Experimental study on the melting-separation of carbon composite pellets in Ti-Nb-bearing Fe concentrate

-

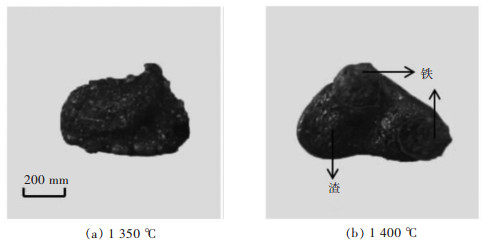

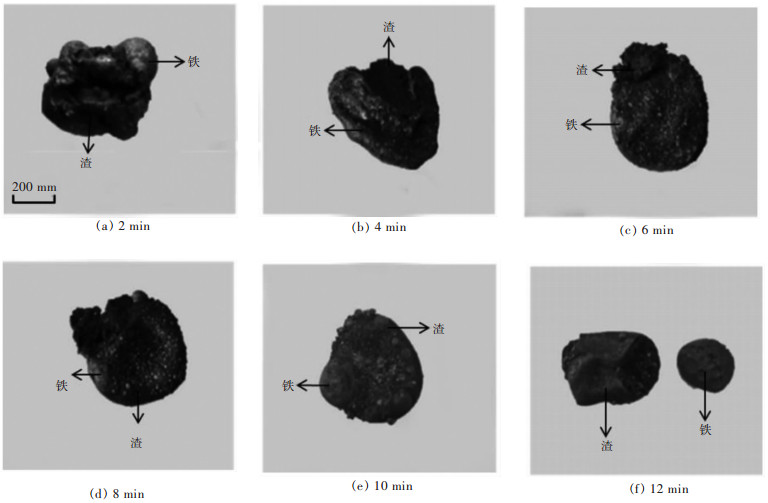

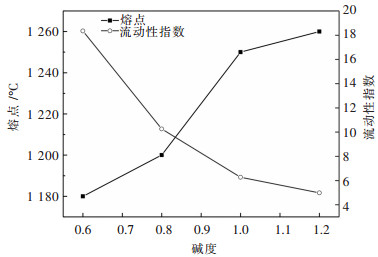

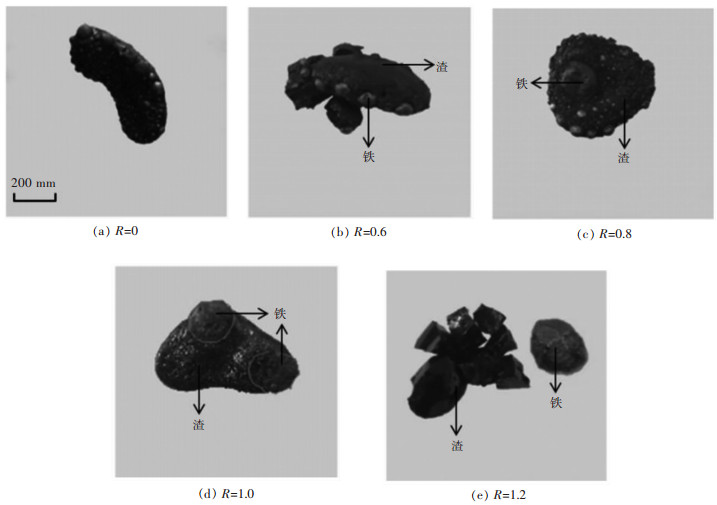

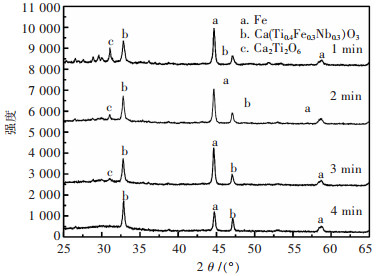

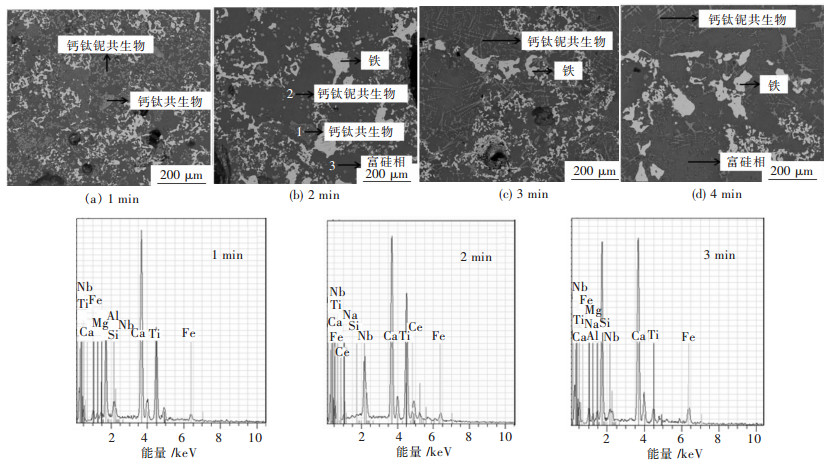

摘要: 为了实现我国白云鄂博地区含钛铌铁精矿资源的高效利用,以含钛铌铁精矿为原料,采用预还原-熔分的加热制度,研究熔分温度、熔分时间和碱度对含钛铌铁精矿含碳球团熔分行为以及渣系性质的影响.进一步采用X射线衍射、扫描电子显微镜等手段表征含碳球团在熔分过程中的微观结构及物相变化.实验结果表明:金属化率86.31 %的预还原含钛铌铁精矿含碳球团在1 400 ℃下熔分12 min后可实现渣铁有效分离,获得珠铁和富铌渣.随碱度升高,渣的熔点升高,渣的流动性指数降低,碱度为1.0时,球团的熔分效果较优;随熔分时间增加,含钛铌铁精矿含碳球团中的Ca2Ti2O6相减少,Ca(Ti0.4Fe0.3Nb0.3)O3相增加,钙钛铌共生物的尺寸增加,呈十字树枝状.Abstract: Effects of the melting-separation temperature, melting-separation time and slag basicity on the melting-separation behavior of carbon composite pellets in Ti-Nb-bearing Fe concentrate and the properties of slag were studied by preproduction-melting-separation experiment in order to realize efficient utilization of Ti-Nb-bearing Fe concentrate in Bayan Obo Area, Inner Mongolia, with Ti-Nb-bearing Fe concentrate being the raw material. Moreover, the microstructure and phase transformation of pellets were characterized by XRD and SEM during melting-separation process. Results showed that complete slag-metal separation of reduced pellets whose metallization rate was 86.31 % could be realized after the melting-separation lasted 12 min at 1 400 ℃. Besides, iron nuggets and Nb-enriched slag were also obtained. The melting point of slag increased and the fluidity index of slag decreased with the increase of basicity. The best melting-separation effect could be achieved when slag basicity was 1.0. With the increase of melting-separation time, Ca2Ti2O6 transformed gradually to Ca(Ti0.4Fe0.3Nb0.3)O3 and the size of Ca(Ti0.4Fe0.3Nb0.3)O3 increased.

-

随着纯电动汽车(EVs)和混合电动汽车(HEVs)的兴起,对锂离子电池的性能有了更高的要求。因正极材料是锂离子电池的“核心”,研究一种高比容量、长循环寿命、环保且成本低的正极材料已迫在眉睫。富镍三元层状正极材料LiNi1-x-yCoxMnyO2[1-3]可以看做LiNiO2、LiCoO2、LiMnO2三者发生固溶而形成的,其具备了LiNiO2的高比容量,LiCoO2的良好循环性、优良导电性及LiMnO2的低成本高安全等优点,是极具发展前景的正极材料[4-5]。

LiNi0.8Co0.1Mn0.1O2(NCM811)正极材料是LiNi1-x-yCoxMnyO2中的一种典型代表,但其也有很多缺点,如容量衰减问题[6]; 循环稳定性及热稳定性不足; 材料的阳离子混排问题[7]、首次库伦效率较低及可逆容量损失较多、存储性能较差等。优化制备工艺、包覆[8]及掺杂[9]改性、制备核壳结构材料[10]等都是解决问题的方法。目前合成正极材料的主要方法是化学共沉淀法[11-12]、固相法及溶胶-凝胶法[13-14],但化学共沉淀法在材料合成过程中,沉淀剂的加入可能会使局部浓度过高,产生团聚或组成不够均匀; 固相法在高温反应时耗能较大、效率低、易混入杂质、完全依靠机械研磨,使原料混合不均匀导致颗粒尺寸差别较大且实验可重复较差; 而溶胶-凝胶法制备材料时,由于该法经过溶液反应过程,所以材料组成较均匀且实验合成温度较低、反应不易引入杂质,产品纯度较高。采用溶胶-凝胶法合成正极材料的研究有很多,但对其烧成温度的研究很少。Li等使用溶胶-凝胶法制备LiNi0.8Co0.1Mn0.1O2正极材料,以50 ℃为一个梯度研究了烧成温度对其性能的影响[15]。材料在750 ℃时电化学性能较优。但高倍率下材料性能较差,5 C时只有108.3 mAh/g且温度梯度跨度过大,没有细化进行研究。

烧成温度低会造成材料结晶性不好,晶体生长不完全; 烧成温度高会使材料表面出现团聚且因锂挥发多而形成缺锂化合物,增加材料的阻抗值。烧成温度的细微差别可能会对晶体形貌,结晶性能、电化学性能等产生影响,因此本文以20 ℃为温度梯度,细化研究了烧成温度对LiNi0.8Co0.1Mn0.1O2正极材料结构、形貌和电化学性能的影响。

1 实验方法

1.1 正极材料的制备

实验采用溶胶-凝胶法制备LiNi0.8Co0.1Mn0.1O2正极材料。所用原料为乙酸镍(Ni(CH3COO)2·4H2O)、硝酸钴(Co(NO3)2·6H2O)、乙酸锰(C4H6MnO4·4H2O)、氢氧化锂(LiOH·H2O)及柠檬酸(C6H8O7·H2O)。按照摩尔比镍:钴:锰为8:1:1、柠檬酸:M(总金属离子)为1:1及锂盐过量5%[15-16](弥补高温烧结过程中锂盐的挥发)称取质量,后加去离子水先把镍、钴、锰盐溶解为溶液1,再把柠檬酸和氢氧化锂溶解成透明溶液2。将溶液2缓慢滴加到溶液1中,水浴锅中磁力搅拌均匀后加氨水调节溶液pH为3.50左右,80 ℃蒸发溶剂数小时成湿凝胶状态,后180 ℃干燥12 h成干凝胶,研磨后在空气气氛下,480 ℃预处理6 h,冷却至室温后取出研磨,后于O2气氛下,480 ℃保温6 h,最后分别于760、780、800、820 ℃不同温度下烧结12 h再研磨过筛得NCM811正极材料。

1.2 材料结构与形貌表征

材料使用X射线衍射(XRD)分析其晶体结构,采用德国Bruker D8 Advance型转靶衍射仪进行测试,扫描范围为10°~80°,步长为0.02°,扫描速率为8 °/min(Cu Kα辐射,λ=0.154 06 nm,60 kV管电压,50 mA管电流)。采用德国ZEISS SIGMA300型扫描电子显微镜(SEM)进行表面形貌观察。

1.3 电化学性能测试

按照质量比8:1:1分别称取正极材料、聚偏氟乙烯(PVDF)和乙炔黑(SP),以N-甲基吡咯烷酮(NMP)为溶剂去溶解聚偏氟乙烯成透明溶液,后分别加入正极材料和乙炔黑,于球磨机上搅拌10 h制成均匀浆料再涂覆于铝箔上。经干燥、辊压、裁片后真空干燥12 h得正极片。以锂片为负极、美国Celgard 2300型号的隔膜、1 mol/L LiPF6的碳酸乙烯酯/碳酸二乙酯(EC/DEC)溶液为电解液,在充满氩气的手套箱内制作CR2032型纽扣电池。在新威电池测试柜上测试其电性能,测试条件为:25 ℃,恒流充放电测试,电压范围为2.75~4.3 V。交流阻抗及循环伏安测试在上海辰华电化学工作站进行,测试条件分别为:25 ℃,频率10-1~105 Hz,电压振幅为5 mV; 25 ℃,电压范围2.5~4.6 V,扫描次数为4次,扫描速率为0.1 mV/s。

2 实验结果分析与讨论

2.1 物相结构分析

不同烧成温度对材料物相结构有着一定的影响,探究了760、780、800、820 ℃ 4种烧成温度下材料的性能。图 1所示为材料的X射线衍射图,从图 1中可以看出4组材料的(003)面的晶面强度是随着烧成温度的增加而逐渐增强的。材料的特征峰都很明显且峰型几乎一致,与PDF卡片中的LiNiO2(89-3601)相似,说明材料呈现R-3m的空间群,表现出α-NaFeO2层状结构[17]。随着烧成温度的提高,(006)峰和(102)峰及(108)峰和(110)峰的分裂程度加强[18],说明烧成温度的提高使得材料的晶型结构更加完善,层状结构更好。一般常用c/a值和I(003)/I(104)值来表征材料的层状结构和阳离子混排度,c/a值大于4.9,材料层状结构较好; I(003)/I(104)值大于1.2,材料阳离子混排度较小[19-21]。对比表 1中的c/a值和I(003)/I(104)值可以看出随着烧成温度的提高,其值都呈现先增大后减小的趋势且800 ℃下有较优的层状结构和较小的阳离子混排度。

表 1 不同烧成温度下NCM811的晶胞参数计算值Table 1. Lattice parameters of NCM811 calculated at different sintering temperature

2.2 材料形貌分析

材料表面形貌如图 2所示。从图 2中可以看出材料形貌呈现不规则块状,随着烧成温度的增加,材料颗粒粒径逐渐增大且材料团聚现象呈现先减小后增大的趋势,780 ℃时材料的粒径约为200~300 nm且材料较少发生团聚,有良好的分散性和结晶性。760 ℃时材料粒径在200 nm左右,此时材料生长不是很完全,有部分一次颗粒尚未结晶,团聚在材料表面,影响材料的性能; 而800 ℃时材料有较好的分散性,材料中部分一次颗粒聚集,烧成时发生团聚,形成粒径较大的二次颗粒,其粒径大概在200~500 nm之间; 820 ℃高温下锂盐挥发较多,其表面形成缺锂化合物且材料团聚现象严重,形成粒径较大的二次颗粒(600 nm左右),阻碍Li+的扩散,致使循环稳定性下降。

2.3 电化学性能分析

图 3所示是材料在新威电池测试柜上测试的电性能曲线图。测试条件:电压为2.75~4.3 V、25 ℃下,恒流充放电测试。以0.1 C(1 C=200 mAh/g)倍率的电流进行首次充放电测试,图 3(a)中随着烧成温度的增加,材料的首次放电比容量呈现先增加后减小的趋势。800 ℃时首次充放电曲线性能最好,比容量有203.86 mAh/g,库伦效率为87.88%,这归因于材料有最小的阳离子混排度和良好的层状结构; 而760 ℃材料性能最差,比容量只有179.02 mAh/g,这是因为材料表面发生团聚且阳离子混排相对较高,使电性能变差; 而820 ℃高温下,材料虽然有较小的阳离子混排度,但高温导致锂盐挥发较多,表面形成缺锂化合物且团聚现象严重,增加了电荷转移阻抗,使材料比容量降低。图 3(b)中,800 ℃下的材料表现出较好的倍率性能,在不同的倍率下其比容量都是最高的,说明该材料有着较低的极化率,其循环可逆性也较好。这归因于800 ℃时材料最低的阳离子混排度及较好的层状结构,良好的层状结构利于Li+在其中的脱嵌,增加了材料的离子和电子电导率,使材料的电性能更好。而在低温或高温下,材料的倍率性能都明显减弱,这是因为低温下材料生长不完全,一次颗粒还未完全长大,阻碍Li+扩散,使其性能下降; 而高温下锂盐挥发过多,材料表面形成缺锂化合物且团聚现象严重,使材料电性能变差。图 3(c)为材料在0.2 C倍率下的循环图。图 3(c)中760 ℃烧成材料在100次循环后有较高的容量保持率,为86.94%,这主要是因为此时材料有着较小的粒径,比表面积相对较大,增加了活性物质与电解质间的界面接触面积,使材料有较好的循环稳定性,但其初始放电比容量较低,只有167.09 mAh/g。780、800 ℃下的材料有着较高的初始放电比容量,分别为192.34、195.23 mAh/g,在100次循环后其容量保持率分别为81.65%和80.27%。而820 ℃材料容量保持率最差,为40.79%,这归因于高温烧结时材料的一次颗粒异常长大且团聚现象严重、形貌不规整,不仅增加了Li+的扩散路径,还让电荷转移阻抗增加,使电性能变差。分析图 3(d)和表 2中数据,800 ℃烧结材料有较好的循环性能,5 C高倍率电流下,200次循环后材料仍有76.71%的容量保持率,这归因于800 ℃烧结时材料有较好的层状结构且阳离子混排度较低,晶体生长较完整,增加了Li+脱嵌速率,利于材料电性能,这与XRD测试结果一致; 而820 ℃烧结的材料循环性能最差,200次循环后只有59.47%的容量保持率,这主要是因为材料团聚现象严重,阻碍Li+的扩散,增加了电荷转移阻抗值,与SEM图测试结果相同。

表 2 不同烧成温度下NCM811的循环性能Table 2. Cyclic performance of NCM811 at different sintering temperature

图 4所示为材料的循环伏安曲线图。结合图 4和表 3可以看出,图 4中所有样品都具有3对氧化还原峰且峰型完整,分别对应H1/M、M/H2及H2/H3相转变,在3 V附近没有氧化还原峰出现,说明了材料中没有Mn3+/Mn4+的变化,Mn以+4价存在,只起稳定结构的作用[22]。首次氧化还原峰的偏离是因为材料中SEI膜的形成及充放电时发生的一些相转变,其也导致了4组材料第1圈扫描时其氧化峰在3.8~4.1 V左右出现,还原峰位置与后面3圈相比没有太大变化。其后3圈扫描时第1对氧化还原峰在3.7 V左右出现,是Ni2+/Ni4+的变化,第2对氧化还原峰在4.0 V左右出现,是Ni3+/Ni4+的变化,而第3对氧化还原峰在4.2 V左右出现,则是Co3+/Co4+的变化。对比材料第4圈的峰电位差值,其差值没有明显差别,说明材料的极化程度都较小,循环可逆性较好。这个结果也与前3组材料的循环稳定性测试相同,第4组材料可能是因为材料表面团聚较严重且形成了缺锂化合物,阻碍Li+扩散且增加了电荷转移阻抗值,使电性能衰减。

表 3 不同烧成温度下NCM811的第4圈氧化还原电位差Table 3. The redox potential difference of NCM811 at the 4th circle at different sintering temperature

图 5所示为材料在1 C倍率下循环50圈后充至3.9 V下的EIS图谱。图 5中原始数据用曲线表示,拟合数据用散点表示且颜色相同,几乎所有图谱都表现出了2个半圆和直线。高频区半圆弧代表Li+通过电解质界面膜层阻抗(RSEI)、中频区半圆弧代表电荷转移阻抗(Rct)、低频区直线表示Li+扩散阻抗[23]。50圈循环后,材料中高频区半圆有明显差异,780,800 ℃下材料的Rct值较小,分别为81.69,76.88 Ω,760 ℃的半圆直径相对较大,其Rct值为181.7 Ω; 而820 ℃下半圆直径最大,表现出其Rct值也最大,为260.4 Ω,这与材料的循环稳定性测试有相同的结果,表现在材料经过相同次数的循环后其容量保持率都较低。

3 结论

1)通过溶胶-凝胶法制备了不同烧成温度下的LiNi0.8Co0.1Mn0.1O2正极材料,XRD和电化学数据显示,材料都有良好的α-NaFeO2型层状结构且阳离子混排度较低。800 ℃烧结的材料表现出较好的电化学性能,在0.1 C时其首次放电比容量为203.86 mAh/g,库伦效率为87.88%,5 C高倍率下循环200次后,容量保持率仍有76.71%。

2)烧成温度对正极材料的形貌有显著影响。材料形貌呈现不规则块状,随着烧成温度的增加,材料颗粒粒径逐渐增大且团聚现象表现出先减小后增大的趋势。低温下材料生长不完全,使材料的结晶性变差,导致材料中Li+扩散受阻,比容量下降; 而高温下锂盐挥发过多,材料表面形成缺锂化合物且表面团聚较严重,形成粒径较大的二次颗粒,使材料的循环稳定性变差。

-

表 1 含钛铌铁精矿的化学成分/(质量分数,%)

Table 1 Chemical composition of Ti-Nb-bearing Fe concentrate /(mass fraction, %)

表 2 无烟煤工业分析及灰分分析/(质量分数,%)

Table 2 Proximate and ash analysis of anthracite /(mass fraction, %)

-

[1] 王中兴.铌-钛超导合金[M].北京:冶金工业出版社, 1988. [2] 任俊, 王文梅, 卢寿慈.铌资源的综合利用[J].国外金属矿选矿, 1998(1):28-32. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=xtxx200708004 [3] 徐广尧. 包头铌资源综合利用关键技术研究[C]//中国稀土资源综合利用与环境保护研讨会. 2007. http://cpfd.cnki.com.cn/Article/CPFDTOTAL-ZGXT200712001005.htm [4] 王云, 朱荣, 郭亚光, 等.铜渣还原磁选工艺实验研究[J].有色金属科学与工程, 2014, 5(5):61-67. http://ysjskx.paperopen.com/oa/DArticle.aspx?type=view&id=2014050011 [5] 蒋曼, 孙体昌, 寇珏, 等.含铌铁精矿煤基直接还原过程中铌的行为研究[J].稀有金属, 2011, 35(5): 731-735. http://www.cqvip.com/QK/93288X/201105/39230649.html [6] 姚玺, 郭汉杰, 李永麒, 等.氢气在不同还原条件还原磁铁矿的试验研究[J].有色金属科学与工程, 2015, 6(5):12-16. http://ysjskx.paperopen.com/oa/DArticle.aspx?type=view&id=201505003 [7] WANG G, WANG J S, DING Y G. New separation method of boron and iron from ludwigite based on carbon bearing pellet reduction and melting technology[J]. ISIJ International, 2012, 52(1):45-51. doi: 10.2355/isijinternational.52.45

[8] 郭学益, 刘静欣, 田庆华, 等.有色金属复杂资源低温碱性熔炼原理与方法[J].有色金属科学与工程, 2013(2):8-13. http://ysjskx.paperopen.com/oa/DArticle.aspx?type=view&id=201302002 [9] 胡伟, 杨晓军, 符寒光.含硼矿中硼的提取工艺技术现状及趋势[J].有色金属科学与工程, 2015, 6(6):65-70. http://ysjskx.paperopen.com/oa/DArticle.aspx?type=view&id=201506012 [10] DING Y, WANG J S, WANG G. Innovative methodology for separating of rare earth and iron from bayan obo complex iron ore[J]. ISIJ International, 2012, 52(10):1772-1777. doi: 10.2355/isijinternational.52.1772

[11] 侯栋科, 彭兵, 柴立元, 等.锌焙砂的选择性还原焙烧硫酸浸出工艺研究[J].有色金属科学与工程, 2014, 5(1):1-8. http://ysjskx.paperopen.com/oa/DArticle.aspx?type=view&id=201401001 [12] 胡伟, 杨晓军, 符寒光.含硼矿中硼的提取工艺技术现状及趋势[J].有色金属科学与工程, 2015, 6(6):65-70. http://ysjskx.paperopen.com/oa/DArticle.aspx?type=view&id=201506012 [13] 苍大强.国内外冶金工业源头节能减排的新方法、新技术[J].有色金属科学与工程, 2015, 6(6):1-6. http://ysjskx.paperopen.com/oa/DArticle.aspx?type=view&id=201506001 [14] 祁成林, 张建良, 陈永星, 等.烧结熔剂高温特性的实验研究[J].过程工程学报, 2009, 9(1):266-269. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=hgyj2009z1058 [15] LIU X, WU S, HUANG W. Influence of high temperature interaction between sinter and lump ores on the formation behavior of primary-slags in blast furnace[J]. ISIJ International, 2014, 54(9):2089-2096. doi: 10.2355/isijinternational.54.2089

[16] 宁晓宇, 薛庆国, 王广, 等.含碳球团直接还原熔分机理[J].北京科技大学学报, 2014(9): 1166-1173. http://cpfd.cnki.com.cn/Article/CPFDTOTAL-ZGJS200603001026.htm [17] 李光森, 李小刚, 金明芳, 等. 含氟烧结矿粘结相流动性的研究[C]//全国炼铁生产技术会议暨炼铁年会. 2006. http://cpfd.cnki.com.cn/Article/CPFDTOTAL-ZGJS200604004028.htm [18] 王艺慈, 罗果萍, 柏京波, 等. F、K、Na对烧结固相反应影响的研究[J].钢铁, 2008, 43(7):12-15. http://industry.wanfangdata.com.cn/dl/Detail/Periodical?id=Periodical_gt200807003 [19] 吴秋玲.渣的粘度和润湿性与石墨的关系[J].耐火与石灰, 2001, 26(2):54-59. http://www.doc88.com/p-0981981511271.html [20] HYUNSOO K, GYU K J. The Role of molten slag in iron melting process for the direct contact carburization: wetting and separation[J]. Isij International, 2010, 50(8):1099-1106. doi: 10.2355/isijinternational.50.1099

[21] 林向飞, 康巍, 李红英.硼和稀土对铝阴极板耐腐蚀性能的影响[J].有色金属科学与工程, 2017, 8(3):42-47. http://ysjskx.paperopen.com/oa/darticle.aspx?type=view&id=2017030007 [22] 田野, 陈树军, 吕庆, 等.碱金属和TiO2对高炉炉渣流动性的影响[J].钢铁钒钛, 2016, 37(5):91-95. http://www.cnki.com.cn/Article/CJFDTotal-SHJI201505010.htm [23] 叶青, 冯兴宇, 杨泰胜, 等.固溶时间对Cu-Ni-Si-Mg合金组织性能的影响[J].有色金属科学与工程, 2017, 8(3):79-83. http://ysjskx.paperopen.com/oa/DArticle.aspx?type=view&id=2017030013 [24] 张波, 姜茂发, 亓捷, 等. CaO-SiO2-Al2O3-FeO-CaF2-La2O3-Nb2O5-TiO2渣系的活度计算模型[J].东北大学学报(自然科学版), 2011, 32(4):524-528. doi: 10.12068/j.issn.1005-3026.2011.04.018 [25] 何福萍, 刘峰, 李建云, 等.固溶方式及时效对Al-Mg-Si-Cu合金组织及性能的影响[J].有色金属科学与工程, 2013, 4(1):44-48. http://ysjskx.paperopen.com/oa/DArticle.aspx?type=view&id=201301009 -

期刊类型引用(5)

1. 邹呈骏,洪佳斌,吴永麟,王春香,李之锋. 电沉积合成镍/氢氧化镍/聚苯胺薄膜及其电容特性. 有色金属科学与工程. 2023(02): 202-209 .  本站查看

本站查看

2. 刘嘉航,吕哲,周艳文,解志文,陈浩,程蕾. 用于热障涂层的高熵陶瓷材料研究进展. 材料导报. 2023(22): 84-94 .  百度学术

百度学术

3. 胡海燕,武源波,刘益峰,唐瑞仁,吴雄伟,肖遥. 基于铝氧键稳定的隧道型钠离子电池正极材料. 有色金属科学与工程. 2022(02): 59-66 .  本站查看

本站查看

4. 夏鼎峰,周苗苗,郭乾坤,胡顺,邹金,钟盛文. 石墨烯复合导电剂对LiNi_(0.5)Co_(0.2)Mn_(0.3)O_2动力学及电化学性能的影响. 有色金属科学与工程. 2022(03): 35-42 .  本站查看

本站查看

5. 李芮,陈煜,丁能文,李之锋,李小成. 锂离子电池负极材料PSi@GO的制备及其电化学性能. 有色金属科学与工程. 2022(05): 16-22 .  本站查看

本站查看

其他类型引用(3)

下载:

下载: