Preparation of coconut shell-based activated carbon for separation and enrichment of ventilation air methane

-

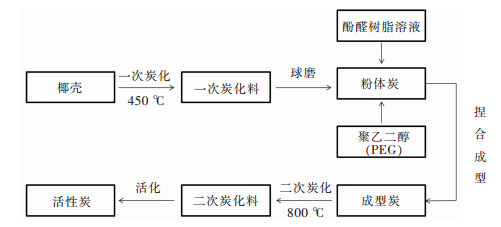

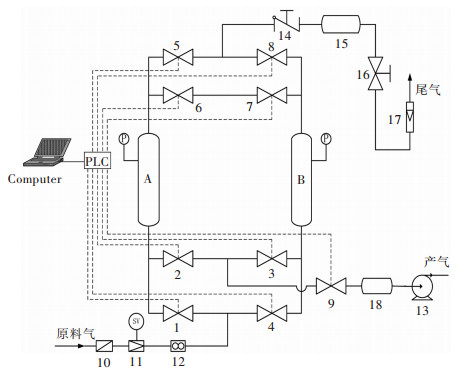

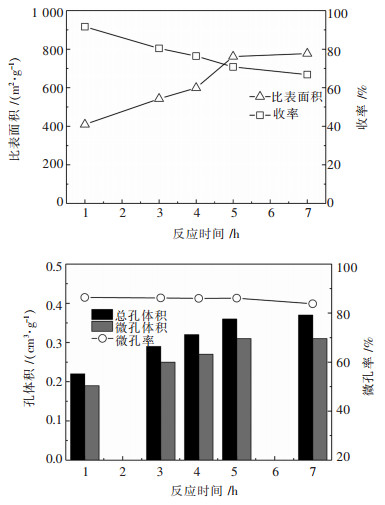

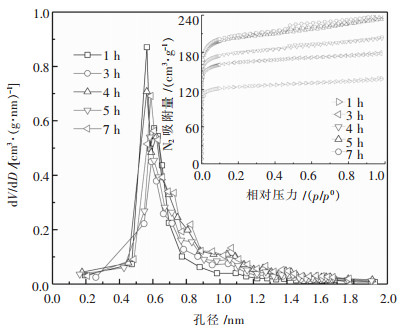

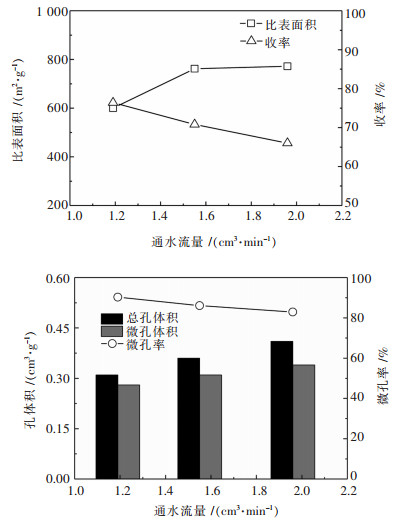

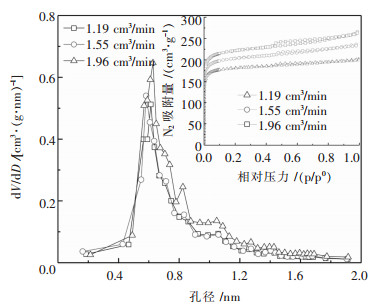

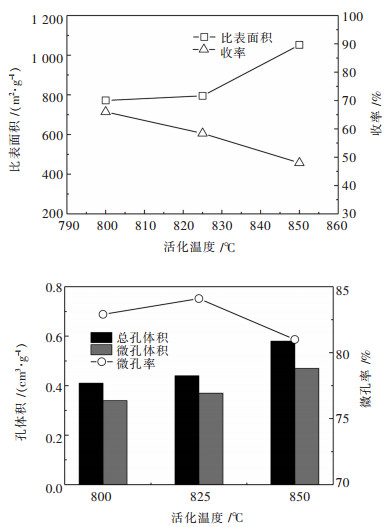

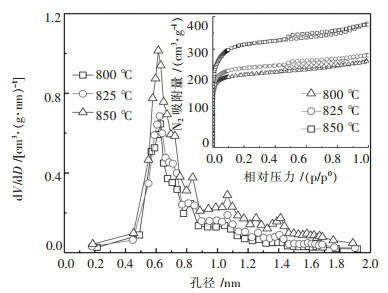

摘要: 以椰壳为原料、酚醛树脂为粘结剂及聚乙二醇(PEG)为造孔剂和分散剂,采用水蒸气活化制备活性炭,以所制备的活性炭为吸附剂,采用真空变压吸附法(VPSA)对乏风瓦斯进行分离富集.分别考察了不同活化条件对活性炭孔结构性能的影响,以及不同VPSA操作条件对乏风瓦斯富集效果的影响.结果表明:以酚醛树脂与粉体炭的质量比为0.5 g/g制备的成型炭作为炭质前驱体进行活化,在活化时间为5 h、通入水量为1.96 cm3/min和活化温度为825 ℃的条件下制备的活性炭,其对应的比表面积、微孔体积及微孔率分别达到795 m2/g、0.37 cm3/g和84.1%;并以该活性炭为吸附剂,在最佳操作条件下,乏风瓦斯(甲烷含量约0.5%)经富集后,产气中CH4浓度和回收率分别为1.51%和96%.Abstract: The activated carbon was prepared by steam activation, with coconut shells as the raw material, phenolic resin as the binder and polyethylene glycol (PEG) as the pore-making agent and dispersant. Then it was used as the adsorbent in the separation and enrichment of ventilation air methane (VAM) by vacuum pressure swing adsorption (VPSA). The porous properties of activated carbon under different activation parameters and the efficiency of the enrichment of VAM under different VPSA conditions were systematically investigated. The results showed that the precursor of activated carbon was a molding carbon made of phenolic resin and powdered carbon with the mass ratio of 0.5 g/g. If the activate carbon was prepared under such operation conditions with the activation time of 5 h, the flow rate of water of 1.96 cm3/min and the activation temperature of 825 ℃, its specific surface area, micropore volume and micropore ratio would be 795 m2/g, 0.37 cm3/g and 84.1%, respectively. With such activated carbon as the adsorbent, under the optimum operation conditions, CH4 concentration in the gas production increased from 0.52 vol. % up to 1.51 vol. % and its recovery rate reached about 96% after the enrichment of VAM.

-

0 前言

锰锌软磁铁氧体材料是一种用途极为广泛的功能材料,主要用于各种信息、电子、电器元件中,如:偏转线圈、回扫变压器、普通变压器、旋转变压器、抗电磁干扰变压器、电感器以及扼流圈等,应用频率从数百赫到几千兆赫,是主要的铁氧体材料[1-6]应用领域; 随着计算机及其外部设备、通讯机、OA设备、高级音频系统、各类控制和测量装置等电子产品的发展,需要转换效率高、重量轻、体积小及性能稳定等特性的电子元件,因此对铁氧体的电磁性能提出了更高的要求,而铁氧体的电磁性能在很大程度上取决于其化学组成、微观结构和形貌及均匀性。

完善的材料加工工艺是生产性能优良铁氧体的重要步骤,但更为关键的是铁氧体前躯体微粉的制备。其制备工艺有传统的氧化物法和湿化学法两种。生产上大多采用氧化物法,即干法,其突出的缺点是"均匀性"差,易引入杂质和污染大; 而湿化学方法生产的前躯体微粉具有纯度高、成分稳定、粒度及形貌可控、活性高等优点,越来越受到人们的重视[7-8]。文章介绍了Fe(Ⅱ)-Mn(Ⅱ)-Zn(Ⅱ)-CO32--NH3-H20系的热力学分析,确定了共沉法制备锰锌软磁铁氧体前躯体微粉的共沉区域,对共沉淀法制备锰锌软磁铁氧体前躯体粉具有重要的指导意义。

1 热力学计算

在Fe(Ⅱ)-Mn(Ⅱ)-Zn(Ⅱ)-CO32--NH3-H2O体系中,以碳酸氢铵与氨水的混合物为沉淀剂,铁、锰、锌均以碳酸盐沉淀的形式析出。[Fe2+]T、[Mn2+]T、[Zn2+]T、[C]T、[N]T分别表示溶液中铁、锰、锌离子及碳、氨的总摩尔浓度。该体系可能存在的化学反应及相应的平衡常数如表 1所示[9]。

表 1 共沉淀体系中可能存在的化学反应及其平衡常数(25℃)

因与金属离子配合的[NH3]≤[N]T,在[N]T的计算中可以忽略不计。根据化学反应平衡及质量守衡可得以下方程:

(1)

(2)

(3)

(4)

(5) 由于[C]T就是溶液中碳的总摩尔浓度,[N]T为溶液中氨的总摩尔浓度,根据以上方程可以得出该体系中的lg[Me]-pH关系图,由该关系图即可确定各金属离子的共沉区域。在[C]T=[N]T=0.1mol/L、[C]T= 0.1mol/L和[N]T=1.0mol/L、[C]T=[N]T=1.0mol/L的条件下计算出不同pH值下溶液中各金属离子的总浓度,计算结果分别如图 1~3。并得出以下结论。

(1) 三种金属离子共沉淀完全(浓度 < 10-5mol/L)的pH值由Zn2+沉淀完全的酸度所决定,因为锌具有较大的氨配合稳定常数,生成可溶的Zn(NH3)i2+。

(2) 三种金属离子共沉淀完全的pH值范围取与锌形成可溶性的氨配合物。决于[C]T、[N]T,即只与碳酸盐和氨水的加入量有关。

(3) 不同的[C]T和[N]T对各金属离子沉淀的pH值影响不同:铁只与[C]T有关,而与[N]T无关;锌与锰则均与[C]T、[N]T有关,而且[N]T对锌的关联度要比锰的大得多。

(4) 随着[N]T的增大,三种金属离子完全沉淀的pH值范围变窄,即由图 1的6.23~9.92变为图 2的6.23~7.39, 但下限是一样的,这是由于较大的[N]T易与锌形成可溶性的氨配合物。

(5) 随着[C]T的增大,三种金属离子沉淀完全的pH值范围变宽,而且[C]T每增加一个数量级三条曲线均向下平移一个单位,即pH值范围由图的6.23~7.3变为图 3的5.70~7.86。

由以上结论可知,从热力学分析得到的方程具有普遍的适用性,只要知道[N]T的浓度,并先做出[C]T=0.1mol/L的曲线,则在任意的[C]T下都可以通过上下平移曲线得到金属离子的共沉区域。

2 热力学分析对试验的指导作用

根据以上热力学分析可以对试验及生产起到指导作用,在试验的过程当中,为了使共沉淀完全,则必须确保共沉条件在三种金属共同沉淀完全的pH值区域,采用正加的加料方式则pH值由小变大,容易导致共沉粉的分层,即共沉粉的不均匀性; 相反,采用反加的加料方式则pH值由大变小,容易导致氢氧化物的析出;而采用并加的加料方式则始终保持pH值的不变,即稳定的保持共沉条件在共沉区域之内,这样不但保证了前躯体微粉成分组成和粒度的均匀性,同时也大大的改善了共沉粉的过滤性能,提高了共沉粉的活性。此外,采用不同组成的沉淀剂则获得不同的沉淀区域,采用氨水的量越多,则共沉区域越小,采用碳酸盐的量越多则共沉的区域越大。

3 结论

通过对Fe(Ⅱ)-Mn(Ⅱ)-Zn(Ⅱ)-CO32--NH3-H2O系的热力学分析,三者的共沉区域主要由Zn2+完全沉淀的区域所决定,而Zn2z沉淀完全的区域又受到[C]T和[N]T的控制。此外,Fe2+沉淀完全的区域只与[C]T有关。而在相同的[C]T条件下,共沉区域随[N]T的增加而变窄,但区域下限不变。在相同的[N]T条件下,任意的[C]T都可以通过上下平移曲线得到金属离子的共沉区域。所以只要知道溶液中[C]T和[N]T,即可确定三种金属离子的共沉区域,从而减少盲目的试验,起到对试验和生产的指导作用。

-

表 1 椰壳原料工业分析和元素分析

Table 1 Proximate and elements analyses of the coconut shells

表 2 实验试剂及气体

Table 2 Agents and gases

表 3 原料气入口流量对富集效果的影响

Table 3 Effect of raw material gas inlet flow on enrichment effect

表 4 尾气流量对富集效果的的影响

Table 4 The effect of exhaust flow on enrichment effect

表 5 吸附时间对富集效果的影响

Table 5 Effect of adsorption time on enrichment effect

表 6 其他活性炭对乏风瓦斯富集效果

Table 6 VAM enrichment performance for other activated carbons

-

[1] 杨林, 杨颖, 刘程琳, 等.用于CH4/N2分离的高效活性炭制备及其吸附平衡和动力学研究[J].华东理工大学学报, 2017, 43(4): 449-458, 494. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=hdlgdxxb201704001 [2] 姜洋.我国煤矿乏风瓦斯技术的发展与应用[J].黑龙江科学, 2017(18): 5. http://www.cnki.com.cn/Article/CJFDTotal-HELJ201718002.htm [3] 周娴.煤矿乏风低浓度甲烷氧化处理实验研究[D].北京: 中国科学院研究生院, 2009. http://cdmd.cnki.com.cn/Article/CDMD-80135-2009156927.htm [4] 曾亿山, 吕善超, 宋旭.旋流自进式钻孔技术在瓦斯抽放中的应用研究[J].煤矿机械, 2010, 31(5): 189-191. doi: 10.3969/j.issn.1003-0794.2010.05.079 [5] 王鑫阳.矿井乏风回收利用技术研究[D].阜新: 辽宁工程技术大学, 2008. http://cdmd.cnki.com.cn/Article/CDMD-10147-2010013402.htm [6] 竹涛, 夏妮, 和娴娴, 等.煤矿乏风瓦斯富集分离技术研究进展与应用[J].洁净煤技术, 2015(6): 95-100. http://d.old.wanfangdata.com.cn/Periodical/jjmjs201506023 [7] 陶鹏万, 王晓东, 黄建彬.低温法富集煤层气中的甲烷[J].天然气化工, 2005, 30(4):43-46. doi: 10.3969/j.issn.1001-9219.2005.04.010 [8] 吴剑峰, 孙兆虎, 公茂琼.从含氧煤层气中安全分离提纯甲烷的工艺方法[J].天然气工业, 2009, 29(2): 113-116. doi: 10.3787/j.issn.1000-0976.2009.02.033 [9] 方华东.孔狭缝及孔网络模型在炭膜气体分离中的应用[D].大连: 大连理工大学, 2007. http://cdmd.cnki.com.cn/Article/CDMD-10141-2007210538.htm [10] MEHRA R Y. Utilizing the mehra process for processing and BTU upgrading of nitrogen-rich natuai gas streams: US, US4623371[P]. 1986-09-18.

[11] DEWAYNE F T, WALTER B C, DAVID E J, et al. Liquid absorbent solutions for separating nitrogen from natural gas: US, US6136222[P]. 2000-10-20.

[12] 吴强, 张保勇, 孙登林, 等.利用水合原理分离矿井瓦斯实验[J].煤炭学报, 2009, 34(3): 361-365. doi: 10.3321/j.issn:0253-9993.2009.03.015 [13] LI X, CAI J, CHEN Z, et al. Hydrate-based methane separation from the drainage coal-bed methane with tetrahydrofuran solution in the presence of sodium dodecyl sulfate[J]. Energy and Fuels, 2012, 26 (2): 1144-1151. doi: 10.1021/ef201804d

[14] OUYANG S, XU S, SONG N, et al. Coconut shell-based carbon adsorbents for ventilation air methane enrichment[J]. Fuel, 2013, 113: 420-425. doi: 10.1016/j.fuel.2013.06.004

[15] 张福凯, 徐龙君, 鲜学福.改性煤变压吸附分离煤层气中甲烷的研究[J].天然气化工, 2008, 33(4): 17-23. doi: 10.3969/j.issn.1001-9219.2008.04.004 [16] 欧阳少波, 徐绍平, 张俊杰, 等. N2/CH4在吸附剂上动态吸附特性的研究[J].化工进展, 2014, 3(10): 2546-2551. http://www.cnki.com.cn/Article/CJFDTotal-HGJZ201410005.htm [17] 常心洁, 刘应书, 刘文海, 等.低压变压吸附法分离净化低浓度瓦斯的试验研究[J].中国煤层, 2006, 3(4):39-43. doi: 10.3969/j.issn.1672-3074.2006.04.011 [18] LI Y, YU M, LIU Y, et al. A novel vPSA process for ventilation air methane enrichment by active carbon[J]. Advanced Materials Research, 2012, 479-481: 648-653. doi: 10.4028/www.scientific.net/AMR.479-481.648

[19] 张建平, 欧阳少波, 熊道陵, 等.聚醋酸乙烯酯制备成型活性炭性能的初步研究[J].有色金属科学与工程, 2018, 9(3): 58-64. http://ysjskx.paperopen.com/oa/DArticle.aspx?type=view&id=2018030005 [20] 吴彩斌, 闵露艳, 习海滨, 等.粉煤灰活性炭吸附含Cr废水试验研究[J].有色金属科学与工程, 2014, 5(3): 70-75. http://ysjskx.paperopen.com/oa/DArticle.aspx?type=view&id=201403013 [21] 唐敏康, 陈苹, 许建红, 等. Fe(Ⅱ)-H2O2不同温度浸润改性活性炭吸附去除水中砷(V)[J].有色金属科学与工程, 2014, 5(4): 66-70. http://ysjskx.paperopen.com/oa/DArticle.aspx?type=view&id=201405017 [22] 刘雪梅, 蒋剑春, 孙康, 等.热解活化法制备微孔发达椰壳活性炭及其吸附性能研究[J].林产化学与工业, 2012, 32(2):126-130. http://d.old.wanfangdata.com.cn/Periodical/lchxygy201202025 [23] 彭碧媛, 康蒙蒙, 江璇, 等.椰壳生物炭对水中Cr(Ⅵ)的吸附性能研究[J].中国资源综合利用, 2017, 35(11): 31-34. doi: 10.3969/j.issn.1008-9500.2017.11.012 [24] 晏荣伟, 侯博, 夏靳松, 等.椰壳活性炭孔结构的调节及对超电容性能的影响[J].人工晶体学报, 2018, 47(3): 550-555, 563. doi: 10.3969/j.issn.1000-985X.2018.03.017 [25] 欧阳少波.煤矿瓦斯真空变压吸附分离与富集的研究[D].大连: 大连理工大学, 2014. http://cdmd.cnki.com.cn/Article/CDMD-10141-1015573740.htm [26] 苏艳敏, 徐绍平, 王吉峰, 等.活性炭的微孔结构对其选择性吸附CH4/N2混合气中CH4的影响[J].天然气工业, 2013, 33(3): 89-94. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=trqgy201303019 [27] OUYANG S, XU S, SONG N. Activated carbons for ventilation air methane enrichment by vacuum pressure swing adsorption[J]. Advanced Materials Research, 2013, 73: 907-911. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=10.4028/www.scientific.net/AMR.773.907

[28] SU S, BEATH A, GUO H, et al. An assessment of mine methane mitigation and utilisation technologies[J]. Progress in Energy and Combustion Science, 2005, 31: 123-170. doi: 10.1016/j.pecs.2004.11.001

下载:

下载: