Study on the microstructure and properties of FeMoCoNiCrTix high-entropy alloy cladding layer on T10 steel

-

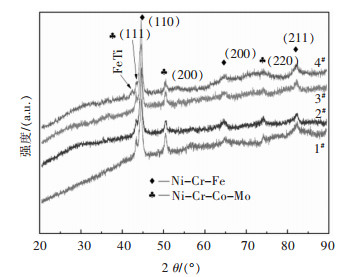

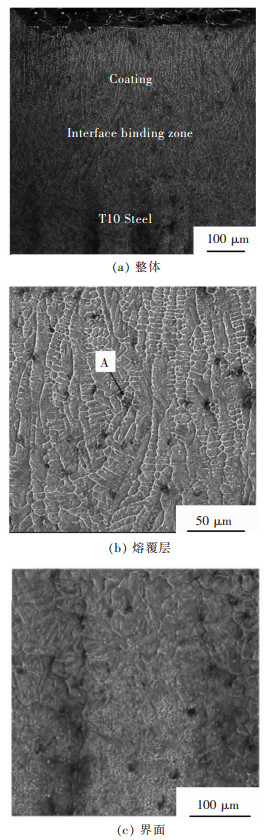

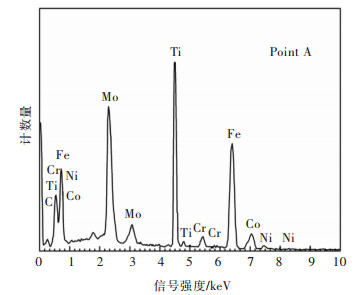

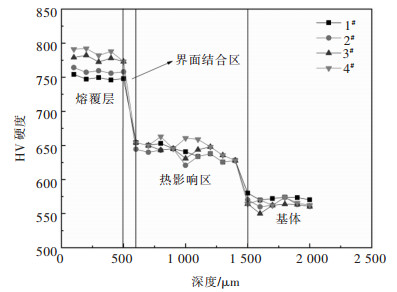

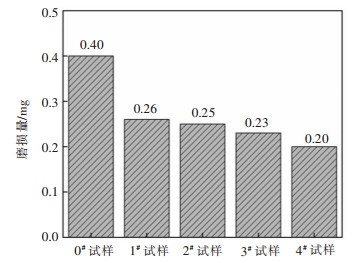

摘要: 采用激光熔覆技术在T10A钢表面制备了FeMoCoNiCrTix(x分别为0.25,0.50,0.75,1.00)高熵合金熔覆层,分析了试样熔覆层及基体界面处的相结构及组织,并利用显微硬度计测试了试样处理前后的截面硬度变化。研究表明,经过激光熔覆在T10A钢表面得到的高熵合金层主要由NiCrFe、NiCrCoMo 2种固溶体为主,其结构分别为BCC结构和FCC结构,熔覆层的组织以柱状枝晶为主,界面处出现等轴晶;随着Ti含量增多,熔覆层由固溶强化变为固溶体与硬质相混合强化,熔覆层的HV硬度达到了792,热影响区的HV硬度达到了620,均高于基体硬度。同时耐磨损性能有了明显提高,磨损方式由粘着磨损逐渐变为磨粒磨损。Abstract: FeMoCoNiCrTix (x is 0.25, 0.50, 0.75, 1.00, respectively) high-entropy alloy cladding layer was prepared on the surface of T10A steel by laser cladding technology. The phase structure and microstructure of the interface between the cladding layer and the substrate were analyzed, and the cross-sectional hardness of the sample before and after the treatment were tested respectively by the microhardness tester. The results showed that the high-entropy alloy cladding layer obtained on the surface of T10A steel by laser cladding technology was mainly composed of NiCrFe and NiCrCoMo, two solid solutions whose structures were BCC and FCC, respectively. The microstructure of the cladding layer mainly comprises columnar dendrites, and equiaxed crystals appeared at the interface; As the Ti content increased, the strengthening effect of the cladding layer changed from solid solution strengthening to solid solution and hard phase mixed strengthening. The HV hardness of the cladding layer and the heat affected zone reached 792 and 620, both higher than that of the substrate. At the same time, the wear resistance of the alloy cladding layer witnessed a significant increase and its wear mode gradually changed from adhesive wear to abrasive wear.

-

Keywords:

- laser cladding /

- Ti content /

- high-entropy alloy cladding layer /

- microhardness /

- wear resistance

-

配置好的环烷酸,皂化后并不是简单的真溶液,而是水分散在油相中的微乳状液体系,萃取稀土时,上述液体系会使微乳状液破乳。通过串级萃取理论计算得出的有机相理论流量不夹带水份,实际生产中皂化好的环烷酸往往又夹带水份,因此,为达到正常的萃取分离效果,保证产品质量,需要对有坑相理论流量进行校正,即先估算一个百分数,但不可避免地使理论值与实际值有时出现偏差。

一 公式推导

今设:

Vs实 进槽有机相实际流量 1/min

Vs理 计算的有机相理论流量

ε 有机相皂化度

C 皂化有机相氨水浓度(N)

V1 未皂化的有机相体积(1)

V2 将V1皂化为皂化度ε的氨水体积

则:

(1)

(2) 将式(2)代入式(1)得

(3) 令

(4)

(5) 二 讨 论

1.系数k与有机相皂化度成正比,皂化度越大K值越大,反之亦然。K和皂化有机相的氨水浓度成反比。

2.公式(4)和(5),适周于氨水皂化有机相时,水均匀分布于有机相中的任何体系。它的导出,为确定▽s实提供理论依据,为准确地计算整个槽体平衡提供可靠依据。

-

表 1 T10A钢化学成分

Table 1 Chemical composition of steel T10A

表 2 高熵合金组元原子半径

Table 2 Atomic radius of high-entropy alloy components

-

[1] MIRACLE D B, SENKOV O N. A critical review of high entropy alloys and related concepts[J].Acta Materialia, 2017, 122:448-511. http://d.old.wanfangdata.com.cn/Thesis/Y3490044

[2] LI Z M, PRADEEP K G, DENG Y, et al. Metastable high-entropy dual-phase alloys overcome the strength-ductility trade-off[J]. Nature, 2016, 534(7606):227-230. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=ebd06914bb230170b9785d9f10053eff

[3] CAI Z B, WANG Y D, CUI X F, et al. Design and microstructure characterization of FeCoNiAlCu high-entropy alloy coating by plasma cladding: In comparison with thermodynamic calculation[J]. Surface & Coatings Technology, 2017, 330:163-169. http://cn.bing.com/academic/profile?id=14a4274a222336e6ae123c282f1e51d3&encoded=0&v=paper_preview&mkt=zh-cn

[4] CHENG Y Q, MA E. Atomic-level structure and structure-property relationship in metallic glasses[J]. Progress In Materials Science, 2011, 56(4):379-473. http://cn.bing.com/academic/profile?id=d7600f0f6ee72eb694550cd1f6f7cd50&encoded=0&v=paper_preview&mkt=zh-cn

[5] HE J Y, WANG H, HUANG H L. A precipitation-hardened high-entropy alloy with outstanding tensile properties[J]. Acta Materialia 2016, 102:187-196. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=686e65b1e7a1e604f94038c6950c51f9

[6] TSAI K Y, TSAI M H, YEH J W. Sluggish diffusion in Co-Cr-Fe-Mn-Ni high-entropy alloys[J]. Acta Materialia, 2013, 61(13):4887-4897. http://cn.bing.com/academic/profile?id=d2387c121893cfa996d1e2024de9831b&encoded=0&v=paper_preview&mkt=zh-cn

[7] 谭雅琴, 王晓明, 朱胜, 等.高熵合金强韧化的研究进展[J].材料导报, 2020, 34(5):5120-5126. http://d.old.wanfangdata.com.cn/Periodical/cldb202005016 [8] CHENG J B, LIANG X B, XU B S. Effect of Nb addition on the structure and mechanical behaviors of CoCrCuFeNi high-entropy alloy coatings[J]. Surface & Coatings Technology. 2014, 240:184-190. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=a971d829788673529d06b43a7dd41005

[9] 李俊魁, 彭竹琴, 马明星, 等. CeO2对AlCoCuFeMnNix高熵合金涂层组织和硬度的影响[J].金属热处理, 2017, 42(11):19-23. http://d.wanfangdata.com.cn/periodical/zgbmgc201301003 [10] 叶海梅, 杨文超, 庞兴志, 等. Ti元素对CoCuFeNiVTix高熵合金耐磨性能的影响[J].广西大学学报(自然科学版), 2017, 42(3):1187-1191. http://d.old.wanfangdata.com.cn/Periodical/gxdxxb201703047 [11] SCHUH B, MENDEZ-MARTIN F, VOELKER B. Mechanical properties, microstructure and thermal stability of a nanocrystalline CoCrFeMnNi high-entropy alloy after severe plastic deformation[J]. Acta Materialia, 2016, 96:258-268. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=2953dcc0e269d071249537d3356d49ce

[12] 刁晓刚, 李卫, 陈佳侠, 等.国内某铁矿半自磨机衬板磨损失效分析[J].矿山机械, 2019, 47(12):30-34. http://d.old.wanfangdata.com.cn/Periodical/ksjx201912008 [13] 张钦英, 陈颢, 任兴润, 等. Al靶溅射功率对CrAlN涂层组织结构及摩擦性能的影响[J].有色金属科学与工程, 2017, 8(5):109-114. http://www.xml-data.org/YSJSYKXGC/html/2017050016.htm [14] 刘龙, 周升国, 王跃臣, 等.直流反应磁控溅射沉积a-C:H薄膜的微结构和摩擦磨损行为[J].有色金属科学与工程, 2016, 7(1):41-47. http://www.xml-data.org/YSJSYKXGC/html/201601009.htm [15] 胡凡, 陈特超, 范江华, 等.离子束溅射镀膜设备及工艺技术研究[J].电子工业专用设备, 2019, 48(4):25-28. http://d.old.wanfangdata.com.cn/Periodical/dzgyzysb201904007 [16] 陈强, 张春渤, 谢建生.离子束增强沉积制备Li掺杂ZnO薄膜[J].常州大学学报(自然科学版), 2014, 26(1):6-9. http://d.old.wanfangdata.com.cn/Periodical/jssyhgxyxb201401002 [17] 张雪, 常伟杰, 张豪, 等.磁控溅射Cr/CrN/CrAlSiN复合涂层高温氧化行为研究[J].江西科技师范大学学报, 2019(6):31-35. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=jxkjsfxyxb201906006 [18] MANWENDRA K, TRIPATHI P P, SUBHAS G. Multivariate analysis and classification of bulk metallic glasses using principal component analysis[J]. Computational Materials Science, 2015, 107:79-87. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=03875efe84717e7621d7779589a5c8d3

[19] 邢逸凡, 王伟丽, 郑风勤.Mn对CoCrFeNi基高熵合金组织及性能的影响[J/OL].热加工工艺, 2020(10):37-40. [20] 苗振旺, 祝夫文, 刘琪.CoCrFeNiCuTix高熵合金的微观组织与耐腐蚀性能研究[J].粉末冶金技术, 2020, 38(1):10-17. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=fmyjjs202001002 [21] PENG Y B, ZHANG W, LI T C. Microstructures and mechanical properties of FeCoCrNi high entropy alloy/WC reinforcing particles composite coatings prepared by laser cladding and plasma cladding[J]. Elsevier Ltd, 2019, 84:44-50. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=e7b5565d72b6dc875b2ea4ce38291d73

[22] LIN Q Y, LIU J P, AN X H. Cryogenic-deformation-induced phase transformation in an FeCoCrNi high-entropy alloy[J]. Taylor & Francis, 2018, 6(4):236-243. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=10.1080/21663831.2018.1434250

[23] 徐泽洲, 何志军, 王志英.CoCrFeNi系高熵合金研究进展[J].辽宁科技大学学报, 2019, 42(5):350-356. http://d.old.wanfangdata.com.cn/Periodical/asgtxyxb201905006 [24] WU W Q, SONG M, NI S, et al. Dual mechanisms of grain refinement in a FeCoCrNi high-entropy alloy processed by high-pressure torsion[J]. Nature Publishing Group UK, 2017, 7(1).

[25] LIU B, WANG J S, LIU Y, et al. Microstructure and mechanical properties of equimolar FeCoCrNi high entropy alloy prepared via powder extrusion[J]. Intermetallics, 2016, 75:25-30. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=c5a4aa842fa97bfd93558adb83390519

[26] 苏允海, 邓越, 窦丽杰, 等.Mo元素含量对FeAlCuCrNiMox系高熵合金组织结构及性能的影响[J].焊接学报, 2019, 40(9):111-115. http://d.old.wanfangdata.com.cn/Periodical/hjxb201909020 [27] 邓越. Mo、Nb、Ti元素对FeAlCuCrNix系高熵合金组织性能的影响[D].沈阳: 沈阳工业大学, 2019. [28] 刘旋, 陈雨琳.不同碳含量碳钢淬火态马氏体精细结构[J].材料热处理学报, 2018, 39(7):86-91. http://d.old.wanfangdata.com.cn/Periodical/jsrclxb201807013

下载:

下载: