Naphthenic acid separation of waste phosphors in acid leaching solution of iron and aluminum

-

摘要: 研究了废旧稀土荧光粉酸浸液在环烷酸萃取过程中关于铁、铝杂质的除杂效果,考察环烷酸对于铁、铝、稀土的选择性;有机相组成、氨水浓度、温度对分离效果的影响;水洗温度、水洗相比对水洗效果的影响;盐酸浓度、相比、反萃时间对反萃效果的影响.结果表明:选择环烷酸:异辛醇:磺化煤油体积比为20:20:60、氨水浓度为2 mol/L、温度为20 ℃、氨水滴加速度为3 mL/min时,分离效果较优;水洗温度为40 ℃、相比(A/O)为2时,铁铝稀土的洗脱率分别为1.5%、4.2%和26.4%;反萃剂盐酸浓度为3 mol/L、反萃相比(A/O)为1、反萃时间为20 min时,铁、铝、稀土萃取率分别高达99.5%、99.8%和99.8%.Abstract: In this paper, the effect of removing impurities of iron and aluminum in the process of naphthenic acid extraction of waste rare earth phosphors was studied. The selectivity of naphthenic acid for iron, aluminum and rare earth was investigated. The effect of organic phase composition, ammonia concentration and temperature on the separation effect; Influence of washing temperature and washing ratio on washing effect; Effect of hydrochloric acid concentration, comparison and back extraction time on back extraction effect. The results showed that the best separation effect was achieved when the volume ratio of naphthenic acid: isooctanol: sulfonated kerosene was 20:20:60, the concentration of ammonia was 2 mol/L, the temperature was 20 ℃, and the droplet acceleration of ammonia was 3 mL/min. When the washing temperature was 40 ℃ and the comparison (A/O) was 2, the elution rates of Fe, Al and Re were 1.5%、4.2% and 26.4%, respectively. When hydrochloric acid concentration was 3 mol/L, reverse extraction ratio (A/O) was 1 and reverse extraction time was 20 min, the extraction rates of iron, aluminum and rare earth were up to 99.5%、99.8% and 99.8% respectively.

-

Keywords:

- waste phosphor /

- selectivity /

- iron and aluminum removal

-

废旧稀土荧光粉中富含大量的珍贵稀土钇、铕、铈、铽等,且含量远大于普通稀土矿中稀土含量,因此具有极高的回收价值[1-3].稀土荧光粉废料经分解、酸浸、除杂、溶剂萃取、分离和提纯后可以得到纯度较高的稀土产品,但在酸浸除杂过程中,往往含有大量的非稀土杂质,如Fe3+、Al3+、Mg2+、Ca2+、Mn2+等[4-5];其中铁、铝离子一般是废旧荧光粉酸浸液中含量较大的杂质离子,是造成环烷酸乳化的主要原因,对后期稀土萃取影响程度较为严重[6-9].现阶段关于废旧荧光粉浸出液中分离除去铁、铝离子的方法主要有以下几种:①沉淀法[10-14]:沉淀法一般包括水解沉淀法、硫化铵沉淀法、草酸盐沉淀法等;使非稀土杂质沉淀,静置,过滤除杂,必要时需要加入活性炭,吸附获得的沉淀物,获得良好的过滤效果;②萃取法[15-17]:将废旧荧光粉酸浸液通过萃取剂(N235、环烷酸、P507等)分离除杂,可以去除酸浸液中大部分的Al、Fe等杂质,且有机相经水洗反萃后可以反复使用;③液膜法[18-20]:通过研究料液类型,流动载体,无机盐,表面活性剂,水乳比,缓冲剂对稀土提取和分离稀土杂质效果的影响,确定最优的实验参数,提高稀土质量和提取率;④离心沉降法[21]:通过离心力作用,控制稀土、铝、铁的沉淀pH,调节溶液pH,进而实现稀土、铝、铁的分离.沉淀法、液膜法、离心沉降法对于稀土酸浸液成分要求比较严格,没有统一适用的方法,不利于工业化生产,且除杂成本较高,无法推广使用.萃取法简单、适用范围广泛、且萃取剂可以重复使用、绿色环保,适用于大规模的推广使用.但是上述方法去除铁铝杂质均难以控制反应进行的程度,工艺操作较为繁杂,过滤存在难度,除杂效果有待提高;而且在萃取过程中往往采用多种萃取剂,易造成萃取剂“中毒”,严重影响萃取效果[22].

针对目前除杂与稀土分离工艺复杂且工艺之间容易互相影响的现状,文中采用单一环烷酸萃取体系同时完成稀土的萃取与铁、铝杂质的分离,从环烷酸对铁、铝、稀土的选择性,分离提纯,水洗,反萃角度考察在非皂化环烷酸体系下除杂的效果,优化试验条件,得出较优工艺条件,降低萃取过程乳化现象发生的可能;且可有效控制反应进行程度,避免了萃取剂“中毒”.可以为工厂生产提供参考价值,因此具有重要的研究意义.

1 实验

1.1 实验原料

本研究所用料液模拟自废旧稀土荧光粉初步浸出除杂后酸浸液,Y-Eu富集液成分如表 1所列,Ce-Te富集液成分如表 2所列.模拟料液为Y-Eu富集液与Ce-Tb富集液混合液,此混合液成分组成可根据混合比例以及浸出工艺参数改变而改变,因此需经过考察铁、铝、稀土浓度对分离效果影响后,再确定模拟料液最佳组成.

表 1 Y-Eu富集液成分Table 1. composition of Y-Eu enriched solution 表 2 Ce-Te富集液成分Table 2. Ce-Te enriched liquid components

表 2 Ce-Te富集液成分Table 2. Ce-Te enriched liquid components

1.2 实验方法

1)稀土料液的配制.模拟初步除杂后的稀土料液,通过料液稀土配分计算所需稀土氧化物的质量,将稀土氧化物溶于3 mol/L的盐酸中;通过分析不同除杂程度下铁、铝含量,计算所需铁、铝氯化物的质量,并溶于3%的盐酸溶液中,最后将稀土溶液与铁、铝溶液均匀混合后定容即为模拟稀土料液.

2)萃取剂的配制.环烷酸、异辛醇、磺化煤油按体积比20:20:60的比例混合,之后用盐酸(1:1)按1:1的比例混合后,振荡5 min后置于分液漏斗中分相,弃去下层水相后用蒸馏水水洗至中性,即为未皂化环烷酸溶液,用于后续稀土料液除铁、铝.

3)实验步骤.在烧杯中按一定的相比,添加含铁铝和稀土的料液以及未皂化的环烷酸((环烷酸:异辛醇:磺化煤油的体积比为20:20:60)[H+]=0.3 mol/L)),并且预先搅拌1 min,使反应达到初步平衡,之后按一定的滴加速率往烧杯中滴加氨水,破坏萃取反应的平衡,使铁铝尽可能多的萃取到有机相中,之后将萃取完的混合液体放置于分液漏斗中静置分层5 min,最后取下层清液测定其pH值、体积以及用ICP测量铁、铝和稀土的含量并计算各元素的萃取率.

1.3 实验原理

环烷酸萃取分离铁、铝、稀土,pH较大时,铝、铁等杂质会优先于稀土被萃取分离出来;pH较小时,铝、铁杂质较稀土更容易被反萃出.且后续萃取分离稀土主要利用环烷酸萃取,为不对后续萃取造成有机相污染,故选用环烷酸萃取剂[23-25].

水溶液中环烷酸对金属离子的萃取顺序如下:

环烷酸萃取铁、铝、稀土化学反应方程式主要如下:

(1)

(2)

(3)

(4) 环烷酸在萃取分离铁、铝、稀土过程中,不断生成氢离子,环烷酸与含铁、铝、稀土混合一定时间后很快达到萃取平衡,此时萃取效果较差,之后往混合料液中滴加氨水将发生反应(4)不断消耗生成的氢离子,使反应(1)、反应(2)、反应(3)往右边进行,铁、铝、稀土萃取率不断增大,当铝离子被大量萃取后浓度降低时,继续滴加氨水则会使浓度依旧高的稀土萃取上去造成共萃的现象,因此可以通过控制氨水滴加量即控制溶液的酸度(pH),使铁、铝和稀土分离.

2 结果与讨论

2.1 环烷酸对铁、铝、稀土的选择性

根据铁、铝和稀土在环烷酸萃取体系中萃取顺序,铁、铝将优先于稀土被萃取至环烷酸有机相中,其料液中铁、铝和稀土浓度直接影响到萃取分离效果.按萃取顺序依次改变料液中初始铁离子、铝离子、稀土离子浓度,考察各物质的萃取率,以及分离系数,确定较优模拟料液配比.

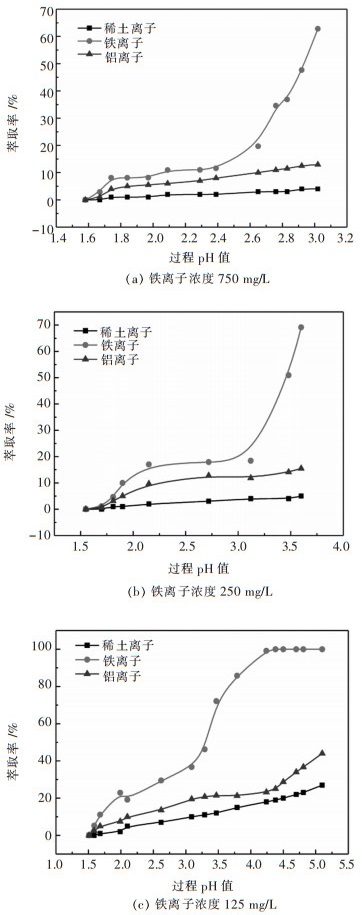

2.1.1 不同铁浓度对分离效果的影响

以环烷酸为萃取剂,有机相环烷酸:异辛醇:磺化煤油的体积比为20:20:60,料液含铝(2 g/L)和稀土(0.3 mol/L).料液与有机相体积比为1:1,分别改变料液铁离子浓度为750 mg/L、250 mg/L、125 mg/L.萃取率结果如图 1所示,对比图 1(a)、图 1(b)、图 1(c)可知,环烷酸在萃取铁、铝和稀土时,随着体系pH值的上升,萃取率都呈上升趋势,并且随着初始铁离子浓度下降,萃取体系的终点pH值逐渐升高,铁离子萃取率升高至100%,铝离子与稀土离子萃取率也上升到45.6%和25%,当铁离子浓度小于125 mg/L时,环烷酸可以在达到铁离子水解pH之前基本完全萃取,从而不造成乳化.故后续实验控制铁离子浓度为125 mg/L.

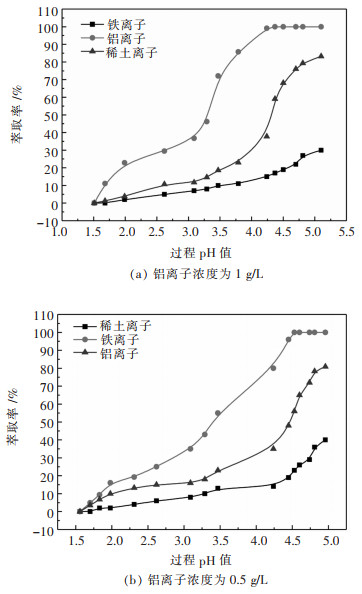

2.1.2 不同铝离子浓度对分离效果的影响

其他条件不变,使料液含铁为125 mg/L,设置料液中含有不同的铝离子浓度.如图 2所示,对比图 1(c)与图 2(a)、图 2(b)可知,在pH为3.5之前,萃取率基本相同,当酸度继续减小时,低铝浓度的溶液pH变化迅速,这是因为铁、铝浓度都较低,萃取反应速率减慢,萃取率变化变慢,稀土浓度相对较高,萃取率上升速度变快,造成当铝浓度为0.5 g/L时,终点稀土萃取率偏高.当铁离子浓度为125 mg/L,铝离子浓度为2 g/L时,铁离子萃取率为100%时,铝离子萃取率仅为40%,当铝离子浓度小于1 g/L时,在pH=4之后,铝离子萃取率远大于稀土离子.铝离子浓度继续减少,铝离子萃取率变化不大,而稀土离子萃取率增大,说明此时环烷酸对铝离子萃取能力减弱.故后续试验控制铝离子浓度为1 g/L.

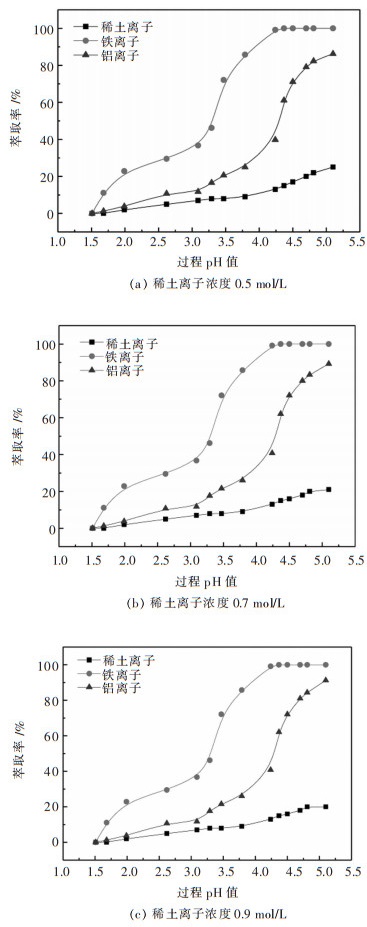

2.1.3 不同稀土离子浓度对分离效果的影响

其他条件不变,按照上述较优条件,仅改变料液初始稀土离子浓度.结果如图 3所示,对比图 2(a)和图 3(a)、图 3(b)、图 3(c)可知,当料液中初始稀土离子不断增大,各离子随过程pH值增大的趋势不变,终点pH值下铁离子萃取率基本保持100%,铝离子萃取率分别为86.2%、90.56%和90.8%,稀土离子萃取率分别为25.17%、20.19%、20.05%.在初始稀土离子浓度大于0.7 mol/L时,各离子萃取率变化趋于稳定,初始稀土离子浓度影响减小.

综上所述,控制环烷酸萃取分离铁铝和稀土的模拟料液组成为:125 mg/L Fe3+、1 g/L Al3+、0.7 mol/LRE3+.控制萃取分离终点pH为5.2,此时铁离子萃取率为100%,铝离子萃取率为90.56%,稀土离子萃取率为20.19%,βAl/RE=37.90.因此后续模拟料液均选用此料液组成.

2.2 萃取条件试验

以控制料液组成含有125 mg/L Fe3+、1 g/L Al3+和0.7 mol/LRE3+作为模拟料液,利用未皂化环烷酸选择性萃取分离铁、铝、稀土.萃取过程中主要考察环烷酸浓度、萃取时间、氨水浓度和萃取温度等对萃取分离效果的影响,进而确定较优参数.

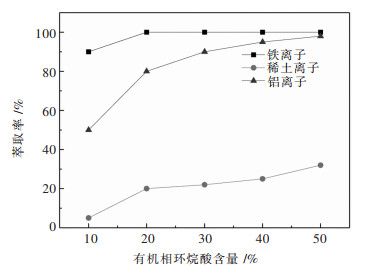

2.2.1 有机相组成对分离效果的影响

试验以上述模拟料液作为原料,萃取条件为相比1:1,仅改变有机相中环烷酸含量,结果如图 4所示,环烷酸体积分数从10%到20%,由于浓度的提高,铁、铝、稀土离子萃取率分别提高了14.22%、29.44%、13.22%;环烷酸体积的分数从30%到40%,有机相变黏稠,分相变慢,易发生乳化,且铝铁稀土离子萃取率提升效果均不明显.综合考虑成本和萃取分离效果,选择环烷酸:异辛醇:磺化煤油的体积比为20:20:60.

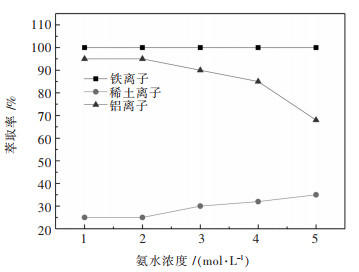

2.2.2 氨水浓度对分离效果的影响

按照上述实验方法,仅控制氨水浓度的变化,分别向溶液中滴加不同浓度的氨水,达到终点pH时,萃取率结果如图 5所示:当氨水浓度达到2 mol/L后,铁的萃取率几乎不变,铝萃取率不断降低至68.12%,稀土萃取率不断上升至30.23%.即氨水浓度的增大,将加速消耗水相中的氢离子,使反应向正反应方向进行,但过高的氨水浓度将很容易造成萃取时局部过碱,使铝离子变为氢氧化铝沉淀,易引发乳化.因此选择氨水浓度为2 mol/L.

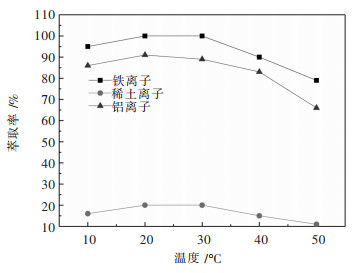

2.2.3 萃取温度对分离效果的影响

其他条件采用上述的较优条件,考察不同温度对分离效果的影响;结果如图 6所示:随着萃取温度的升高,环烷酸对铁、铝、稀土萃取率呈现先升高后下降的趋势.当萃取温度为20 ℃时,铁、铝、稀土的萃取率分别为100%、91%、20%;30 ℃时,铁、稀土萃取率呈上升趋势,铝萃取率下降;继续升高温度,整体呈现出下降趋势,因为温度过高时,滴加的氨水会在反应前挥发掉部分,在溶液中生成气泡,影响萃取过程,导致萃取率下降,除此之外,温度过高还会导致有机相挥发加剧,造成有机相损失增多,实际萃取剂减少,从而使萃取率降低.同时考虑升高温度对能源需求增大,综合考虑萃取情况,选择萃取的较优温度为20 ℃.

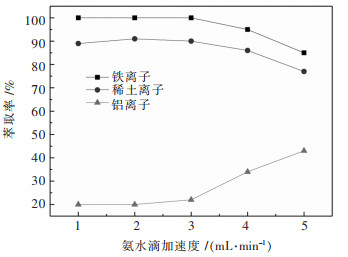

2.2.4 氨水滴加速度对分离效果的影响

其他条件不变,仅改变不同的滴加速度,分别往溶液中滴加2 mol/L的氨水,控制终点pH值为5.2,萃取率结果如图 7所示:随着氨水滴加速度的提高,从1 mL/min到3 mL/min时,铁、铝、稀土的萃取率变化不大,因为控制了pH的初始和最终,即控制了氢离子的变化量,进而氨水的消耗量也相近,所以此时消耗的氨水量基本相同;之后继续提高氨水滴加速度,铁、铝萃取率快速下降,稀土萃取率快速上升,这是由于当氨水滴加速度超过一定限度时,体系中氨水消耗氢离子速度大于氢离子产生的速度,萃取体系pH值快速增大,铁、铝离子形成氢氧化物沉淀,铁、铝萃取率降低,而稀土萃取率升高,综合考虑反应速率与萃取情况,选择较优氨水滴加速度为3 mL/min.此时有大部分的铁、铝和20%稀土共萃进入有机相中,反萃后可直接将反萃液通过中和水解净化步骤,将部分铁、铝沉淀下来,稀土富集液又循环进入分离流程,进而减少稀土的损失.

2.3 水洗条件试验

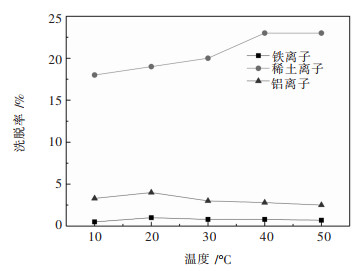

2.3.1 水洗温度

取100 mL负载有机相,按相比1:1添加去离子水,利用分液漏斗振荡水洗30 min,调节不同的水洗温度,分层后取水相测量铁离子、铝离子、稀土离子浓度,计算各离子的洗脱率,结果如图 8所示:增加水洗温度,稀土离子的洗脱率增加,超过40 ℃后,洗脱率不再变化,而铝离子和铁离子洗脱率基本不变.故选择水洗温度为40 ℃.

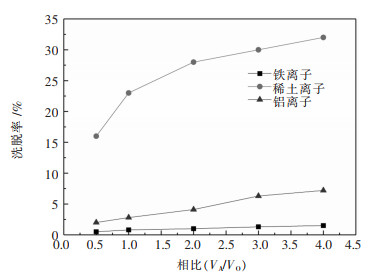

2.3.2 水洗相比

调节水洗温度为40 ℃,其他条件不变,设置不同的相比(A/O),各离子洗脱率如图 9所示:随着相比(A/O)的增加,铁离子洗脱率几乎不变,而铝离子和稀土离子洗脱率成上升趋势;水洗相比低于2时,无法将稀土从负载有机相中较好的洗脱下来,当相比大于2且不断增加时,由于环烷酸的水溶性相对较大,会将有机相直接溶解到水中,所以铁铝稀土洗脱率都会增大,为保证后续稀土离子浓度不至于过低而再进行富集,所以选择相比为2,此时分离效果较好.

2.4 反萃条件试验

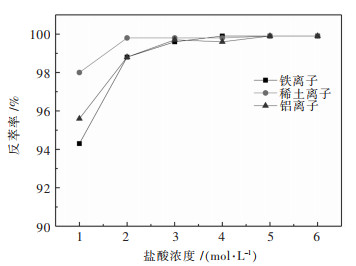

2.4.1 盐酸浓度对反萃效果的影响

以负载环烷酸为反萃对象,以盐酸溶液为反萃剂,反萃剂与有机相的体积比(VA/VO)为1:1,在常温下分别取不同浓度的盐酸于分液漏斗中振荡反萃20 min,静置分层后,结果如图 10所示:随着盐酸浓度的上升,各离子反萃率均为先增加,后趋于稳定,当在盐酸浓度为3 mol/L之后,反萃率达到99%不再上升,此时反萃达到饱和状态.故选取反萃剂盐酸浓度为3 mol/L.

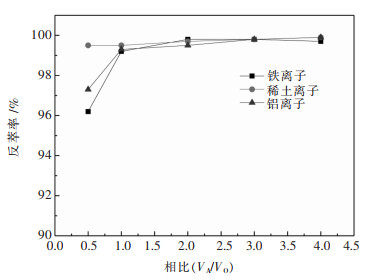

2.4.2 相比对反萃效果的影响

其他反萃条件不变,仅改变相比(A/O),结果如图 11所示:增大水相与有机相的体积比(VA/VO),稀土的反萃率基本无变化,铁、铝的反萃率先增大后稳定不变.当水相与有机相体积比为1:1时,铁,铝、稀土的反萃率均大于99%,且之后变化不大,可知此时反萃反应已达平衡,故选择水相与有机相的体积比为1:1更为合适.

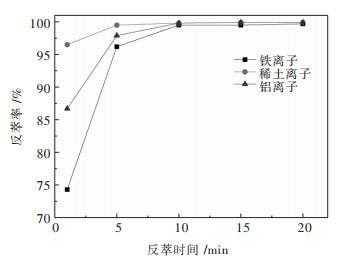

2.4.3 反萃时间对反萃效果的影响

设置不同的反萃时间,考察其对反萃效果的影响,如图 12所示,随着反萃时间的增加,铁、铝、稀土的反萃率先增加后趋于稳定,当反萃时间为1 min时,铁、铝、稀土的反萃率分别为74.3%、86.7%和96.5%,这是由于反萃时间过短,接触时间不足,无法完全达到反萃反应的平衡.当反萃时间为10 min时,铁、铝、稀土萃取率分别高达99.5%、99.8%和99.8%.这是由于随着反萃反应的进行,接触时间增加,反萃反应逐渐达到平衡,之后再增加反萃时间,反萃率将变化较小,且接触时间越长,有机相溶于水相越多,有机相损失增大.综合考虑后,选择反萃时间为10 min.

2.5 有机相红外光谱分析

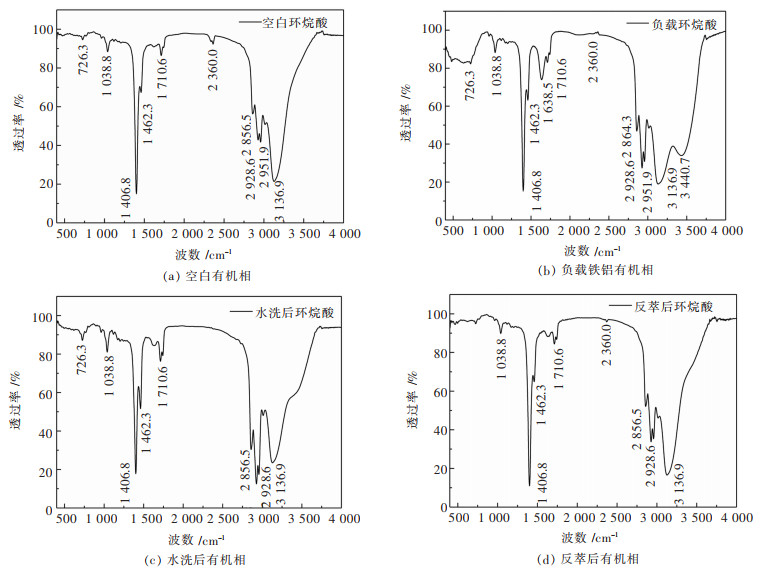

试验分别取空白环烷酸、负载环烷酸、水洗后环烷酸、反萃后环烷酸进行红外光谱分析[26],结果如图 13所示,特征峰如表 3所列.

表 3 特征峰Table 3. Characteristic peak

图 13分别为空白有机相、负载铁铝有机相、水洗后有机相、反萃后有机相的红外光谱,对比上表,图 13(a)可以发现碳碳单键(C-C)键吸收峰位在400~900 cm-1处,此处的峰因特征性不强,所以在此处并不多加分析.羧酸中的碳氧单键(C-O)在1 406.8 cm-1、1 462.3 cm-1处由于收缩共振会出现两个相邻较近的峰,两峰位置相距会在60 cm-1范围左右,在1 710.6 cm-1处的振动吸收峰是六元环羧酸中羰基(碳氧双键(C=O))的伸缩振动,碳氧双键会以二缔合体的形式存在,由于氢键的影响,吸收位置会向低波处移动,因此可以从图 13中看出碳氧双键的峰位在1 710.6 cm-1附近.在六元环中,环状烃类的C-H键的变形振动一般会出现在两处,一处在960~1 275 cm-1处,由于吸收较弱,易受到干扰,用处不大,所以不做分析,与碳碳单键处于同一个位置,因此不多加分析.另一处是650~900 cm-1处的变形振动或者组频所产生的峰强,由于原子间的相互影响而使体系内的π电子(或p电子)分布发生变化的一种电子效应,即所谓的共轭效应,是确认六元环不饱和的重要依据;在根据不饱和苯环上C=C-H峰位,可以判断出由于六元环中碳碳双键的共轭效应,在2 360.0 cm-1处出现了一个新的峰碳碳双键(C=C),进而更加证明了六元环中所含有的不饱和碳碳双键,六元环上的羧基距离六元环上碳碳双键位置较远,因此受伸缩振动影响较强,因此峰的位置会在较低的波段.在2 856.5 cm-1处出现的峰和在2 938 cm-1和2 951.9 cm-1处,分别为六元环中的对称收缩(对位)-CH2键所产生和不对称(间位)-CH2所产生,羧酸类羟基峰强一般为2 500-3 400 cm-1峰尖,一般为缔合羟基,所以在3 136.9 cm-1处的峰强位羧酸中羟基所产生.

对比图 13(a)、图 13(b)、图 13(c)、图 13(d)可以看出,具有4个特征峰(羧酸中的碳氧单键(C-O)在1 406.8 cm-1,羧酸中的羰基(碳氧双键(C=O))在1 710.6 cm-1处,在2 360.0 cm-1处的碳碳双键(C=C),在3 136.9 cm-1处的峰强位羧酸中羟基(-OH))环烷酸六元环,对比图 13(a)、图 13(d)两图,可以发现环烷酸在萃取的过程中没有发生变化,对比图 13(a)、图 13(b)两图,萃取后负载有机相相对于空白有机相多1 638.5 cm-1,3 440.67 cm-1峰,说明在萃取过程中,铁、铝和羧基发生了反应,生成了新官能团.对比图 13(a)、图 13(c)、图 13(d)可知,水洗过程中2 360.0 cm-1处的峰变缓,说明在水洗过程中六元环中的碳碳双键受到影响,峰强变弱,其他峰几乎不变,说明水洗过程没有将铁,铝从有机相中分离.对比图 13(a)、图 13(b)、图 13(c)、图 13(d),3 440.7 cm-1峰消失,并且反萃后有机相和空白有机相峰基本一致.说明反萃过程中,铁铝已基本反萃,形成羧酸基,反萃后有机相和空白有机相官能团基本不变,可以重复利用.

3 结论

1)研究了离子型稀土浸出液在连续萃取过程中对于铁、铝杂质的除杂效果,结果表明:当铁离子浓度为125 mg/L,铝离子浓度为1 g/L,0.7 mol/L稀土时,铁、铝、稀土分离效果最佳,分离的终点为pH=5;选择环烷酸:异辛醇:磺化煤油体积比为20:20:60,氨水浓度为2 mol/L时,温度为20 ℃时,氨水滴加速度为3 mL/min,分离效果较优;水洗温度为40 ℃,相比(A/O)为2时,水洗效果较优;反萃剂盐酸浓度为3 mol/L,反萃相比(A/O)为1,反萃时间为20 min时,反萃效果较优.

2)通过对空白有机相、负载铁铝有机相、水洗后有机相、反萃后有机相进行红外光谱分析,对比各图特征峰可知:反萃前后环烷酸结构一致,整个萃取过程环烷酸可以循环使用.

-

表 1 Y-Eu富集液成分

Table 1 composition of Y-Eu enriched solution

表 2 Ce-Te富集液成分

Table 2 Ce-Te enriched liquid components

表 3 特征峰

Table 3 Characteristic peak

-

[1] 杨幼明, 邓声华, 谢芳浩, 等.从荧光粉废料中提取稀土工艺研究[J].有色金属(冶炼部分), 2012(10): 23-26. http://d.old.wanfangdata.com.cn/Periodical/ysjs-yl201210008 [2] 陈丽杰, 李子良, 龚傲, 等.从稀土废料中回收稀土的研究进展[J/OL].中国稀土学报: 2019(4): 1-25. [3] 毛林春, 曾斌, 余攀, 等.从废弃荧光粉中提取稀土试验研究[J].湿法冶金, 2013, 32(6): 395-397. http://d.old.wanfangdata.com.cn/Periodical/sfyj201306020 [4] 金会心, 郑晓倩, 杨松, 等.含稀土磷矿酸浸出稀土及杂质[J].过程工程学报, 2017, 17(1): 69-74. http://d.old.wanfangdata.com.cn/Periodical/hgyj201701011 [5] 刘庆生, 李江霖, 常晴, 等.离子型稀土矿浸出前后工艺矿物学研究[J].稀有金属, 2019, 43(1): 92-101. http://d.old.wanfangdata.com.cn/Periodical/xyjs201901012 [6] ZHAO ZHUO, XU GUILI.Present situation and development trend of technology of rare earth elements in waste phosphor[J].Journal of the Chinese Society of Rare Earths, 2015, 33(6): 641-649. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=zgxtxb201506001

[7] PATRICK M, EDUAFO, MARK L. Strauss and brajendra mishra.experimental investigation of recycling rare earth metals from waste fluorescent lamp phosphors[J]. Rare Metal Technology, 2015: 253-259.

[8] TIAN X, YIN X, GONG Y, et al. Characterization, recovery potentiality, and evaluation on recycling major metals from waste cathode-ray tube phosphor powder by using sulfuric acid leaching[J]. Journal of Cleaner Production, 2016, 135: 1210-1217. doi: 10.1016/j.jclepro.2016.07.044

[9] XUE N N, ZHANG Y M, JING H, et al. Separation of impurities aluminum and iron during pressure acid leaching of vanadium from stone coal[J]. Journal of Cleaner Production, 2017, 166: S095965261731870X. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=72d710beca3a50e5a41e2e0f22cabb86

[10] 杨幼明, 王莉, 肖敏, 等.离子型稀土矿浸出过程主要物质浸出规律研究[J].有色金属科学与工程, 2016, 7(3): 125-130. http://ysjskx.paperopen.com/oa/DArticle.aspx?type=view&id=2016030022 [11] 孟祥龙, 冯宗玉, 黄小卫, 等.氧化钙沉淀硫酸稀土过程中杂质的分布与去除[J].稀有金属, 2018, 42(10): 1114-1120. http://d.old.wanfangdata.com.cn/Periodical/xyjs201810014 [12] 欧阳克氙, 饶国华, 姚慧琴, 等.南方稀土矿抑铝浸出研究[J].稀有金属与硬质合金, 2003, 31(4): 1-3. http://d.old.wanfangdata.com.cn/Periodical/xyjsyyzhj200304001 [13] 邱廷省, 方夕辉, 伍红强, 等.离子型稀土矿中铝铁杂质的浸出与抑制规律(英文)[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(9): 2986-2990. http://d.old.wanfangdata.com.cn/Periodical/zgysjsxb-e201409032 [14] 刘志强, 朱薇, 郭秋松.高铝稀土料液萃取除铝工艺的研究[J].材料研究与应用, 2012, 6(4): 256-258. http://d.old.wanfangdata.com.cn/Periodical/gdysjsxb201204008 [15] 刘骏, 张磊, 代晓彬, 等.环烷酸萃取分离混合氯化稀土溶液中的铝[J].有色金属(冶炼部分), 2017(5): 41-43. http://d.old.wanfangdata.com.cn/Periodical/ysjs-yl201705011 [16] 韩旗英, 刘志强, 杨金华, 等.用环烷酸从稀土料液中萃取除铝新工艺技术[J].稀土, 2013, 34(3): 74-77. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=xitu201303015 [17] 周洁英, 杨新华, 洪侃, 等.从稀土分解液中连续去除铁、铝[J].湿法冶金, 2016, 35(6): 513-516. http://d.old.wanfangdata.com.cn/Periodical/sfyj201606013 [18] 刘安荣, 聂登攀, 王在谦, 等.乳状液膜法从磷矿浸出液中提取稀土的研究[J].化工矿物与加工, 2015, 44(10): 11-15. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=hgkwyjg201510004 [19] 谢子楠, 陈前林, 赵丽君.液膜对不同酸度磷矿浸出液中稀土的提取[J].过程工程学报, 2013, 13(2): 197-201. http://d.old.wanfangdata.com.cn/Periodical/hgyj201302004 [20] 谢子楠, 陈前林, 赵丽君.乳状液膜对磷矿酸解液中稀土离子的提取研究[J].中国稀土学报, 2013, 31(3): 269-274. http://d.old.wanfangdata.com.cn/Periodical/zgxtxb201303003 [21] 赵治华, 桑晓云, 张文斌, 等.离心沉降法去除稀土溶液中杂质铝和铁[J].稀土, 2007, 28(6): 95-97. http://d.old.wanfangdata.com.cn/Periodical/xitu200706023 [22] 杨凤丽, 邓佐国, 徐廷华.环烷酸萃取钇工艺中存在的问题及优化措施[J].湿法冶金, 2005(3): 139-142. http://d.old.wanfangdata.com.cn/Periodical/sfyj200503006 [23] 曾青云, 曾清全, 常卿卿.环烷酸体系萃取分离稀土和铝的实验研究[J].有色金属科学与工程, 2012, 3(2): 17-19. http://ysjskx.paperopen.com/oa/DArticle.aspx?type=view&id=201111033 [24] 王科超, 钟亮.环烷酸萃取分离稀土料液中铝的研究[J].上海有色金属, 2012, 33(2): 66-6. http://d.old.wanfangdata.com.cn/Periodical/shysjs201202004 [25] 李剑虹, 张兴, 徐莹, 等.环烷酸萃取体系中稀土和铝分配比及分离系数的研究[J].矿冶, 2010, 19(1): 66-69+76. http://d.old.wanfangdata.com.cn/Periodical/ky201001017 [26] 尹文萱, 刘玉峰, 张元福, 等.环烷酸-酸性磷酸酯-庚烷体系萃取有机相的红外光谱研究[J].光谱学与光谱分析, 2006(5): 825-827. http://d.old.wanfangdata.com.cn/Periodical/gpxygpfx200605011 -

期刊类型引用(5)

1. 原伟泉,匡敬忠,胡海祥,梁斌珺,于明明. 离子型稀土浸出过程杂质形成与去除研究进展. 金属矿山. 2024(07): 119-128 .  百度学术

百度学术

2. 李伟鑫,张荣荣,刘勇奇,巩勤学. 用Cyanex272从硫酸盐体系中萃取除铝. 湿法冶金. 2021(02): 159-162 .  百度学术

百度学术

3. 赖安邦,贺强,邱江,许城,肖燕飞. 氧化钙反加料沉淀富集稀土浸出液中稀土的研究. 稀有金属. 2021(07): 866-878 .  百度学术

百度学术

4. 孙亮,李玉虎,宋健清,张敏. 焙烧制度对稀土精矿中铁、铝等杂质浸出行为的影响. 有色金属科学与工程. 2021(04): 27-32+81 .  本站查看

本站查看

5. 贺强,赖安邦,邱江,王瑞祥,肖燕飞. 抗坏血酸钠搅洗降低混合稀土氧化物中SO_4~(2-)含量的研究. 中国稀土学报. 2020(04): 497-506 .  百度学术

百度学术

其他类型引用(0)

下载:

下载: