Effect of homogenization treatment on the pick-up defect on the surface of extruded 6063 aluminum alloy

-

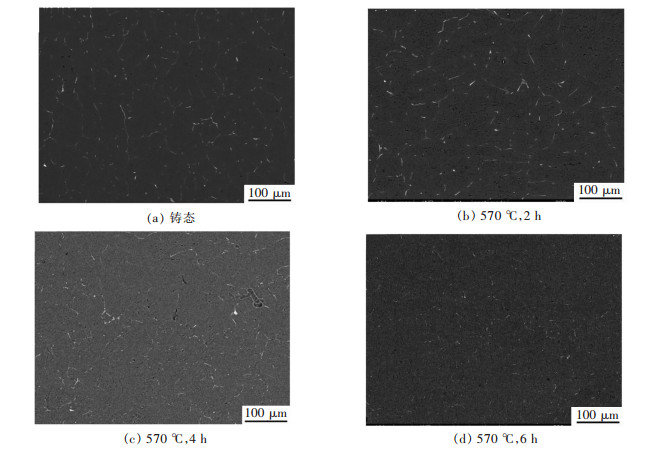

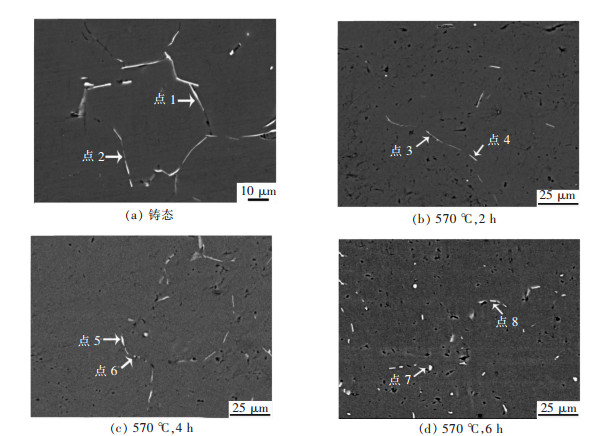

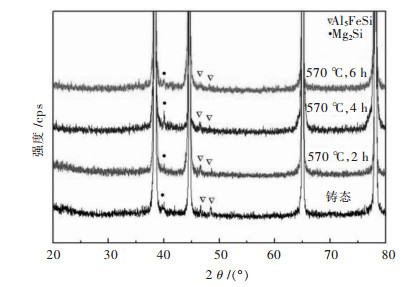

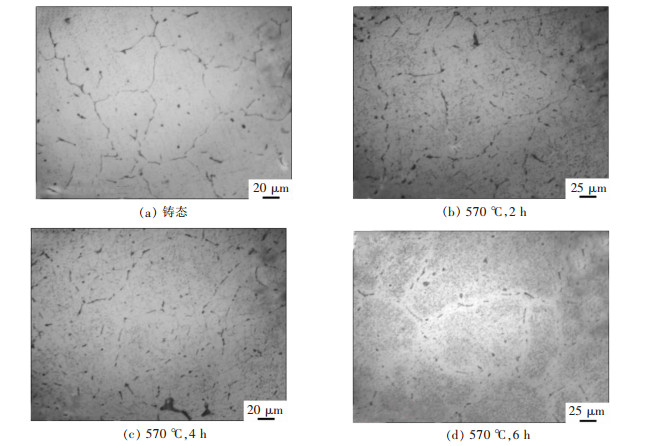

摘要: 采用扫描电镜、金相显微镜和X射线衍射等手段分析不同处理态的合金组织,研究了均匀化处理对6063铝合金型材表面渣粒缺陷的影响,结果表明:铸态合金由富集于晶界呈连续网状的非平衡共晶相与过饱和α-Al固溶体组成;非平衡共晶相由Mg2Si与β-Al5FeSi相组成;在均匀化退火过程中发生非平衡共晶相的溶解,针状的β-Al5FeSi相向颗粒状α-Al8FeSi相的转变.铸态合金挤出的型材表面有大量渣粒,570 ℃下随均匀化退火处理保温时间的延长,非平衡共晶相逐渐消失,挤压型材表面渣粒数量不断减少. 570 ℃保温6 h退火处理是6063合金铸锭较适宜的均匀化处理工艺.Abstract: The microstructures of as-cast and homogeneous alloys were analyzed by metalloscope, scanning electron microscope and X-ray diffraction. The effect of homogenization treatment on the pick-up defect on the surface of extruded 6063 aluminum alloy were investigated. The results show that as-cast alloy consists of supersaturated α-Al solid solution and non-equilibrium eutectic phase in network structure which uniformly distributes along grain boundaries. The non-equilibrium eutectic is composed of Mg2Si phase and β-AlFeSi phase. During the process of homogenization treatment, the non-equilibrium eutectic structure broke and dissolved, and the acicular β-AlFeSi phase transformed to spherical α-AFeSi phase. A large number of pick-up defects were observed on the surface of extruded alloy without homogenization treatment. The non-equilibrium eutectic phase disappeared and the number of pick-up defects decreased gradually with the increase of holding time of homogenization treatment at 570 ℃. In conclusion, the proper homogenization treatment of 6063 alloy is at 570 ℃ for 6h.

-

Keywords:

- 6063 aluminum alloy /

- pick-up defect /

- homogenization treatment /

- AlFeSi phase

-

硬质合金是由一种或多种高硬度、高模量的间隙化合物与过渡族金属或其合金组成的复合材料[1].超细WC-Co硬质合金具有比普通WC-Co硬质合金更高的硬度、更好的耐磨性、更高横向断裂强度以及更良好的断裂韧性等优越性能,被广泛应用于金属切削加工、耐磨零件等领域,具有巨大的市场需求.研究表明制备超细晶WC-Co硬质合金的关键在于:成分均匀、结构可控的超细/纳米晶WC-Co复合粉末的制备;抑制剂的种类、加入量及加入方式;烧结工艺的优化等[2-3].

目前,国内外众多学者对制备具有高强度、高硬度的超细硬质合金已进行大量研究[4-11].郑虎春等[4]以超细WC粉末和超细WC-6Co复合粉末为原料,添加VC/Cr3C2作为晶粒长大抑制剂,同时进行配碳,采用高能球磨和气压强化烧结制备晶粒度小于0.5 μm的WC-0.5Co超细硬质合金,显著提高了WC-0.5Co超细硬质合金的硬度;王进军[5]采用喷雾转化、低温还原碳化工艺制备WC-6Co复合粉末,不添加抑制剂,经过湿磨、成型和烧结,成功制备出WC晶粒度在400 nm的WC-Co硬质合金;赵世贤等[6]采用不同粒度的WC粉与超细Co粉混合得到初始粉末,利用SPS技术和一种包括真空预处理和SPS烧结的新制备方法,研制出超细WC-Co硬质合金.但是超细硬质合金现有制备工艺中均包含有WC与Co粉的湿磨工艺,使得WC在湿磨过程中发生晶格畸变,储存大量畸变能,在后续烧结中易使WC晶粒异常长大;同时湿磨容易引入杂质,杂质的混入可能在烧结过程中与合金粉末反应生成不必要的相,降低合金性能.

以空心球WC-6Co复合粉末为原料[12-13],省去WC粉与Co粉的混合球磨工艺且不添加晶粒长大抑制剂,能有效避免球磨工序引起的如畸变、引入杂质等不利因素.同时利用放电等离子烧结技术(SPS)的快速升温烧结、温度分布均匀等优点[14-16],直接将空心球WC-Co复合粉末利用放电等离子烧结技术烧结制备出超细晶硬质合金.研究SPS烧结温度、保温时间和烧结压力对合金组织与性能的影响,并得出较好烧结工艺,以期为超细晶硬质合金的发展提供可靠的依据.

1 实验

1.1 原料

实验所用的原料均来自湖南顶立科技有限公司与江西理工大学钨基粉末冶金与新材料实验室合作研发的WC-6Co复合粉[12-13],其成分见表 1,复合粉为空心球结构,平均粒径约为30 μm,球壁厚较均匀,约1.8 μm.粉体形貌如图 1所示.

表 1 WC-6Co复合粉成分Table 1. Composition of WC-6Co powder成分 Ct Cf O Co W 含量/% 5.77 0.16 0.21 6.00 87.86 注:Ct为总碳量; Cf为游离碳. 1.2 实验方法

将WC-6Co复合粉置于直径为20 mm的石墨模具中,放入SPS炉腔内,利用电流的变化来控制温度,按照试验所需的工艺烧结制备出超细晶WC-6Co硬质合金.在王凯等[17]的研究基础上,烧结温度分别设置为1 200 ℃、1 250 ℃、1 300 ℃,保温时间分别设置为1 min、5 min、10 min,烧结压力分别设置为40 MPa、50 MPa、60 MPa,逐一研究烧结温度、保温时间与烧结压力对合金组织结构、性能的影响,最后根据合金综合性能得出较好烧结工艺.

用JSM-7001E型场发射扫描电镜对复合粉形貌及合金组织进行观察;采用阿基米德原理测定WC-6Co合金的密度;采用AcoMT系列微机型全自动钴磁测量仪测定WC-6Co的钴磁含量;采用YSK-ZV型数字式的矫顽磁力计测定WC-6Co合金的矫顽磁力;采用维氏硬度计测定WC-6Co的维氏硬度;采用洛氏硬度计测定利用WC-6Co的洛氏硬度. Palmqvist公式计算合金断裂韧性,如式(1)所示,其中li为压痕至裂纹尖端的长度(mm).

$${K_{IC}} = 0.15\sqrt {\frac{{H{V_{30}}}}{{\sum {{l_i}} }}} $$ (1) 2 结果与分析

2.1 烧结温度对合金性能的影响

烧结温度是合金致密化的主要动力,是影响合金致密化的主要因素.为了研究烧结温度对合金性能的影响,固定设置保温时间为5 min、烧结压力为50 MPa,分别设定烧结温度为1 200 ℃、1 250 ℃和1 300 ℃的3组实验,研究温度对合金密度、硬度、矫顽磁力和钴磁含量的影响,实验结果变化趋势如图 2所示.

由图 2中可以看出,3个试样的密度随着烧结温度的升高而升高.分析认为:首先随着烧结温度的升高产生的液相数量增加,能有效填充合金孔隙,促进烧结致密化的进行;其次烧结温度越高,黏结金属相Co的挥发损失越严重,使得合金中的Co含量降低,WC含量相对升高,使制备的合金密度上升. 3个试样的硬度随烧结温度的升高而升高,分析认为是由于合金的致密度上升导致的,当烧结温度为1 300 ℃时合金硬度最大,为2 134;但同时,试样的钴磁比1 250 ℃和1 200 ℃制备的合金更低,说明在1 300 ℃会产生更多的脱碳相,脱碳相的存在会使合金的硬度升高、密度变大,但合金强度、韧性变差[18].

烧结温度越高,合金的矫顽磁力越低,在钴含量相差不大的情况下,矫顽磁力与钴相的分散度有关,而钴相的分散程度随WC晶粒的变化而变化.过高的烧结温度会使合金晶粒长大且合金组织变的不均匀,还会使合金的矫顽磁力降低,合金的断裂韧性也就变的更差[18].综合考虑合金的密度、硬度、磁饱合强度、矫顽磁力和断裂韧性性能,认为烧结温度设置为1 250 ℃时合金性能较好.

2.2 保温时间对合金性能的影响

为了研究保温时间对合金组织和性能的影响,固定烧结温度为1 250 ℃,烧结压力为50 MPa,分别设置保温时间为1 min、5 min和10 min,实验结果变化趋势如图 3所示.由图 3可以看出:保温时间在5 min和10 min时的合金密度近似且比1 min时的大.由于1 min的保温时间太短,合金烧结不致密,当达到5 min时合金的密度达到相对稳定;随着保温时间的延长,密度基本保持不变.但是时间过长,会导致WC晶粒异常长大,硬度下降.综合考虑烧结工艺简化和性能的影响,分析认为保温时间5 min较为适宜.

2.3 烧结压力对合金组织和性能的影响

为了研究烧结压力对合金组织和性能的影响,固定设置烧结温度为1 250 ℃、保温时间5 min,设置烧结压力分别为40 MPa、50 MPa和60 MPa,实验结果变化趋势如图 4所示.

由图 4可以看出:随着烧结压力的增加,样品的密度呈现增加的趋势.这是因为随着烧结压力的增加,放电等离子烧结系统在压力的作用下,烧结体晶粒表面容易活化,通过表面扩散的物质快速传递;提高烧结压力,有利于增大粉末颗粒的表面及内部原子的扩散速率、增强液相的流动, 可促进粉末颗粒间重新排列组合,加速烧结进程,有利于烧结样品中气孔的去除,有助于烧结体的致密[14].烧结压力越大,合金的硬度也越高,分析认为是由于烧结压力越大合金的致密度越大造成的.烧结压力越大,密度上升,当压力超过50 MPa时,密度变化不大,此时压力对合金致密化作用有限,为节省生产成本,分析认为较好烧结压力为50 MPa.

2.4 较好烧结工艺制备硬质合金组织性能分析

根据上述实验结果,分析认为较好的烧结工艺为烧结温度1 250 ℃、保温时间5 min、烧结压力50 MPa,按此工艺烧结制备超细晶硬质合金.并测得较好工艺下合金的相关性能和组织结构. 图 5所示为较好工艺制备的WC-6Co硬质合金显微组织,从图 5中可以看出,较好烧结工艺制备的合金晶粒细小、WC晶粒尺寸分布均匀,孔隙很少.

表 2所列为较好工艺与文献[17-19]制备的WC-6Co硬质合金性能对比表.从表 2中可以看出,较好工艺制备的合金致密性比文献[17]更高,硬度变化不大,但断裂韧性显著提高;与文献[19]相比,2种合金性能变化不大,文献[19]的矫顽磁力更高一些,这是因为文献[19]加入了晶粒长大抑制剂.说明文中提出的工艺在不添加抑制剂、省去球磨工艺的情况下也能提升超细晶硬质合金的综合性能.

3 结论

1)较好烧结工艺为烧结温度1 250 ℃、保温时间5 min、烧结压力50 MPa;该工艺制得的合金显微组织均匀,密度、硬度和断裂韧性等性能良好.

2)随着烧结温度的上升,合金的致密度和硬度随之升高;保温时间长,密度上升,但是时间过长,会导致WC晶粒异常长大,使硬度下降;烧结压力越大,密度上升,当压力超过50 MPa时,密度变化不大.

-

表 1 试验合金的化学成分组成/(质量分数,%)

Table 1 Composition analysis of experimental alloy /(mass fraction, %)

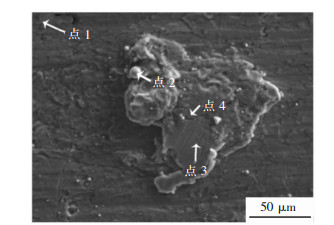

表 2 型材表面渣粒化学成分/(质量分数,%)

Table 2 Composition of pick-up defect on the profile surface /(mass fraction, %)

表 3 不同处理态合金析出相元素组成/(原子百分比,%)

Table 3 Composition of phases in alloy with different treatments /(atomic ratio, %)

-

[1] BIROL Y. Optimization of homogenization for a low alloyed AlMgSi alloy[J]. Materials Characterization, 2013, 80(6):69-75. http://www.sciencedirect.com/science/article/pii/S1044580313000806

[2] 王慧婷, 史娜, 刘章, 等. 6XXX系铝合金表面腐蚀及其防腐的研究现状[J].表面技术, 2018, 47(1):160-167. http://d.old.wanfangdata.com.cn/Periodical/bmjs201801025 [3] 陈朝轶, 张鹏, 刘静, 等. 6063铝合金阳极氧化膜腐蚀行为研究[J].热加工工艺, 2013, 42(16):38-40. http://d.old.wanfangdata.com.cn/Periodical/rjggy201316011 [4] 邬宝平. "毛刺"及"震痕"产生的原因及解决思路[J].南方金属, 2016, 213(6):59-61. doi: 10.3969/j.issn.1009-9700.2016.06.019 [5] 罗淞, 林高用, 曾菊花, 等.硬质相对6061铝合金异型散热型材表面质量的影响[J].中国有色金属学报, 2011, 21(7):1521-1526. http://d.old.wanfangdata.com.cn/Periodical/zgysjsxb201107004 [6] 孙瑜, 黄继武, 赵毅, 等.均匀化处理对6063铝合金微观组织结构的影响[J].热加工工艺, 2012, 41(2):187-191. doi: 10.3969/j.issn.1001-3814.2012.02.057 [7] 党小荔, 杨伏良, 刘欢.一种Al-Mg-Si-Cu铝合金的均匀化处理[J].热加工工艺, 2013, 42(4):1-6. http://d.old.wanfangdata.com.cn/Periodical/rjggy201304001 [8] 曾渝.微量Mn及均匀化工艺对Al-Mg-Si合金铸锭微观组织的影响[J].金属热处理, 2017, 42(5):18-21. http://d.old.wanfangdata.com.cn/Periodical/jsrcl201705004 [9] 杨迎新, 张乐平. 6063铝型材表面斑点腐蚀的机理分析[J].有色金属科学与工程, 2002, 16(4):38-40. http://ysjskx.paperopen.com/oa/darticle.aspx?type=view&id=200204013 [10] 廖儒福, 林高用, 张锐, 等. 6082铝合金铸锭均匀化热处理工艺研究[J].有色金属加工, 2013, 42(3):35-39. http://d.old.wanfangdata.com.cn/Periodical/ysjsjg201303012 [11] MNODA T, HAYAKAWA H, YOSHIDA H. A mechanism of pick-up formation on 6063 aluminum alloy extrusions[J]. Journal of Japan Institute of Light Metals, 1999, 49(6):253-257. doi: 10.2464/jilm.49.253

[12] MINODA T, HAYAKAWA H, YOSHIDA H. Effect of iron content on the surface quality of 6063 aluminum alloy extrusion[J]. Journal of Japan Institute of Light Metals, 2000, 50(50):491-494.

[13] WANG M, XU W, HAN Q. Effect of heat treatment on controlling the morphology of AlFeSi phase in A380 Alloy[J]. International Journal of Metalcasting, 2016, 10(4):1-8. doi: 10.1007/s40962-016-0068-9

[14] 汤振齐, 刘宁, 陈天宝, 等.热加工对含钪6066铝合金组织和性能的影响[J].热处理, 2016, 31(5):1-10. http://d.old.wanfangdata.com.cn/Periodical/rcl201605003 [15] 赵鸿金, 曾文锋, 孔军, 等. 7055铝合金多级均匀化工艺研究[J].有色金属科学与工程, 2013, 4(3):49-53. http://ysjskx.paperopen.com/oa/darticle.aspx?type=view&id=201303010 [16] 倪威, 倪红军, 王平, 等.主要合金元素对6063铝型材表面质量的影响及控制[J].有色金属(冶炼部分), 2017(5):59-63. doi: 10.3969/j.issn.1007-7545.2017.05.015 [17] 王中霞, 唐永兵, 周文标.大截面铝合金工业型材表面麻面缺陷的改善[J].轻合金加工技术, 2012(2):42-45. doi: 10.3969/j.issn.1007-7235.2012.02.010 [18] MA X. Surface quality of aluminium extrusion products[D]. Enschede: University of Twente, 2011.

[19] 邓小民.铝合金挤压材"麻面"缺陷产生机制的研究[J].轻合金加工技术, 2001, 29(12):25-27. doi: 10.3969/j.issn.1007-7235.2001.12.008 -

期刊类型引用(5)

1. 喻亮,刘远,张亚坚,姜艳丽. 热轧变形对含0.5%B的6063铝合金导电率和组织性能的影响. 热加工工艺. 2024(13): 138-141 .  百度学术

百度学术

2. 张鹏,胡武,李建明,黄显赞,廖斌. 液氮通入量及挤压速度对6063铝合金型材表面质量的影响. 装备制造技术. 2023(01): 86-88 .  百度学术

百度学术

3. 韩双,陈继强,谢钢平,孔重良. 刮削模具对铝合金焊丝表面刮削效果的影响. 江西冶金. 2022(02): 1-5 .  百度学术

百度学术

4. 王泽群,向文杰,张婷蕊,王孟君,潘学著,王岗. Fe元素对6063铝合金挤压型材表面渣粒的影响. 矿冶工程. 2021(02): 110-114 .  百度学术

百度学术

5. 闫金顺,赵鸿来. 6063-TiCe铝合金散热器的挤压工艺优化. 热加工工艺. 2021(15): 84-87 .  百度学术

百度学术

其他类型引用(3)

下载:

下载: