Study on the control of D inclusion in the SWRH82B steel by CaO-SiO2-Al2O3-CaF2 refining slag

-

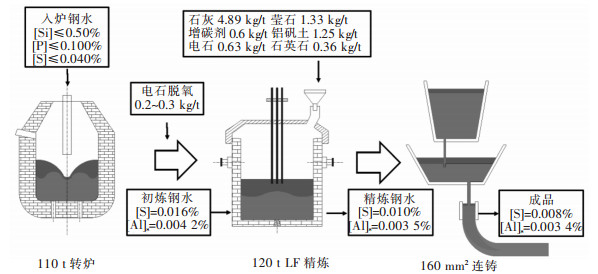

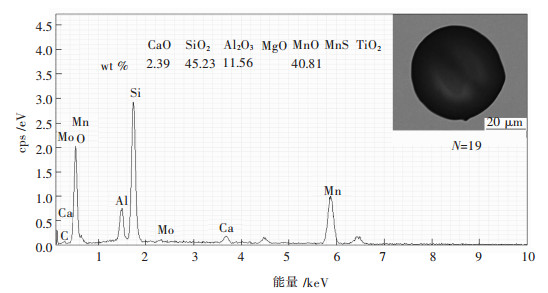

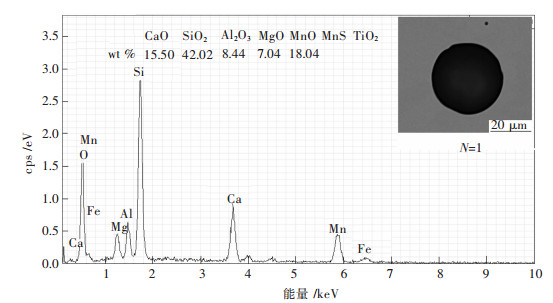

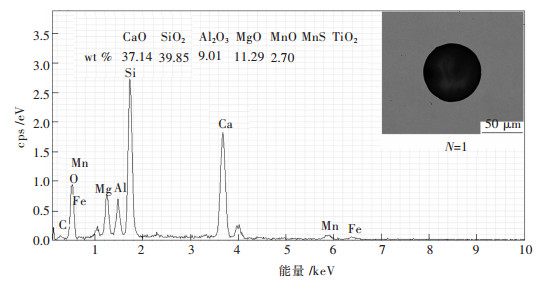

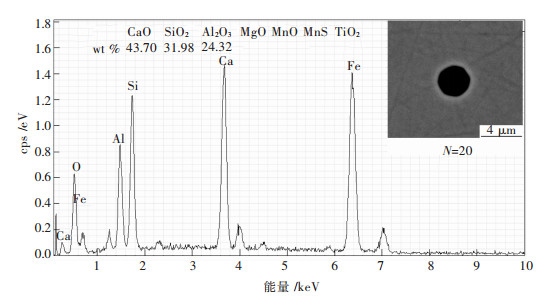

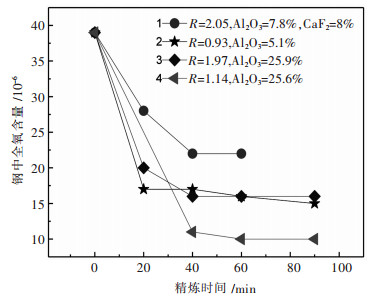

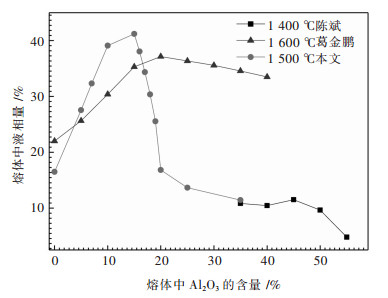

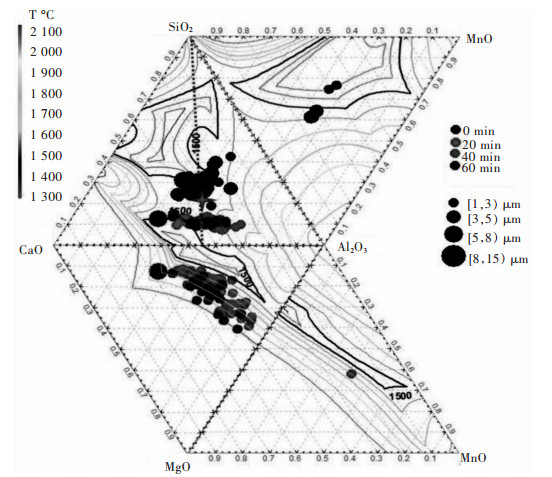

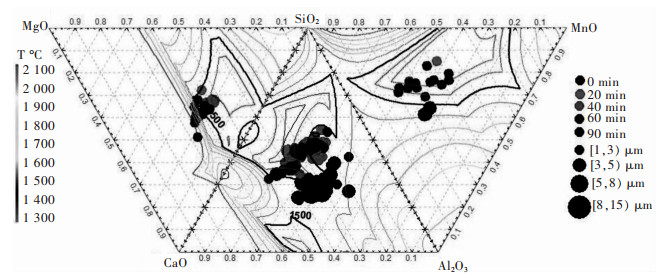

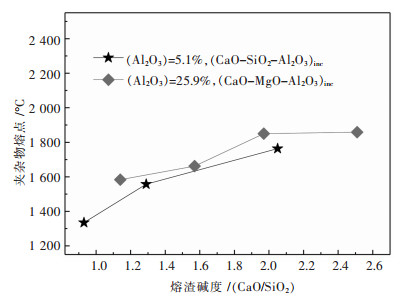

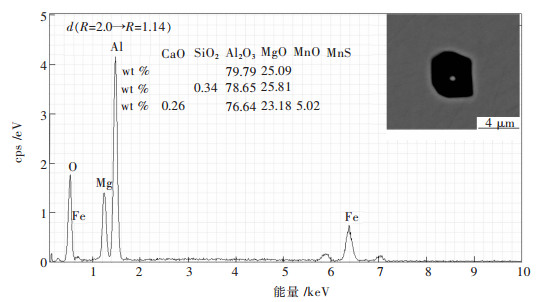

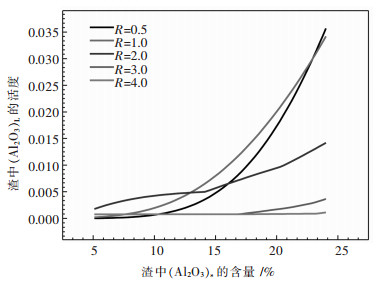

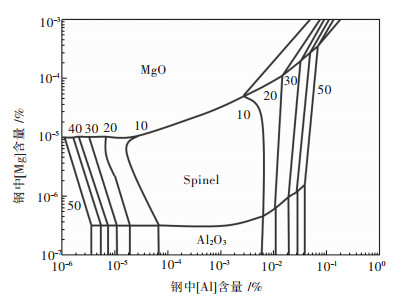

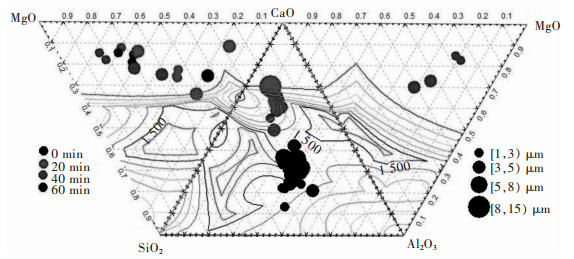

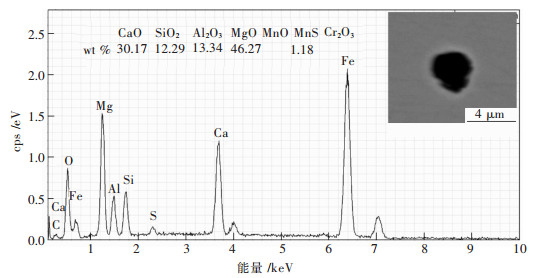

摘要: 通过钢渣平衡实验研究,分析了精炼渣成分对82B钢液T.O和点状不变形夹杂物成分的影响;通过Fact-Sage热力学计算,得出硅锰脱氧82B钢中MgO·Al2O3尖晶石夹杂的生成条件.结果表明:降低精炼渣碱度、提高Al2O3含量均利于钢水全氧含量的降低;随着Al2O3含量的提高,复合氧化物夹杂的熔点升高.当熔渣碱度为0.93、Al2O3含量为5.1%时,夹杂物熔点最低;熔渣碱度为1.14、Al2O3含量为25.6%时,高Al2O3活度的熔渣导致MgO·Al2O3尖晶石夹杂生成;熔渣碱度为1.97、Al2O3含量为25.9%时,由于碱度升高,钢中无MgO·Al2O3尖晶石类夹杂物生成;熔渣碱度为0.93、Al2O3含量为5.1%时,由于Al2O3含量降低,钢中无MgO·Al2O3尖晶石类夹杂物生成,且夹杂物熔点较低.Abstract: The effect of refining slag on the total oxygen content and D class inclusions in SWRH82B steel was studied by laboratory slag/steel reaction equilibrium experiments; The formation conditions of MgO·Al2O3 spinel inclusions is explained from chemistries of molten steels and slag compositions by Fact-Sage software. The results show that low basicity and high Al2O3 content of refining slag is beneficial to the removal of D class inclusions; The melting point of primary style composite oxide inclusions become higher while basicity and Al2O3 content of refining slag is getting increase. Melting point get to lowest when basicity and Al2O3 content is 0.93 and 5.1% respectively; Compare with controlled trial, MgO·Al2O3 spinel inclusions exist in steel when basicity and Al2O3 content of slag is 1.14 and 25.6% respectively.

-

Keywords:

- 82B Steel /

- refining slag /

- inclusions /

- MgO·Al2O3 spinel

-

原地浸出工艺在我国南方离子型稀土矿中推广应用已有二十多年的历史[1],工艺的不足逐渐显现,主要体现在2个方面:一是资源问题,表现在资源综合回收率偏低,据不完全统计,半数以上企业的资源综合回收率达不到75%[2-3];二是环境问题,表现在地质灾害频发,如江西龙南离子型稀土矿山因原地浸矿发生规模小、数量多的滑坡等地质灾害[4]。不同矿山具有不同的开采技术条件,需要进行专门的浸渗环节设计,但目前国内矿山生产管理粗放,常常简单套用一成不变的方法,甚至生搬硬套其他矿山的工艺和参数[5-6],是产生上述问题的主要原因。

研究表明,上述“资源-环境”问题均主要与矿山“注液-收液”的浸渗过程密切相关。浸渗过程的资源损失主要有浸矿盲区、母液渗漏和反吸附3部分[7],其中,前2项损失主要是注液工程、收液工程布置不合理及注液强度不当引起的。浸矿液流经矿体会对矿体的抗剪强度产生弱化作用[8-9],尤其是当注液强度大于矿山的出渗能力时,矿山浸润面不断上升,当浸润面达到临界水位面以上时,即可在瞬间发生滑坡[10]。而浸润面的高低形状则取决于矿山的水文地质条件、渗透性能、注液强度与出渗能力等因素。

对“浸渗环节”,很多学者基于室内试验,在机理层面研究了浸矿过程的浸出动力学[11-13]与传质过程[14-17],以筛选浸矿剂[18-20]、优化浸矿工艺;部分学者基于矿山生产现场试验,研究了原地浸矿过程中矿山内浸润面、土水压力及边坡表面裂缝的变化规律[4,21],提出矿山滑坡的防控措施[22]。这些研究成果为浸渗环节“事中观测,事后总结”阶段提供了有力的帮助,但难以用于“事先预测(设计)”阶段。因此,池汝安等[23]指出,从矿山宏观水动力学角度研究浸取剂溶液在矿体内部的渗流规律,可以更好地指导离子型稀土矿的原地浸出。

本文选取浑圆形裸脚式稀土矿山为研究对象,建立原地浸矿“注液-收液”轴对称简化模型,基于地下水动力学和Dupuit假定,在已知矿山地形条件及注液条件下推导矿山稳定浸润线方程,为原地浸矿浸渗环节的“事先预测(设计)”提供理论依据。

1 浑圆形裸脚式矿山原地浸矿稳定浸润线理论分析

1.1 矿山“注液-收液”轴对称简化模型

我国南方离子型稀土矿区多为低山丘陵地形,山头多为不规则的浑圆形 [24]。离子型稀土矿原地浸出工艺注液工程一般为梅花形布置的注液孔,沿山顶往山腰的一定范围内布置,注液孔直径一般为Φ=0.15~0.30 m,深度一般为见矿0.5~1.0 m。收液工程则根据矿山具体的工程地质条件确定,其中,裸脚式矿山具有较完整的天然基岩底板,且在山脚或山谷处有基岩出露,常在山脚开挖集液沟收集母液[25],其工艺如图1所示,图2所示为江西某浑圆形稀土矿山照片。

对于浑圆形裸脚式矿山,沿过中心轴线截取剖面,可得到“注液-收液”轴对称简化模型,如图3所示,对该模型作如下主要假设:

1)假设地表径流与地下径流分水岭在平面上重合处可作为中心轴线(r = 0),过中心轴线作垂直的H轴,取水平r轴与集液沟底板山脚出露点(图3中点C,坐标为r3,单位为m)相交,建立坐标系。

2)原地浸矿工艺要求集液沟能及时排除出渗母液,因此,可取点C为水头基准点(Hc = 0)。

3)基岩底板坡度一般较小,地形一般会有起伏,模型中简化为直线坡,按平均值β取值(单位:(°))。

4)修建集液沟时会挖除坡脚表层黏土直至矿层(见图1),因此,山坡出渗点B(坐标为r2,单位为m)处的坡度α(单位(°))一般较大。

5)图3中地下水的运动分为2个部分:①浸润线之上的注液区为非饱和渗流,属于土壤水分运动范畴,此处水流主要为在重力作用下的垂直向下渗流。单孔注液时,溶液从注液孔往周围非饱和矿体入渗,距离孔越远,矿体饱和度越低,湿润体的形状类似为椭球体[26-28];孔网注液时,由于孔与孔之间的相互影响,使得溶液在孔底以下一定范围外的非饱和矿体中的入渗变得均匀[25]。因此,图3中注液区(注液范围为r1,单位为m)的边界条件简化为均匀的入渗强度W(单位水平面积、单位时间内入渗补给到地下水的水量,单位为m/d)。②浸润线之下基岩底板之上的区域为饱和渗流,属于地下水动力学范畴,此处水流主要为在重力、基岩坡度及液面比降作用下的水平流动。本文浸润线方程主要由第二部分水流在地下水动力学原理下进行推导,因此,当基岩底板坡度比较平缓、液面比降不太大的情况下,可以忽略垂向分流速而采用Dupuit假定。

6)随着注液的持续进行,矿体内部逐渐从基岩底板开始往上饱和,浸润线也越来越高,直至趋于稳定。一般情况下,原地浸矿生产周期6~8个月,浸矿剂溶液在前40天左右注完[4],而后注入上清液,此时矿体内的浸润线已接近于稳定浸润线(图3中虚线所示)。因此,可以用稳定浸润线近似代替实际最高浸润线。

7)本文不考虑矿山土体渗透系数的空间变异性及各向同性。

1.2 稳定浸润线方程的推导

将图3视为轴对称问题,即假设在环向没有水流,过水断面为以点O为圆心的圆柱面,水头线为上凸的曲线。分析图3的流线可知,水流有径向和垂向2个方向的分流速,属于轴对称二维流。若允许引进Dupuit假定,忽略垂向分流速,则水流可简化为径向的一维流动计算[29]。

对于裸脚式稀土矿山,基岩底板一般从分水岭向集液坑方向(流线方向)呈顺坡倾斜(本文不考虑角度的正负值,取图3中α>β>0 °),当β<20 °时,渗流长度可以用径向距离来近似表示[29],水力坡度表示为-dH/dr。此时,H(r)=h(r)+tanβ·(r3-r),dH/dr= dh/dr-tanβ。依据水均衡原理,利用分段法,可得任意渗流断面处的总流量公式为:

(1) 式(1)中:Q(r)为任意渗流断面处的总流量数值,单位m3/d;W为注液入渗强度数值,单位m/d;r为任意渗流断面径向坐标数值,单位m;r1为注液范围数值,单位m;r2为出渗点B坐标数值,单位m。

根据Dupuit微分方程

(2) 式(2)中:β为基岩坡度数值,单位(°)。

对于注液区域(0≤r≤r1),可得

(3) 分离变量后,令λ = W/ks,作0→r的不定积分

(4) 由于H与r之间的函数关系未知,式(4)左边第三项无法积分,但可根据积分中值定理近似求解。令

,rm介于0→r之间,由于浸润线方程光滑,可近似取rm = r/2。因此,得到倾斜底板注液区域(0≤r≤r1)稳定浸润线方程 (5) 对于非注液区域(r1≤r≤r2),可得

(6) 分离变量后,作r1→r的不定积分

(7) 同理,根据积分中值定理近似求解式(7)左边第三项。令

,rd介于r1→r之间,由于浸润线方程光滑,可近似取rd=(r1+r)/2。因此,得到倾斜底板非注液区域(r1≤r≤r2)稳定浸润线方程 (8) 由于浸润线在渗出点B处与下游坡面相切[30],即B点应该满足以下2个条件

(9) (10) 式(9)、式(10)中:H2为出渗点B(r = r2)处水头数值,单位m;r3为C点坐标数值,单位m;α为出渗点B处的坡度数值,单位(°);JB为出渗点B处水力梯度。

将式(10)及点(r2, H2)代入式(8),并联合式(9),可得

(11) (12) 由于H1>H2>0,定f1=tanβ·(2r3-r1-r2),将点(r2, H2)代入式(11),可得

(13) 由于H0>H1,定f2=tanβ·(2r3-r1),将点(r1, H1)代入式(6),可得

(14) 综合式(5)、式(8)—式(14)可得到倾斜底板稳定浸润线方程

(15) 式(15)为一般情况下矿山稳定浸润线方程,对于基岩底板水平的情况,令β = 0°,可将式(15)简化为

(16) 根据式(15),均匀稳定注液入渗(λ>0)的条件下,注液区的浸润线是椭圆线的上半支,非注液区的浸润线是抛物线与对数曲线组成的复杂形状。令式(15)中的λ = 0、r1=0(即不注液),可求得H0=H1=H2=tanβ·r3,过水断面高度h0=h1=h2=0,与实际情况相符。经验表明,当注液入渗量不足时,基岩面难以形成完整的浸润线。因此,如果得到完整的浸润线,应该满足条件H0≥tan β·r3,将该条件代入式(15),即可求得给定注液范围下的最低注液强度或给定注液强度下的最小注液范围。

2 浸润线计算误差的参数分析

2.1 有限元模型与工况

为了进一步分析浸润线方程式(15)及式(16)的计算误差,根据矿山的地形条件和注液条件,提出4个参数:出渗坡度(α)、基岩坡度(β)、注液范围(r12/r32)和相对渗透系数(λ),按图3简化模型建立有限元模型,将有限元计算结果作为对照值,分析上述4个参数对浸润线方程计算误差的影响规律。其中,α可根据山脚集液沟设计和施工情况确定;β应根据矿山工程勘探资料给出的地质剖面图确定;r12/r32根据矿山注液方案中矿体分布情况确定,同时避开边坡坡度陡峭处;λ根据矿山注液方案和土体渗透系数ks确定,注液方案给出了矿山注液范围的面积A(单位:m2)和注液总强度Q(单位:m3/d),ks通过室内、外土体渗透性实验确定,则相对渗透系数λ=Q/(Aks)。

矿山建模高度为30 m,长度r3 = 50 m,计算工况见表1。

表 1 计算工况汇总Table 1. Summary of calculation conditions参数 取值 工况数 α /(°) 30.96 34.29 36.87 41.42 45.00 51.34 56.31 63.43* 71.57 82.41 10 β /(°) 0 2.29 4.57 7.97* 10.20 12.41 14.57 — — — 7 r12/r32 0.01 0.04 0.09 0.16 0.25* 0.36 0.49 — — — 7 λ 0.04 0.08 0.12 0.16 0.20* 0.24 0.28 0.32 0.36 — 9 注: “—”现场资料未提供数据;标有“*”的为模型参数的基本值,即:进行某一个参数的敏感性分析时,该参数按表1中数据从小到大取值,另外3个参数则取基本值。2.2 计算误差参数分析

典型工况(各参数均取基本值)下,浸润线对比分析如图4所示。由图4可知,方程计算浸润线基本位于数值计算浸润线之上,但两者非常接近,其计算误差沿流场方向逐渐增大,即注液段误差最小,中间段误差次之,出渗段(出渗点附近)误差最大;但在出渗点处,方程计算浸润线却位于数值计算浸润线之下。这是因为:本文浸润线方程的推导引入了Dupuit假定,该假定在地下分水岭附近及出渗点附近并不满足[29],分水岭附近,垂向流速较大,铅垂面十分接近流面,不能假定为等水头面,Dupuit假定忽略了垂向流速,因此,公式计算值一般要比实际值偏大;出渗段等水头面往往比较弯曲,水力梯度逐渐变大,以利地下水渗出成为地表水,并产生“水跃”现象,而Dupuit假定不能考虑“水跃”现象,且本文浸润线方程在出渗点处满足浸润线与出渗边坡相切的条件,造成浸润线在该处“弯曲”严重,因此,公式计算值一般要比实际值更小。

为进一步分析各参数对不同部位浸润线方程计算结果的影响,下面以分水岭(r = 0 m)、中间点(r12/r32 = 0.5)与出渗点(r = r2)分别分析4个参数对浸润线方程计算误差的影响规律。

浸润线计算误差随出渗坡度的变化曲线如图5所示,由图5可知:浸润线计算值在分水岭及中间点较数值解偏大,且随出渗坡度的增大而小幅增大,误差最大值为11.42%;浸润线计算值在出渗点较数值解偏小,且误差的绝对值随出渗坡度的增大呈现先增大后减小的变化趋势,当出渗坡度α=41.42°时,误差最小值为-13.51%。由于修建集液沟时会挖除坡脚表层黏土,出渗坡度α一般较大,因此,出渗坡度α对浸润线计算误差较小。

浸润线计算误差随基岩坡度的变化曲线如图6所示,由图6可知:浸润线计算值在分水岭及中间点较数值解偏大,在出渗点较数值解偏小,且误差的绝对值随基岩坡度的增大近似线性增大,该误差的产生是由于本文浸润线方程中水力梯度的计算忽略了基岩坡度的影响,而采用水平距离近似表示渗流长度,因此基岩坡度越大,误差越大。由于原地浸矿基岩坡度一般较小(β<15°),因此,出渗坡度对浸润线计算误差的影响较小。

浸润线计算误差随注液范围和相对渗透系数的变化曲线分别如图7和图8所示,由图7和图8可知:浸润线计算误差随注液范围和相对渗透系数具有类似的变化规律,即误差的绝对值随着注液范围或相对渗透系数的增大而减小。定义矿山相对注液强度Wr为矿山实际注液流量与矿山总面积下饱和注液流量之比,即Wr = λ·r12/r32,可知,图7和图8均反映的是浸润线方程计算误差随矿山相对注液强度Wr的变化规律,当相对注液强度Wr很小时,矿山基岩上甚至不能形成完整的浸润线,此时浸润线计算误差较大,这种情况只发生在原地浸矿注液初期;在注液稳定期,矿山相对注液强度Wr较大,矿山基岩上形成了较高的浸润线,浸润线方程计算误差较小。

3 结 论

1)选取浑圆形裸脚式稀土矿山为研究对象,建立原地浸矿“注液-收液”轴对称简化模型,基于地下水动力学和Dupuit假定,推导得到矿山稳定浸润线方程,方程以分段函数表示,其中注液区的浸润线是椭圆线的上半支,非注液区的浸润线是抛物线与对数曲线组成的复杂形状。

2)以有限元计算结果为对照值,分析出渗坡度、基岩坡度、注液范围和相对渗透系数等参数对浸润线方程计算误差的影响,发现方程计算浸润线基本位于数值计算浸润线之上,但两者非常接近,其计算误差沿流场方向逐渐增大,但对于原地浸矿而言,各参数取值对方程计算误差的影响较小。

3)原地浸矿浸润线的高低与形状是矿山“注液-收液”渗流场形成与发展的结果,同时浸润线的高低与形状又跟矿山边坡稳定性、矿体浸泡体积百分比及资源浸取率等密切相关,因此浸润线方程可为原地浸矿“注液-收液”浸渗环节的“事先预测(设计)”提供理论依据。

4)浸润线方程的求解需要确定地形条件(α、β和r3)和注液条件(r1和λ),模型参数比较多,某些参数不易获取,且模型和参数均作了一定程度上的简化,计算结果应充分评估后使用。

-

表 1 SWRH82B钢化学成分/(质量分数,%)

Table 1 Composition of SWRH82B Steel /(mass fraction, %)

表 2 精炼渣化学成分/(质量分数,%)

Table 2 Composition of the refining slag /(mass fraction, %)

-

[1] 汪庆国, 李京社, 唐海燕, 等. LD-LF-CC工艺生产的82B钢铸坯洁净度研究[J].中国冶金, 2011, 21(11):34-39. http://www.cnki.com.cn/Article/CJFDTotal-ZGYE201111011.htm [2] 缪新德, 于春梅, 石超民, 等.轴承钢中钙铝酸盐夹杂物的形成及控制[J].北京科技大学学报, 2007(8):771-775. doi: 10.3321/j.issn:1001-053x.2007.08.005 [3] 葛金朋.控制GCr15轴承钢中夹杂物的渣系研究[D].北京: 北京科技大学, 2016. [4] 孙彦辉, 方忠强.钙处理中间产物的形成及其对氧化铝夹杂的改性[J].北京科技大学学报, 2014, 36(12):1615-1625. http://d.old.wanfangdata.com.cn/Periodical/bjkjdxxb201412008 [5] YOUSEF P, MANSOUR S. Oxide inclusions at different steps of steel production[J]. Iron and Steel Research (International), 2007, 14(5):39-46. doi: 10.1016/S1006-706X(07)60072-7

[6] 王海华.不同精炼条件弹簧钢中夹杂物及其析出热力学研究[D].武汉: 武汉科技大学, 2014. http://cdmd.cnki.com.cn/article/cdmd-10488-1014395456.htm [7] 柴国强, 王福明.硬线钢Al2O3-SiO2-MgO-CaO-MnO系夹杂物低熔点区域控制[J].北京科技大学学报, 2009, 31(1):141-144. doi: 10.3969/j.issn.1008-2689.2009.01.026 [8] 赵和明, 谢兵. LF炉精炼渣冶金性能的研究现状[J].钢铁钒钛, 2002, 23(4):53-58. doi: 10.3969/j.issn.1004-7638.2002.04.012 [9] 雪殷, 孙彦辉, 帅焦, 等.精炼渣成分对硅锰脱氧弹簧钢夹杂物影响的实验室研究[A]//第11届中国钢铁年会[C]. 2017: 1-7. http://cpfd.cnki.com.cn/Article/CPFDTOTAL-ZGJS201711003053.htm [10] 张立恒, 王国承, 朱青德. HP295钢中非金属夹杂物形成的热力学分析[J].有色金属科学与工程, 2011, 2(6):22-28. http://ysjskx.paperopen.com/oa/DArticle.aspx?type=view&id=20110605 [11] 姜敏, 陈斌, 杨文, 等.合金结构钢中尖晶石夹杂物生成的热力学研究[J].特殊钢, 2008, 29(1):16-18. doi: 10.3969/j.issn.1003-8620.2008.01.006 [12] PARK J H, TODORKI H. Control of MgO-Al2O3 Spinel inclusions in stainless steels[J]. ISIJ International, 2010, 50(10):1333-1346. doi: 10.2355/isijinternational.50.1333

[13] PARK J H, TODORKI H. Inclusions in stainless steels-areview[J]. Steel Research int, 2017, 88(12):1-26.

[14] 蔡茜娜, 汪志刚.钇基稀土对51CrV4弹簧钢冲击韧性的影响[J].有色金属科学与工程, 2018, 9(4):97-101. http://ysjskx.paperopen.com/oa/DArticle.aspx?type=view&id=201804016 [15] 尹振江, 彭园龙.钇基稀土对51CrV4弹簧钢夹杂物影响[J].有色金属科学与工程, 2017, 8(4):26-30. http://ysjskx.paperopen.com/oa/DArticle.aspx?type=view&id=201704005 [16] 卓晓军, 毕丽艳.硅锰钛脱氧钢中锰钛氧化物夹杂的热力学计算以及MnS的溶解度[A].第七届(2009)中国钢铁年会[C].2009: 8. http://cpfd.cnki.com.cn/Article/CPFDTOTAL-ZGJS200911006168.htm [17] 卓晓军, KIM H-S, KANG Y-B, 等.硅锰钛脱氧钢中以锰钛氧化物和硫化锰夹杂物物为形核核心的晶内铁素体形成研究[A]. 2005中国钢铁年会[C]. 2005: 8. http://cpfd.cnki.com.cn/Article/CPFDTOTAL-ZGJS200510004153.htm [18] 赖朝彬, 赵青松.晶内铁素体及其组织控制技术研究概况[J].有色金属科学与工程, 2014, 5(6):53-60. http://ysjskx.paperopen.com/oa/DArticle.aspx?type=view&id=201406009 [19] 王昆鹏, 姜敏, 王新华, 等.钢帘线和切割丝用钢夹杂物控制技术的进展[J].特殊钢, 2016(2):26-31. doi: 10.3969/j.issn.1003-8620.2016.02.008 [20] WANG K, JIANG M, WANG X, et. Formation mechanism of CaO-SiO2-Al2O3-(MgO) inclusions in Si-Mn-killed steel with limited aluminum content during the low basicity slag refining[J]. Metallurgical and Materials Transactions B, 2015, 47(1). http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=7cd9a8fedcb7e4bb2b9987ae36150f82

[21] 姜敏, 王昆鹏, 侯泽旺, 等.低氧特殊钢中大尺寸DS类夹杂物生成机理[J].工程科学学报, 2016(6):780-786. http://d.old.wanfangdata.com.cn/Periodical/bjkjdxxb201606006 [22] 姜敏, 王昆鹏, 王新华, 等.高品质切割丝中夹杂物生成与演变机理[A].第十九届(2016年)全国炼钢学术会议[C].2016: 1. http://cpfd.cnki.com.cn/Article/CPFDTOTAL-ZGJS201605001145.htm [23] 王海涛, 郝宁, 金利玲, 等. CaO-SiO2-Al2O3-MnO系低熔点区域控制[J].中国稀土学报, 2006, 24(S):68-73. http://d.old.wanfangdata.com.cn/Periodical/bjkjdxxb200706006 [24] 陈斌.钢液-炉渣间的反应平衡及合金钢中非金属夹杂物的研究[D].北京: 北京科技大学, 2007. [25] 董文亮.超低氧齿轮钢精炼渣的工艺优化及镁铝尖晶石夹杂控制研究[D].武汉: 武汉科技大学, 2014. http://cdmd.cnki.com.cn/Article/CDMD-10488-1014389479.htm -

期刊类型引用(2)

1. 刘德峰,张世佳,张臻悦,郭文达,池汝安. 风化壳淋积型稀土矿浸润线空间分布特征及影响因素敏感性分析. 稀土. 2025(01): 1-13 .  百度学术

百度学术

2. 王忠锋,冯羽生,黄伟玲. 不同结构组态对导流筒搅拌槽混合效率影响分析. 有色金属科学与工程. 2024(06): 814-821+855 .  本站查看

本站查看

其他类型引用(1)

下载:

下载: