Preparation of carbon nanotube conductive paste and its effect on electrochemical performance of LiNi0.8Co0.1Mn0.1O2

-

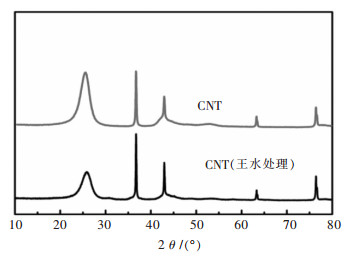

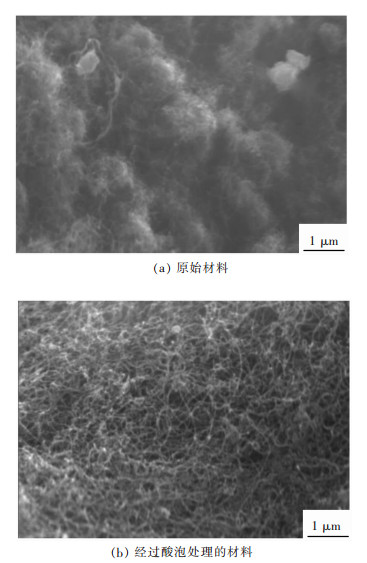

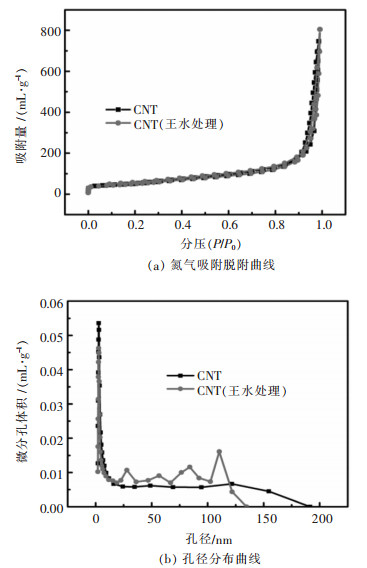

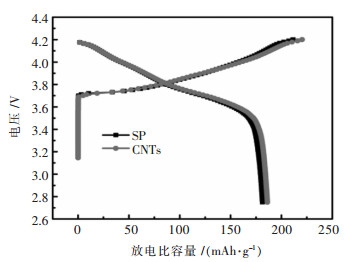

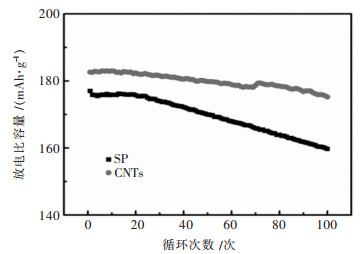

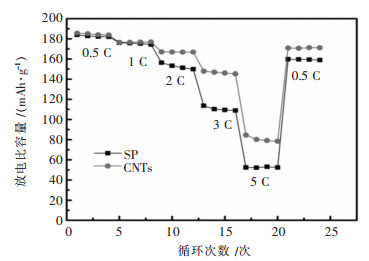

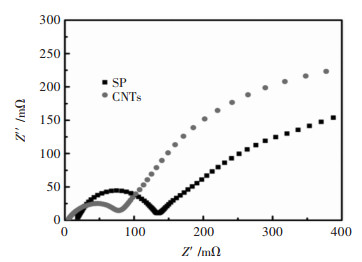

摘要: 用CVD法制备碳纳米管,通过强酸超声处理后溶解在N-甲基吡咯烷酮(NMP)中制备成碳纳米管导电浆料,利用XRD,SEM,BET考察了制备的碳纳米管导电剂浆料的结构和表面形貌,并考察了其作为导电剂对LiNi0.8Co0.1Mn0.1O2锂离子电池电化学性能的影响;研究结果表明经过王水处理后的碳纳米管获得了更好的分散性,并且得到了更多的介孔。添加了碳纳米管导电浆料的电池首次放电比容量是186.1 mAh/g,而未添加碳纳米管导电浆料的电池首次放电比容量是181.2 mAh/g。添加了碳纳米管导电浆料的电池循环性能更好,100次循环容量保持率是95.95%;添加了碳纳米管导电浆料的电池大倍率性能优越,在2C、3C、5C倍率下要明显高于单独用SP做导电剂的电池(1 C=180mA/g)。并且,添加碳纳米管导电浆料的电池电极界面阻抗要小。

-

关键词:

- CVD /

- 王水 /

- 碳纳米管 /

- LiNi0.8Co0.1Mn0.1O2 /

- 导电剂

Abstract: Carbon nanotubes were prepared by CVD method, and dissolved in N-methylpyrrolidone (NMP) by ultrasonic treatment with strong acid to prepare conductive paste of carbon nanotubes. The structure and surface morphology of the prepared carbon nanotube conductive agent slurry were investigated by XRD, SEM and BET, And the effect of adding it as a conductive agent on the electrochemical performance of LiNi0.8Co0.1Mn0.1O2 lithium ion battery was investigated.The results show that the carbon nanotubes have better dispersibility and more mesopores after treatment with aqua regia. the battery adding carbon nanotube conductive paste shows good capacity performance, and its first discharge capacity is 186.1 mAh/g, while the battery using the common conductive agent first discharge capacity is 181.2 mAh/g, This shows good cycling performance, capacity retention rate was 95.95% after 100 cycles, carbon nanometer was added The battery of the conductive paste has superior large-rate performance, and is significantly higher at 2C, 3C, and 5C rates than the battery added the conductive of SP (1 C=180mA/g).Moreover, the cell electrode interface impedance of the carbon nanotube conductive paste was added is small.-

Keywords:

- CVD /

- Aqua regia /

- Carbon nanotube /

- LiNi0.8Co0.1Mn0.1O2 /

- Conductive agent

-

钇铁合金主要用于钕铁硼永磁体的添加剂[1],铸造领域[2]、球化剂[3]、核燃料稀释剂等.用钇铁合金变质剂可提高耐磨件的工体寿命[4],由此可见,钇铁合金正在各个领域被广泛使用[5].然而在大多数稀土铁合金中非稀土杂质的检测都已制定了相应的国家或行业标准分析方法[6]但由于钇铁合金为新型产品,对该产品中非稀土杂质的测定仍无相应的国家或行业标准.随着钇铁合金在各领域广泛应用,对其非稀土杂质(铝、硅、钙、镁、锰)的检测也将越来越重要.电感耦合等离子体原子发射光谱法(ICP-AES)分析技术自20世界60年代问世以来,并因其具有的检出限低,基体效应小,精密度高,灵敏度高,线性范围宽以及多元素同时分析等诸多优点而得以广泛应用[7-8].所提方法研究了采用电感耦合等离子体原子发射光谱法(ICP-AES)[9]、基体匹配法[10-11]测定钇铁合金中铝、硅、钙、镁、锰,方法简单、快捷、准确.

1 试验

1.1 仪器与试剂

ULTIMA 2电感耦合等离子体原子发射光谱仪.标准溶液:取1.0000 g/L被测元素储备溶液,采用逐级稀释法分别配制成100 mg/L、10 mg/L单一标准溶液,盐酸(1+9)介质.

盐酸为优级纯, 试验用水为超纯水(电阻率18 MΩ·cm)

1.2 仪器工作条件

输出功率为1.0 kW,反射功率小于2 W,观测高度14 mm,高斯积分,冷却气流量12 L/min,护套气0.3 L/min,进样速率1.0 mL/min,积分时间0.3~0.5 s.

1.3 试验方法

1.3.1 标准溶液的配制

配置二套标准, 一套为基体匹配(用于测定样品);一套为不带基体(用于测定试剂空白).

采用基体匹配方法配制标准溶液,基体为2.0000 g·L-1金属钇与金属铁(其中:铁35%、钇65%)混合溶液.用多元素含量阶梯配制方式配成3个标准溶液系列,3个标准溶液中铝、硅、钙、镁、锰各为0、1.00、2.00 mg/L,盐酸(1+19)介质,用作样品检测;另采用不加基体方法配制标准溶液,用多元素含量阶梯配制方式配成3个标准溶液系列,3个标准溶液中铝、硅、钙、镁、锰各为0、1.00、2.00 mg/L,盐酸(1+19)介质,用作试剂空白检测.

1.3.2 样品制备及检测

称取钇铁合金样品0.2000g于100 mL烧杯中,加盐酸(1+1)溶液10 mL,低温加热分解清亮,取下冷却,用水定容于100 mL容量瓶中,混匀,同时以相同条件制试剂空白.用相应标准溶液,按仪器工作条件对样品与试剂空白进行检测.最后结果扣除试剂空白.

2 结果与讨论

2.1 分析谱线的选择

谱线的选择主要考虑无基体干扰、共存元素干扰、激发电位低、根据光谱线波长表[12-13]预选出几条强度大的谱线进行轮廓扫描,选出一条背景平坦、信倍比大、的分析谱线[14].各元素分析线的选择见表 1.

表 1 各元素的分析线及检出限Table 1. Analytical spectral lines and detection limits of the elements元素 分析线/nm 检出限ρ/(mg·L-1) 测定下限ρ/(mg·L-1) Al 396.152 0.015 0.050 Si 288.158 0.016 0.053 Ca 393.366 0.0042 0.014 Mg 279.553 0.0034 0.011 Mn 257.610 0.0043 0.014 2.2 共存元素干扰试验

选用钇铁合金53JYFe01样品为试验对象.分别在样品中单一加入共存元素(Al、Si、Ca、Mg、Mn)量,加入量为一般钇铁合金样品最高出现含量的2.5倍(即5.00 mg/L),进行干扰试验.实验证明,各共存元素在5.00 mg/L含量时,在所选用分析谱线范围内互不干扰.见表 2.

表 2 共存元素干扰试验Table 2. Coexisting element interference test项目 Al Si Ca Mg Mn 53JYFe01原含量 0.837 0.858 0.0100 0.072 0.454 Al加入5.00 mg/L / 0.855 0.0102 0.071 0.457 Si加入5.00 mg/L 0.840 / 0.0097 0.072 0.456 Ca加入5.00 mg/L 0.830 0.850 / 0.070 0.453 Mg加入5.00 mg/L 0.838 0.856 0.0103 / 0.460 Mn加入5.00 mg/L 0.835 0.860 0.0105 0.078 / 注:空白处表示加入的干扰元素正好是所对应的共存元素,固不列数据. 2.3 标准溶液的基体匹配

1)基体匹配法相对于去基体法,在分析结果上并无明显差异.见表 3以钇铁合金53JYFe01为例,分别列出了基体匹配法与去基体法结果.基体匹配法相对于去基体法最大的差异是:前者步骤简单而后者步骤繁琐,繁琐的步骤引起误差的概率也随之增大.

表 3 基体匹配与去基体结果对比Table 3. Matrix matching and matrix results contrast方法 Al

/(mg·L-1)Si

/(mg·L-1)Ca

/(mg·L-1)Mg

/(mg·L-1)Mn

/(mg·L-1)基体匹配法 0.837 0.858 0.0100 0.072 0.0454 去基本法 0.821 0.840 0.0091 0.070 0.0439 2)基体匹配法可以消除盐效应.溶液的粘度等物理性质均随溶液含盐的增加而增大,从而影响溶液的进样量、雾化效率及气溶胶传输效率并最终影响谱线强度.消除盐效应的根本方法是基体匹配,保持标准溶液和分析溶液有相同的含盐量[15].试验采用基体匹配配制方式,很好的解决了盐效应.

由于工业化生产的钇铁合金产品中,钇-铁比例一般为65%-35%之间,所以方法以此比例为基体研究对象.而在工业生产中钇-铁比例也不能排除存在波动,为了使方法的适用范围更广泛,因此增加基体波动影响试验.分别配制钇-铁比例为60%-40%与70%-30%的基体,其他杂质各为0.10 g/L进行测定.实验证明钇-铁基体比例在60%~40%与70%~30%之间变化时对测定无明显影响,见表 4.

表 4 钇-铁基体比例在60%~40%与70%~30%波动影响实验Table 4. Effects of matrix proportion of Y and Fe on determination results元素 参照值/(mg·L-1) 钇-铁(60%~40%)

测定值/(mg·L-1)钇-铁(70%~30%)

测定值/(mg·L-1)Al 0.100 0.103 0.102 Si 0.100 0.109 0.097 Ca 0.100 0.103 0.100 Mg 0.100 0.102 0.101 Mn 0.100 0.105 0.098 2.3 仪器工作条件和工作参数的选择

在化学实验中,影响实验结果的因素多,所波及的水平和所需实验次数也多.如果进行所有的实验,不但在成本上造成浪费,且给实验者带来许多无须有的麻烦,而最终还不一定选择到最佳的条件组合.正交试验正是克服以上的不足,它利用一种科学的表格──正交表来安排实验,以期获得满意的效果[16].所提方法根据影响测定的主要因素,采用4因素3水平正交设计,按L9(34)正交表安排试验.以(I-Ib)和I/Ib的综合值为评价指标,选择最佳仪器工作条件和工作参数,因Si的谱线相对较弱,则以Si线为试样对象,正交设计实验表见表 5,最佳值见1.2仪器工作条件.

表 5 正交设计因素、水平Table 5. Results of orthogonal test for instrumentation conditions水平 功率/kW 观测高度/mm 冷却气流

量/(L·min-1)护套气流

量/(L·min-1)1 0.95 12 12.0 0.20 2 1.0 14 12.5 0.25 3 1.1 15 13.0 0.30 2.4 方法的检出限和精密度

连续测定混合基体空白溶液11次,按3倍标准偏差计算到检出限[17],以10倍的标准偏差作为方法的测定下限,结果见表 1.

按试验方法对钇铁合金样品53JYFe01进行了分析,所得结果见表 6,各元素测定结果的相对标准偏差(n=11)在0.74%~4.58%之间.

表 6 钇铁合金分析结果(n=11)Table 6. Determination results of Y-Fe alloy元素 测定值

/(mg·L-1)RSD% Al 0.837 4.50 Si 0.858 4.58 Ca 0.0100 1.75 Mg 0.072 0.74 Mn 0.454 1.46 2.5 分析结果的准确度试验

因国内尚无钇铁合金标准样品,对钇铁合金样品53JYFe01进行标准加入回收试验,试验结果见表 7.

表 7 钇-铁合金样品53JYFe01进行标准加入回收试验Table 7. Recovery test by standard addition method元素 样品测定

值/(mg·L-1)加入量

/(mg·L-1)测定值

/(mg·L-1)回收率

/%Al 0.837 0.100 0.942 105.0 Si 0.858 0.100 0.961 103.0 Ca 0.0100 0.100 0.106 96.0 Mg 0.072 0.100 0.17 98.0 Mn 0.454 0.100 0.551 97.0 Al 0.837 1.00 1.799 96.2 Si 0.858 1.00 1.852 99.4 Ca 0.0100 1.00 0.964 95.4 Mg 0.072 1.00 1.040 96.8 Mn 0.454 1.00 1.377 92.3 3 结论

各元素测定结果的相对标准偏差(n=11)在0.74%~4.58%之间,回收率在92.30%~105.00%之间.钇-铁基体比例在60%~70%-40%~30%对测定无明显影响.试验证明方法满足钇铁中铝、硅、钙、镁、锰分别在0.003%~0.1%的分析测定.

-

表 1 王水处理前后碳纳米管的比表面积、孔径和孔体积

Table 1 Specific surface area, pore size and pore volume of multi-walled carbon nanotubes before and after aqua regia treatment

-

[1] 谢天锋, 陈玲, 莫有德, 等.锂离子电池正极材料磷酸钒锂研究进展[J].化工技术与开发, 2016, 45(7):35-38. doi: 10.3969/j.issn.1671-9905.2016.07.011 [2] 杨东.碳纳米管在磷酸铁锂电池导电剂方面的应用研究[J].世界科学, 2013(12):49-50. doi: 10.3969/j.issn.1000-0968.2013.12.027 [3] 卢星河, 郑立娟, 崔旭轩.动力型锂离子电池的研究进展[J].化工新型材料, 2010, 38(3):41-43. doi: 10.3969/j.issn.1006-3536.2010.03.014 [4] IIJIMA S. Helical microtubules of graphitic carbon[J]. nature, 1991, 354(6348): 56-63. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=CC0211204815

[5] 刘玲玲, 张红梅.石墨烯在锂离子电池中的应用[J].当代化工研究, 2018(6):65-66. doi: 10.3969/j.issn.1672-8114.2018.06.043 [6] WANG Z H, YUAN L X, SHAO Q G, et al. Mn3O4 nanocrystals anchored on multi-walled carbon nanotubes as high-performance anode materials for lithium-ion batteries[J]. Materials Letters, 2012, 80: 110-113. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=f6efbfdcad30681aa50763e8dd2bb34a

[7] EOM J Y, KWON H S, LIU J, et al. Lithium insertion into purified and etched multi-walled carbon nanotubes synthesized on supported catalysts by thermal CVD[J]. Carbon, 2004, 42(12/13): 2589-2596. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=f7e9e7a6326406125d95b96ed4406659

[8] LIU X Y, PENG H J, ZHANG Q, et al. Hierarchical carbon nanotube/carbon black scaffolds as short-and long-range electron pathways with superior Li-ion storage performance[J]. ACS Sustainable Chemistry & Engineering, 2013, 2(2): 200-206. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=bdcdd440f5b60caa583e188fbc4525c7

[9] WANG K, WU Y, LUO S, et al. Hybrid super-aligned carbon nanotube/carbon black conductive networks: A strategy to improve both electrical conductivity and capacity for lithium ion batteries[J]. Journal of Power Sources, 2013, 233: 209-215. http://cn.bing.com/academic/profile?id=220038c790d48f720d9f0de3ddf4160c&encoded=0&v=paper_preview&mkt=zh-cn

[10] 杨中发, 王庆杰, 石斌, 等.导电剂对锂离子电池正极性能的影响[J].电池, 2015, 45(1):34-36. doi: 10.3969/j.issn.1001-1579.2015.01.011 [11] LIN H B, HUANG W Z, RONG H B, et al. Surface natures of conductive carbon materials and their contributions to charge/discharge performance of cathodes for lithium ion batteries[J]. Journal of Power Sources, 2015, 287: 276-282. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=1fd630aec53b8fc210efe98af3d2b415

[12] 彭弯弯, 徐唱, 李之锋, 等.面密度和压实密度对锂离子电池快充性能的影响[J].有色金属科学与工程, 2017, 8(3):69-73. http://ysjskx.paperopen.com/oa/DArticle.aspx?type=view&id=2017030011 [13] 夏雨, 王双双, 王义飞.碳纳米管在锂离子电池中的应用[J].储能科学与技术, 2016, 5(4):422-429. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=cnkxyjs201604005 [14] 刘润, 庄卫东, 班丽卿, 等.影响锂离子电池电极性能的一些因素[J].稀有金属, 2016, 40(10): 1066-1075. http://d.old.wanfangdata.com.cn/Periodical/xyjs201610015 [15] 闫坤, 杨娟玉, 于冰, 等.导电剂形貌对硅碳负极电化学性能的影响[J].稀有金属, 2016, 40(10): 1029-1037. http://d.old.wanfangdata.com.cn/Periodical/xyjs201610010 [16] 郭进康, 钟盛文, 王强, 等.分散剂对石墨烯正极浆料的影响[J].有色金属科学与工程, 2016, 7(6):73-76. http://ysjskx.paperopen.com/oa/DArticle.aspx?type=view&id=2016060012 [17] 段志伟, 揭晓华, 张艳梅.多壁碳纳米管的酸处理工艺研究[J].材料导报, 2012, 26(16): 28-30. doi: 10.3969/j.issn.1005-023X.2012.16.008 [18] JIAO Z, WU Q, QIU J. Preparation and electrochemical performance of hollow activated carbon fiber-Carbon nanotubes three-dimensional self-supported electrode for supercapacitor[J]. Materials & Design, 2018, 154: 239-245. http://cn.bing.com/academic/profile?id=6a2ec1d0b5a7cd375c73885e6cf99987&encoded=0&v=paper_preview&mkt=zh-cn

[19] CHEN J, DING N W, LI Z F, et al.Organic cathode material for lithium ion battery[J]. Progress in Chemistry, 2015, 27 (9): 1291-1301. http://d.old.wanfangdata.com.cn/Periodical/gfzxb201704008

下载:

下载: