Effect of Co and P on mechanism of Ni-diamond composites electro-deposition

-

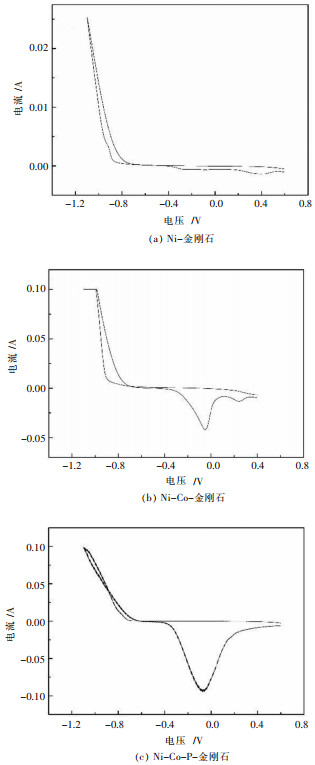

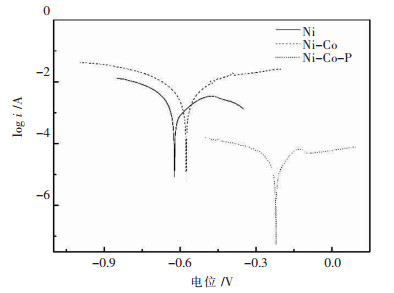

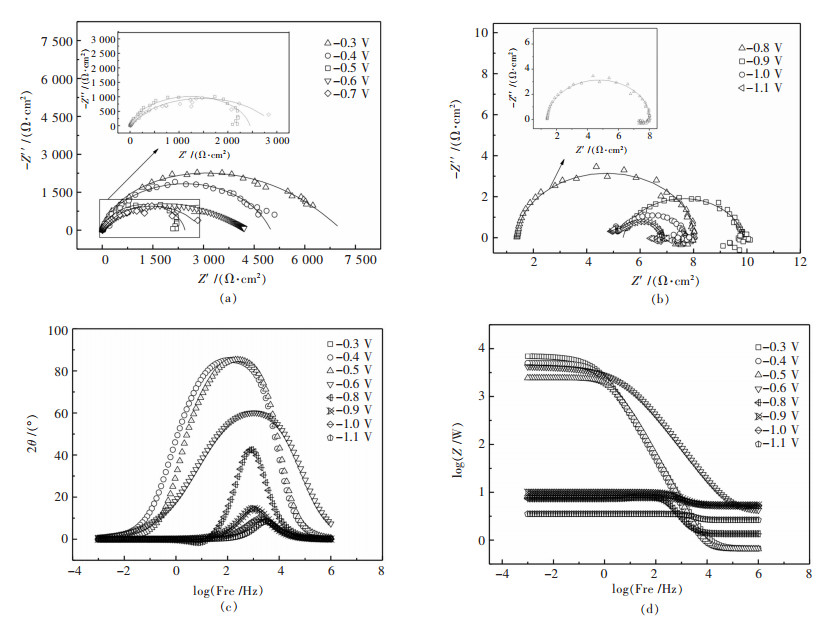

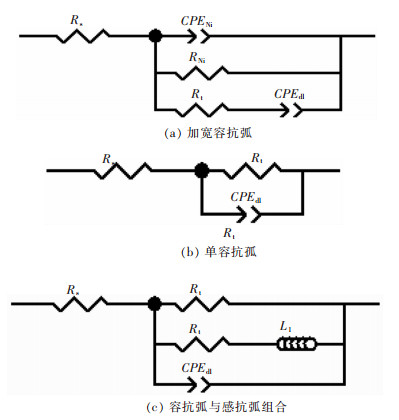

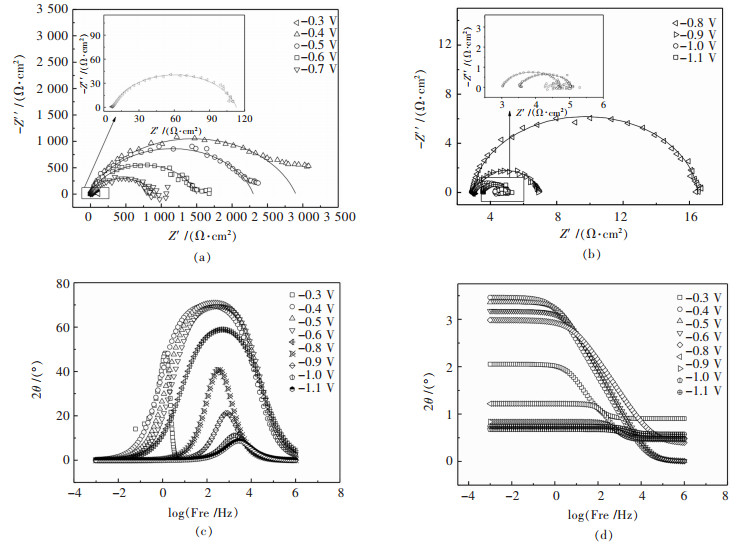

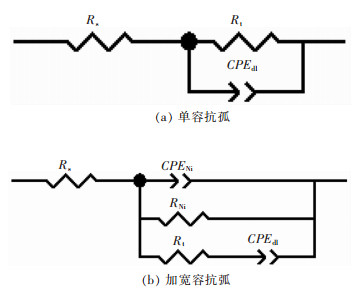

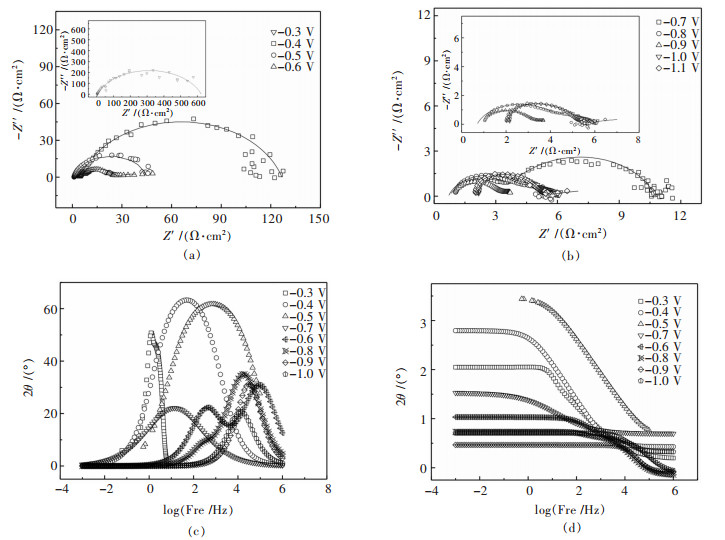

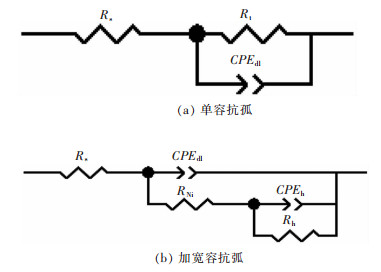

摘要: 在电镀液中添加金刚石微粉,采用复合电镀方法可以制备Ni-金刚石复合镀层,为了研究元素添加对复合镀层工艺的影响,采用电化学方法研究Ni-金刚石复合电沉积机理,分析Co、P元素的加入对复合电沉积过程的影响规律.结果表明:通过循环伏安与动电位极化分析,Co或Co、P的共同加入使得复合电沉积过程中沉积电位正移,说明其可降低阴极表面Ni结晶的驱动力,促进金属的沉积.通过电化学阻抗分析,表明随着Co和P的加入,阴极沉积过程出现2个时间常数,说明阴极沉积反应分2步进行,Co比Ni优先在阴极沉积,并且Ni-Co-P-金刚石复合镀层具有较小的电荷转移电阻,说明Co和P的加入可促进阴极电沉积速率.Abstract: The Ni-diamond composite coating can be obtained by the electro-deposition with the diamond particles added in electrolyte. To obtain the rapid fabrication method of Ni-diamond composite coating, the electrochemical method was used to investigate the mechanism of Ni-diamond electro-deposition. The effect of Co and P addition on electro-deposition process of Ni-diamond was studied. The results show that, by analyzing the cyclic voltammetry, the electro-deposition potential of Ni-diamond become positive with the addition of Co or Co and P, which means the crystallization drive force of nickel is decreased and the deposition of nickel is improved. By the electrochemical impedance spectroscopy analyzing, the deposition process of cathode presents two time constants. The cathodic deposition reaction is carried out in two steps, and the Co is deposited before the Ni deposition. Then, the transfer resistance of Ni-Co-P is smaller. The deposition rate is enhanced by the Co and P addition.

-

0 引言

新城金矿是我国20世纪70年代发现的蚀变岩型金矿床的典型代表,除具有成矿规模大、工业价值高的优点外,也存在着开采技术条件复杂等问题,尤其是-480m到-530m水平的Ⅴ#矿体属于极破碎难采矿体,经多方论证和比较,采用垂直走向布置的机械化盘区上向进路充填采矿法进行开采。本文采用ANSYS软件对采场结构参数进行数值模拟。

1 数值模拟的必要性

为了研究Ⅴ#极破碎难采矿体回采时的稳定性,并确定合理的回采结构参数,必须采用数值模拟的方法,定量地计算和分析回采过程中围岩中的应力、位移和和破坏的分布状况,确定它们在假定条件下随回采进行的动态变化过程,从而对围岩的稳定性状态做出判断;通过对多种方案的计算和分析,比较不同的回采结构参数下的围岩稳定性状态,做出最优的开采设计,确定最合理的采场结构参数, 从而保证安全生产,提高生产效益。

当前,数值模拟的方法有很多种,如有限元、离散元、边界元、无界元以及流行元等[1]。在已有的数值模拟方法中,有限元方法是比较适合模拟和分析地下开挖稳定性问题的方法。有限元模拟分析的基本思路是:首先将要分析的连续体分割成数目有限的单元,在结点上引进等效力以代替实际作用于单元上的力,对于每个单元根据分块近似的思想,选择一个简单函数来近似地表示位移分量的分布规律,并建立单元结点力和位移之间的关系,再把所有单元的这种特性关系集合起来,就得到一组以结点位移为未知量的代数方程式,由此方程组求出物体上有限个离散结点上的位移分量,进而根据物理方程和几何方程来求得单元的应力和变形。三维有限元数值模拟可以定量地计算和分析回采过程中采场围岩中的应力、位移和塑性区、破坏区的分布状况,确定它们随每步回采的动态变化过程,从而对采场围岩的稳定性状态做出判断[2]。软件ANSYS具有多种有限元分析的能力,包括从简单线性静态分析到复杂的非线性瞬态动力学分析。一个典型的ANSYS分析过程可分为建立模型、加载并求解、查看分析结果3个步骤。

2 计算力学模型

为了达到数值模拟的准确性,在选取参数时采用新城金矿前期工作所测得的矿区岩体的物理力学参数;对矿区工程地质、水文地质特别是对矿区岩体结构面,节理、裂隙的调查、统计和分析结果作为程序的初始条件。岩体的初始应力条件是指由岩体自重而引起的应力状态。模型的垂直与水平应力荷载分别是由原地应力场来决定的。在这个阶段,将要分步开挖的矿岩及不同的岩石性质都将分成不同的块体。在开挖时只要将要挖掉的块体删除或把其材料属性重新设置为零即可。

2.1 岩体与充填体力学参数

岩体物理力学参数是根据矿区内不同的岩体分别选取的,为简化计算,分析时将井下介质分为4类:上盘岩体、矿体、下盘岩体和充填体。由于岩体节理裂隙问题单独考虑,所以用岩石试块平均抗压强度代替岩体的强度参数。其不同类型的岩体物理力学性质如表 1所示。

表 1 不同岩体物理力学参数

2.2 原岩应力场

新城金矿地应力场的规律是:最大主应力为竖直方向,其他两个主应力一个是水平方向垂直矿体走向,另一个是水平方向且与矿体走向一致。模拟中取最大主应力方向为Y方向,水平方向为X方向,另一个为Z方向,原岩应力场经实测并回归如下:

式中:σmax——最大水平主应力;

2.3 计算模型尺寸

为了使数值模拟计算充分反映采场开挖的准确性,拟对两种不同的采场结构模型进行计算,这两个结构模型分别是Ⅲ盘区模型和矿体整体模型,运用ANSYS中的平面应变模型SOLID单元plane42对其进行分析。

Ⅲ盘区模型尺寸为30m×50m,即沿走向长30m,埋藏深度从-480m水平到-530m水平,高50m。如图 1所示。

矿体整体模型尺寸为120m×50m, 即沿走向长120m,,埋藏深度从-480m水平到-530m水平,高50m。如图 2所示。

2.4 计算方案

当采用上向进路充填采矿法进行采场开挖时,破坏了围岩应力固有的平衡,引起应力的重新分布,进而达到新的平衡。但随着开采的不断进行,应力不断改变,围岩应力场不断调整,并处于一个周而复始的动态平衡中,直到采矿活动的停止。从力学的角度看,采矿过程是引起一系列围岩应力动态平衡的原因,因此,围岩中的力学行为状态与采场的结构参数有着密切的关系,同样也可以在对矿区整体和单个采场采用上向进路充填采矿法开采时的应力、应变、位移计算中,研究极破碎矿体的采场结构参数。

2.4.1 Ⅲ盘区模型计算方案

为了确定盘区内合理的采场结构参数,拟对Ⅲ盘区采场4种结构参数(P1~4)进行计算,并认为进路开采时每采一条充填一条。其结构参数如表 2。

表 2 采场结构参数 m

2.4.2 矿体整体模型计算方案

数值模拟的目的之一就是从宏观的角度分析整个矿体在开采过程中因不同的盘区开采顺序而导致的不同应力分布情况。在实际生产中为了增大生产力,往往是Ⅰ、Ⅲ盘区先行开采,Ⅱ、Ⅳ盘区紧随其后。根据经验,Ⅰ、Ⅲ盘区相对Ⅱ、Ⅳ盘区超前的层数对整个矿体在开采过程中的应力分布有很大的影响,故矿体整体模型计算方案制定如下:

方案一:Ⅰ、Ⅲ盘区比Ⅱ、Ⅳ盘区超前3层。即Ⅰ、Ⅲ盘区先用上向进路法进行回采,当采至第4层时,Ⅱ、Ⅳ盘区也开始回采,比Ⅰ、Ⅲ盘区滞后3个分层。

方案二:Ⅰ、Ⅲ盘区比Ⅱ、Ⅳ盘区超前5层。即Ⅰ、Ⅲ盘区先用上向进路法进行回采,当采至第6层时,Ⅱ、Ⅳ盘区也开始回采,比Ⅰ、Ⅲ盘区滞后5个分层。

3 计算结果分析

计算采用ANSYS有限元程序中的平面应变模型,对所选方案进行了模拟研究。

3.1 Ⅲ盘区模型计算分析

由于所要分析的Ⅲ盘区处在整个矿体中,当矿体的其他盘区进行开采时,必然将引起整个应力场的变化,所分析的Ⅲ盘区也将有不同的变形情况出现,所以有必要从整体出发,来分析Ⅲ盘区进行开采时的应力、应变情况。边界条件如下:两侧水平方向位移为零,-530m水平、垂直方向位移为零。上部承受13.2MPa的压力。材料设置为矿体和充填体。

图 3~6为4种模型在同等条件下Y方向上的位移分布图。其最大值分别为0.098、0.089、0.111、0.099m,差别不是很大。图 7~10为4种模型在同等约束条件下的等效应力分布图。

通过数值模拟并对结果进行分析,应力最为集中的地方处于两步进路开采时靠近矿体一侧的顶板上,具体对4种采场结构参数模型位移和应力情况比较见表 3。

表 3 Ⅲ盘区模型位移、应力模拟结果

从表 3可以看出,模型P1和模型P3无论从最大位移还是从最大等效应力方面,都明显比其他两个模型数值上要大些,从这个方面来讲,模型P2和模型P4较模型P1和模型P3要优。通过对模型P2和模型P4进行比较后发现,二者在位移和应力集中方面近似相同,但是结合矿山实际情况,对产量要求较高,故模型P4要较模型一更为切合实际,这也与矿山现阶段的实际情况相符(试验采场采用5m×7m的进路规格)。

3.2 矿体整体模型计算

矿体整体模拟的主要目的是对Ⅰ、Ⅲ盘区超前Ⅱ、Ⅳ盘区的层数进行研究,根据经验,往往是Ⅰ、Ⅲ盘区先进行回采,Ⅱ、Ⅳ盘区紧随其后,便于增大生产能力,但是,超前的层数不同,Ⅱ、Ⅳ盘区进路回采时应力集中状态就不同,根据上文所计算出的最佳进路规格,选取进路为5m×7m规格。边界条件为:矿体两侧水平方向位移为零,矿体底面水平方向和竖直方向位移均为零,矿体承受13.2MPa上覆围岩压力。材料设置为矿体和充填体。

通过数值模拟并对结果分析处理后得知,矿体整体模型在4个盘区同时回采时,其应力主要集中在一步正在开采进路的顶板和侧帮处,随着Ⅰ、Ⅲ盘区比Ⅱ、Ⅳ盘区超前的层数不同,应力集中的程度也有所不同。具体数据如表 4所示。

表 4 矿区整体模型位移、应力模拟结果

由表 4数据可知,方案一除了在Y方向上的位移略小于方案二,其余几个方面均比方案二的数值大,应力较集中,故选择方案二,即Ⅰ、Ⅲ盘区比Ⅱ、Ⅳ盘区超前5层,也就是25m。

4 结论

通过对新城金矿极破碎难采矿体使用有限元程序ANSYS软件进行数值模拟、计算分析并参照现场经验,得出如下结论:

(1)采场的应力分布与其结构参数密切相关,合理的进路参数可以明显地改善应力状态。

(2)通过对单个盘区开采现状的模拟,采用4种不同的进路参数进行计算,得出最佳进路规格,与现场试验采场采用的参数基本相同,验证了数值模拟的正确性。

(3)建立了矿体整体模型,在得出最佳进路规格的基础上,采用了两种超前高度进行模拟计算,最终得出合理的超前高度为25m。

(4)数值模拟作为一种特殊意义下的实验,是科技发展的潮流,不仅减少了试验工作量,更对实际工程具有指导意义。

-

表 1 镀液成分

Table 1 Composition of plating electrolyte

成分 含量/(g·L-1) NiSO4·6H2O 205~505 NiCl2·5H2O 45 H3BO3 45 金刚石 10~80 表 2 不同镀液成分共沉积电位

Table 2 Electrodepositon voltage of electroplatings at different electrolyte concentrations

成分 沉积电位/V Ni-金刚石 -0.72 Ni-Co-金刚石 -0.69 Ni-Co-P-金刚石 -0.62 -

[1] SHRESTHA N K, MASUKO M, SAJI T. Composite plating of Ni/SiC using azo-cationic surfactants and wear resistance of coatings[J]. Wear, 2003, 254(5/6): 555-564. https://www.sciencedirect.com/science/article/pii/S0043164803001388

[2] CHEN L, WANG L, ZENG Z, et al. Effect of surfactant on the electrodeposition and wear resistance of Ni-Al2O3 composite coatings[J]. Mater Sci Eng, A, 2006, 434(1/2): 319-325. http://www.sciencedirect.com/science/article/pii/S0921509306012263

[3] 刘美霞, 黄柱, 李天白, 等. Al2O3含量对Ni-W-Al2O3复合镀层性能的影响[J].有色金属科学与工程, 2016, 7(4): 55-60. http://ysjskx.paperopen.com/oa/DArticle.aspx?type=view&id=20160410 [4] 黄柱, 刘美霞, 李天白, 等.电沉积Ni-W-WC复合镀层摩擦磨损性能[J].有色金属科学与工程, 2016, 7(3): 66-70. http://ysjskx.paperopen.com/oa/DArticle.aspx?type=view&id=2016030012 [5] ZHAO H, LIU L, HU W, et al. Friction and wear behavior of Ni-graphite composites prepared by electroforming[J]. Mater Des, 2007, 28(4): 1374-1378. doi: 10.1016/j.matdes.2006.01.001

[6] ZHAO Q, LIU Y, Electroless Ni-Cu-P-PTFE composite coatings and their anticorrosion properties[J]. Surf Coat Technol, 2005, 200(7): 2510-2514. doi: 10.1016/j.surfcoat.2004.06.011

[7] ZOU T Z, TU J P, ZHANG S C, et al. Friction and wear properties of electroless Ni-P-(IF-MoS2) composite coatings in humid air and vacuum[J]. Mater Sci Eng, A, 2006, 426(1/2): 162-168. http://www.sciencedirect.com/science/article/pii/S0921509306003480

[8] 王美娟, 王日初, 彭超群, 等. Ni-金刚石复合镀层的制备[J].中南大学学报(自然科学版), 2013, 44(7): 2688-2695. http://d.wanfangdata.com.cn/Thesis/Y2421687 [9] PETERSSON I, AHLBERG E. Kinetics of the electrodeposition of Pb-Sn alloys: Part Ⅰ. At glassy carbon electrodes[J]. Journal of Electroanalytical Chemistry, 2000, 485(2): 166-177. doi: 10.1016/S0022-0728(00)00113-3

[10] 王立平, 高燕, 薛群基, 等. Ni-Co/纳米金刚石复合镀层抗磨损性能的研究[J].中国表面工程, 2005, 70(1): 24-26. http://cpfd.cnki.com.cn/Article/CPFDTOTAL-ZGVE200404001060.htm [11] LEE E C, CHOI J W. A study on the mechanism of formation of electrocodeposited Ni-diamond coatings[J]. Surf Coat Technol, 2001, 148(2/3): 234-240. https://www.sciencedirect.com/science/article/pii/S0257897201013524

[12] GUGLIELMI N, Kinetics of the deposition of inert particles from electrolytic baths[J]. Journal of the Electrochemical Society, 1972, 119(8): 1009-1012. doi: 10.1149/1.2404383

[13] 姚颖悟, 王超.钛基锡锑中间层上二氧化铅电沉积过程的研究[J].电镀与精饰, 2012, 34(2): 6-8. http://www.cqvip.com/QK/95989X/201202/40988494.html [14] PELLICER E, PAN S, SIVARAMAN K, et al. Effects of the anion in glycine-containing electrolytes on the mechanical properties of electrode posited Co-Ni films[J]. Materials Chemistry and Physics, 2011, 130(3):1380-1386. doi: 10.1016/j.matchemphys.2011.09.032

[15] 王新志, 王吉坤, 麦振海.锌电积过程中添加剂对阴极的影响[J].冶金丛刊, 2007(6): 38-40. http://industry.wanfangdata.com.cn/yj/Detail/Periodical?id=Periodical_yjck200706013 [16] 姚素薇, 刘冰, 郭鹤桐. Ni-Co-P非晶态合金的电沉积及其性能研究[J].化工学报, 1996, 47(1): 48-52. http://www.oalib.com/paper/4209779 [17] HERRAIZ-CARDONA I, ORTEGA E, P REZ-HERRANZ V.Impedance study of hydrogen evolution on Ni/Zn and Ni-Co/Zn stainless steel based electrodeposits[J]. Electrochimica Acta, 2011, 56(3): 1308-1315. doi: 10.1016/j.electacta.2010.10.093

[18] BAKHIT B, AKBARI A, NASIRPOURI F, et al. Corrosion resistance of Ni-Co alloy and Ni-Co/SiC nanocomposite coatings electrodeposited by sediment codeposition technique[J]. Applied Surface Science, 2014, 307:351-359. doi: 10.1016/j.apsusc.2014.04.037

[19] VAZQUEZ A, JORGE, PRITZKER M. Steady-state model for anomalous Co-Ni electrodeposition in sulfate solutions[J]. Electrochimica Acta, 2012, 66139-150. https://www.sciencedirect.com/science/article/pii/S0013468612001053

[20] TIAN L, XU J, QIANG C. The electrodeposition behaviors and magnetic properties of Ni-Co films[J]. Applied Surface Science, 2011, 257(10): 4689-4694. doi: 10.1016/j.apsusc.2010.12.123

[21] HASSANI S, RAEISSI K, GOLOZAR M. Effects of saccharin on the electrodeposition of Ni-Co nanocrystalline coatings[J]. Journal of Applied Electrochemistry, 2008, 38(5): 689-694. doi: 10.1007/s10800-008-9488-4

[22] 牛朝霞. 纳米结构Ni-SiC复合薄膜的电化学制备及其相关理论研究, 杭州: 浙江大学, 2006. [23] 张晖, 李成涛, 宋利君, 等.镍基690合金在超纯水中常温下的电化学行为及高温高压下的腐蚀行为[J].材料保护, 2013, 46(10): 37-39. http://www.wenkuxiazai.com/doc/724c18a41eb91a37f1115cd3.html [24] 李凌杰, 于生海, 雷惊雷, 等. AZ31和AZ61镁合金在模拟海水中的腐蚀电化学行为[J].电化学, 2008, 14(1): 95-99. http://industry.wanfangdata.com.cn/dl/Detail/Periodical?id=Periodical_dhx200801020

下载:

下载: