Research on the effect of lance height change of converter oxygen lance on the molten pool

-

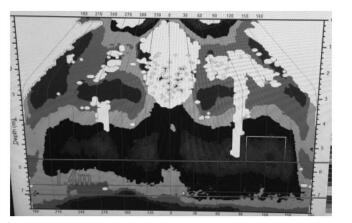

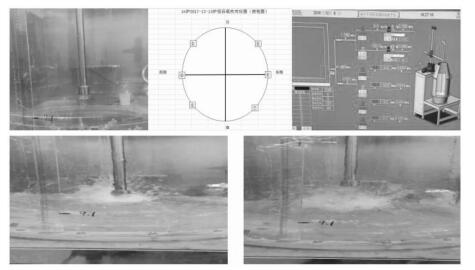

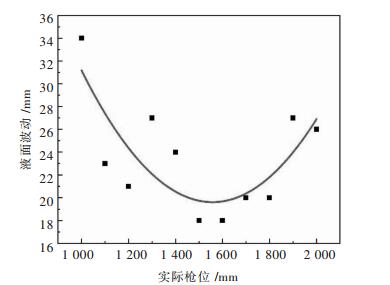

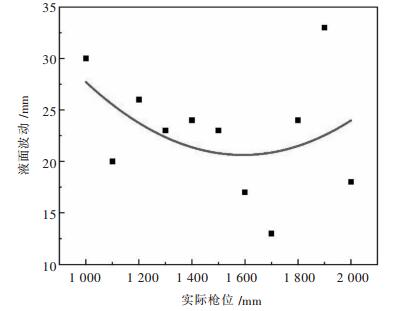

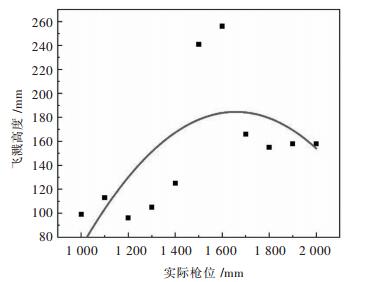

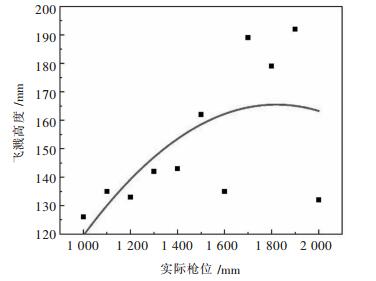

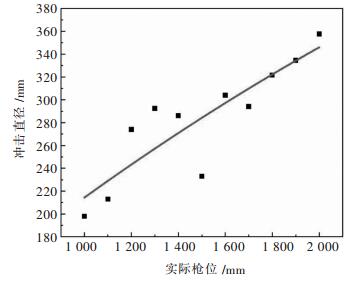

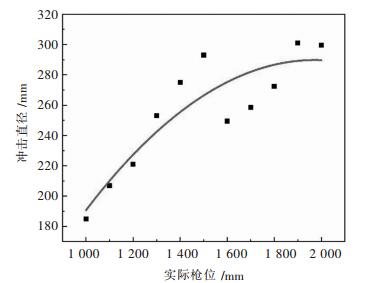

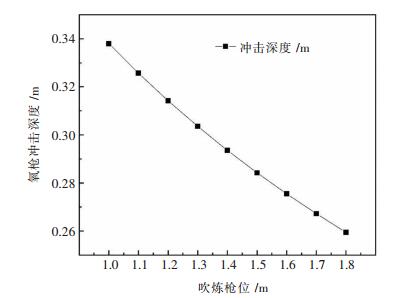

摘要: 为研究吹炼过程中枪位变化对转炉内产生的不同状态,设计吹炼过程水模型实验,并辅助相应计算,发现枪位变化对炉内的液面波动、飞溅高度、冲击直径、冲击深度有一定影响,枪位1.3 m时液面波动和飞溅影响最小。吹炼过程中枪位变化制造了炉内各种波动和高氧化性炉渣,作用于炉衬发生侵蚀。实验发现转炉内波动分2种,一是低枪位区钢渣“朝夕式”运动、二是中高枪位区钢渣“瀑布式”运动。为提高冶金效果,根据实验结论对转炉枪位控制工艺优化,将过程枪位从1.6~1.5 m降低至1.5~1.4 m、终点枪位从1.4 m降低至1.3 m。工艺调整后,吹炼时间比优化前缩短26 s,炉渣中FeO的质量分数降低7.48%,吹炼终点钢液中残锰质量分数提高了0.052%,炉衬侵蚀比优化前明显减轻。Abstract: In order to study the different states of lance height in the converter during the blowing process, a water model experiment for the blowing process was designed and the corresponding calculations were analyzed. It was found that the change of lance height had some effect on the liquid level fluctuation, splash height, impact diameter and impact depth in the converter, and the liquid level fluctuation and splash received minimum effect when the lance height was 1.3 m. The change of lance height during the blowing process produced various fluctuations and highly oxidative slag in the converter, which acted on the erosion of the converter lining. From the experiment we found that there were two types of fluctuations in the converter. One was the "snowfall" movement of the steel slag in the low lance height area, and the other was the "waterfall" movement of the steel slag in the middle and high lance height area. In order to improve the metallurgical effect, the converter lance height control process was optimized according to the experimental conclusions. The process lance height was reduced from 1.6~1.5 m to 1.5~1.4 m and the end lance height was reduced from 1.4 m to 1.3 m. After the process optimization, the blowing effect improved significantly showcased in such facts: the blowing time was shortened by 26 s; the percentage content of FeO in the slag was reduced by 7.48; the percentage of residual manganese in the molten steel at the end of the blowing process was increased by 0.052; the converter lining erosion was greatly reduced.

-

上转换发光材料作为一种可潜在应用于生物荧光标记、光学温度传感器、安全编码、立体显示、太阳能电池等领域的发光材料引起了广泛的关注[1-5].迄今为止,上转换发光材料绝大多数都是掺杂稀土离子的化合物,利用稀土元素的亚稳态能级特性,可以吸收多个低能量的长波辐射,经多光子加和后发出高能量的短波辐射,从而可使人眼看不见的红外光转变为可见光.由于目前常用的激发源为波长800~1 000 nm的激光二极管(LD),因此在这些波长处具有主吸收带的稀土离子如Er3+、Ho3+、Tm3+等成为研究较多的用于实现上转换发光的激活离子[6-10],而其中Er3+由于具有丰富的能级,在红外波段存在几个波长的较强吸收,可以实现上转换绿光和红光发射等优点,成为首选的红外转变可见上转换荧光和激光材料的激活剂.而Yb3+离子常作为上转换发光离子的敏化剂,它的引入可以通过能量传递增强共掺杂的稀土离子的上转换发光,这主要是由于Yb3+离子能级结构比较特殊,它只有一个激发态,不会发生诸如浓度猝灭、激发态吸收等影响材料发光性能的现象,并且在950~1000 nm波段有很强的2F7/2→2F5/2跃迁吸收[11].同时Yb3+离子和Er3+离子还可以发生交叉弛豫现象,也可以对Er3+离子的上转换发光颜色进行调控.

此外,要实现有效的上转换发光,材料必须具有较低的声子能量,这样可以降低材料中的多声子弛豫过程,延长激发态的寿命[12-16].稀土钛酸盐因其具有较高的热稳定性、化学稳定性、优异的发光性能、较低的声子能量,而被广泛应用于发光材料的基质中[17-18].而其中具有烧绿石结构的Y2Ti2O7,因其具有较低的声子能量(< 712 cm-1)而被认为是一种良好的上转换发光基质[19-23].因此,文中采用传统溶胶-凝胶法制备了Yb3+和Er3+共掺杂Y2Ti2O7上转换发光材料,研究了Yb3+离子浓度对Er3+离子上转换发光性能的影响并探讨了其发光机理.

1 实验

实验采用传统溶胶-凝胶法制备所有样品荧光粉,用柠檬酸络合所有金属离子,在加热搅拌条件下形成湿凝胶,然后烘干形成干凝胶,最后在高温炉中煅烧得到样品荧光粉.所用原料为氧化钇(Y2O3,99.999%)、氧化镱(Yb2O3,99.990%)、氧化铒(Er2O3,99.990%),钛酸四正丁酯(C16H36O4Ti,HPLC 99.5%),柠檬酸(C6H8O7·H2O,优级纯),无水乙醇(分析纯).具体步骤如下:首先,根据化学分子式(Y0.98-xYbxEr0.02)2Ti2O7(x=0, 0.02, 0.04,…,0.1)计算各种原料的用量.其次,将柠檬酸溶解于无水乙醇中,充分搅拌,溶解后加入钛酸四正丁酯,继续搅拌30 min备用.第三,将稀土氧化物用硝酸溶解形成溶液,再把溶解好的Y(NO3)3、Yb(NO3)3和Er(NO3)3溶液缓慢加入到上述的钛酸四正丁酯溶液中,并在90 ℃水浴下加热搅拌直至生成湿凝胶.第四,将得到的湿凝胶放入120 ℃的烘箱中干燥24 h得到干凝胶.最后,将干凝胶研磨后放入高温炉中,在1 200 ℃下进行煅烧,并保温6 h,随炉冷却后即可得到样品荧光粉.

采用德国布鲁克D8 Advance型X-射线衍射仪对样品进行XRD测试,以Cu-Kα(λ=0.154 06 nm)为靶,扫描范围为10°~90°,扫描速率为6°/min.采用北京卓立汉光SENS-9000荧光光谱仪对样品进行上转换发光光谱测试,泵浦源为LD半导体激光器,激发波长为980 nm,扫描范围为500~750 nm,分辨率为0.5 nm.以上所有的测试都是在室温下完成的.

2 结果与讨论

图 1所示为不同Yb3+离子掺杂浓度下样品的XRD谱.

图 2所示为Y2Ti2O7在c轴方向的结构.由图 1可知,所有样品的衍射峰与标准谱图(JCPDS No.89-2065)相一致,说明所合成的样品为纯相,结构为面心立方的烧绿石结构.由图 2中Ti4+和Y3+与O2-的配位情况可以看出,Ti4+和Y3+在Y2Ti2O7基质中均只有一个格位且处于配位体中心. Ti4+与六个O2-形成八面体,Y3+与八个O2-形成多面体.从图 1中没有看到Yb2O3和Er2O3的衍射峰,说明Yb3+和Er3+已掺杂进入Y2Ti2O7基质晶格中.当Yb3+和Er3+掺杂进入Y2Ti2O7基质时,由于Yb3+和Er3+的离子半径与Y3+相近且价态一致,所以Yb3+和Er3+占据了Y3+格位.由图 1还可知,Yb3+和Er3+的掺入没有改变晶体的结构,但是样品的衍射峰整体向高角度方向进行了偏移.这是由于Yb3+离子半径(0.087 nm)和Er3+离子半径(0.089 nm)比Y3+离子半径(0.090 nm)小,Yb3+和Er3+的掺杂引起了Y2Ti2O7晶格收缩所导致的.

图 3所示为不同Yb3+浓度掺杂样品的上转换发光谱.在980 nm激发下,发射谱主要由2组发射峰组成:峰值波长位于547 nm的绿光发射和位于677 nm的红光发射,分别对应于Er3+离子的2H11/2/4S3/2→ 4I15/2跃迁和4F9/2→4I15/2跃迁.从图 3中可以看出,当Yb3+离子共掺入样品中后,Er3+离子的上转换发光显著增强,且随着Yb3+离子浓度的增加而增强. 547 nm的绿光随着Yb3+离子浓度的增加变化较为缓慢,当Yb3+离子浓度高于6%(摩尔分数)时,绿光发射强度没有显著变化. 677 nm的红光随着Yb3+离子浓度的增加而急剧增强.图 4所示为不同Yb3+浓度掺杂样品的CIE坐标.表 1所列为不同Yb3+浓度掺杂样品的CIE坐标值,不同样品的CIE坐标值随着Yb3+离子浓度的增加而变化.由图 4和表 1可知,Yb3+离子可以对Er3+离子的上转换发光颜色起着调控的作用.随着Yb3+离子掺杂浓度的升高,样品上转换发光颜色由绿色逐渐变为红色.

表 1 不同Yb3+浓度掺杂样品的CIE坐标值Table 1. The CIE chromaticity coordinates value of different Yb3+ concentration doped samples

为了探究Er3+离子的上转换发光机理,测量了在不同激发功率下样品的上转换发光强度. Er3+离子的上转换发光强度I与激发功率P之间存在如下的关系[24]:

(1) 式中:n表示上转换发光过程中发射一个可见光子所吸收的红外光子的个数.图 5所示为980 nm激发下Y2Ti2O7:0.02Er3+, 0.02Yb3+样品的上转换发光强度I和激发功率P之间的对数关系.通过对547 nm和677 nm 2个上转换发光峰值的发光强度和激发功率取对数后的线性拟合可知,对于547 nm的绿光可以得到n=1.79,对于677 nm的红光则有n=1.58.由此可以推断出上转换绿光和红光的发射均属于双光子过程.

图 6所示为Yb3+和Er3+离子上转换发光能级示意. Er3+离子基态4I15/2能级上粒子可以直接吸收一个泵浦光子跃迁至激发态4I11/2能级.而在Yb3+离子和Er3+离子共掺的样品中,由于Yb3+离子在980 nm处具有很大的吸收截面,并且其2F5/2→2F7/2跃迁与Er3+的4I15/2→ 4I11/2跃迁能级能量相匹配,Yb3+离子和Er3+离子之间可以发生共振能量传递.因此也可以通过Yb3+离子到Er3+离子间能量传递过程(ET)使得Er3+离子基态4I15/2能级上的粒子激发到4I11/2能级. 4I11/2能级上的粒子再吸收一个泵浦光子跃迁至4F7/2能级,然后无辐射弛豫至2H11/2/4S3/2,这两个能级上的粒子跃迁回基态的过程中发射出峰值波长为547 nm的绿光.

对于上转换红光发射,其发光过程较为复杂,大体可以通过2个途径来实现:一是2H11/2/4S3/2能级上的粒子通过无辐射跃迁弛豫至4F9/2能级,然后在回到基态的过程中发射出峰值波长为677 nm的红光;二是通过交叉弛豫过程(CR),即Er3+离子4I11/2能级上的粒子先通过无辐射跃迁至4I13/2能级,然后发生交叉弛豫过程,2F5/2(Yb)+4I13/2(Er)→2F7/2(Yb)+4F9/2(Er),从而使得粒子布居在4F9/2能级.这一交叉弛豫过程由于发生在Yb3+离子和Er3+离子之间,因此只有在Yb3+和Er3+共掺的体系中才能实现,并且占据着主导地位.因为如果途径1占据主导地位,由于上转换绿光和红光均由4F7/2能级无辐射弛豫得到的,而无辐射跃迁的概率由材料本身决定的,因此可以判断上转换红光和绿光的比值(红绿比R)并不会随着Yb3+离子浓度的变化而发生显著变化.图 7所示为不同Yb3+离子浓度掺杂样品的红绿比(R),从图 7中可以看出红绿比随着Yb3+离子浓度的增加而增大,这种原因就是由于交叉弛豫过程随着Yb3+离子浓度的增加而增强所导致的,所以途径2占据主导地位.

3 结论

采用溶胶-凝胶法制备了不同Yb3+离子浓度掺杂的样品荧光粉.所得结论如下:

1)样品为面心立方结构的烧绿石相,稀土离子Yb3+和Er3+的掺入并没有改变晶体的结构.

2)在980 nm激发下,样品的上转换绿光和红光发射的主发射峰分别位于547 nm和677 nm,并且上转换绿光发射随着Yb3+离子浓度的增加变化缓慢,而上转换红光发射则随着Yb3+离子浓度的增加而增强.样品的发光颜色可以通过改变Yb3+离子掺杂浓度来调控,随着Yb3+离子浓度的增加,样品发光由绿色逐渐变为红色.

3)上转换绿光和红光发射均属于双光子过程.

4)在Yb3+离子和Er3+离子共掺杂体系中,交叉弛豫过程是上转换红光发射的主要发光机理.

-

表 1 水模试验用枪头参数

Table 1 Tip parameters for water model test

表 2 模型参数修正项计算

Table 2 Model parameter correction calculation

表 3 水模型熔池深度

Table 3 Water model bath depth

表 4 水模型枪位设定

Table 4 Water model gun position setting

表 5 水模型顶吹流量设定

Table 5 Water model top blowing flow setting

表 6 水模型底吹流量设定

Table 6 Bottom blowing flow setting of water model

表 7 不同枪位下的冲击深度计算

Table 7 Calculation of impact depth under different gun positions

表 8 工艺参数调整明细

Table 8 Process parameter adjustment details

表 9 2018年8月份管线钢生产炉次

Table 9 Pipeline steel production heat in August 2018

表 10 2019年6月份管线钢生产炉次

Table 10 Pipeline steel production heat in June 2019

表 11 2018年8—9月份炉渣中(FeO)质量分数

Table 11 (FeO) content in slag from August to September 2018

表 12 2019年渣中(FeO)质量分数

Table 12 2019 slag (FeO) content

表 13 2018年8月残锰控制情况

Table 13 Control of residual manganese in August 2018

表 14 2019年6月残锰控制情况

Table 14 Control of residual manganese in June 2019

-

[1] 闫心怡, 沈明刚, 冯超. 300t顶底复吹转炉氧枪枪位的水模型研究和应用[J].特殊钢, 2018, 39(1):6-8. http://d.old.wanfangdata.com.cn/Periodical/tsg201801002 [2] 陈敏. 210t顶底复吹转炉水模型实验研究[D].武汉: 武汉科技大学, 2011. http://www.cqvip.com/Main/Detail.aspx?id=36989149 [3] 朱新华, 李秀娟.转炉炼钢氧枪枪位辅助控制的研究[J].河北理工大学学报, 2006, 10(5):6-7. http://d.old.wanfangdata.com.cn/Periodical/nfgt200605002 [4] 蔡伟, 杨利彬, 王东, 等.转炉冶炼低碳钢炉衬侵蚀及溅渣冷态模拟和应用[J].钢铁, 2012, 28(4):7-12. doi: 10.3969/j.issn.1672-9587.2012.04.002 [5] 杨文远, 崔淑贤, 郑丛杰, 等.宝钢转炉溅渣护炉的炉渣控制及炉衬侵蚀机理[J].钢铁研究学报, 1999, 11(5):34. http://d.old.wanfangdata.com.cn/Conference/201015 [6] 刘浏, 佟溥翘, 崔淑贤, 等.转炉溅渣护炉系统优化技术基础理论研究[J].钢铁, 1997, 32(增刊1):571. http://d.old.wanfangdata.com.cn/Conference/377121 [7] 王念欣.转炉底吹动态模型的应用[J].中国冶金, 2009, 19(1):24-26. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=zgyj200901007 [8] 包丽明, 吕国成, 刘坤. 180t转炉底吹和顶吹复吹射流与熔池作用的水模型研究[J].特殊钢, 2018, 39(1):6-8. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=tsg201504003 [9] 杨文远, 冯超, 王明林, 等.大型转炉高供氧强度吹炼的水模试验[J].钢铁研究学报2017, 29(10):38-46. http://cpfd.cnki.com.cn/Article/CPFDTOTAL-ZGJS201711003176.htm [10] 李智峥, 朱荣, 刘润藻, 等.转炉氧枪枪位对炼钢熔池流速的影响[J].北京科技大学学报, 2014, 36(1):15-20. http://www.cqvip.com/QK/90748A/2014S1/66747568504849528349484852.html [11] 蔡开科.转炉冶炼低碳钢终点氧含量控制[J].钢铁, 2009, 44(5):27-31. http://d.old.wanfangdata.com.cn/Periodical/csjsllyj2016082978 [12] 王海奇, 包燕平.顶底复吹转炉冶炼低碳钢的工艺研究[J].特殊钢, 2010, 31(6):28-31. http://d.old.wanfangdata.com.cn/Periodical/tsg201006009 [13] 范丽伟, 郭世宝, 刘艳玲, 等.转炉冶炼低碳钢脱磷工艺研究[J].河南冶金, 2011, 19(2):10-12. http://d.old.wanfangdata.com.cn/Periodical/henyj201102003 [14] 刘怡生.转炉炼钢模型控制优化实践[J].山西冶金, 2019, 2(1):128-130. http://d.old.wanfangdata.com.cn/Periodical/shanxiyj201902050 [15] 刘威, 李京社, 杨宏博, 等.供氧压力对顶吹转炉内流场影响数值模拟[J].中国冶金, 2014, 24(12):19-26. http://d.old.wanfangdata.com.cn/Periodical/zgyj201412005 [16] 王鹏, 印传磊, 吴伟, 等. 100 t顶底复吹转炉氧枪喷头优化的试验研究[J].炼钢, 2017, 33(6):9-14. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=lg201706003 [17] 李明明, 李强, 邹宗树.转炉顶吹过程渣-金-气三相作用特性[J].钢铁研究学报, 2015, 27(4):19-24. http://d.old.wanfangdata.com.cn/Periodical/gtyjxb201504004 [18] 何顺生, 杨文远, 李任春, 等.邯宝大型转炉炼钢工艺优化的研究[J].炼钢, 2019, 35(5):19-22. http://d.old.wanfangdata.com.cn/Periodical/lg201905005 [19] 李小环.转炉终点残锰量控制及优化[J].中国冶金, 2016, 26(5):57-60. http://d.old.wanfangdata.com.cn/Periodical/zgyj201605011 [20] 倪翀奕, 廖相巍, 费鹏, 等.超低碳钢转炉冶炼终点控制技术[J].鞍钢技术, 2014(4):16-19. http://d.old.wanfangdata.com.cn/Periodical/agjs201404004 -

期刊类型引用(1)

1. 赵小杨,王佳,温慧霞,李红喜,杨启山. 稀土掺杂钼酸盐发光材料的研究进展. 稀土. 2022(01): 25-38 .  百度学术

百度学术

其他类型引用(1)

下载:

下载: