸川雄净.大量生產規模における不純物元素の精錬限界の挑戰[C]//東京: 日本鉄鋼協会高温プロセス部会精錬フォ-ラム, 1996: 1-3. [12] 胡招凡, 张炯明, 蔡珍, 等.结晶器电磁搅拌对IF钢连铸坯表层纯净度的影响[J].钢铁研究学报, 2011, 23(10):15-19. https://www.cnki.com.cn/Article/CJFDTOTAL-IRON201110006.htm [13] 李金柱.首京唐公司高品质汽车板冶金工艺研究[D].北京: 北京科技大学, 2017: 100-106. [14] 王新华.高品质冷轧薄板钢中非金属夹杂物控制技术[J].钢铁, 2013, 48(9):1-7, 15. https://www.cnki.com.cn/Article/CJFDTOTAL-GANT201309001.htm [15] 王睿.邯钢超低碳IF钢冶炼工艺及冷轧板缺陷控制研究[D].北京: 北京科技大学, 2017: 53-56. [16] 王金永, 刘建华, 刘建飞, 等. Ti-IF钢凝固过程中TiN的析出机理和规律[J].北京科技大学学报, 2014, 21(8):1025-1031. https://www.cnki.com.cn/Article/CJFDTOTAL-BJKD201408006.htm [17] 石绍清, 尹振江, 卢帝维, 等.水平连铸管坯钢中的非金属夹杂物[J].北京科技大学学报, 2007, 29(增刊1):93-97. https://www.cnki.com.cn/Article/CJFDTOTAL-BJKD2007S1024.htm [18] 唐萍, 李玉林, 贾成橙, 等. IF钢铸坯表层大型夹杂物分布及来源研究[J].炼钢, 2016, 32(4):73-78. https://www.cnki.com.cn/Article/CJFDTOTAL-LGZZ201604011.htm [19] 刘俊山, 张华, 倪红卫, 等.汽车板深冲用DC06IF钢230mm铸坯夹杂物分布研究[J].特殊钢, 2018, 39(4):51-54. https://www.cnki.com.cn/Article/CJFDTOTAL-TSGA201804015.htm [20] 邓建军, 王睿, 郝阳, 等. IF钢冷轧板表面条状缺陷成因及控制[J].钢铁钒钛, 2017, 38(2):156-160. https://www.cnki.com.cn/Article/CJFDTOTAL-GTFT201702040.htm

下载:

下载: