Effect of ore blending optimization on the metallurgical properties of sinter

-

摘要: 针对永锋钢铁公司烧结原料结构, 明确烧结目标, 进行烧结杯优化配矿实验, 以达到提高烧结矿成矿率、利用系数、成品矿品位、转鼓强度以及降低其返矿率的目的.实验运用扫描电镜观察成品矿形貌显微结构; 用成品烧结矿还原实验的检测数据, 探究优化配矿对成品烧结矿还原性能的影响; 并对比现场烧结配矿前、后的各项指标.实验结果表明:在现场烧结配矿条件下(在将巴混配比提高6 %, 燃料比降低至4 %, 烧结负压为11 kPa)通过优化配矿, 成品烧结矿转鼓强度可达到70.93 %, 成品率及利用系数分别为84.44 %、1.77 (t/m2h), 烧结矿品位为53.7 %, 还原度高达83.5 %, 可以保证高炉稳定生产.Abstract: The structure of sintering material of Yongfeng Iron and Steel Limited Company having been studied to clarify the sintering targets where the sintering pot was optimized for ore matching experiments to achieve the objectives of increasing the ore-forming rate, utilization coefficient, finished mineral grade and drum strength and reducing return fines ratio. Scanning electron microscopy was used to observe the shape of the finished sinter; the effect of optimized ore blending on the reduction performance of the finished sinter was investigated through the reduction test; indicators before and after the optimization of ore blending experiment were compared. The experimental results showed that under such on-site sintering ore blending conditions (the blending ratio of BRBF increasing by 6 %, the fuel ratio reducing to 4 % and the sintering negative pressure being 11 kPa), after ore blending optimization, the drum strength, yield, utilization coefficient, sinter grade and reduction degree of finished mineral were 70.93 %, 84.44 % 1.77 (t/m2·h), 53.7 %, and 83.55 %, respectively, which could guarantee stable production of blast furnace.

-

Keywords:

- ore blending optimization /

- ore-forming rate /

- drum strength /

- reduction degree

-

2017年, 我国钢铁市场趋于缓和, 市场需求逐步改善, 促进了钢铁企业进一步达到盈利状态; 为提高吨钢利润, 降低生产成本, 提升行业竞争力, 钢铁生产企业对铁矿石原料的要求也越来越高, 同样, 钢铁企业的能耗量占我国总能耗的16.3 %[1], 为降低原料能源消耗, 优化配矿也是最捷径的节能方法, 所以必须通过对铁矿粉进行配矿来改善烧结矿的各项冶金性能指标.我国主要的高炉炼铁原料为烧结矿, 因此烧结矿质量的好坏也是高炉顺行的关键, 烧结配矿结构不仅与铁矿粉、熔剂、燃料有关, 而且与铁矿粉之间的合理搭配有关[2].生产实践指出, 铁矿粉的常温性能主要决定烧结生产的经济指标, 而其高温性能是烧结生产技术指标及烧结矿性能的关键[3-5].永锋钢铁公司为稳定炉料结构, 降低能耗, 提高产量及质量水平, 进行了烧结杯试验以调控原料结构, 达到高炉冶炼要求.本实验主要依据永锋钢铁公司原料条件, 进行优化配矿研究.

1 实验原料成分及配矿方案

实验主要以巴混(高硅)、混匀料、精粉、大混匀、Pb粉、返矿为含铁原料, 以白云石、生石灰为熔剂, 以焦粉为燃料, 进行不同比例的配矿研究, 原料成分结果如表 1所列, 配矿方案如表 2所列, 实验基础特性检测指标如表 3所列.由表 1可知, 铁品位由高到低为:地方精粉>巴混>Pb粉>大混匀>混匀.由原料基础特性指标可知, 巴混、Pb粉及地方精粉同化温度均较低, 同化性能较好.

表 1 原料成分/(质量分数, %)Table 1. Raw material composition /(massfraction, %) 表 2 实验配矿方案/(质量分数, %)Table 2. Experimental matching ore scheme /(massfraction, %)

表 2 实验配矿方案/(质量分数, %)Table 2. Experimental matching ore scheme /(massfraction, %) 表 3 实验原料基础特性Table 3. Basic characteristics of experimental raw material

表 3 实验原料基础特性Table 3. Basic characteristics of experimental raw material

在配矿方案中, 1#为现场配矿比例; 在现场配矿情况的基础上, 分别调整各含铁原料比例、负压及燃料比:其中, 2#为巴混配比提高4 %, 负压为11 kPa; 3#为巴混配比提高6 %, 负压为11 kPa, 燃料比降低至4 %; 4#为Pb粉配比提高6 %, 负压为12 kPa; 5#为巴混配比提高4 %, 负压为12 kPa, 燃料比降低至4 %.用配制好的矿粉进行烧结杯试验, 其主要步骤为混料、装料、点火烧结、落下筛分及转鼓检测.最后依据国家标准进行还原检测.配矿实验均是进行3组烧结杯实验后得出的相应优化结果.

2 试验结果及分析

2.1 优化配矿前后成品烧结矿成分分析

优化前后的烧结矿成分分析如表 4、表 5所列.对比表 4、表 5可知, 由于实验设备的限制, 烧结杯实验中的烧结矿品位略微降低, 但与1#基准烧结杯实验相比, 2#、3#配矿方案的铁品位略有降低, 4#、5#配矿方案的铁品位略微提高.提高含铁品位, 可有效降低高炉焦比及提高产量, 研究发现[6], 铁品位提高1 %, 可降低焦比2 %, 提高产量3 %.同时, 烧结矿碱度也有所变化; 提高碱度, 会促进铁酸钙的发展, 增强烧结矿被还原能力, 可提高烧结矿质量水平[7].烧结过程中, 碱度不仅对烧结矿的产量及质量有影响, 同样也在高炉冶炼中, 对高炉升温还原过程及其炉料结构产生重大影响[8-12].张立恒等[13]研究了碱度对高铬型钒钛矿烧结过程的影响, 结果表明, 随着碱度的提高, 烧结矿垂直烧结速度、利用系数、转鼓强度均有所提高, 但其成品率、抗磨指数均有下降; 同样, 烧结矿的还原粉化指数RDI+6.3提高, 而RDI-0.5和RDI-3.15指标降低.它对于高炉而言, 其软熔区间变窄, 软熔带下移, 透气性逐步提高, 会促进高炉顺行.

表 4 优化前两台烧结机所生产烧结矿化学成分/(质量分数, %)Table 4. Chemical composition of the sinter produced by two sintering machines before optimization /(massfraction, %) 表 5 优化后烧结杯实验生产烧结矿化学成分/(质量分数, %)Table 5. Chemical composition of the sinter produced by sinter pot experiment after optimization /(massfraction, %)

表 5 优化后烧结杯实验生产烧结矿化学成分/(质量分数, %)Table 5. Chemical composition of the sinter produced by sinter pot experiment after optimization /(massfraction, %)

2.2 优化后的烧结矿返矿率、成品率、垂速、固体燃料及利用系数

表 6所列为优化后的成品矿返矿率、成品率等冶金性能指标.由于受烧结杯实验设备的影响, 对比基准实验1可知, 烧结矿返矿率均有所提高, 成品率及垂速降低, 固体燃料消耗整体提高(除实验3外), 利用系数也普遍降低.但以上指标均变化较小, 均可在现场烧结机上进行改善, 以满足冶炼要求.

表 6 优化后成品矿的返矿率、成品率、垂速、固体燃料及利用系数Table 6. Return ore rate, yield, sintering speed, solid fuel and productivity of sintered product after optimization

2.3 优化配矿对成品烧结矿转鼓强度的影响

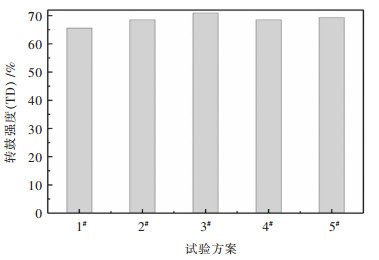

图 1所示为优化配矿后不同方案的成品烧结矿转鼓强度之柱状图.由图 1可知, 在降低燃料比的条件下, 随着巴混含量的提高, 铁品位、SiO2含量及碱度均维持在较高水平; 与其他配矿方案相比、实验3的转鼓强度最高, 其值为70.93 %, T>70 %, 达到我国优质烧结矿要求.这是由于成品烧结矿中SiO2含量对于烧结矿质量影响较为明显[14-15], 在烧结过程中, SiO2作为液相的主要组分, 其含量较少时, 液相生成量及黏结相变少, 从而导致烧结矿强度下降.而随着SiO2含量的提高, 烧结过程大量的液相会黏结其周围的铁精粉, 黏结相的增多增加烧结矿强度; 同时实验3中生成较多针状铁酸钙也进一步提高烧结矿转鼓强度[16].

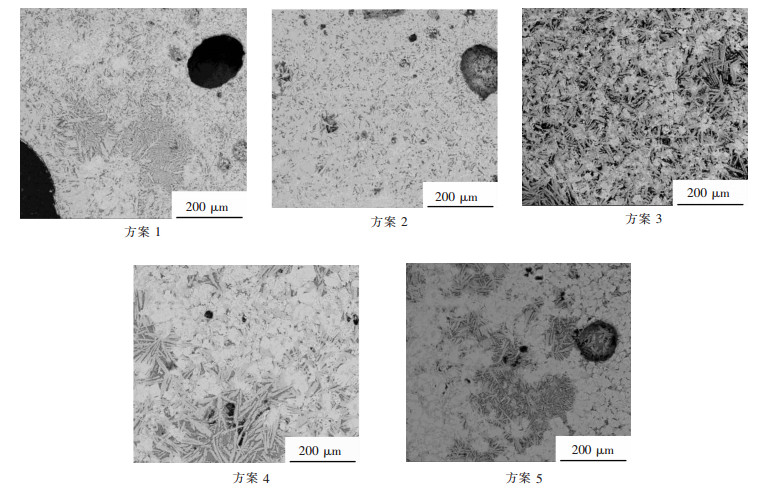

2.4 配矿方案对成品烧结矿显微结构的影响

由图 2可以看出, 在各配矿方案的各SEM照片中, 方案1、方案2、方案4、方案5均出现少量的针状或纤维状铁酸钙, 以及大量片状铁酸钙.而方案3中出现大量的针状铁酸钙.实验证明, 在碱度R为1.7~2.1, 温度为1 275 ℃左右时, 可大量生成针状铁酸钙; 且在还原过程中它最先被还原, 强度高; 可以说.铁酸钙针状是还原性最好的显微结构[17].

2.5 配矿方案对成品烧结矿还原性的影响

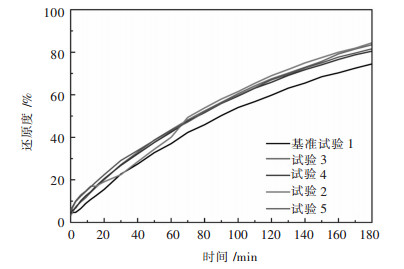

还原性是检验烧结矿的重要指标.在高炉内, 若提高烧结矿的还原性, 可增加其间接还原的比例, 从而达到节能降耗的目的[18].按照国标(GB/T13241-1991)方法[19]分别将基准实验1、实验2、实验3、实验4及实验5的烧结矿试样破碎、并选取500 g、10~2.5 mm粒级试样进行烧结矿还原性实验.该实验用立式电炉还原炉, 还原气体为30 %CO+70 %N2, 流量为15 L/min.实验开始前, 在氮气保护性气氛下将炉温升至900 ℃, 温度到达后放入试样, 将气体切换为还原性气体.试样放置在石墨坩埚中, 并连接炉体上部的天平, 并由计算机实时记录天平重量变化, 并将还原180 min的试样的还原度作为实验最终还原度.实验结果如图 3所示.

从图 3中可知, 基准实验1、实验2、实验3、实验4及实验5的还原度分别为74.5 %、84.4 %、83.5 %、80.5 %和81.6 %.但综合FeO含量来看, 实验3的烧结矿FeO含量只有6.78 %, 而基准实验烧结矿样品FeO含量为9.82 %, 其余试样的FeO含量均超过了10 %, 这是由于FeO会随着SiO2含量的升高而降低, 而还原度则会随FeO的上升逐步降低; 这是因为FeO是Fe2+来换算, Fe2+多存在于各种矿物之中, 如橄榄石(2FeO·SiO2)、钙铁橄榄(CaO·FeO·SiO2)等, 随着FeO含量的提高橄榄石等矿物质量分数提高, 赤铁矿与铁酸钙含量会逐步减少, 而矿物在还原过程的递减顺序为赤软矿→铁酸钙→磁铁矿→钙铁橄榄石→硅酸铁的缘故.因此还原性会随FeO含量的增加而降低, 同时因FeO的升高, 烧结矿内部结构会变得致密, 孔隙度降低, 同样也会影响烧结矿的还原性[20].为此、实验3中的铁酸钙均以针状形式存在, 且孔隙较多, 铁氧化物与还原气体充分反应, 易被还原.这就证明在本实验3的条件下、其烧结矿还原性能最好; 同时也说明铁矿粉的类别、性质以及其孔隙度等是决定烧结矿还原性的重要指标; 对于高碱度烧结矿, 其铁酸钙的还原性较好, 而对于含有铁橄榄石及钙铁橄榄石的烧结矿, 其还原性较差[21].

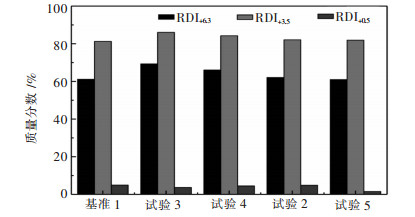

图 4所示为转鼓指数大于68 %的烧结矿低温还原粉化实验结果.其中实验3的RDI+6.3和RDI+3.5分别达到了69.3 %和86 %.蓝荣宗, 王静松等[22]认为, 在富氧高炉中, 烧结矿低温还原分化率高于传统高炉, 所以对于低温还原粉化率较低的烧结矿, 可在后续研究过程中应用于富氧高炉中.以综合成矿率、转鼓指数、还原性能和低温还原粉化性能等指标衡量, 实验3的烧结矿之冶金性能最好.

3 结论

1) 在永锋钢铁公司所拥有的原料条件下, 可适当提高巴混含量的同时降低燃料比, 以降低原料成本, 获得更高的经济效益.因此, 可以在原有配矿原料基础上提高巴混比例6 %, 降低燃料比至4 %, 负压设定为11 kPa, 此配矿方案可用于指导生产实践.

2) 通过实验研究可知, 实验方案3的FeO含量为6.78 %、成品率为84.44 %、利用系数为1.77(t/m2h)、转鼓强度为70.93 %、还原度为83.5 %、低温还原粉化率RDI+6.3和RDI+3.5分别为69.3 %和86 %, 是目前条件下该公司较优的配料方案; 它可作为永锋钢铁公司烧结配矿的生产指导方案在生产中应用.

-

表 1 原料成分/(质量分数, %)

Table 1 Raw material composition /(massfraction, %)

表 2 实验配矿方案/(质量分数, %)

Table 2 Experimental matching ore scheme /(massfraction, %)

表 3 实验原料基础特性

Table 3 Basic characteristics of experimental raw material

表 4 优化前两台烧结机所生产烧结矿化学成分/(质量分数, %)

Table 4 Chemical composition of the sinter produced by two sintering machines before optimization /(massfraction, %)

表 5 优化后烧结杯实验生产烧结矿化学成分/(质量分数, %)

Table 5 Chemical composition of the sinter produced by sinter pot experiment after optimization /(massfraction, %)

表 6 优化后成品矿的返矿率、成品率、垂速、固体燃料及利用系数

Table 6 Return ore rate, yield, sintering speed, solid fuel and productivity of sintered product after optimization

-

[1] 苍大强.国内外冶金工业源头节能减排的新方法、新技术[J].有色金属科学与工程, 2015, 6(6):1-6. http://ysjskx.paperopen.com/oa/DArticle.aspx?type=view&id=201506001 [2] 刘振林, 温洪霞, 冯根生, 等.济钢常用铁矿石烧结基础特性的研究[J].钢铁, 2004, 39(7):7-11. doi: 10.3321/j.issn:0449-749X.2004.07.002 [3] 武轶, 吴胜利, 杜建新.马钢常用铁矿石的烧结基础特性研究[J].钢铁研究, 2008, 36(4):5-8. http://d.old.wanfangdata.com.cn/Periodical/gtyj200804002 [4] 石凤丽, 郭卓团, 安胜利, 等.蒙古矿及配矿后的烧结基础特性实验研究[J].内蒙古科技大学学报, 2012, 31(3):205-208. doi: 10.3969/j.issn.2095-2295.2012.03.001 [5] 刘东辉, 吕庆, 孙艳芹, 等.铁矿粉基础特性对烧结矿性能的影响[J].钢铁研究学报, 2013, 25(11):29-34. http://d.old.wanfangdata.com.cn/Periodical/gtyjxb201311006 [6] 张汉泉.烧结球团理论与工艺[M].北京:化学工业出版社, 2015: 213. [7] 陈子罗, 张建良.烧结矿适宜的SiO2质量分数和碱度[J].钢铁, 2016, 51(12):8-14. doi: 10.3969/j.issn.1006-6764.2016.12.003 [8] 杜鹤桂.高炉冶炼钒钛磁铁矿原理[M].北京:科学出版社, 1996. [9] 王筱留.钢铁冶金学炼铁部分[M].北京:冶金工业出版社, 1995. [10] 周取定, 孔令坛.铁矿石造块理论及工艺[M].北京:冶金工业出版社, 1992. [11] 王喜庆.钒钛磁铁矿高炉冶炼[M].北京:冶金工业出版社, 1994. [12] 唐贤荣, 张青岑.烧结理论与工艺[M].长沙:中南工业大学出版社, 1992. [13] 张立恒, 李万礼, 岳宏瑞, 等.碱度对高铬型钒钛矿烧结过程的影响[J].有色金属科学与工程, 2014, 5(4):18-22. http://ysjskx.paperopen.com/oa/DArticle.aspx?type=view&id=201404032 [14] ZHAO Y, WU K, SHEN W, et al. Guiding sintering ore matching based on a new evaluation method about sintering basic characteristics[J]. Iron and Steel, 2015, 50(9): 23-27. http://d.old.wanfangdata.com.cn/Periodical/gt201509004

[15] ZHANG Y Z, FENG X P, LI Z G, et al. Study on strengthening of low silica sinter and application in production[J]. Iron and Steel, 2004, 39(8):38-42. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=gt200408006

[16] GAO Y J.Study on Mechanism of SiO2 Content on Sinter Strength[Dissertation].Tangshan: Hebei United University, 2011.

[17] 陈耀铭, 陈锐.烧结球团矿微观结构[M].长沙:中南大学出版社, 2011:80. [18] PAN W, WU K, ZHAO X, et al.Reduction kinetics of Shougang iron ore sinter[J]. Univ Sci Technol Beijing, 2013, 35(1):35-40. http://d.old.wanfangdata.com.cn/Periodical/bjkjdxxb201301006

[19] State Bureau of Technical Supervision.GB/T 13241-1991 Iron ores-Determination of Reducibility[M]. Beijing: China Standard Press, 1991.

[20] 郝素菊.高炉炼铁500问[M].北京:化学工业出版社, 2008. [21] 蒋大军, 何木光, 甘勤, 等.高碱度条件下FeO对烧结矿性能的影响[J].中国冶金, 2008, 18(11):14-21. doi: 10.3969/j.issn.1006-9356.2008.11.004 [22] 蓝荣宗, 王静松, 韩毅华, 等.高还原势气氛下烧结矿低温还原粉化试验研究[J].有色金属科学与工程, 2012, 3(1):5-9. http://ysjskx.paperopen.com/oa/DArticle.aspx?type=view&id=201201002 -

期刊类型引用(3)

1. 刘林程,左海滨,许志强. 碳对石膏还原分解的影响. 江西冶金. 2021(03): 1-9+69 .  百度学术

百度学术

2. 王兴建,孙长余,孟凡俭,张智恩,张加财,张新禹,俞新宇. 不同碱度和Al_2O_3质量分数烧结矿还原行为的研究. 辽宁科技大学学报. 2021(02): 81-84+91 .  百度学术

百度学术

3. 赵佐军. 基于六西格玛精益管理提高烧结矿还原性实践. 烧结球团. 2019(05): 32-37 .  百度学术

百度学术

其他类型引用(0)

下载:

下载: