Numerical simulation and parameter optimization of oxygen bottom blowing smelting process

-

摘要: 采用数值模拟方法,分别研究熔池深度、气体流量、氧枪倾角、氧枪直径等参数变化对熔池气含率、熔体平均速度和平均湍动能的影响.结果表明:当熔池深度为1.3~1.5 m时,熔池内部气液两相搅拌强烈,气含率存在较大值为17.5 %,熔池处于较好的运动状态;气含率、熔体平均速度和平均湍动能随气体流量的增加呈现先减小后增大趋势,选取适宜气体流量为0.6~0.7 kg/s;熔池气含率随氧枪倾角的逐渐增大先增大后减小,而熔体平均运动速度和平均湍动能呈现先减小后增大趋势,选取适宜氧枪倾角为20°~25°;氧枪直径为30~35 mm时,熔池气含率和平均湍动能处于较大值,约为13 %和0.8 m2/s2,熔池处于较好的运动状态.Abstract: Using numerical simulation method, the influences of bath depth, gas flow and oxygen lance inclination, as well as lance diameter on gas holdup, melt average velocity and turbulent kinetic energy are studied respectively. The results show that, when the bath depth is around 1.3~1.5 m, the gas-liquid phase in the bath is agitated strongly and the bigger bath gas rate is 17.5 %. The bath motion is in the better state. With the gas flow increasing, the bath gas rate, melt average velocity and average turbulent kinetic energy decrease firstly, and then increase. The optimal parameter is in the range of 0.6~0.7 kg/s. The bath gas rate increases first and then decreases as oxygen lance inclination increases, while the melt average velocity and average turbulent kinetic energy decrease first and then increase. The proper parameter is in the range of 20°~ 25°.When the lance diameter is in the range of 30~35 mm, there exist bigger values for bath gas rate and turbulent kinetic energy which are 13 % and 0.8 m2/s2 respectively. At this moment, the bath motion is in the better state.

-

作为我国自主研发、具有自主知识产权的新型强化熔炼技术,氧气底吹熔池熔炼工艺因其清洁高效等优点而广泛应用于铜、铅冶炼行业[1, 2].随着工艺的不断推广以及技术升级,氧气底吹熔炼工艺得到充分发展,但熔池熔炼过程反应机理及流体运动规律尚不明确,原因在于熔炼过程温度高、规模大,传统研究方法难以展示其内在现象.计算机技术与流体力学的发展开辟了数值模拟研究传统冶金新路径,通过仿真模拟,使冶金过程中速度、压力、温度等主要变量具象化,从而揭示冶金过程反应机理及多相流体运动规律[3].

富氧空气经氧枪射入熔池搅动熔体,并作为反应物参与反应,因此熔池气相的运动状态直接决定了熔池反应机理及流体运动规律.目前采用数值模拟方法对高温冶金的研究成为热点[4-6],邵品[7]模拟了底吹冰铜吹炼炉双氧枪在不同对喷角度下气液两相流行为,通过对比湍动能分布与气含量确定了最佳对喷角度;王仕博[8]通过模拟顶吹熔炼过程单个气泡在熔体中的运动情况,指出气泡在运动过程中产生大大小小的涡旋,并通过涡旋发生能量传递;娄文涛[9]对艾萨炉内气泡运动情况进行模拟,利用水模实验加以验证,研究结果吻合良好;闫红杰[10]模拟了氧枪布置方式对熔池的搅拌作用,通过分析气含率、氧枪间距及角度等参数确定了底吹熔炼氧枪最佳布置方式;张振扬[11]通过模拟特定气体流量下气泡形成尺寸、熔池气含率和氧枪口压力变化,分析了熔池气液两相流动情况.然而采用数值模拟方法对氧气底吹熔炼工艺参数优化的相关文献报道较少,因此本文以熔池气含率、熔体平均速度和平均湍动能为衡量标准,对熔池深度、气体流量、氧枪倾度以及氧枪直径等参数进行优化,以期为底吹炉工艺强化和炉型改进提供理论指导.

1 模型建立

1.1 物理建模

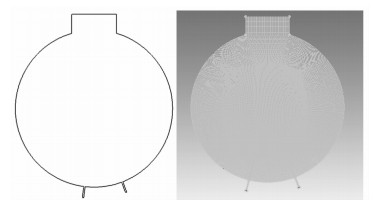

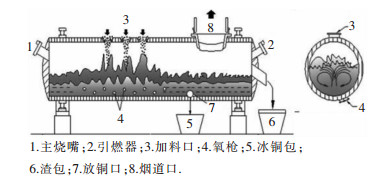

以国内某公司氧气底吹熔炼炉为研究对象,结构示意图如图 1所示.熔炼炉长度为15 m,氧枪直径为0.03 m,一共9支,分两排交叉布置,与竖直方向夹角分别为7°和22°,单排氧枪间距为1.0 m,熔池熔炼炉内径为3.5 m,熔池深度为1.4 m.

为简化计算,截取底吹熔炼炉纵截面作为二维研究平面,建立简化模型并划分网格.如图 2所示,网格为非结构网格,对气液两相主要作用区域进行网格加密,网格总数为12万,质量大于0.75,能够满足模拟所需精度.

1.2 数学模型及求解条件

底吹熔池熔炼过程涉及传热传质、相变及化学反应,过程极其复杂,而本文主要研究不同工艺参数下气相在熔体内运动情况,因此作出以下假设.

1) 气液两相均为不可压缩流体,物性参数不随时间、空间变化.

2) 炉内熔体为铜锍相,忽略渣层影响,初始状态为静止状态.

3) 不考虑化学反应.

VOF多相流模型能够精确模拟气泡的自由液面,对流体中大气泡的运动和气液界面的稳态和瞬态处理具有优良表现[13-17],因此本文采用VOF多相流模型.VOF多相流模型遵循质量守恒、能量守恒和动量守恒定律,控制方程如下:

1) 连续性方程:

$$ \frac{\partial }{{\partial t}}\left( {{\alpha _q}{\rho _q}} \right) + \nabla \cdot \left( {{\alpha _q}{\rho _q}{v_q}} \right) = {S_{{\alpha _q}}} + \sum\nolimits_{p = 1}^n {\left( {{{\dot m}_{pq}} - {{\dot m}_{qp}}} \right)} $$ (1) 式(1)中,${\dot m_{pq}}$是p相到q相的质量输送,${\dot m_{qp}}$是q相到p相的质量输送,单位为kg;αq为第q相的体积分数;Sαq为源相,默认情况下为0;vq为第q相的速度,单位为m/s;ρq为第q相的密度,单位为kg/m3.

2) 动量方程:

$$ \frac{{\partial \left( {\rho v} \right)}}{{\partial t}} + \nabla \cdot \left( {\rho vv} \right) = - \nabla P + \nabla \cdot \left[{\mu \left( {\nabla v + \nabla {v^T}} \right)} \right] + \rho g + F $$ (2) 式(2)中P为压力,单位Pa;g为重力加速度,单位m/s2;F为作用于控制容积上的体积力,单位:N;v为流体速度,单位:m/s;μ为有效黏度,单位:Pa·s.

氧枪入口设置为质量流量入口边界条件,入口气体为不可压缩空气,入口压力为0.6 MPa;烟道出口处设置为压强出口边界条件,出口压力设置为微负压;使用标准壁面方程.由于本文模拟熔池内部气液两相运动行为情况,熔炼炉内仅有空气和铜锍2种流体,具体物性参数见表 1所列.

表 1 熔炼炉内铜锍和气体物性参数Table 1. Property parameters of melt and gas in smelting furnace物质 密度

/(kg·m-3)比热容

/(J·kg-1·K-1)粘度

/(Pa·S)表面张力

/(N·m-1)热导率

/(W·m-1·K-1)铜锍 4600 628 0.004 0.33 3 气体 1.225 952 1.9×10-5 / 0.0245 注:“/”指未测定该值. 2 参数优化标准

在实际生产过程中,熔池气含率、熔体平均速度和平均湍动能是反映熔池熔炼状态的重要参数.熔池气含率越高,气液交互面积及气相浓度越大,越有利于熔池中冶金反应的进行;熔体平均速度和平均湍动能越大,表明熔池气液两相搅拌越强烈,但熔体运动程度存在一个最佳范围,否则容易造成熔体喷溅、加料口堵塞等问题.

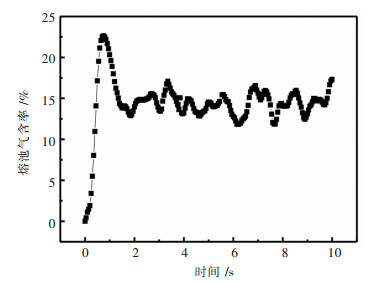

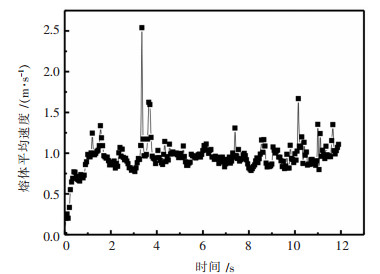

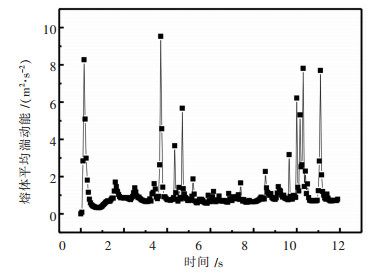

图 3、图 4、图 5所示分别为在一定熔炼工艺条件下,熔池气含率、熔体平均运动速度和平均湍动能随时间变化曲线.分析可知,随着熔炼过程的进行,熔池气含率、熔体平均速度和平均湍动能均呈现先增大后逐渐稳定趋势,其中由于底吹熔炼过程中氧枪喷吹存在“气泡后坐”现象,湍动能存在脉冲式波动现象.熔池气含率、熔体平均运动速度和平均湍动能随时间增大趋于稳定,表明熔池运动达到动态平衡,因此采用熔池动态平衡状态下气含率、熔体平均速度和平均湍动能变化作为熔炼工艺参数优化的衡量标准.

3 工艺参数优化

3.1 熔池深度变化对优化标准的影响

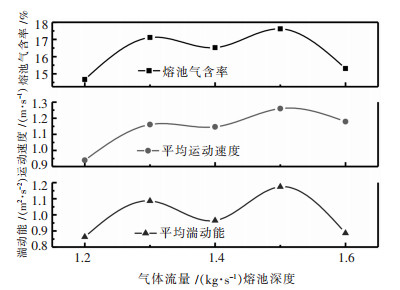

调整氧气底吹熔炼过程熔池深度分别为1.3 m、1.4 m、1.5 m、1.6 m,当熔池运动达到动态平衡时,熔池气含率、熔体平均速度和平均湍动能等参数变化趋势如图 6所示.

由图 6可知,随着熔池深度的增大,熔池气含率、熔体平均速度和熔体平均湍动能呈现基本相同的变化趋势,即先迅速增大,随后处于一个较稳定阶段,最后逐渐下降.在一定气体流量下,熔池深度越大,气相在熔体中的运动距离越长,气液两相间能量转化程度增大,导致熔体平均速度逐渐增大,而气相速度衰减严重,相应延长了气体在熔体中停留时间,使熔池气含率增大.当熔池深度增大到一定程度后,熔体体积增大趋势高于液相中气体体积增大趋势,造成熔体单位体积气体含量减小,相应熔池气含率降低,且气相动能传递更大质量的液相,导致熔体平均速度和平均湍动能减小.

为保持较高的熔池气含率及合适的熔体平均速度和湍动能,且符合实际生产中转炉安全需求[18],选取适宜的熔池深度为1.3~1.5 m.

3.2 气体流量变化对优化标准的影响

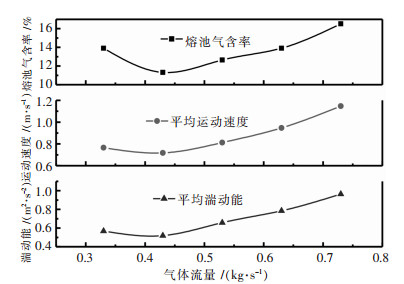

设定气体流量分别为0.35 kg/s、0.45 kg/s、0.55 kg/s、0.65 kg/s、0.75 kg/s,当熔池运动达到动态平衡时,熔池气含率、熔体平均速度和平均湍动能等参数变化趋势如图 7所示.

由图 7可知,随着气体流量逐渐增大,熔池气含率、熔体平均速度和平均湍动能均呈现先减小后增大的趋势.当气体流量较小时,气体在熔体中运动速度较小,导致气体在熔体中停留时间较长,熔池气含率较高;随着气体流量逐渐增大,气体运动速度逐渐增大,相应停留时间缩短,熔池气含率逐渐降低.根据文献[19]的研究结果,当气体流量增大至一定程度后,气体对熔体产生强烈搅拌作用并以涡旋形式运动,相应增大了气体在熔体中运动距离,从而使熔池气含率迅速增大.与此同时,随着气体流量的增大,气液两相间能量传递程度迅速增大,导致熔体平均速度和平均湍动能增大.

因此适当增加气体流量可以提高熔池气含率,有利于熔池反应快速进行,但过大的气体流量会造成熔体喷溅、加料口堵塞等问题,根据熔池气液两相运动状态,选取合适的气体流量范围为0.6~0.7 kg/s.

3.3 氧枪倾角变化对优化标准的影响

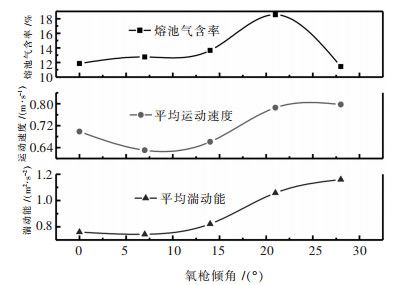

分别建立不同氧枪倾角下底吹炉二维模型,当熔池运动达到动态平衡时,熔池气含率、熔体平均速度和平均湍动能等参数变化趋势如图 8所示.

由图 8可知,随着氧枪倾角的逐渐增大,熔池气含率和熔体平均湍动能呈现先增大后减小趋势,熔体平均速度则呈先减小后增大趋势.当氧枪角度在0°~15°时,气含率与湍动能增大趋势缓慢,其原因在于,氧枪角度的增大导致气体在炉内X轴方向分速度增大而Y轴方向分速度减小,相应延长了气体在熔体中运动距离,导致气体在熔体中停留时间延长,熔池气含率增大.气相在炉内X轴方向的运动受到液相阻力增大,动能转化为内能程度增大,造成熔体平均速度逐渐较小.随着氧枪倾角继续增加,熔池气含率、熔体平均速度和平均湍动能迅速增大,但当氧枪角度增大至一定程度后,熔池气含率迅速下降,表明氧枪角度存在一个适宜的范围,使气含率保持最大值的同时,熔体平均速度和平均湍动能处在较适宜的范围以抑制熔体喷溅现象,因此选取底吹熔炼炉氧枪角度为20°~25°范围内较好.

3.4 氧枪直径变化对优化标准的影响

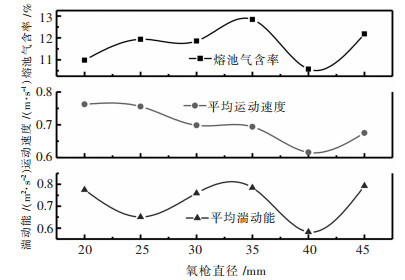

改变氧枪直径分别为20 mm、25 mm、30 mm、35 mm、40 mm、45 mm,当熔池运动达到动态平衡时,熔池气含率、熔体平均速度和平均湍动能等参数变化趋势如图 9所示.

由图 9可知,在气体流量不变情况下,随着氧枪直径增大,熔池气含率呈先增大后降低趋势,而熔体平均速度逐渐下降,熔体平均湍动能呈现起伏波动趋势,超过40 mm之后三者均呈现上升趋势.分析认为,氧枪直径较小时,气体喷入熔池初速度较大,但氧枪直径越小,熔池中形成气泡越小,气泡浮力越小阻力越大,气液两相接触面积越大,总能量一定情况下气液两相间动能损失越大,因此熔体平均速度随着氧枪直径增大而逐渐减小,而熔池气含率却逐渐增大.随着氧枪直径进一步增大,熔池形成气泡尺寸增大,气体射入熔体初速度减小;气泡浮力增大,在上浮过程中,上浮速度增大导致在熔体中停留时间缩短,相应熔池气含率降低,而气体初速度减小导致气液两相间动能转化程度减小,熔体平均速度降低.因此氧枪直径存在一个适宜的范围,以保证较大熔池气含率和较适宜熔体平均速度和平均湍动能.因此,选择氧枪直径适宜的范围为30~35 mm,此时熔池运动处于较好的状态.

4 结论

采用数值模拟的方法对底吹炉内部的流体流动状况进行模拟,并对熔炼工艺参数进行优化,以为生产提供理论指导.研究结论如下:

1) 当熔池深度为1.3~1.5m、喷吹气体流量为0.6~0.7 kg/s、氧枪倾角为20°~25°以及氧枪直径为30~35 mm时,气液两相搅拌强烈,熔池气含率、熔体平均运动速度和平均湍动能处于较优值,熔池运动状态较好,熔炼反应能够快速进行.

2) 文中采用二维模型进行计算,所得结果与实际生产有一定差异,但对氧气底吹熔炼工艺参数优化具有一定指导意义.

-

表 1 熔炼炉内铜锍和气体物性参数

Table 1 Property parameters of melt and gas in smelting furnace

物质 密度

/(kg·m-3)比热容

/(J·kg-1·K-1)粘度

/(Pa·S)表面张力

/(N·m-1)热导率

/(W·m-1·K-1)铜锍 4600 628 0.004 0.33 3 气体 1.225 952 1.9×10-5 / 0.0245 注:“/”指未测定该值. -

[1] 崔志祥, 申殿邦, 王智, 等.高富氧底吹熔池炼铜新工艺[J].有色金属(冶炼部分), 2010, 48(3): 17-20. http://www.cnki.com.cn/Article/CJFDTOTAL-METE201003005.htm [2] 朱祖泽, 贺家齐.现代铜冶金学[M].北京:科学出版社, 2003:319-320. [3] 李林波, 曾文斌, 朱军, 等.CFD数值模拟技术在冶金中的应用[J].钢铁研究学报, 2011, 23 (12):1-4. http://www.cnki.com.cn/Article/CJFDTOTAL-IRON201112002.htm [4] SHUI L, CUI ZX, MA XD, et al.Understanding of Bath Surface Wave in BottomBlown Copper Smelting Furnace[J]. METALLURGICAL AND MATERIALS TRANSACTIONS B, 2016, 47(1): 135-144. doi: 10.1007/s11663-015-0466-z

[5] LIM M, LI Q, ZOU Z S, et al. Computational investigation of swirling supersonicjets generated through a nozzle-twisted lance[J]. metallurgical and Materials transactions B, 2017, 48(1):713-725. doi: 10.1007/s11663-016-0851-2

[6] ERWEE M W, REYNOLDS Q G, ZIETSMAN J H. Comparison of 2D and 3D computational multiphase fluid flowmodels of oxygen lancing of pyrometallurgical furnacetap-holes[J]. JOM, 2016, 68(6): 1556-1562. doi: 10.1007/s11837-016-1873-6

[7] 邵品, 张延安, 刘燕, 等.底吹冰铜吹炼炉中气-液流动状况的数学模拟[J].东北大学学报(自然科学版), 2012, 33(9):1303-1306. http://www.cnki.com.cn/Article/CJFDTOTAL-DBDX201209022.htm [8] 王仕博. 艾萨炉顶吹熔池流动与传热过程数值模拟研究[D]. 昆明: 昆明理工大学, 2013. [9] 娄文涛, 张邦琪, 施哲.艾萨炉水模型内气泡运动的模拟[J].中国有色冶金, 2010, 39(1):48-53. http://www.cnki.com.cn/Article/CJFDTOTAL-YSYL201001014.htm [10] 闫红杰, 刘方侃, 张振杨, 等, 崔志祥, 申殿邦.喷枪布置方式对熔池熔炼过程的影响[J].中国有色金属学报, 2012, 22(8): 2393-2400. http://www.cnki.com.cn/Article/CJFDTOTAL-ZYXZ201208036.htm [11] 张振扬, 闫红杰, 刘方侃, 等.富氧底吹熔炼炉内氧枪结构参数的优化分析[J].中国有色金属学报, 2013, 23(5): 1471-1478. http://www.cnki.com.cn/Article/CJFDTOTAL-ZYXZ201305040.htm [12] 郭学益, 王亲猛, 廖立乐, 等.铜富氧底吹熔池熔炼过程机理及多相界面行为[J].有色金属科学与工程, 2014, 5(5):28-34. http://ysjskx.paperopen.com/oa/DArticle.aspx?type=view&id=201408006 [13] WANG X L, DONG H F, ZHANG X P, et al. Numerical simulation of single bubble motion in ionic liquids[J]. Chemical Engineering Science, 2010, 65(22): 6036-6047. doi: 10.1016/j.ces.2010.08.030

[14] LIANOS C A, GAR C, HERNANDEZ H S, et al. Multiphase modeling of the fluid dynamics of bottom argon bubbling during ladle operations[J]. ISIJ International, 2010, 50(3): 396-402. doi: 10.2355/isijinternational.50.396

[15] CHEN W Y, WANG J B, JIANG N, et al. Numerical simulation of gas-liquid two-phase jet flow in air-bubble generator[J]. Central South University of Technology, 2009, 15(1): 140-144. doi: 10.1007/s11771-008-0333-z

[16] WANG H, ZHANG Z Y, YANG Y M, et al. Numerical investigation of the interaction mechanism of two bubbles[J]. International Journal of Modern Physics C, 2010, 21(1): 33-49. doi: 10.1142/S0129183110014938

[17] LIU H P, QI Z Y, XU M G. Numerical simulation of flow and interfacial behavior in three-phase argon-stirred ladles with one plug and dual plugs[J]. Steel Research International, 2011, 82(4): 440-458. doi: 10.1002/srin.201000164

[18] 闫红杰, 夏韬, 刘柳, 等.高铅渣还原炉内气液两相流的数值模拟与结构优化[J].中国有色金属学报, 2014, 24(10):2642-2651. http://www.cnki.com.cn/Article/CJFDTOTAL-ZYXZ201410028.htm [19] YAN S Y, WANG Q M, TIAN Q H, et al. Simulation of gas phase motion in oxygen bottom blown copper smelting process[C] //F. Kongli.2016 Sustainable Industrial Processing Summit and Exhibition. Hainan, 2016: 245-253.

-

期刊类型引用(7)

1. 郗文龙,宋锦波,牛丽萍,刘素红. 大型底吹炉气含率的数值模拟. 材料与冶金学报. 2023(03): 224-229 .  百度学术

百度学术

2. 袁启盛,张斌,戴志海,詹佳鑫,林王军,彭金鹏. 底吹炼铜喷口区多相流动特性数值模拟研究. 世界有色金属. 2021(02): 6-10 .  百度学术

百度学术

3. 刘跃,常玲玲,李会荣,管小荣. 铝箔剪切机碎屑收集管优化设计. 有色金属科学与工程. 2021(04): 82-87+125 .  本站查看

本站查看

4. 张妍. 有色金属富氧底吹熔炼用氧枪设计与实验研究. 世界有色金属. 2020(13): 181-183+186 .  百度学术

百度学术

5. 郭学益,田庆华,刘咏,闫红杰,李栋,王亲猛,张佳峰. 有色金属资源循环研究应用进展. 中国有色金属学报. 2019(09): 1859-1901 .  百度学术

百度学术

6. 万章豪,徐志峰,黄金堤,严康. 立式釜内H_2SO_4-O_2-铜阳极泥三相搅拌模拟及灰色综合评价. 有色金属科学与工程. 2018(04): 21-28 .  本站查看

本站查看

7. 郭学益,闫书阳,王亲猛,田庆华. 氧气底吹熔炼氧枪枪位优化. 中国有色金属学报. 2018(12): 2539-2550 .  百度学术

百度学术

其他类型引用(5)

下载:

下载: