Simulation of strong coupling electromagnetic current in aluminum reduction cells and its application in new cathodes

-

摘要: 已在工业应用的各新型阴极结构铝电解槽的电磁流场行为仍未完全明晰.论文首先在ANSYS平台上建立铝电解槽瞬态三维三相磁流体模型,并应用该模型对采用3种新型阴极结构的某420 kA槽开展电磁流场强耦合计算.结果表明,相较于普通阴极,3种新型阴极方案均可使槽内铝液、电解质流速下降,其中,凸台型阴极对应的电解质流速降幅较大,不利于氧化铝颗粒的熔解和扩散;在降低铝液-电解质界面波动方面,3种方案均有一定程度的效果,凸台型结构可使得界面大变形面积减小;此外,在电流效率上,应用凸台型阴极结构将使电流效率略微降低.该模型可为大型铝电解槽结构方案的选型提供基础工具.Abstract: Though various new cathodic structures of aluminum reduction cells have been applied in industry, their electro-magneto-flow is still not completely clear. In this paper, a transient 3 D three-phase MHD model in aluminum reduction cells was established on ANSYS platform, and then was utilized to calculate the strong coupling of electro-magneto-flow in some 420 kA cells with three kinds of new cathodic structures. The results show that compared with common cathode, three new cathodic schemes can decrease the flow rate of aluminum liquid and electrolyte in the cells. The flow rate of electrolyte in the case of boss-type cathode declines significantly, which is not conducive to the melting and dispersion of alumina particle. In the reduction of aluminum liquid and electrolyte interface fluctuation, the above-mentioned three schemes all have certain effects. The boss-type structure can reduce the interfacial regions with large deformation. In addition, such structure will slightly decrease current efficiency. This model can provide a basic tool for choosing structure scheme of large aluminum reduction cells.

-

Keywords:

- aluminum electrolysis /

- new cathode /

- MHD /

- physical field simulation

-

工业铝电解槽的核心区域为槽膛,铝液和熔融电解质2种高温熔体在槽膛内受到重力、电磁力和阳极气泡作用力等多种力而不断运动[1-3].铝电解槽内的电场、磁场和流场之间相互影响、相互作用.其中,铝液层和熔融电解质层的不同步运动会使得铝液-电解质界面发生变形,引起熔体内部的电磁场发生变化,从而产生扰动电磁力,由此又会进一步导致熔体的流场形态和铝液-电解质的相间界面形态发生变化.这种自激励效应引起的不稳定现象在许多文献中均有描述[4-5]. LINDSAY和DAVIDSON等[6]以及BOJAREVICS等[7]分析了槽中磁流体运动的各个影响因素,并提出铝液层内部电流的水平分量和磁场的垂直分量相互作用形成的洛伦兹力是唯一有重要影响的因素.因此,为了提高槽内熔体的稳定性,进而保证电解槽的平稳运行,需要对熔体区域的垂直磁场和水平电流进行优化.

为达到上述目的,学术界和工业界相继开发了多种阴极优化结构.这些方案主要是从减小铝液中水平电流、改善槽内电流分布的角度提出,例如TOWNSEND[8]、张红亮[9]提出的非均匀导电阴极,BAYER[10]、曹国法[11]提出的高导电钢棒方案;另一部分则基于降低熔体流速、阻碍铝液流动的思路提出,例如NORA[12]、冯乃祥[13]所设计的凸台型阴极结构.上述2类方案均以优化磁流体稳定性为目的.此外,对于磁流体稳定性理论的研究,也有学者进行了建模计算. WANG等[14]和LI等[15]研究了异形阴极电解槽的磁流体行为,结果表明异形阴极结构能够降低铝液水平电流,同时能减缓槽两端的熔体波动,由于能够降低铝液的流速,铝液-电解质界面的扰动幅度也得以降低. BOJAREVICS[16]建立二维浅水模型,并依此比较了普通阴极和凸台型阴极对500 kA槽的磁流体稳定性影响,通过对比研究,结果显示在同样的铝液高度下,采用普通阴极得到的磁流体稳定性较好,只有在铝液体积相等时,2种结构对应的磁流体稳定性效果相近.但上述研究大多基于稳态建模计算,仅对普通阴极槽和异型阴极槽的稳态熔体流场分布、稳态铝液-电解质界面进行了比较.鉴于现有的铝电解槽多物理场仿真建模方法仍不完善,同时对磁流体行为机理的认识尚不够深入,尤其对于阴极结构的优化方面,相较于工业中对新型阴极电解槽开展了大量试验,相关的理论研究却较为滞后,且在系统性和研究深度上尚有不足,同时也未能对各类优化方案的理论效果做出全面的对比和评估.

论文首先建立和实际体系较为相符的瞬态三维三相铝电解槽磁流体计算模型,进而应用该模型计算对比分析了3种具有代表性的阴极优化结构对420 kA级铝电解槽中水平电流分布、熔体流场行为、铝液界面波动和槽电流效率的影响,从而系统地评判各类阴极结构的优化效果.

1 理论基础及模型

1.1 控制方程

由流体力学基本原理可知,多相流的瞬态计算基于Navier-Stokes方程,其质量、动量、体积的守恒方程分别列于式(1)~式(3):

$$ \frac{\partial }{{\partial t}}({r^\alpha }{\rho ^\alpha }) + \nabla \cdot ({r^\alpha }{\rho ^\alpha }{U^\alpha }) = 0 $$ (1) $$ \begin{array}{l} \frac{\partial }{{\partial t}}({r^\alpha }{\rho ^\alpha }{U^\alpha }) + \nabla \cdot ({r^\alpha }({\rho ^\alpha }{U^\alpha } \times {U^\alpha }))\ {\rm{ }} =-{r^\alpha }\nabla p + \nabla \cdot ({r^\alpha }\nu _{eff}^\alpha (\nabla {U^\alpha } + {(\nabla {U^\alpha })^T})) + S_M^\alpha + {M^\alpha } \end{array} $$ (2) $$ \sum\limits_{\alpha = 1}^3 {{r^\alpha }} = 1 $$ (3) 式(1)~式(3) 中t表示时间,α相的密度、体积分数和流速分别用ρα、rα琢和Uα琢来表示;veffα为α相的有效黏度;sMα为α相所受到的外部体积力;Mα代表其它相对α相的内部作用力.

铝电解槽内的流体相主要为熔融电解质、铝液和离散的阳极气泡,对于该三相系统,式(2) 的具体计算方式列于表 1.

表 1 瞬态三维三相流模型中动量守恒方程的相关项Table 1. Terms of momentum conservation equation in three-dimensional transient MHD modelα $\nu _{eff}^\alpha $ $S_M^\alpha $ ${M^\alpha }$ Bath ${\nu ^b} + {\nu _t}$ ${r^b}F_{EM}^b$ ${C^{b, m}}({U^m} -{U^b}) + {C^{b, p}}({U^p} -{U^b})$ Molten aluminum ${\nu ^m} + {\nu _t}$ ${r^m}({\rho ^m} -{\rho ^b})g + {r^m}F_{EM}^m$ ${C^{m, b}}({U^b} -{U^m})$ Bubble ${\nu ^p} + {\nu _t}$ ${r^p}({\rho ^p} -{\rho ^b})g$ ${C^{p, b}}({U^b} -{U^p})$ 其中上标b、m、p分别代表电解质、铝液和气泡. U为流速.对于多相流计算,选用欧拉-欧拉多相流模型. vt为湍流黏度,由于槽内熔体作高强度湍流运动(雷诺数大于105),且从计算适用性与效率的角度考虑,选用标准k-ε着模型计算.为了更准确地捕捉近壁面处低雷诺数区域的流动,使用标准壁面函数对流动边界层进行近似处理.

各流体相之间的内部作用力以各相间的曳力为主.可将铝液层和电解质层的相间界面看作自由面,此时它们之间的曳力Cb,m可通过式(4) 得到:

$$ {C^{b, m}} = C_D^{b, m}{\rho ^{b, m}}{A^{b, m}}\left| {{U^b}-{U^m}} \right| $$ (4) 其中:

$$ {\rho ^{b, m}} = {r^b}{\rho ^b} + {r^m}{\rho ^m} $$ (5) $$ {A^{b, m}} = \frac{{2\left| {\nabla {r^b}} \right|\left| {\nabla {r^m}} \right|}}{{\left| {\nabla {r^b}} \right| + \left| {\nabla {r^m}} \right|}} $$ (6) 其中,CDb,m代表电解质和铝液两相间曳力系数,其具体数值当前无法精确测量.鉴于实际两相交界处流体湍动程度强烈,和颗粒两相流惯性区相似,都以惯性力主导,故可近似取值为0.44.

使用Cp,b(或Cb,p)来描述阳极气泡与电解质的相间曳力.电解质中的气泡可视为离散相,电解质可视为连续相,根据相关理论,Cp,b可根据式(7) 进行计算:

$$ {C_{p, b}} = \frac{3}{4}\frac{{C_D^{p, b}}}{d}{r^b}{\rho ^p}\left| {{U^b}-{U^p}} \right| $$ (7) 其中CDp,b同样代表阳极气泡与电解质相间曳力系数,d为阳极气泡的平均当量直径,取1 cm.曳力系数CDp,b的计算还要纳入到气泡形状变化的影响,采用Ishii-Zuber曳力模型加以描述,计算方法见式(8).

$$ \begin{array}{l} C_{D, sph}^{p, b} = \max (\frac{{24}}{{{{{\mathop{\rm Re}\nolimits} }_p}}}(1 + 0.1{\mathop{\rm Re}\nolimits} _p^{0.75}), 0.44)\\ C_{D, dist}^{p, b} = \min (\frac{2}{3}E{o^{1/2}}, \frac{8}{3})\\ C_D^{p, b} = \max ({C_{D, sph}}, {C_{D, dist}}) \end{array} $$ (8) 无量纲Eötvös数(Eo)用于衡量体积力和表面张力之间的大小关系:

$$ Eo = \frac{{\Delta \rho g{d^2}}}{\sigma } $$ (9) 其中,Δρ代表电解质和阳极气泡之间的密度差,σ为电解质-气泡的界面张力.

此外,模型还需确定生成阳极气泡的速率,即单位时间进入计算域的气泡量.阳极气泡主要由CO2和CO组成,分别计CO2和CO的摩尔百分比为a %和b %,于是可由式(10) 计算阳极气泡局部质量生成率mloc(kg·s-1·m-2):

$$ {m_{loc}} = \frac{{J_n^a}}{{{{10}^3}F}}\frac{{22a + 14b}}{{2a + b}} $$ (10) 式(10) 中,Jna代表阳极-电解质界面的局部法向电流密度;F为法拉第常数.区别于传统多相流在稳态分析中施加恒定电场分布,多相流瞬态计算所需的阳极-电解质界面电流密度Jna随时间变化,其分布与瞬时流体行为息息相关.

同时,为了获知电流密度Jna,还需对电解槽进行电场建模计算.对于槽内的炭阳极、熔体(电解质和铝液)、阴极和钢棒等导体部分,可根据电流守恒定律以及欧姆定律对其内部的电压和电流分布进行计算:

$$ \nabla \cdot J = \frac{{\partial J}}{{\partial x}} + \frac{{\partial J}}{{\partial y}} + \frac{{\partial J}}{{\partial z}} = 0 $$ (11) $$ J = \sigma E $$ (12) 式(11)~式(12) 中J为电流密度,E为电场强度,σ为电导率.结合电场强度E与标量电势φ的关系E=-▽φ,即可得到铝电解槽内电场分布.

值得一提的是,瞬态计算中由于熔体运动造成铝液-电解质界面出现变形,使熔体区域各个位置的局部阻抗发生改变,进而各区域电流重新分配,从而使得阳极-电解质界面处的电流密度Jna各不相同.

对于此前没有建立起多场强耦合模型的流体稳态分析研究,未考虑铝液-电解质界面变形和熔体流动的影响,所得的熔体流动最主要的推动力电磁力密度FEM也仅仅与空间位置有关.而瞬态三维三相磁流体模型不但纳入了铝液起伏对电场的影响,还加入了因熔体流动而产生的磁感应电流.在此情况下,计算得到的电磁力密度不仅是时间与空间的函数,还与具体的相有关.在任一时刻t,α相在空间内任一点(x, y, z)受到的电磁力密度FEMα可由式(13)~式(15) 计算:

$$ F_{EM}^\alpha (x, y, z, t) = {J^\alpha } \times B $$ (13) $$ \nabla \cdot {E^\alpha }(x, y, z, t) = 0 $$ (14) $$ {J^\alpha }(x, y, z, t) = {\sigma ^\alpha }({E^\alpha } + {U^\alpha } \times B) $$ (15) 式(13)~式(15) 中Jα、Eα和σα分别代表α相的电流强度、电场强度和电导率.

1.2 模型边界条件与网格

计算所用420 kA级铝电解槽的关键参数如表 2所列.

表 2 某420kA电解槽关键参数Table 2. Key parameters of 420kA aluminum reduction cell参数 数值 电流/kA 420 阳极炭块/mm 1700×660×540 阴极炭块/mm 3680×665×485 阴极钢棒/mm 2200×100×200 阴极开槽/mm 3680×125×245 铝液高度/mm 220 电解质高度/mm 180 极距/mm 45 阳极炭块数量 48 阴极炭块数量 24 钢棒数量 96 槽内电-磁-流场三者之间相互影响、相互作用,但MOREAU [17]研究认为槽内磁场的分布主要由边界条件决定,熔体波动对磁场分布的影响很小可以不加考虑.为了保证计算的可行性,合理简化模型以降低计算量,求解计算中仍沿用了上述假设,并在计算域内施加稳态磁场.开展磁流体计算前,先应用前期开发的稳态磁场计算方法[18],分别计算得到不同阴极结构下420 kA级铝电解槽的稳态磁场分布.

同时,根据式(10) 设定电解质-阳极界面视作气体入口,电解质区域顶面为气体出口,此外,其它流体边界为无滑移壁面.

在ANSYS建立所用计算模型并划分网格,再导入CFX中进行相关设定开展仿真计算. 图 1所示为计算所用的瞬态三维三相铝电解槽全槽模型.

1.3 材料属性

计算涉及的主要流体相的物性参数列于表 3.

表 3 主要流体相物性参数Table 3. Physical Parameters of fluid phase材料 铝液 电解质 气泡 密度/(kg·m-3) 2270 2130 0.398 黏度/(kg·m-1·s-1) 1.18×10-3 2.513×10-3 5.055×10-5 计算的初始条件为静止状态,即电解质-铝液界面平整无波动.鉴于强耦合计算存在收敛性问题,设定时间步长为0.1 s.考虑到多场耦合计算三维瞬态模型带来的计算量巨大,计算周期长且对计算环境要求高,设定计算时间步数为有限的4 000步,计算过程约耗时25 d.

2 阴极结构优化方案

为对比各阴极优化方案对槽内磁流体行为的影响,选取以下3种典型阴极优化结构进行建模研究:

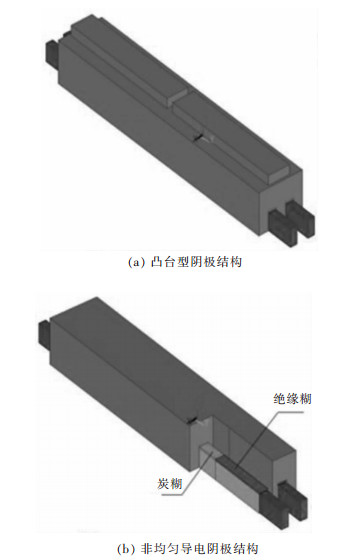

1) 基于阻流角度提出的凸台型阴极方案.选取的是一种具有代表性的设计结构,见图 2(a),凸台结构宽0.3 m,高0.11 m.

2) 非均匀导电阴极.目前存在的设计繁多,但主要思路都是通过加入导电性不同的材料,提高电流从槽体中部汇入阴极的比例.采用方案的具体结构如图 2(b),将阴极钢棒与炭块之间的部分炭糊换为不导电材料,长度为65 cm.该方案较为简单,但降低水平电流效果较好.

3) 高导电钢棒阴极.选用钢棒电导率为1.6×106 S/m,该值大约是普通钢棒的2倍.

同时,为了叙述方便,把采用普通阴极方案和上述3种方案建立的铝电解槽模型依次标记为方案1~方案4.

3 结果与分析

3.1 铝液内水平电流的对比与分析

学术界普遍存在一种观点,铝液中的水平电流是直接引起熔体波动的电流分量,其大小和分布与磁流体行为之间有着紧密联系.因此,在对磁流体行为进行对比前,先对比各方案下铝液层内部的水平电流.

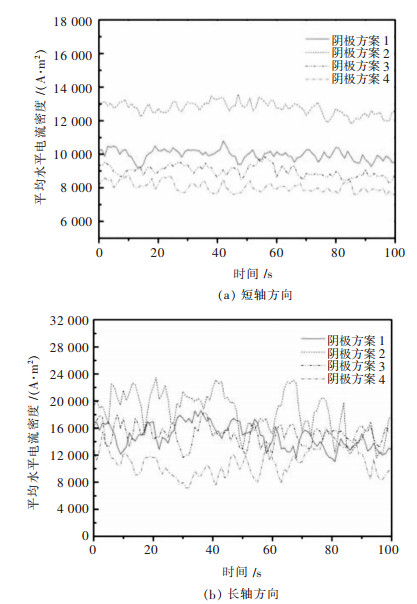

图 3(a)和图 3(b)所示为槽内流场相对平稳的100 s中时间段,各方案对应的铝液内短轴方向和长轴方向的平均电流密度随时间的变化.观察图 3(a),与方案1相比,方案3和方案4的短轴方向平均电流密度整体上均有所降低,并且方案4造成的降幅更大,方案2短轴方向的水平电流反而有所上升;由图 3(b)可知,方案4可以降低铝液内部长轴方向的水平电流,但也会使其随时间的波动更为剧烈,方案3的铝液长轴方向水平电流变化不明显,但方案2却使长轴方向的水平电流升高,并且波动幅度同样有所上升.综合对比,在铝液水平电流的优化上,方案4最为有效,方案2反而使铝液中的水平电流有所升高.

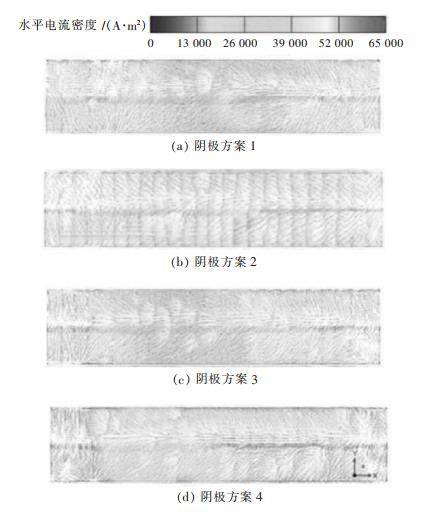

图 4所示分别为某时刻各方案的铝液中部水平电流分布形态.由图 4可以看出,尽管4种方案阴极结构各不相同,其水平电流分布还是遵循了一定的规律.首先,流体域中央处水平电流密度都相对较高,这取决于电解槽结构特点;其次,在铝液水平电流的分布形态上,方案1、方案3和方案4较为相似,其水平电流值也依次降低,而方案2长轴方向电流的分布形态显现出周期性的间断,究其原因是熔融铝液的导电能力远大于阴极,电流流经铝液时更倾向于从阴极表面的凹槽中汇入阴极,水平电流流经各个凹槽上方时流向转变,从而呈现出规律的不连续.

3.2 熔体流场计算结果的对比与分析

计算得到4种方案铝液中部流场形态绘于图 5.由图 5可以看出,与方案1相比,方案3与方案4对应的铝液流场分布没有明显变化,只是使铝液的流速有所降低;与此同时,方案2的铝液流场形态与方案1有较大差异,由于受到阴极凸台的阻滞,槽内铝液的流动呈现出周期性的间断.

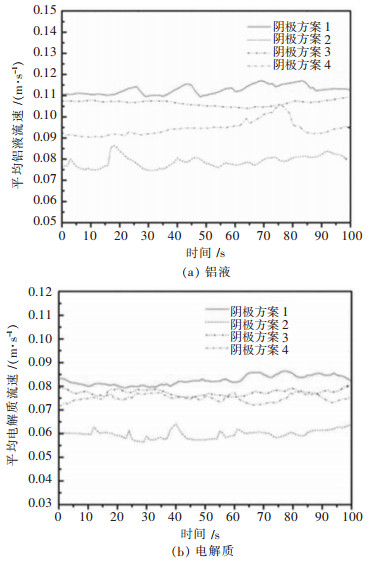

图 6比较了不同时刻方案1~方案4铝液和电解质中部平均水平流速.可以看出,由于电解质层和铝液层间存在相间曳力,阴极结构的变化也会影响铝液上方电解质层的流动,且电解质流速和铝液流速降幅大小关系较为一致.其中,方案2减缓槽内熔体流速的效果最优,方案4也有较好的减熔体流速效果,但同时会使得平均流速产生波动,而方案3降低熔体流速的效果最弱.因此,3种新型阴极结构方案均可使熔体流速降低,且基于降水平电流思路提出的方案3和方案4的熔体流速降幅与它们对应的降低水平电流的效果成正比.

需要指出的是,保持一定程度的电解质流速对电解槽的稳定运行相当关键.对于计算研究的3种优化结构,方案2对应的电解质平均流速下降的幅度较大,这对于下料后氧化铝颗粒的熔解和扩散可能有负面效果.

3.3 铝液-电解质界面波动计算结果对比与分析

在多相流计算中,可通过槽内空间的各相体积分数得到铝液-电解质界面.一般将体积分数满足rb=rm=0.5的等值面视为铝液-电解质界面.

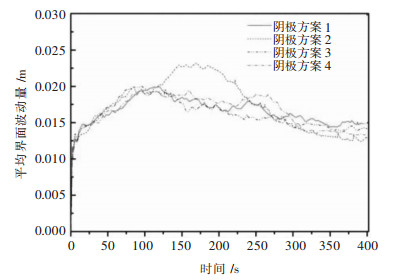

通过计算得到了不同阴极方案下铝液-电解质两相界面的瞬时分布. 图 7所示为从界面静止初始状态起方案1~方案4铝液-电解质界面平均波动量随时间的变化对比(ζmean为界面平均波动量,其大小可反映整体界面的变形幅度).

由图 7可知,对于方案1~方案4,前期界面波动量一直在不断变化.到300 s左右界面波动逐渐平稳.要对比判断不同方案对磁流体稳定性的影响,应根据界面趋近平稳后的最终状态分析.比较界面较为平稳时各方案的界面波动量,界面变形量从小到大依次为方案2,方案4和方案3.与普通阴极结构相比,3种阴极优化结构均可降低界面波动量,但降幅并不明显.

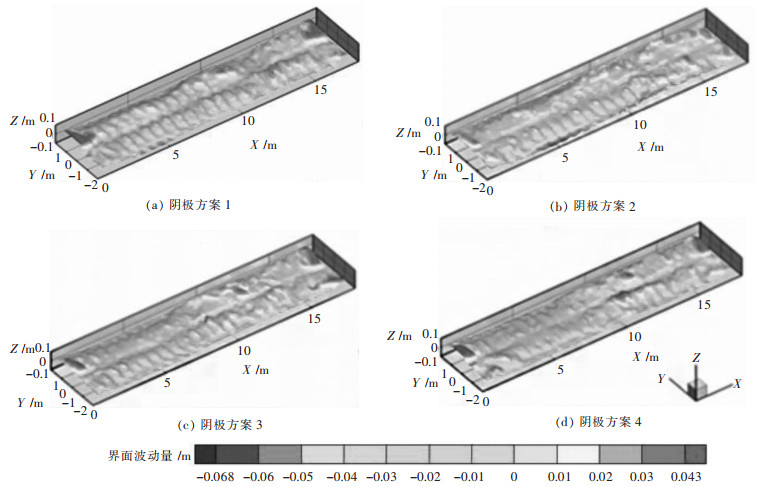

图 8所示为某时刻方案1~方案4对应的铝液-电解质界面形状分布.可知,与方案1相比,方案3和方案4的整体界面形状未发生明显改变,槽端部和中部界面均存在较大幅度的上凸,而方案2对应的界面大变形面积有所减少,相较来说整体界面形状更加平滑.

3.4 4种阴极优化方案对应的电流效率计算与比较

工业中一般认为降低铝液的波动就可以提高槽电流效率,然而相关研究[19]表明,电流效率的大小取决于电解反应产物在熔体中的扩散速度,而反应产物的扩散行为是在微观尺度下进行的,只用宏观尺度下界面波动的大小难以对槽电流效率做出比较.根据相关研究中提出的电流效率模型[20],使用湍流动能耗散率可更准确地评判电解反应产物在熔体中的扩散行为,并可根据界面重构法来分析计算相应的槽电流效率.据此探索性地对比了方案1~方案4的420 kA槽电流效率.

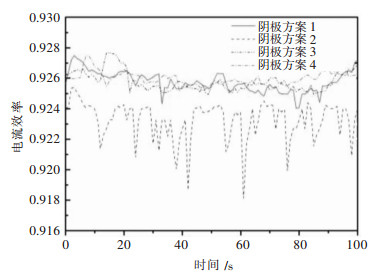

通过上述模型计算对比了各方案下槽电流效率随时间的变化如图 9.可以看出,基于阻挡铝液流动思路设计的方案2对应的电流效率有所降低,波动幅度也有所增大.这是因为凸台型阴极结构会使界面处熔体流场产生周期性的间断,加强流体之间的相互作用,熔体的湍流动能耗散率也随之升高,从而使槽电流效率降低.

4 结论

1) 建立了一种电-磁-流场强耦合的铝电解槽磁流体计算模型,实现了电解槽的电-磁-流强耦合仿真,并应用该模型计算对比了3种阴极优化结构的理论效果.

2) 在水平电流方面,与采用普通阴极相比,采用高导电阴极钢棒结构可使铝液水平电流有较大程度的下降,采用非均匀导电阴极结构仅能在一定程度上降低槽宽度方向上的水平电流,而采用凸台型阴极方案将使铝液水平电流出现大幅上升.

3) 对于磁流体行为方面,3种新型阴极方案均可降低熔体流速和铝液-电解质界面波动幅度,其中,凸台型阴极造成的流速降幅最大,也能使界面形状更加平整,同时由于电解质流速下降的幅度较大,不利于下料后氧化铝颗粒的熔解和扩散.非均匀导电与高导电钢棒结构对应的熔体流速降幅和二者降低水平电流的效果成正比.

4) 槽电流效率方面,非均匀导电和高导电钢棒结构没有造成显著影响,而凸台型阴极会使槽电流效率略微降低,这是因为该阴极结构加快了铝液-电解质界面处的流体运动.

-

表 1 瞬态三维三相流模型中动量守恒方程的相关项

Table 1 Terms of momentum conservation equation in three-dimensional transient MHD model

α $\nu _{eff}^\alpha $ $S_M^\alpha $ ${M^\alpha }$ Bath ${\nu ^b} + {\nu _t}$ ${r^b}F_{EM}^b$ ${C^{b, m}}({U^m} -{U^b}) + {C^{b, p}}({U^p} -{U^b})$ Molten aluminum ${\nu ^m} + {\nu _t}$ ${r^m}({\rho ^m} -{\rho ^b})g + {r^m}F_{EM}^m$ ${C^{m, b}}({U^b} -{U^m})$ Bubble ${\nu ^p} + {\nu _t}$ ${r^p}({\rho ^p} -{\rho ^b})g$ ${C^{p, b}}({U^b} -{U^p})$ 表 2 某420kA电解槽关键参数

Table 2 Key parameters of 420kA aluminum reduction cell

参数 数值 电流/kA 420 阳极炭块/mm 1700×660×540 阴极炭块/mm 3680×665×485 阴极钢棒/mm 2200×100×200 阴极开槽/mm 3680×125×245 铝液高度/mm 220 电解质高度/mm 180 极距/mm 45 阳极炭块数量 48 阴极炭块数量 24 钢棒数量 96 表 3 主要流体相物性参数

Table 3 Physical Parameters of fluid phase

材料 铝液 电解质 气泡 密度/(kg·m-3) 2270 2130 0.398 黏度/(kg·m-1·s-1) 1.18×10-3 2.513×10-3 5.055×10-5 -

[1] DUPUIS M, BOJAREVICS V. Newest MHD-Valdis cell stability studies[J]. Aluminium, 2014, 90(1/2): 42-44. http://www.genisim.com/download/ALUMINIUM2014.pdf

[2] 刘业翔, 李劼.现代铝电解[M].北京:冶金工业出版社, 2008:222. [3] AGNIHOTRI A, PATHAK S U, MUKHOPADHYAY J. Effect of metal pad instabilities on current efficiency in aluminium electrolysis[J]. Transactions of the Indian Institute of Metals, 2014, 67(3): 315-323. doi: 10.1007/s12666-013-0349-4

[4] 徐宇杰, 李劼, 张红亮, 等.基于非线性浅水模型的铝电解磁流体动力学计算[J].中国有色金属学报, 2011, 21(1):191-197. http://www.cnki.com.cn/Article/CJFDTOTAL-ZYXZ201101025.htm [5] STEEVE R, BENOIT B, GILLES S, et al. Unsteady MHD modelling applied to cell stability[J]. Light Metals, 2013, 68:577-584.

[6] LINDSAY R I, DAVIDSON P A. Stability of interfacial waves in aluminum reduction cell[J]. J Fluid Mech, 1998, 362: 327-331. doi: 10.1017/S0022112097008045

[7] BOJAREVICS V, ROMERIO M V. Long waves instability of liquid metal-electrolyte interface in aluminum electrolysis cells: A generalization of Sele's criteria[J]. European Journal of Mechanics B/fluids, 1994, 13: 33-56.

[8] TOWNSEND D W. Slotted cathode collector bar for electrolyte reduction cell: United States: US4795540[P]. 1989-01-03.

[9] 张红亮, 李劼, 杨帅, 等. 一种非均匀导电的铝电解槽阴极结构: 中国: CN202047141[P]. 2011-11-23. [10] BAYER I, OLMSTEAD B R. Composite Collector Bar: United States: US20100258434[P]. 2010-10-14.

[11] 曹国法, 曹志伟, 王旭东, 等. 高导电率电解槽阴极导电棒: 中国: CN202081182[P]. 2011-12-21. [12] DE NORA V. Cell for aluminium electro winning: United States: US6093304[P]. 2000-07-25.

[13] 冯乃祥. 一种异形阴极碳块结构铝电解槽: 中国: CN100478500C[P]. 2007-10-17. [14] WANG Q, LI B, WANG F, et al. Magnetohydrodynamic model coupling multiphase flow in aluminum reduction cell with innovative cathode protrusion[C]//Sadler B. Light Metals 2013. San Antonio, TE: TMS, 2013: 615-619.

[15] LI B, WANG F, ZHANG X, et al. Modeling of interface of electrolyte/aluminum melt in aluminum reduction cell with novel cathode structure[C]//Suarez C E. Light Metals 2012. Orlando, FL: TMS, 2012: 865-868.

[16] BOJAREVICS V. MHD of Aluminium Cells with the Effect of Channels and Cathode Perturbation Elements[C]//Sadler B. Light Metals 2013. San Antonio, TE: TMS, 2013: 609-614.

[17] MOREAU R, EVANS J W. Analysis of the hydrodynamics of aluminum reduction cells[J]. Journal of the Electrochemical Society, 1984, 131(10): 2251-2259. doi: 10.1149/1.2115235

[18] LI J, LIU W, LAI Y, et al. Improved finiteelement model for electro-magnetic analysis in aluminumcells[J]. JOM, 2008, 60(2): 58-61. doi: 10.1007/s11837-008-0020-4

[19] STERTEN A, SOLLI P A. An electrochemical current efficiency model for aluminium electrolysis cells[J]. Jounal of Applied Electrochemistry, 1996, 26: 187-193. doi: 10.1007/BF00364069

[20] LI J, XU Y, ZHANG H, et al. An inhomogeneous three-phase model for the flow in aluminium reduction cells[J]. International Journal of Multiphase Flow, 2011, 37(1): 46-54. doi: 10.1016/j.ijmultiphaseflow.2010.08.009

-

期刊类型引用(2)

1. 龚丹丹,张勇,周红丽,钱汉麟,马爱顺,任嗣利,李明周. 钨矿碱分解工艺制备仲钨酸铵全流程仿真计算. 中南大学学报(自然科学版). 2024(01): 43-54 .  百度学术

百度学术

2. 魏兴国,廖成志,侯文渊,段鹏,李贺松. 高密度阳极铝电解槽电-热场耦合仿真研究. 中南大学学报(自然科学版). 2023(02): 744-753 .  百度学术

百度学术

其他类型引用(0)

下载:

下载: