Simultaneous and efficient leaching of mercury and antimony from mercury tailings

-

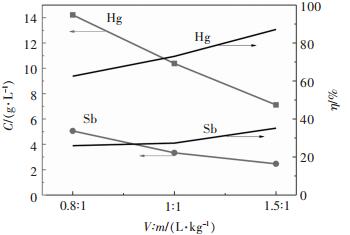

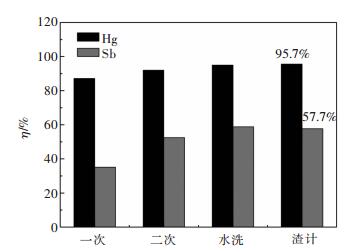

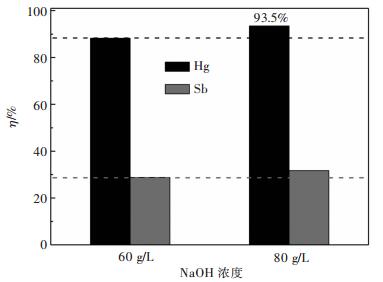

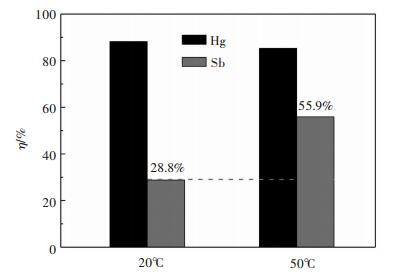

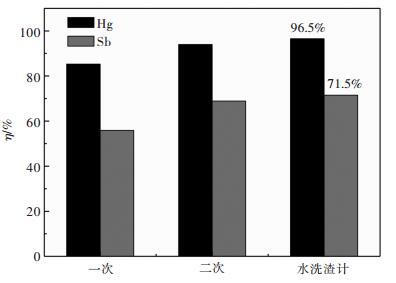

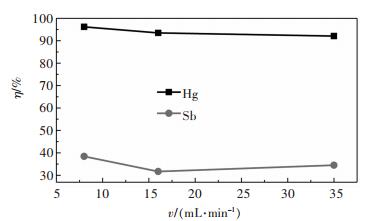

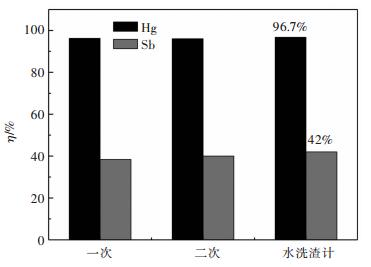

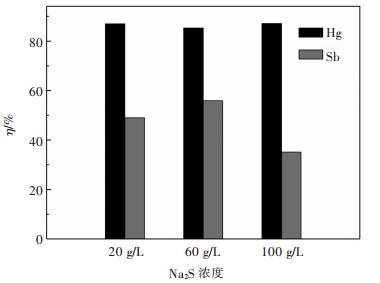

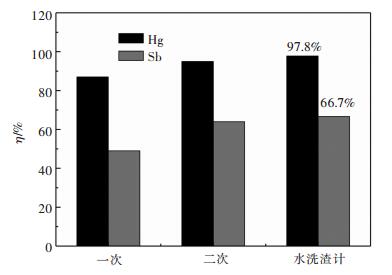

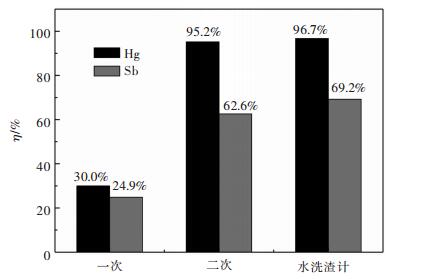

摘要: 汞尾矿是汞矿采选冶过程产生的一种危险废弃物,长期堆存对生态环境具有较大危害。另一方面,尾矿中含有的汞、锑也是有价金属。在汞尾矿无害化处理过程中,实现高价值汞、锑的回收,意义重大。开发了硫化钠溶液体系同步柱浸汞尾矿中汞锑新工艺,考察了关键工艺对汞和锑浸出率的影响,获得汞锑同步高效浸出的优化参数,明确了浸出液循环利用和汞锑浓度提升方案。结果表明,经过浸出液循环和二次浸出,汞尾矿中汞和锑浸出率分别可达到96.7%和69.2%,浸出液中汞和锑的浓度可达到22.8 g/L和10.0 g/L。Abstract: Abstract:Mercury tailing is a kind of hazardous waste produced during metallurgy of mercury mines. Long-term preservation of mercury tailings does great harm to ecological environment. On the other hand, mercury and antimony in tailings are also valuable metals. It is significant to recover mercury and antimony during harmless treatment of mercury tailing. In this paper, an effective method-leaching mercury and antimony from mercury tailing by using Na2S solution based on column leaching-was proposed. The effects of key process parameters on leaching ratios are studied. And the optimization conditions for the simultaneous separation of mercury and antimony are obtained. The strategies for the recycling of leaching solution and the increase of mercury and antimony concentrations are suggested. The results show that the leaching ratios of mercury and antimony are up to 96.7% and 69.2% after two-time leaching. The concentrations of mercury and antimony are 22.8 g/L and 10.0 g/L, respectively.

-

Keywords:

- mercury tailing /

- leaching /

- mercury antimony /

- leaching ratio

-

江西龙南是华南造山系南岭造山带风化壳离子吸附型稀土矿富集区,也是我国乃至全球重要的重稀土资源生产地[1]. 从20世纪70年代发现至今,经过几十年的开采,矿区内的富矿基本开采完,现在主要是“复灌”回收稀土资源,即对前期原地浸矿开采过的矿块进行二次或三次稀土资源回收,表明前期原地浸矿工艺的资源回收率不高.对于采用硫酸铵回收离子相资源的工艺来说,影响原地浸矿资源回收率的因素众多,主要有3个方面:①不同矿区地质条件和矿体赋存差异大[2];②注液孔网参数及布置位置不当,引起浸矿盲区,收液工程布置不合理降低了溶液回收率[3];③浸矿剂浓度、浸出时间、浸矿方式、渗流速度、液固比等[4],但浸出效果主要取决于浸矿剂溶液在稀土矿床中的渗透效果[5].

目前,生产上评价稀土矿体浸出效果的方法是:现场取松散矿样,将矿样装入浸矿柱,利用柱浸试验结果计算得到的浸出率作为矿体的浸出率[6]. 显然在评价稀土矿体的浸出率时未考虑矿体的原状结构对离子交换效率的影响,尽管室内柱浸试验的浸出率超过96 %[7],但由于重塑矿体时破坏了原矿的孔隙结构,不同孔隙结构的矿体渗流规律也有明显差异[8-9],因而重塑矿体的浸出率和未扰动矿体的浸出率可能相差很大.现有的研究结果表明,天然土壤的形成过程中,受胶结作用、触变硬化、时间效应及淋溶等影响,使土颗粒或团聚体具有一定的排列方式,表现为各向异性的力学特性,土样在重塑过程中结构性丧失,因而原状土和重塑土的渗透性存在明显差异[10].

土-水特征曲线描述了土壤含水量与基质势之间的关系,土体中孔隙的大小及分布决定基质势的大小[11],已有的很多经典土-水特征曲线模型都与土体孔径分布有关,并在土-水特征曲线的基础上提出预测非饱和土强度和渗透系数的公式[12],因而土-水特征曲线可以有效反映土壤孔隙结构及其变化. Ning Lu等[13]利用土-水特征曲线计算得出重塑Georgia高岭土单位质量的总孔隙体积为0.396 m3/g,比表面积为19.83 m2/g;田伟新[14]基于土-水特征曲线分析陇东原状黄土的孔径分布特征,得到原状黄土的比表面积为2.2858 m2/g,总孔隙体积0.416 m3/g. 文中通过测试龙南稀土原状矿体及其重塑矿体的土-水特征曲线,运用该曲线分析两者的孔径分布及其渗透性变化,为分析龙南类型稀土矿体的“复灌”现象提供参考.

1 土-水特征曲线的测试

原状矿体的土-水特征曲线测试地点位于江西省龙南县足洞稀土矿区,单环法测得该类型矿体的渗透系数为2.0×10-5 m/s,室内土工试验得到矿体的基本物理性质指标见表 1,利用激光粒度分析仪测得该矿体的粒径累积曲线,如图 1所示.

表 1 矿体的物理性质指标Table 1. Physical properties of ore body密度

/(g·cm-3)含水量

/%孔隙比 土粒相

对密度液限

/%塑限

/%塑性

指数1.63 15.32 0.92 2.72 41.46 30.34 11.12 原状矿体的土-水特征曲线的测试现场如图 2所示,在边坡上人工开挖形成一个台阶,采用中科院南京土壤所研制的TEN型张力计测试矿体的土-水特征曲线. 试验前先将试验场地平整,试验时将饱和除气后的张力计埋入预先挖好的孔洞之中,捣实管壁周围松土,使陶土头与周围土壤接触紧密,试验中共埋入8根张力计. 仪器安装后,在埋置8根张力计处浇适量水,24 h后开始读数,当数据采集仪显示的基质吸力数值稳定不变时,记录基质吸力,并取出张力计,在埋置张力计处,用环刀取未扰动矿样,测试矿样的含水量和孔隙比.试验结果见表 2.

表 2 土-水特征曲线的测试结果Table 2. Test results of swcc矿体

编号原状矿体 重塑矿体 基质吸力/kPa 体积含水率 基质吸力/kPa 体积含水率 1 6 0.30 1.7 0.34 2 15.2 0.26 5.8 0.32 3 28.9 0.24 9.6 0.31 4 40 0.22 21.4 0.25 5 43 0.21 28.0 0.21 6 72 0.15 68.8 0.14 7 91.4 0.12 83.1 0.094 室内重塑矿体的土-水特征曲线的测试过程:将现场测试完毕的原状矿体经室内烘干、研磨后,保持与原状矿体相同的颗粒级配和孔隙比,配制成7种不同含水率的重塑矿体,并在试样上部覆一层保鲜膜,静置24 h后,插入张力计,1 d后开始读数,当数据采集仪显示的基质吸力数值稳定不变时,记录基质吸力,并取出张力计,在埋置张力计处,用环刀取样,测试矿样的含水量.试验结果见表 2. 利用常水头试验测得重塑矿体的渗透系数为1.2×10-5 m/s.

2 孔径及其分布的分析

2.1 土-水特征曲线的拟合

描述土壤的土-水特征曲线的理论和方法很多,代表性的土-水特征曲线模型主要有Gardner模型、Brooks & Corey(BC)模型、Fredlund & Xing(FX)模型,Van Genuchten(VG)模型[15-18].

Gardner基于单一孔隙大小提出土壤的土-水特征曲线模型为:

$${\theta _w} = {\theta _r} + \frac{{{\theta _s} - {\theta _r}}}{{1 + {{\left( {\frac{\psi }{{{a_1}}}} \right)}^{{b_1}}}}}$$ (1) 式(1)中:θ>w为体积含水率;θs为饱和体积含水率;θr为残余体积含水率;ψ为基质吸力,单位为kPa;a1是与进气值有关的参数,单位为kPa;b1表示基质吸力大于进气值之后与土体脱水速率有关的参数.

BC模型的表达式为:

$${\theta _w} = {\theta _r} + \left( {{\theta _s} - {\theta _r}} \right){\left( {\frac{\psi }{{{a_2}}}} \right)^{{b_2}}}$$ (2) 式(2)中a2为土体进气值,单位为kPa;b2为孔径分布参数.该模型形式简单,对于具有较窄孔径分布的均质和各向同性的粗质地土效果较理想,而对细质地土和未扰动的原状土通常精度较差.

FX模型的表达式为:

$${\theta _w} = {\theta _s}{\left\{ {\ln \left[ {e + } \right]{{\left( {\frac{\psi }{{{a_1}}}} \right)}^{{b_1}}}} \right\}^{ - c}}$$ (3) 式(3)中,c是与残余含水量有关的参数.该模型是基于统计分析理论推导得到的,适用于描述全吸力范围的任何土壤质地类型的土-水特征曲线.

Van Genuchten[18]提出一个平滑的封闭型4参数土-水特征曲线模型,它同样适用于所有的土壤质地类型,也不受吸湿、脱湿过程的严格限制,并认为土壤饱和时,土壤吸力等于零.该模型的表达式为:

$${\theta _w} = {\theta _r} + \frac{{{\theta _s} - {\theta _r}}}{{{{\left( {1 + {a_1}{\psi ^{b1}}} \right)}^c}}}$$ (4) 根据上述各模型的适用范围和龙南足洞矿区稀土矿体的物理力学特性,选用上述模型,分别对原状矿体和重塑矿体实测数据进行函数拟合,4个土-水特征曲线模型与实测点的相关系数平方均在0.9以上,为找出对原状矿体和重塑矿体拟合效果最优的模型,对由参数结果所建立的模型计算值与实测数据之间的残差平方和进行分析,分析结果见表 3.

表 3 土-水特征曲线拟合的残差平方和Table 3. SSE of fitting swcc拟合模型 原状矿体残差平方和 重塑矿体残差平方和 Gardner 模型 0.000 584 0.000 894 BC 模型 0.000 627 0.000 946 FX 模型 0.000 193 0.000 250 VG 模型 0.000 067 0.000 273 由表 3的残差分析结果可知:原状矿体的拟合模型中,VG模型误差最小,对实测数据的拟合效果最佳,重塑矿体的拟合模型中,FX模型误差最小,对实测数据的拟合效果最好.原状矿体和重塑矿体土-水特征曲线拟合结果如图 3所示,相关参数见表 4.

表 4 土-水特性曲线的拟合参数Table 4. Fitting parameters of swcc项目名称 θr a b c R2 原状矿体(VG 模型) 0.01 0.014 1.114 0.837 0.983 重塑矿体(FX 模型) / 17.390 2.488 0.804 0.982 注:"/"表示无数据. 由于张力计法只能量测0~100 kPa范围的基质吸力,本次试验实测的基质吸力最大值仅为91.4 kPa,为进一步分析原状矿体和重塑矿体的小孔径,根据拟合公式计算孔径分布.

2.2 矿体孔径计算

利用土-水特征曲线计算矿体孔径分布,步骤如下:①将土-水特征曲线中的体积含水量转化成质量含水量w;②将土-水特征曲线中的基质吸力转化成相对湿度RH;③将质量含水量转化成每单位质量矿体内水填充孔隙的体积Vp;④计算开尔文半径rk和水膜的厚度t;⑤计算实际的孔隙半径rp和每单位质量矿体内孔隙体积的减少量ΔVp;⑥计算孔隙体积减小过程中的平均开尔文半径(rk)avg和平均孔隙半径(rp)avg;⑦在孔隙几何形态确定的条件下,计算表面积变化量ΔS;⑧通过将前述的孔隙体积增量相加,计算每单位质量矿体内的累积孔隙体积∑(ΔVp). 根据上述步骤,利用土-水特征曲线计算得到原状矿体和重塑矿体的孔径分布,结果见表 5、表 6.

表 5 原状矿体孔径分布计算结果Table 5. Calculation results of pore size distribution of undisturbed ore bodyΨ/kPa w /

(g·g-1)RH /% Vp /(cm3·g-1) rk /Å t /Å rp /Å △Vp /

(cm3·g-1)(rk)avg /Å (rp)avg /Å △S /

(m2·g-1)Σ(△Vp) /

(cm3·g-1)5 0.224 0 99.99 0.224 4 28 8000.0 143.0 288 143.0 / / / / / 20 0.184 0 99.98 0.184 4 72 000.0 90.1 72 090.1 0.040 1 180 000.0 180 116.6 0.004 0.040 1 50 0.133 0 99.96 0.133 3 28 800.0 66.4 28 866.4 0.051 1 50 400.0 50 478.3 0.020 0.091 2 100 0.090 0 99.93 0.090 2 14 400.0 52.7 14 452.7 0.043 1 21 600.0 21 659.5 0.040 0.134 3 150 0.070 0 99.89 0.070 1 9 600.0 46.0 9 646.0 0.020 0 12 000.0 12 049.4 0.033 0.154 3 300 0.044 0 99.78 0.044 1 4 800.0 36.5 4 836.5 0.026 1 7 200.0 7 241.3 0.072 0.180 4 500 0.031 0 99.64 0.031 1 2 880.0 30.8 2 910.8 0.013 0 3 840.0 3 873.7 0.067 0.193 4 1 000 0.020 0 99.28 0.020 0 1 440.0 24.5 1 464.5 0.011 0 2 160.0 2 187.6 0.101 0.204 4 3 000 0.012 0 97.85 0.012 0 480.0 17.0 497.0 0.008 0 960.0 980.7 0.163 0.212 4 5 000 0.010 0 96.43 0.010 0 288.0 14.3 302.3 0.002 0 384.0 399.6 0.100 0.214 4 10 000 0.009 0 93.00 0.009 0 144.0 11.4 155.4 0.001 0 216.0 228.8 0.088 0.215 4 12 000 0.008 4 91.66 0.008 4 120.0 10.7 130.7 0.000 6 132.0 143.0 0.084 0.216 0 15 000 0.008 2 89.68 0.008 2 96.0 9.9 105.9 0.000 2 108.0 118.3 0.034 0.216 2 20 000 0.007 9 86.48 0.007 9 72.0 9.0 81.0 0.000 3 84.0 93.5 0.064 0.216 5 50 000 0.007 4 69.55 0.007 4 28.8 6.6 35.4 0.000 5 50.4 58.2 0.172 0.217 0 80 000 0.007 3 55.94 0.007 3 18.0 5.7 23.7 0.000 1 23.4 29.6 0.068 0.217 1 100 000 0.007 2 48.38 0.007 2 14.4 5.3 19.7 0.000 1 16.2 21.7 0.092 0.217 2 120 000 0.007 1 41.84 0.007 1 12.0 5.0 17.0 0.000 1 13.2 18.3 0.109 0.217 3 累计结果 / / / / / / 0.007 1 / / 1.313 0.224 4 注:"/"表示无数据. 表5 中第一行$\Delta {V_{\rm{p}}}$、(rk)avg、(rp)avg、\$\Delta S$ 和$\sum {\left( {\Delta {V_{\rm{p}}}} \right)} $无数据,该数据是由上一行与所在行数据综合计算的结果,遂从第二行开始产生数据. 表 6 重塑矿体孔径分布计算结果Table 6. Calculation results of pore size distribution of remoulded ore bodyΨ/kPa w /

(g·g-1)RH /% Vp /(cm3·g-1) rk /Å t /Å rp /Å △Vp /

(cm3·g-1)(rk)avg /Å (rp)avg /Å △S /

(m2·g-1)Σ(△Vp) /

(cm3·g-1)5 0.236 99.99 0.236 5 288 000.0 143.0 288143.0 / / / / / 20 0.180 99.98 0.180 4 72 000.0 90.1 72 090.1 0.056 1 180 000.0 180 116.6 0.006 0.056 1 50 0.104 99.96 0.104 2 28 800.0 66.4 28 866.4 0.076 2 50 400.0 50 478.3 0.030 0.132 3 100 0.070 99.93 0.070 1 14 400.0 52.7 14 452.7 0.034 1 21 600.0 21 659.5 0.031 0.166 3 150 0.060 99.89 0.060 1 9 600.0 46.0 9 646.0 0.010 0 12 000.0 12 049.4 0.017 0.176 4 300 0.050 99.78 0.050 1 4 800.0 36.5 4 836.5 0.010 0 7 200.0 7 241.3 0.028 0.186 4 500 0.040 99.64 0.040 1 2 880.0 30.8 2 910.8 0.010 0 3 840.0 3 873.7 0.052 0.196 4 1 000 0.037 99.28 0.037 1 1 440.0 24.5 1 464.5 0.003 0 2 160.0 2 187.6 0.027 0.199 4 3 000 0.031 97.85 0.031 1 480.0 17.0 497.0 0.006 0 960.0 980.7 0.123 0.205 4 5 000 0.028 96.43 0.028 1 288.0 14.3 302.3 0.003 0 384.0 399.6 0.150 0.208 4 10 000 0.026 93.00 0.026 1 144.0 11.4 155.4 0.002 0 216.0 228.8 0.175 0.210 4 12 000 0.025 91.66 0.025 1 120.0 10.7 130.7 0.001 0 132.0 143.0 0.140 0.211 4 15 000 0.024 89.68 0.024 0 96.0 9.9 105.9 0.001 0 108.0 118.3 0.169 0.212 4 20 000 0.023 86.48 0.023 0 72.0 9.0 81.0 0.001 0 84.0 93.5 0.214 0.213 4 50 000 0.022 69.55 0.022 0 28.8 6.6 35.4 0.001 0 50.4 58.2 0.344 0.214 4 80 000 0.021 55.94 0.021 0 18.0 5.7 23.7 0.001 0 23.4 29.6 0.678 0.215 4 100 000 0.020 48.38 0.020 0 14.4 5.3 19.7 0.001 0 16.2 21.7 0.925 0.216 4 120 000 0.019 41.84 0.019 0 12.0 5.0 17.0 0.001 0 13.2 18.3 1.094 0.217 4 累计结果 / / / / / / 0.019 0 / / 4.205 / 注院野/冶表示无数据. 表5 中第一行$\Delta {V_{\rm{p}}}$、(rk)avg、(rp)avg、$\Delta S$和$\sum {\left( {\Delta {V_{\rm{p}}}} \right)} $无数据,该数据是由上一行与所在行数据综合计算的结果,遂从第二行开始产生数据. 从表 5和表 6的计算结果可知,原状矿体的单位质量累积孔隙总体积为0.224 4 cm3/g,比表面积为1.313 m2/g;重塑矿体的单位质量累积孔隙总体积为0.236 5 cm3/g,比表面积为4.205 m2/g,表明重塑过程中孔隙体积变化不明显,但是比表面积变化非常大,增加3.2倍,比表面积增加,使重塑矿浸润效果更好,有利于浸矿剂与矿体颗粒充分接触,提高浸矿效率.

为直观展示重塑过程的孔径变化,根据表 5和表 6孔径分布的计算结果,分别绘制出原状矿体和重塑矿体单位质量矿体的孔隙体积与平均孔隙半径的关系图,如图 4所示,以及单位质量矿体累积孔隙体积与平均孔隙半径的关系图,如图 5所示.

由图 4可以看出,该类型的离子型稀土矿原状矿体和重塑矿体的主要孔隙半径集中在0.0018~18.02 μm之间;孔隙半径rp<0.06 μm时,原状矿体和重塑矿体的单位质量的孔隙体积基本相同,表明矿体在重塑过程中该孔隙半径范围内的孔隙基本未受到扰动;孔隙半径在0.06~3.0 μm范围内,原状矿体比重塑矿体单位质量的孔隙体积大,说明原状矿体的孔隙数量多于重塑矿体的孔隙数量;孔隙半径为3.0~18.02μm范围内,重塑矿体的孔隙数量多于原状矿体的孔隙数量.

从图 5可以看出:孔隙半径在0.001 8~0.3 μm范围内,原状矿体的累积孔隙体积大于重塑矿体的累积孔隙体积;而在0.3~18.02 m的孔隙半径变化范围内,重塑矿体的累积孔隙体积大于原状矿体的累积孔隙体积.

上述计算结果表明:经过重塑之后的矿体,虽然颗粒级配、孔隙比与原状矿体相同,但在孔径分布上与原状矿体有明显差异,重塑过程主要影响孔径0.06~18.02 μm的孔隙分布,使得该范围孔隙内表面积的吸附水膜增加,自由水通过的孔隙尺寸减小,重塑矿体的渗透性有所降低.

由原矿和重塑矿的土-水特征曲线可知,当基质吸力小于进气值以及基质吸力大于残余含水量对应的吸力值时,矿体的含水量基本不发生变化.因此无法利用土-水特征曲线计算上述两个含水量段对应的孔隙分布情况,即该离子型稀土矿体中孔径小于0.001 8 μm的微小孔隙以及孔径大于18.02 μm的大孔隙分布情况还有待进一步研究.

3 结 论

1)利用张力计对赣南典型的离子型稀土矿体进行了现场和室内的土-水特征曲线测试试验,分别采用Gardner模型、BC模型、FX模型、VG模型拟合原状矿体和重塑矿体的土-水特征曲线,拟合结果表明,原状矿体适合采用VG模型拟合,而重塑矿体适合采用FX模型拟合.

2)基于拟合得到的土-水特征曲线计算稀土矿体的孔径分布,结果得出:试验点原状矿体的单位质量矿体的累积孔隙体积为0.224 4 cm3/g,比表面积为1.313 m2/g;重塑矿体单位质量矿体的累积孔隙体积为0.236 5 cm3/g,比表面积为4.205 m2/g,表明重塑过程对矿体比表面积影响很大,重塑有利于浸矿剂与矿体颗粒充分接触,提高浸矿效率.

3)重塑过程对孔隙半径小于0.06 μm的孔隙影响很小;孔隙半径在0.06~3.0 μm范围内,原状矿体的孔隙数量多于重塑矿体的孔隙数量;孔隙半径为3~18.02 μm范围内,重塑矿体的孔隙数量多于原状矿体的孔隙数量,即重塑过程改变了孔径0.06~18.02 μm的孔隙分布,使重塑矿体的渗透性有所降低.

-

-

[1] 赵天从, 汪键.有色金属提取冶金手册-锡锑汞[M].北京:冶金工业出版社, 1999. [2] 周春, 刘立刚, 孙晓优.江西有色金属矿区废弃地综合利用生态恢复评价[J].有色金属科学与工程, 2016, 7(6): 115-123. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=jxysjs201606020 [3] 林海, 江昕昳, 李冰, 等.有色金属尾矿植物修复强化技术研究进展[J].有色金属工程, 2019, 9(11): 122-132. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=ysjs201911017 [4] 施择, 孙鑫, 宁平, 等.云南新平铜尾矿库周边土壤重金属污染评价[J].矿业工程, 2014, 23(4): 92-96. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=ky201404022 [5] 张国平, 刘丛强, 吴攀, 等.贵州万山汞矿尾矿堆及地表水的环境地球化学特征[J].矿物学报, 2014, 24(3): 231-238. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=kwxb200403004 [6] 唐帮成, 王仲如.模拟降雨对汞尾矿中总汞的影响[J].广州化工, 2016, 44(7): 153-155. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=gzhg201607053 [7] 王林荫, 杨晨.汞锑矿采选固体废物危险性研究[J].山西建筑, 2018, 44(26): 193-195. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=shanxjz201826106 [8] 陈晓博, 马玄恒, 郑卫琳, 等.某矿汞锑废弃物污染防治实践[J].现代矿业, 2018(4): 153-154. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=xdky201804042 [9] 尚慧洁.我国汞污染及防治现状综述[J].广州化工, 2018, 46(6): 25-26. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=gzhg201806010 [10] 胡国成, 张丽娟, 齐剑英, 等.贵州万山汞矿周边土壤重金属污染特征及风险评价[J].生态环境学报, 2015, 24(5): 879-885. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=tryhj201505024 [11] 张正洁, 刘舒, 陈扬, 等.典型含汞废物处理处置污染防治可选技术研究[J].资源再生, 2017(7): 62-65. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=ysjszsyly201307017 [12] 王明勇, 乙引.一种新发现的汞富集植物-乳浆大戟[J].江苏农业科学, 2010(2): 354-356. doi: 10.3969/j.issn.1002-1302.2010.02.147 [13] 王道涵, 吕艾静, 王营军, 等.内蒙古草原植物羊草对外源汞的积累特征[J].安全与环境学报, 2018, 18(4): 1550-1554. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=aqyhjxb201804054 [14] 饶泽文, 田德柱, 欧阳臻, 等.湿法炼锑过程钟锑铁的水解分离[J].湿法冶金, 2019, 38(5): 375-379. [15] 何云龙, 徐瑞东, 何世伟, 等.铅阳极泥处理技术的研究进展[J].有色金属科学与工程, 2017, 8(5): 13-18. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=jxysjs201705006 [16] 张喆秋, 袁露成, 黄林青, 等.砷、锑、铋在铜冶炼过程中的分布及其在冶炼副产物中的回收综述[J].有色金属科学与工程, 2019, 10(1): 13-19. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=jxysjs201901003 [17] WANG Q F, LIU Y, WU Z B. Laboratory study on mercury release of the gypsum from the mercury coremoval wet flue gas desulfurization system with additives[J]. Energy & Fuels, 2018, 32(2): 1005-1011. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=e9b06cb3fa1f11d415e8e72ea1b49b62

[18] 马永鹏.有色金属冶炼烟气中汞的排放控制与高效回收技术研究[D].上海: 上海交通大学, 2014. [19] 石靖, 易宇, 郭学益.湿法冶金处理含砷固废的研究进展[J].有色金属科学与工程, 2015, 6(2): 14-20. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=jxysjs201502003 [20] 周根茂, 曾毅君, 孟舒.用碱法从低品位难选辉钼矿中浸出钼的试验研究[J].湿法冶金, 2015, 34(6): 466-470. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=sfyj201506007 [21] 郭钟群, 金解放, 王观石, 等.风化壳淋积型稀土矿浸取动力学基础理论研究[J].有色金属科学与工程, 2017, 8(5): 114-119. doi: 10.13264/j.cnki.ysjskx.2017.05.019 [22] 谢锋, 畅永锋, 路殿坤, 等.一种对汞尾矿进行脱毒处理的方法: 201710765350.0[P]. 2017-08-30. [23] 袁再六.一种含汞废渣综合利用方法: 201410492353.8[P]. 2014-09-23. [24] 杨帆, 谢刚, 李荣兴, 等.辉锑矿碱性体系浸出锑的试验研究[J].云南冶金, 2019, 48(1): 40-44. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=ynyj201901010

下载:

下载: