Thickness optimization for stage pillar based on blasting vibration

-

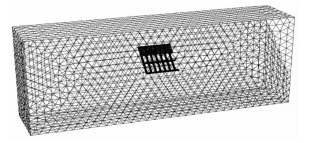

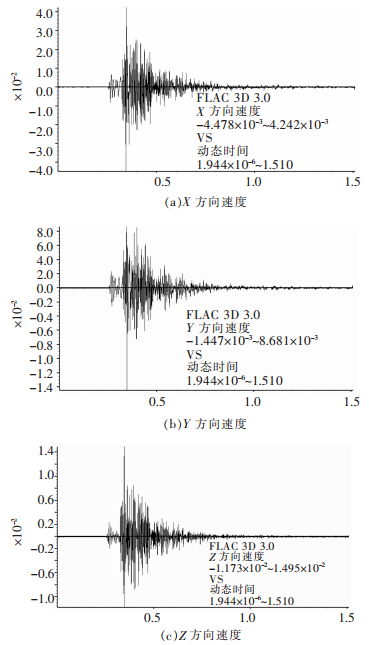

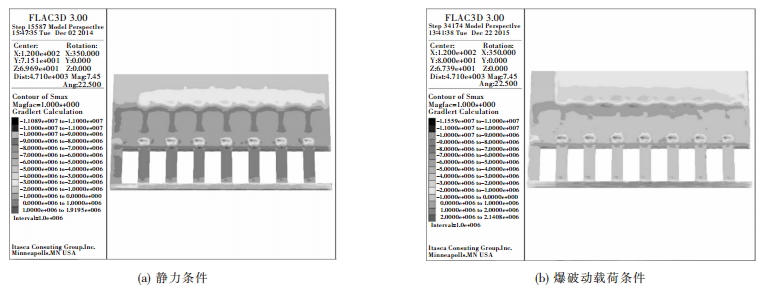

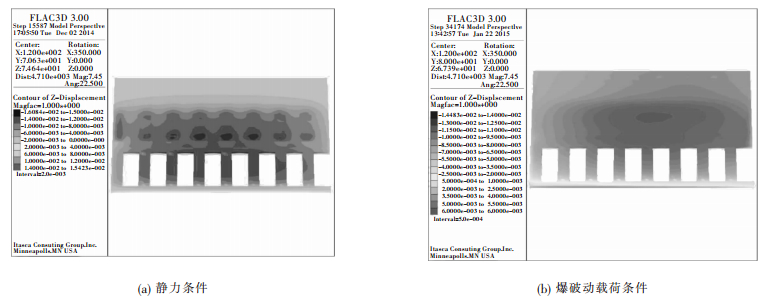

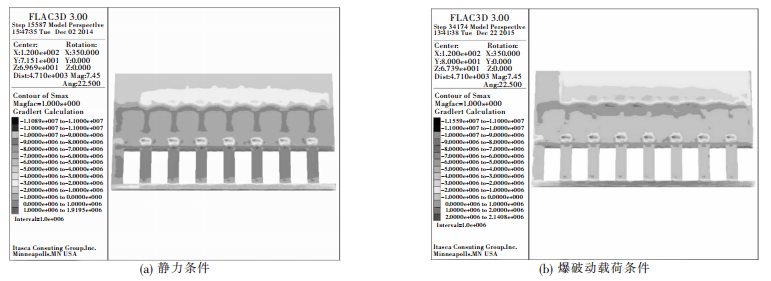

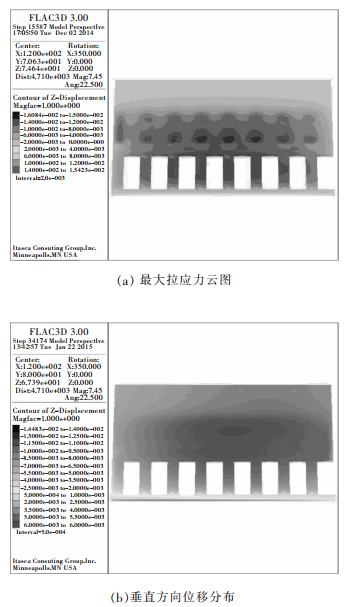

摘要: 为研究阶段矿柱的最小预留安全厚度,以上饶市某铜矿-100 m至-150 m中段采场回采为研究背景,针对爆破震动对矿山实际开采的影响,应用FLAC3D数值模拟软件对原设计阶段矿柱厚度5 m进行验算,并提出合理的阶段矿柱最小预留安全厚度.通过重点分析其静力和爆破动荷载条件下阶段矿柱的最大拉应力、垂直位移、塑性破坏域的模拟结果,结果表明:在静力条件下,阶段矿柱厚度分别为5 m和6 m时,采场均保持稳定;在爆破动荷载条件下,阶段矿柱厚度为6 m时,采场保持稳定,但为5 m时,采场处于欠稳定状态.结合理论模型的分析结果,最终确定阶段矿柱最小预留安全厚度为6 m.Abstract: To determine the minimum reserve safe thickness level of stage pillar, the middle stope mining from -100 m to -150 m in a copper mine in Shangrao City was studied. According to the effects of blasting vibration to practical mining, the designed stage pillar with thickness of 5 m is checked by FLAC3D. A reasonable minimum reserve safe thickness level of stage pillar is proposed. Through comparative analysis of simulation results under static and dynamic load blasting conditions, the results show that stopes are stable under static condition when the thickness of stage pillar is 5 m or 6 m. Under the blasting dynamic load condition, the stope is stable if the thickness of stage pillar is 6 m. However, when it is 5 m, the stope is in a less stable state. On the basis of analyzing theoretical model, the minimum reserve safe thickness level of stage pillars with thickness of 6 m is concluded.

-

Keywords:

- stage pillar /

- numerical simulation /

- blast loading /

- thickness optimization

-

自从美国数学家曼德勃罗(Benoit Mandelbrot)在法兰西学院讲课时,首次提出了分维和分形的设想之后,产生的“分形热”便开始经久不息,分形作为一种新的概念和方法正在许多领域开展应用探索。国内首先由谢和平院士[1-2]把分形理论引入到岩石力学,随后又将分形运用到岩石损伤过程,说明分形维数越大,材料损伤越严重。之后彭瑞东等[3]利用分形理论对工业CT扫描得到的岩石切片图像进行了分析,研究了岩石的孔隙率与分形维数之间的关系。邹飞等[4]用单轴加压实验得到整个时间序列的数字图像,处理图像得到分形维数与应变之间有很好的线性关系。但热图像研究方面,以往学者[5-10]大多通过加载过程中平均红外温度、最大红外温度和最小红外温度等红外特征参数变化以及热图、差值来间接反映岩石内部变化信息,由于岩石往往岩性、物理力学性质复杂程度不同,AIRT只是表示红外辐射整体温度水平,并不能准确表达辐射场的演化特征,很难给出明确清晰的结论。为了能够对岩石变形破坏过程进一步研究,以分形理论为主导通过盒维数法计算热图像分形维数,分析分形维数的变化[11-13]。随后刘善军等[14]引入分形,提出了用特征粗糙度为指标定量描述含孔岩石加载过程中红外辐射温度场的演化特征。

因此,本文根据分形理论用盒维数法计算出粉砂岩热图像特征粗糙度。通过特征粗糙度与应力-时间对比分析粉砂岩各个阶段的特性,其研究结果能对岩石失稳或破坏起到指导和预测作用。

1 单轴压缩下粉砂岩实验与分析

本次实验采用4块尺寸为50 mm×50 mm×100 mm的粉砂岩试件,编号分别为F1、F2、F3和F4, 。实验开始前,把各台监测仪器设备同时打开,时间一一对应,进行同步监测。实验全部在RLW-3000型伺服试验系统上完成,加载速度匀速,保持0.2mm/min,直到试件破坏(图 1)。采用美国SC3000红外实时成像系统(系统的空间分辨率为320×240像素,光谱范围在8~12μm,温度灵敏度达到0.03 ℃,成像速率调为50/s)进行观测,记录加载过程中各试件表面的红外热图像。

1.1 红外热图像特征粗糙度

美国SC3000红外实时成像系统,成像速率调为50/s,从加压初期到最终破坏产生大量热图像,在这些图像中每隔50张图像提取一张图像,得到500-600张左右热图像。每张热图像代表着一个温度数值矩阵,根据周宏伟等人[15]的粗糙表面分形维数估算方法进行计算,M×N的热图像不一定能被整数划分,首先对M×N的热图像进行分割,使其能够被分割成L×L的子块,在整个加载过程,粉砂岩表面温度变化为2摄氏度左右,可以令盒子高度h=L/M。

若L取不同的尺寸,分割成的子块数和盒子高度随之变化,总的盒子数也相应变化。按分形理论,立方体总数N(L)与L之间存在如下关系:

N(L)=kL-D

式中,D为分形维数,k为比例系数

不同的L值,得到对应不同的N(L), 将N(L)与L之间的关系绘制在双对数坐标中,通过直线拟合,直线斜率就代表热图像的分形维数。根据葛世荣等[16]的研究,分形维数并不能唯一确定岩石表面的粗糙度,需要纵坐标上的截距lgk作为辅助参数,结合分形维数D和比例系数k提出了特征粗糙度。特征粗糙度的计算公式:

Ra=k1/D

其中Ra表示特征粗糙度,表征热像粗糙度。Ra越大,说明温度场分布越粗糙;反之Ra越小,说明温度场越光滑,越整齐。

根据Matlab编程计算特征粗糙度,作出特征粗糙度、应力随时间变化曲线,如图 2.

根据图 2,特征粗糙度整体变化呈现拱形状,期间不断的上下交替, 整个加载到最后破坏的过程中最大变化量为0.4左右。加载初期,粉砂岩处在压密阶段,特征粗糙度迅速增加,很快达到最大值,增加0.15左右;A点处,特征粗糙度开始转变为向下降,阶段特征表现明显;弹性变形阶段,特征粗糙度开始有缓慢下降趋势,温度开始均匀化。随后到达应力峰值点C,期间特征粗糙度持续下降,特征粗糙度值开始有了明显的波动变化,随着继续加压,粉砂岩微裂隙大量增加,特征粗糙度上下波动的幅度和频率得到加强,且在峰值点C处试件F1、F4特征粗糙度有开始变大趋势,F2、F3变大的趋势不明显,基本在整个CD段,试件F1,F4特征粗糙度都处在上升阶段,此现象即为岩石失稳破裂的红外温变前兆。在D点附近,特征粗糙度异常突变说明岩石已经破坏。

1.2 粉砂岩温度场方差与应力随时间变化

方差表示的是各像元偏离平均值的程度,求出每一张热图像的方差随时间的变化,作出图 3.

根据图 3,加载初期,粉砂岩处于压密阶段,方差先是迅猛增加,很快达到最大值,说明辐射温度场各像元取值偏离平均值的程度较大。随后到A点,方差开始向下转变。之后塑性阶段(AB阶段),方差继续变小,各像元取值偏离平均值的程度逐渐缩小。压力继续增加,进入塑性-峰后阶段(BD阶段),此阶段粉砂岩内部微破裂逐渐发展产生裂纹,方差发生大幅度的向下的跳跃,且频率较之前也较多。D点附近,方差与特征粗糙度同样的发生突跳,试件F1、F3、F4突然变大,F2变小,说明岩石已破裂。

1.3 粉砂岩AIRT随时间变化图

平均红外温度(AIRT)对红外热图像描述能了解粉砂岩表面整体温度水平,为此可以作出AIRT随时间变化曲线如图 4.

图 4中,整个加载期间AIRT值的变化一直是小幅度上升与下降交替,开始到最后基本保持一直增加的趋势,阶段特征不是特别明显。因每个试件结构复杂程度和周围温度不同,岩石起始温度有一定差异,且在加载过程中所有试件中最大的变化量为0.6K左右。加载初期,AIRT近乎直线式的增加;从300s开始,AIRT上下波动的幅度和频率也开始明显加强,AIRT整体增加趋势变缓;岩石临近破裂,AIRT有小幅度的下降或上升,但红外异常不是特别明显,对岩石失稳破坏的红外前兆效果不理想。说明AIRT不能有效表达岩石加载过程中红外辐射温度场的分异现象和岩石破裂前兆现象。

2 相关性分析

在粉砂岩加载的整个过程,因AIRT阶段特征不明显,且红外异常不理想,这里主要研究的是特征粗糙度和方差与对应应力的相关关系密切程度。在压密阶段(OA段),弹性阶段(AB段),塑性-峰后阶段的相关系数分别如表 1,表 2和表 3.

表 1 压密阶段(OA段)相关系数Table 1. Correlation coefficient of compaction stage岩石试件编号 特征粗糙度 方差 F1试件 0.2000 0.8308 F2试件 0.8822 0.9554 F3试件 0.6326 0.8239 F4试件 0.5870 0.8840 表 2 弹性变形阶段(AB段)相关系数Table 2. Correlation coefficient of elastic deformation stage岩石试件编号 特征粗糙度 方差 F1试件 -0.5088 -0.6657 F2试件 -0.5908 0.7344 F3试件 -0.9105 -0.9800 F4试件 -0.8395 -0.8653 表 3 塑性-峰后阶段(BD段)相关系数Table 3. Correlation coefficients of plastic peak and post peak phase岩石试件编号 特征粗糙度 方差 F1试件 -0.6788 0.2825 F2试件 0.6821 0.8377 F3试件 -0.5825 0.6708 F4试件 -0.4710 -0.4325 根据以上3个表格,在压密阶段,方差介于显著相关和高度相关之间,而特征粗糙度其中的F2、F3和F4属于显著相关而F1表现为基本不相关。弹性变形阶段,方差和特征粗糙度开始向下转变,试件应与应力呈现负性相关,其中特征粗糙度表现良好,全部呈现负性相关,且其中的F3、F4呈现高度相关,F1、F2变成显著相关。对于方差,试件F2表现为正性的显著相关,试件F3和F4为负性的高度相关和F1是负性显著相关。最后在塑性-峰后阶段,特征粗糙度与应力相关程度比较理想,F1、F2、F3表现为显著相关,只有F4表现为低度相关。而对于方差,试件F2、F3的方差为显著相关,F4为负性低度相关,F1却为基本不相关。

3 讨论

粉砂岩孔隙率比较大,在加压过程中会伴随有微裂隙产生,进而发生相互错动摩擦产生热量,同时因岩石内部结构破坏,会发生张破裂吸热。摩擦热效应和张破裂吸热2种状态一直伴随着岩石加载的整个过程,只是在某个阶段某一种状态表现的更为突出。摩擦热效应占优,则表现为放热,否则即为吸热。

特征粗糙度是描述岩石表面红外温度场的光滑程度,方差是描述岩石表面红外温度偏离平均值的程度,而AIRT描述的是岩石表面整体的平均温度水平。对于AIRT,在加载的整个过程中基本保持一直增加,表明岩石整体温度水平逐渐变大。在粉砂岩压密阶段(OA段),特征粗糙度和方差都迅速变大,说明虽然粉砂岩表面温度整体的温度开始变大,但变化的不均匀、参差不齐,部分点温度急剧增大,在这个阶段摩擦热效应占优,表现出放热,且在这个阶段中据表 1可以看出方差在这个阶段与应力相关性更高。随着继续加压进入弹性变形阶段(AB段),特征粗糙度值和方差都开始转变为下降趋势,说明温度场开始变光滑,各温度偏离平均值程度在缩小,温度差异变小且温度分布开始变得均匀,异常变大点逐渐减少,粉砂岩整体温度上升且分布也开始变得均匀,表现为放热。由表 2也可以看出在这个阶段特征粗糙度和方差与应力的相关程度相当,二者对这个阶段的刻画效果也是相当。最后在塑性-峰后阶段,BC阶段特征粗糙度波动开始变多且幅度明显变大。而图 3中与之对应的阶段方差的波动数量和幅度也明显增加,该现象解释为粉砂岩微裂隙的快速增加以及张破裂的产生,在这个阶段中张破裂和摩擦热效应相互交替占优。随着继续加压,岩石内部张破裂加剧,期间整体表现为吸热,特征粗糙度和方差却有上升也有下降,说明在破坏阶段(CD段)粉砂岩局部温度变化复杂。在D点产生变异,特征粗糙度值发生异常大的跳动,图 2中的试件F1、F2、F3和F4特征粗糙度突然变大,这也说明了可以通过特征粗糙度的突变可以预测、监测粉砂岩破坏,对以后岩石破坏研究提供一定的指导意义。

4 结论

本文基于特征粗糙度、方差与应力随时间变化曲线以及AIRT随时间变化情况对粉砂岩在加载各阶段中表面辐射温度进行研究,通过比较分析得出结论如下:

1)整体来看,特征粗糙度和方差能较好刻画粉砂岩各个阶段特有的性质,与所加荷载呈现同步性。其中特征粗糙度的跳动频率及幅度较方差和AIRT都大,且特征粗糙度对岩石加载过程的红外温度场变化更为敏感。

2)压密阶段,特征粗糙度和方差是快速上升,方差与应力相关系数较特征粗糙度更高,说明此阶段用方差来刻画更好。弹性变形阶段,特征粗糙度和方差开始变小且它们与应力相关系数相当,说明用任一个来刻画都行。塑性-峰后阶段,特征粗糙度相关系数较方差更稳定,用特征粗糙度刻画较好。

3)塑性-峰后阶段,特征粗糙度开始有大幅度的跳动,且在应力峰值点特征粗糙度开始转向变大,此为红外温变前兆信息。

4)特征粗糙度表达岩石表面温度场光滑程度,而方差描述了各点温度偏离平均值的程度。研究中将2种方法结合起来效果可能更理想。

-

表 1 分段空场嗣后充填法的采场结构参数

Table 1 Stope structural parameters of sublevel open stope filling methodⅠ

参数名称 参数值/m 阶段高度 50 分段高度 13~20 生产盘区长度 90 采场长度 等于矿体宽度 采场宽度 30 矿房宽度 18 矿柱宽度 12 底柱高度 5 表 2 材料物理力学参数

Table 2 Material physical and mechanical parameters

材料名称 容重γ/(kN·m-3) 弹性模量E/GPa 泊松比V 抗拉强度σc/MPa 内摩擦角φ/(°) 粘聚力c/MPa 1:4充填体 20 0.59 0.14 0.19 9.77 1.26 1:10充填体 20 0.08 0.07 0.05 13.5 0.24 松散介质 21 0.02 0.3 0 30 0.038 矿体 31 7.19 0.25 2.395 47.29 3.061 围岩 26 8.36 0.29 2.5 51.84 3.611 表 3 爆破动荷载作用下与静力条件下数值模拟结果对比

Table 3 Numerical simulation results comparison table of under blasting load and static conditions

阶段矿柱厚度/m 作用条件 最大拉应力/MPa 垂直位移/cm 塑性区分布 稳定性 5 静力条件下 1.92 1.564 阶段矿柱有少量塑性区 基本稳定 5 爆破动荷载作用下 2.14 1.616 阶段矿柱塑性区增多,但未贯通 欠稳定 6 爆破动荷载作用下 1.93 1.592 无 基本稳定 -

[1] 王金安, 李大钟, 马海涛.采空区矿柱-顶板体系流变力学模型研究[J].岩石力学与工程学报, 2010, 29(3):577-582. http://www.cnki.com.cn/Article/CJFDTOTAL-YSLX201003020.htm [2] 宋卫东, 曹帅, 付建新, 等.矿柱稳定性影响因素敏感性分析及其应用研究[J].岩土力学, 2014, 35(1):271-277. http://www.cnki.com.cn/Article/CJFDTOTAL-YTLX2014S1039.htm [3] 费汉强, 黄英华.大体积充填体下隔离中段凿岩硐室顶板安全厚度研究[J].采矿技术, 2011, 11(6):46-48. http://www.cnki.com.cn/Article/CJFDTOTAL-SJCK201106018.htm [4] 江文武, 徐国元, 马长年, 等.基于尖点突变理论的矿房间矿柱的稳定性分析[J].金属矿山, 2007, 42(9):39-45. http://www.cnki.com.cn/Article/CJFDTOTAL-JSKS200709014.htm [5] 张钦礼, 曹小刚, 王艳利, 等.基于尖点突变模型的采场顶板-矿柱稳定性分析[J].中国安全科学学报, 2011, 21(10):52-57. http://www.cnki.com.cn/Article/CJFDTOTAL-ZAQK201110009.htm [6] 高峰, 周科平, 胡建华, 等.充填体下矿体开采安全顶板厚度数学预测模型[J].岩土力学, 2008, 29(1):177-181. http://www.cnki.com.cn/Article/CJFDTOTAL-YTLX200801035.htm [7] 罗辉, 杨仕教, 陶干强, 等.基于FEM-ANN-MCS动态模糊可靠度的矿柱稳定性分析[J].煤炭学报, 2010, 35(4):551-554. http://www.cnki.com.cn/Article/CJFDTOTAL-MTXB201004008.htm [8] 赵奎, 蔡美峰, 饶运章, 等.采空区块体稳定性的模糊随机可靠性研究[J].岩土力学, 2003, 24(6): 987-990. http://www.cnki.com.cn/Article/CJFDTOTAL-YTLX200306026.htm [9] 刘洪强, 张钦礼, 潘常甲, 等.空场法矿柱破坏规律及稳定性分析[J].采矿与安全工程学报, 2011, 28(1): 138-143. http://www.cnki.com.cn/Article/CJFDTOTAL-KSYL201101028.htm [10] 陈庆发, 古德生, 周科平, 等.对称协同开采人工矿柱失稳的突变理论分析[J].中南大学学报(自然科学版), 2012, 43(6):2338-2342. http://www.cnki.com.cn/Article/CJFDTOTAL-ZNGD201206046.htm [11] 黄敏.铜绿山矿充填体下残矿回采关键参数数值模拟优化研究[D].长沙:中南大学, 2012. [12] 赵奎, 邵海, 徐峰, 等.某铜矿不同采矿进路布置开采稳定性数值模拟[J].有色金属科学与工程, 2013, 4(2):46-50. http://ysjskx.paperopen.com/oa/DArticle.aspx?type=view&id=201302010 [13] 王学滨.屈服矿柱渐进破坏及应力分布数值模拟[J].中国地质灾害与防治学报, 2006, 17(2):50-56. http://www.cnki.com.cn/Article/CJFDTOTAL-ZGDH200602011.htm [14] 赵兴东.谦比西矿深部开采隔离矿柱稳定性分析[J].岩石力学与工程学报, 2010, 29(增刊1): 2616-2622. http://www.cnki.com.cn/Article/CJFDTOTAL-YSLX2010S1008.htm [15] 魏巍.洞室群围岩稳定性数值模拟分析[D].北京:北京交通大学, 2010. [16] 任红岗, 谭卓英, 蔡学峰, 等.露天-地下联合开采中洞室群动力响应分析[J].北京科技大学学报, 2011, 33(6):647-652. http://www.cnki.com.cn/Article/CJFDTOTAL-BJKD201106002.htm [17] 高丹盈, 宋帅奇, 杨林.真三轴应力下塑性混凝土性能及破坏准则[J].水利学报, 2014, 45(3):360-367. http://www.cnki.com.cn/Article/CJFDTOTAL-SLXB201403014.htm [18] 王新民, 曹刚, 张钦礼, 等.康家湾矿深部难采矿体采场稳定性及结构参数优化研究[J].河南理工大学学报(自然科学版), 2007, 26(6):634-640. http://www.cnki.com.cn/Article/CJFDTOTAL-JGXB200706006.htm [19] 王晓军, 冯萧, 赵奎, 等.多因素组合影响阶段矿柱上采顶板临界厚度研究[J].岩土力学, 2013, 34(12):3505-3512. http://www.cnki.com.cn/Article/CJFDTOTAL-YTLX201312025.htm

下载:

下载: