Effect of grinding concentration on product size distribution characteristics

-

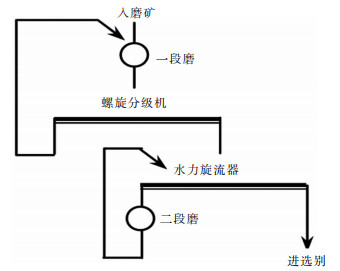

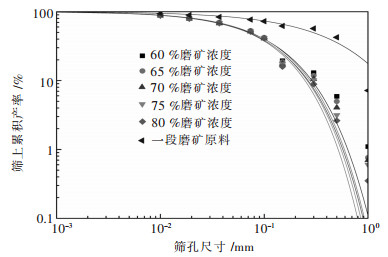

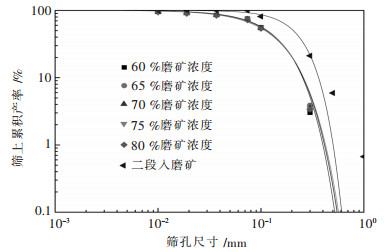

摘要: 磨矿浓度是影响磨矿产品粒度组成特性的关键因素.根据柿竹园矿石性质,在实验室和工业试验中分别考察不同浓度下一段磨和二段磨的产品粒度组成特性.结果表明,实验室条件下一段磨矿浓度在75 %、二段磨矿浓度在65 %时能获得均匀性好、合格产品粒度粗和有用磨矿耗能低的磨矿产品质量.工业试验条件下一段磨矿和二段磨矿产品中合格粒级产率分别增加2.23 %和3.96 %、平均粒度分别加粗1.13 μm和3.8 μm,过粉碎分别减轻0.88 %、1.35 %,磨矿过程技术效率分别增加2.79 %、4.86 %,能耗利用率分别增加4.39 %、6.12 %.同时,分级溢流产品中合格粒级产率增加0.72 %,平均粒度加粗1.4 μm,过粉碎减轻6.76 %,分级溢流产品质量得到全面优化.对选矿厂而言,稳定磨矿浓度非常有必要.Abstract: Grinding concentration is an important factor that can influence particle size characteristics of grinding product. According to the ore property in Shizhuyuan, the particle size characteristics of the first and second grinding products in different grinding concentrations from 60 % to 80 % in laboratory experiments and industrial tests were studied. The results show that the best grinding products with good uniformities, fine dissociation and low useful energy can be obtained at first grinding concentration of 75 % and the second of 65 % in laboratory experiments. In industrial tests, recoveries of eligible products in the first increased 2.23 % and second was 3.96 %, average grading were respectively heightened 1.13 μm and 3.8 μm, reduced degree of over grinding reduced 0.88 % and 1.35 %, grinding technical efficiencies increased 2.79 % and 4.86 %, and incremental use ratios of energy consumption were 4.39 %and 6.12 %. At the same time, the quality of grader overflow products were roundly optimized, eligible fraction increased by 0.72 %, average grading heightened 1.4 μm, and over crushed reduced by 6.76 %. In sum: the steady grinding concentration is necessary for the concentrator.

-

0 引言

在土木、水利、矿山等工程建设和生产领域,许多工程实践都与土体渗透性密切相关[1-3]。为了表征流体在土体(多孔介质)中的运动规律,通常开展渗流研究与分析。在土体渗流过程中,由于流体的物理作用和土体与水体之间的化学作用,对土体的抗剪强度产生一定影响[4]。渗流还会产生渗透力,当渗透力过大时,就会引起渗透破坏,如边坡破坏、地面隆起、堤坝失稳等现象[5-7]。因为土体渗流过程会引起许多工程问题,从而影响社会经济效益和生命财产安全,研究土体的渗流规律及其影响因素具有重要意义。

流体在多孔介质中的渗透特性及影响因素主要取决于两个方面[8-9]:一是流体的理化性质(如化学组成、温度和黏度等); 二是多孔介质的自身特性(如颗粒级配、粒径和孔隙度等)[10-12]。本文结合土体渗流的相关研究,系统地分析了流体的理化性质(化学组成、溶液浓度、温度、pH值等)对土体渗流规律的影响,阐述该影响的内在机理,并分析了各因素之间存在的联系。在此基础上,探讨了该领域未来的研究方向,便于读者系统了解流体对于土体渗流规律的影响及其作用机理。

1 渗透特性指标与影响因素

渗透系数是反映土体渗透特性的定量指标,是土体透水性的比例系数,相当于水力梯度为1时的渗流速度。在流体力学中,渗流速度与渗透流体的密度成正比,与渗透流体的黏度成反比,其关系可用公式(1)表示:

(1) 式(1)中:ρ是流体密度,kg/m3;g是重力加速度,m/s2;μ是流体的动力黏度,N·s/m2。

研究表明,颗粒的物理性状对土体渗透性的影响很大,因颗粒的物理性状影响孔径,从而在很大程度上影响流速,根据Poiseuille法则,流速与孔径的平方成正比:

(2) 式(2)中:d为土颗粒的孔径,m。

根据达西定律,单位渗水量与水力梯度成正比,结合式(1)和式(2),可得:

(3)

(4) 式(3)、式(4)中:C为与土体中与孔隙几何形状相关的无量纲常数;i为水力梯度,无量纲;q为单位渗水量,m3/s;k为土体的渗透系数,m/s。结合式(3)和式(4),可得:

(5) 由此可知,影响渗透系数的因素取决于两个方面:一是多孔介质的自身特性(Cd2),二是流体的自身特性(ρg/μ)。本文主要讨论流体的理化特性对渗流规律的影响。

2 流体的化学组成对土体渗透特性的影响

流体的化学组成对土体渗透特性具有重要影响。不同化学组成的流体在土体中发生渗流时,土体首先发生渗透固结,然后发生化学固结,固结过程致使土体孔隙增大,从而使得渗透系数增大。同时, 流体所含的重金属离子与土体发生化学反应,并生成难溶物质,堵塞土体的孔隙,导致渗透系数降低。流体在土体中的渗透特性与流体本身的黏度有关,黏度增大致使渗透系数降低。流体中阳离子价态也影响其渗透特性,土颗粒通常带负电荷,其双电层上的阳离子与流体中阳离子发生置换反应,从而改变土体上吸附的离子,进而改变土体渗透特性。

ANEKPONG等采用标准固结仪对8种渗流溶液进行了固结测试,探究了阳离子价数对渗透特性的影响[13]。所用渗流溶液分为3类:一价阳离子溶液,如LiCl溶液、NaCl溶液、KCl溶液;二价阳离子溶液,如CaCl2溶液、MgCl2溶液、ZnCl2溶液、CuCl2溶液;三价阳离子溶液,如FeCl3溶液。在围压分别为100、200、300、400 kPa,溶液浓度为0.1 mol/L时,测定了8种渗流溶液的渗透系数(图 1)[13]。渗透系数的计算公式如下:

(6) 式(6)中:k为渗透系数,cm/s;cv为固结系数,cm2/s;αv为压缩系数,cm2/kg;γp为渗流溶液的单位重量,kg/cm3;e为孔隙比,无量纲。

由图 1可见,流体中阳离子的化学价态不同,土体渗透系数也不同。当围压为100 kPa时,在一价阳离子溶液渗流过程中,除LiCl外,其余溶液渗透系数均高于纯水的渗透系数;在二价和三价阳离子溶液渗流过程中,除ZnCl2外,其余溶液渗透系数均高于纯水的渗透系数。由此可知,流体中阳离子的化学价态会影响土体的渗透特性,在围压相同时,大多数含阳离子溶液的渗透系数高于纯水。另外,改变围压,渗透系数明显被围压作用主导,随着围压逐渐增大,渗透系数逐渐减小。

JONES通过小比例阳离子溶液(例如,小比例Ca2+溶液是阳离子中有10% Ca2+,其余为Na+)渗透试验发现,具有小比例二价阳离子的水溶液可以有效地减少黏土孔隙堵塞,从而提供土体的渗透通道[14]。小比例Ca2+溶液渗透时,黏土上吸附的阳离子与Ca2+发生交换反应,从而抵抗土粒分散,防止了黏土孔隙发生阻塞。采用Mg2+代替Ca2+可以得到相似的结果。由此可知,小比例的二价阳离子溶液可以增强黏土的渗透性。

ARIENZO等的研究表明,含Na+、K+的溶液可降低黏土的渗透系数。随着溶液中Na+、K+浓度减小,渗透系数逐渐降低,并且含K+溶液渗透系数下降速度明显小于含Na+溶液[15]。

朱伟等采用柔性壁渗透仪考察了Ca2+溶液对砂-黏土混合土渗透系数的影响[16]。结果表明,相比于纯水,Ca2+溶液可增大黏土的渗透系数,这是由于Ca2+与黏土颗粒表面的一价阳离子发生置换反应,黏土颗粒表面的阳离子价数变大,使双电层厚度减小,有效孔隙率增大,致使土体的渗透系数增大。

土颗粒表面双电层包括了吸附层和扩散层,示意图见图 2。双电层厚度与孔隙中流体中阳离子价数成反比,阳离子价数越高,双电层越薄。

许四法等采用小型渗透装置对膨润掺砂混合土进行了渗透试验,用Ca2+溶液进行渗漏[17]。在Ca2+溶液渗漏过程中,膨润土自身为层状结构,膨润土颗粒表面的Na+易与溶液中的Ca2+发生离子交换,使得混合膨润土表面的阳离子价数变大,膨胀性能降低,渗透系数增大。

刘磊等通过柔性壁渗透试验研究发现,Ca2+溶液可增大土工合成衬垫材料的渗透系数[18],其原因是溶液中的Ca2+与土体中Na+和K+发生置换反应,使土体中颗粒双电子层厚度减小,从而导致孔隙空间增加,渗流通道变大,土工合成衬垫渗透系数随之增大。

张志红等研究了重金属离子(Cu2+)侵入对黏土渗透特性的影响。以CuCl2溶液作为渗透液进行室内渗流试验,当Cu2+侵入黏土时,土体渗透系数增大[19-20]。分析认为,随着流体中Cu2+增多,化学固结作用愈发明显,双电层厚度减小,黏土体颗粒间斥力减小,形成凝聚,导致渗透过程中吸附水发生解吸附现象,扩大了有效孔隙的流动通道,从而增大了黏土体的渗透特性。

唐晓武等通过室内变水头渗透试验,研究了KCl溶液与CuSO4溶液对粉质黏土、改良土的渗透特性的影响[21]。其中,改良土是将疏浚土(疏浚工程时挖出来的土)作为添加材料掺入粉质黏土形成的。研究发现,两种溶液均会使渗透系数增大。改良土的离子吸附量明显高于粉质黏土,在离子吸附量相同的情况下,改良土的渗透性不及粉质黏土。对于粉质黏土,阳离子影响了土颗粒的双电层厚度,使土体结构发生变化,渗流通道变大,渗透系数增加;对于改良土,阳离子可能被疏浚土中的有机质吸附,故其离子吸附量明显高于粉质黏土,有机质的黏结作用也影响渗透系数。

刘和平等研究了重金属离子Pb2+、Cd2+在黏土衬层中渗透、迁移及转化过程[22]。通过室内试验模拟Pb2+、Cd2+等二价离子在黏土衬层中的渗透过程,实验前期,含Pb2+、Cd2+的渗透液的渗透系数比蒸馏水大;在渗流稳定后,其渗透系数小于蒸馏水。分析认为Pb2+、Cd2+与黏土粒子发生物理化学变化,黏土胶体颗粒具有巨大的表面能,渗透液中的物质吸附在颗粒表面上,同时发生离子置换反应,使一些可溶性物质转化为难溶性物质,导致孔隙堵塞,渗透性能降低。

汤小明等通过室内变水头渗透试验研究了酒精溶液对黏土渗透特性的影响。酒精渗透土体,致使土颗粒表面电荷密度降低,促进双电层压缩减小,从而使得渗透系数增大[23]。该研究采用0.01 mol/L CaSO4溶液和99.7%(V/V)酒精作为渗透流体,其中,0.01 mol/L CaSO4溶液用于测定土体本身的渗透系数,并与酒精这种可溶性有机渗透溶液进行对比。首先测定天然黏土,渗透水渗流稳定后,渗透系数为2.60 × 10-8 cm/s;有机溶液渗流稳定后,渗透系数为4.53 × 10-8 cm/s。这表明在酒精作用下天然黏土的渗透系数增大约1倍。

综上可知,流体化学组成是影响土体渗透特性的主要因素之一。一些重金属离子可使土体中可溶性物质转变为难溶性物质,进而堵塞渗流通道,减小渗透系数。对于很多盐溶液,其中的金属离子会与土颗粒表面的离子发生置换反应,减小双电子层厚度,使粒间排斥力削弱,更容易促进凝聚,从而增大渗透系数。物理化学变量会影响土体的分散或凝聚状态,这对土体的渗透性有很大影响。

3 流体的浓度对土体渗透特性的影响

流体的浓度对土体渗透特性具有一定影响,土体与流体之间存在的浓度差会产生化学势,土颗粒间斥力起主导作用,致使土颗粒破碎,阻塞渗流通道。当流体浓度足够大时,土颗粒间产生约束力,随着流体浓度继续增加,土颗粒间约束力增大,组构变化(絮凝)造成孔隙封闭效应,使渗透系数减小。

对于不同化学组成的流体溶液,浓度有不同的影响。例如,随着浓度增加,有机溶液黏度逐渐增大,从而使渗透系数减小。对于含金属离子的渗透溶液,随着离子浓度增大,双电层厚度减小,渗透系数随之增大。

潘雪英等研究了丙三醇溶液对粉质黏土渗透性的影响[24]。选用不同浓度的丙三醇溶液进行变水头渗透试验,丙三醇溶液渗透系数变化规律如图 3所示,随着丙三醇溶液浓度增大,渗透系数呈先增加后减小的规律。在初始阶段,有机溶液会提高土体的渗透性。分析其原因是:相比于水,丙三醇溶液与土颗粒结合较弱,黏土颗粒表面吸附较少,孔隙增大,促进渗透系数增大;丙三醇溶液也可能与黏土矿物之间进行反应,改变土体骨架结构,扩大渗流通道,从而增大渗透系数,随着丙三醇溶液浓度继续增大,渗透特性不断增大,直至渗透系数达到峰值。继续增大丙三醇溶液的浓度,流体黏度不断增大,当流体黏度影响大于孔隙影响时,渗透系数开始减小。

JONES通过渗透试验得到,浓度突变会导致黏土堵塞,如果逐渐降低盐溶液浓度,则不会发生堵塞,说明高盐浓度差可能会抑制渗透作用[14]。由于两种溶液之间的化学势差异,淡水可能会进入黏土骨料稀释盐水,这样会增加骨料中的压力,导致黏土颗粒破碎,小颗粒黏土堵塞流动通道。如缓慢降低盐浓度,则可避免高盐浓度差,骨料压力和黏土碎粒不会大幅增加,从而不会导致流动通道阻塞。

许四法等通过模型试验研究了Ca2+浓度对膨润土掺砂混合土渗透性的影响[17]。试验所用膨润土是钠基膨润土,经过渗透后,不同浓度的Ca2+溶液中Ca2+浓度均明显降低,其原因可能是被土体吸附或与Na+交换,钠基膨润土逐渐变为钙基膨润土,从而导致渗透性增大。

刘磊等通过柔性壁测试系统进行了室内渗透试验,随着CaCl2溶液浓度增加,土工合成衬垫材料的渗透系数增大[18]。在10 μmol/L浓度下,渗透系数增加到2.5×10-9 cm/s;在30 μmol/L浓度下,渗透系数为5.6×10-9 cm/s。建立溶质运移耦合动力学模型时考虑了膜效应和离子交换效应,计算结果与试验结果吻合。因此,在分析溶质渗流特征时,需考虑化学-渗透耦合效应的影响。

MISHRA等研究了不同浓度的NaCl溶液和CaCl2溶液对不同混合土渗透系数的影响,随着盐溶液浓度增加,所有混合土的渗透系数均增大。其原因是双电子层厚度减少,颗粒间孔隙增大,渗透性增加[25]。

张志红等研究了Cu2+侵入对土体渗透特性的影响,Cu2+浓度与渗透系数关系如图 4[19]所示,当Cu2+浓度小于0.5 g/L时,渗透系数随Cu2+浓度的增大而降低;当Cu2+浓度大于0.5 g/L时,渗透系数随Cu2+浓度增大而升高;当Cu2+浓度大于5 g/L时,渗透系数趋于稳定。当Cu2+浓度较小时,CuCl2溶液在土体渗透时形成渗透压力差,在压力差作用下黏土体发生渗透固结,这时渗透固结起主导作用,导致土体压密,渗透系数减小;增大CuCl2溶液浓度,黏土体化学固结现象开始凸显并占主导作用,孔隙逐渐变大,渗透系数随之越大。

杨德欢等对饱和重塑压实黏土进行室内变水头渗透试验,探究了水化学环境下土体渗透作用机理[26]。以NaCl溶液为渗透液,浓度分别设置为0(蒸馏水)、0.05、0.1、0.2、0.5、1.0、2.0、4.0 mol/L,分析了NaCl溶液浓度对黏土渗透性的影响。结果表明,NaCl溶液浓度对黏土的渗透性有很大影响。干密度为1.40 g/cm3时,随着NaCl溶液浓度增大,渗透系数先升后降;干密度为1.50 g/cm3时,随着NaCl溶液浓度增大,渗透系数降低。分析认为,随着NaCl溶液浓度增大,粒间约束力增大,组构变化(絮凝)造使得孔隙封闭效应增大,渗透系数减小。

梁健伟等采用可调节水头高度的常水头试验研究了蒸馏水和不同浓度的NaCl溶液在极细颗粒黏土中渗透特性[27]。结果表明,随着NaCl溶液浓度增大,土体渗透系数增大。分析认为其作用机理是电荷电场作用和渗流孔隙的微尺度效应,颗粒表面电位随着渗流溶液离子浓度的增大而下降,对孔隙水的静电引力减弱,结合水膜的厚度减小,使得孔隙通道增大,渗透性随之增大。

谷任国等通过对极细颗粒黏土进行固结试验,测得不同浓度NaCl溶液的固结系数,进而推导渗透系数,从而分析流体浓度对渗透系数的影响[28]。结果表明,渗透系数与NaCl溶液浓度成正比,NaCl溶液浓度越大,渗透特性越大。未固结前,有些阳离子吸附在孔隙中,当有渗流溶液通过时,沉淀物发生溶解,并且已吸附的阳离子也逐渐解吸。土颗粒表面的阳离子浓度高,具有扩散趋势。土颗粒表面双电层包括吸附层和扩散层,在渗流过程中,扩散层带着阳离子一起运动。双电层厚度与离子浓度的平方根成反比,随着NaCl溶液浓度增大,扩散层会减小,使渗流通道扩大,渗透系数随之增大。

MALUSIS等测定了不同浓度KCl溶液对含颗粒膨润土的土工合成黏土的化学渗透效率系数[29-30]。当KCl浓度差在0.003 9~0.047 0 mol/L时,土工合成黏土作为一种半透膜,其稳态值(在稳定状态下测得的化学渗透效率系数)在0.08~0.69之间。随着KCl溶液浓度增加,化学渗透系数反而减小。根据试验数据可以得出影响化学渗透系数的因素为:溶质的水合离子半径、膨润土中的矿物质、膨润土的物理性质。采用不同浓度CaCl2溶液浸泡土工合成黏土衬垫,发现低浓度(< 20 mmol/L)CaCl2溶液可使其渗透系数增大2~13倍。

流体浓度对土体渗透特性的影响可分为两种情况:第一种情况,因流体浓度增大,流体自身黏度增大,从而使渗透系数减小;第二种情况,流体浓度变化引起土体与流体之间的浓度差改变,这种浓度差产生化学势,土颗粒之间斥力作用占主导,使土颗粒发生破碎,阻塞渗流孔隙,减小土体渗透性;但是,在流体浓度足够大时,土颗粒之间产生约束力,当约束力大于排斥力时,将发生颗粒团聚,从而使土体渗透性增大。

4 流体pH值对渗透特性的影响

不同pH值的流体呈现不同程度的腐蚀性,使土体内部组分及微观结构发生变化,进而不同程度地改变土体渗透特性[31]。土体在酸碱溶液中,土颗粒间部分胶结物质被酸碱溶液溶蚀,发生水化、溶解、沉淀等一系列化学反应,土体结构连接变弱,同时生成高度分散性的次生矿物,分子结构发生变化,土颗粒间的表面摩擦和颗粒间的连锁作用减弱。

孙重初研究了酸性溶液(pH < 7)对黏土物理性质的影响。通过分析红黏土在强酸侵蚀后可溶盐含量和成分变化,发现酸性溶液对红黏土有极强的溶蚀作用,酸性溶液浓度越大,作用效果越强[32]。酸液侵蚀使得红黏土可塑性(液限、塑限、塑限指数)大幅度下降。

肖桂元等利用不同pH值溶液模拟酸雨对红黏土淋溶,通过渗透试验、物相分析及扫描电镜,得出红黏土渗透性的影响机制[33]。土壤中的交换性酸基离子在迁移过程中与土体发生离子交换,导致土体中土颗粒原有的双电层结构发生改变。红黏土的主要矿物被酸性溶液溶解,破坏了红黏土团粒,导致土体结构疏松,内部孔隙增大,渗透系数随之增大。酸性溶液pH值越小,土体物质溶解越多,对土体渗透性影响越大。

王婷等通过三轴试验和常规渗透试验分析了纯水及pH=3.0、4.0、5.0的酸性溶液在重塑黄土中渗透特性的变化规律[34]。当围压为100~300 kPa时,不同pH值所对应的渗透系数(t=8 h)如图 5所示,随着pH值减小,渗透系数随之增加。这说明土样在酸性溶液的渗透作用下,酸性越强,渗透特性越好。渗透特性变化取决于水-土之间的相互作用,包括溶蚀、沉淀及离子交换吸附。在渗流作用下,以碳酸钙为主的胶结物质发生溶蚀作用和沉淀结晶作用,改变了土颗粒的组成和联结方式,而阳离子交换吸附作用则改变了土颗粒表面的双电层。酸性溶液会破坏阳离子交换吸附平衡,影响土颗粒的亲水性和双电层,双电层增厚表明重力水减少,结合水增多,渗透性降低。

杨秀娟等开展了变水头渗透试验,即重塑黄土经过不同酸碱度溶液(pH=1和pH=4的HCl溶液,pH=7的去离子水,pH=10和pH=13的NaOH溶液)浸泡30 d后,并采用原浸泡溶液作为渗透溶液,得到重塑黄土的渗透系数[35]。结果表明,在中性溶液环境下,土体渗透系数最小;在碱性环境下,pH值越大,土体渗透系数越大;在酸性环境下,pH值越小,土体渗透系数越大。

刘华等通过GDS三轴渗透仪对各种酸溶液侵蚀的黄土进行试验,并通过扫描电镜进行微观分析[36]。当各种酸溶液浓度增大,其渗透系数均随之降低,酸溶液侵蚀使得黄土的内部骨架结构改变,大孔隙减少,小孔隙增大,有效孔隙减小,从而致使渗透系数减小。通过微结构分析,酸溶液侵蚀的黄土内部骨架结构破坏及新生胶结结构生成造成黏滞作用,同时,生成物阻塞渗流通道,从而导致渗透系数减小。

刘汉龙等研究了酸碱污染土的渗透特性,分析了不同酸碱溶液浓度变化对土的工程性能的影响[37]。当土体受到不同程度的酸碱污染后,其渗透特性随之发生改变。随着流体酸碱溶液浓度增大,渗透系数也增大,并且碱污染对土体渗透系数影响更大,这主要是由于碱溶液中含有大量的Na+,Na+进入固定层和扩散层,使扩散层变厚,削弱了土颗粒间的连接力,增大了粒间距离,从而导致碱污染土的渗透系数比酸污染土大。

XU等的研究表明,随着流体pH值降低,黄土的渗透特性逐渐增加。当酸性流体进入黄土试样后,酸腐蚀导致黄土孔隙扩大;酸溶液也会导致土颗粒的双电层厚度减小,从而形成凝聚土颗粒,使黄土的渗透特性增加[38]。

陈宝等利用膨胀渗透仪对不同初始干密度膨润土进行渗透试验,采用NaOH溶液模拟碱性孔隙水[39]。如图 6所示,对于相同初始干密度试样,随着碱溶液浓度升高,渗透系数逐渐增大。

诸利一等开展了不同孔隙比尾矿砂的变水头渗透试验,探究了在不同酸碱环境(pH=3、pH=7、pH= 11)渗透特性变化规律,结果如图 7所示[40]。在孔隙比相同时,酸性环境下,尾矿砂的渗透系数最大,渗透性最优。分析认为,酸性溶液H+与尾矿中的CaCO3、MgCO3等碳酸化合物反应,致使尾矿砂孔隙改变,从而使渗透性变好。在碱性溶液环境下,Ca2+、Mg2+等与OH-发生反应,形成化合物沉淀吸附在尾矿表面,造成堵塞效应,导致渗透性降低。

MOMENI等研究了酸性水和碱性水对低塑性黏土性质的影响,通过变水头渗透试验测得不同pH值溶液的渗透性能,应用扫描电镜分析土体微观结构演化机理[41]。结果显示,相比于中性水(pH=7),溶液的酸碱度越高,土体的渗透特性越好。pH变化引起土体敏感性主要由多个因素决定,主要是土体有无碳酸盐、总阳离子交换容量,总阳离子交换容量取决于土中黏粒和有机质含量。酸性溶液改变了土壤的出水阳离子浓度、浸水阳离子浓度和交换性阳离子浓度等理化性质,从这些方面来影响渗透性。

可以看出,流体pH值对土体渗透特性也存在较大影响。pH值不同的情况下,流体自身将具备一些腐蚀性,渗流同时会侵蚀土体内部的细观结构,致使渗透特性增大。对于一些特殊土体,碱性溶液会与土颗粒表面的Ca2+、Mg2+等发生反应,形成化合物沉淀土颗粒表面,堵塞渗流通道,导致渗透性减小。

5 流体温度对渗透特性的影响

流体温度在一定程度上可影响渗透系数,主要原因在于渗透系数与其黏滞度有关。水的黏度系数与温度关系如图 8所示,温度越高,黏滞系数越小,渗透系数越大。在20 ℃越下渗透系数可用式(7)计算:

(7) 式(7)中:kT、k20分别为T ℃和20 ℃时土的渗透系数,m/s;ηT、η20分别为T ℃和20 ℃时溶液的黏滞系数,kPa·s。

流体温度会引起土体物理特性变化,如温度升高使得膨润土的膨胀率增大,影响土中颗粒迁移,致使渗透系数降低。流体温度对土体中结合水与自由水相互转换存在一定影响。随着流体温度升高,强结合水转化为弱结合水和自由水,使土颗粒的离子水化半径减小,导致渗透系数增大。

刘雪玲等通过室内一维砂柱试验研究了温度(5、40、60、80 ℃)对含有蒙脱石矿物成分砂样的渗透特性影响[42]。如图 9所示,当流体温度在20 ℃以下,试样的渗透系数变化幅度不大;随着流体温度升高,砂样的渗透系数不断下降,温度越高,渗透系数的下降幅度越大。分析认为是砂样中蒙脱石矿物成分具有高膨胀性,流体温度越高,其膨胀率越大,试样中细粒发生迁移或释放,从而导致流动通道堵塞,渗透系数降低。随着温度升高,流体在砂样的渗透系数逐渐降低,当水头越大,土体渗透系数越小,根据达西定律可知,水头差越大,砂样中渗透速度越大,从而加速砂样的细粒的迁移或释放,加重孔隙堵塞,造成渗透性能降低。

何俊等采用GDS全自动渗透仪,在不同温度下,对颗粒状和粉末状膨润土进行了室内渗透试验,改造试验仪器使土样和水都处于恒温状态,以探究温度对渗透性能的影响[43]。对于颗粒状膨润土,当试验溶液为去离子水时,试样的渗透系数随温度升高而逐渐下降;当试验溶液为CaCl2溶液时,渗透系数随温度升高而逐渐上升。对于粉末状膨润土,当试验溶液为去离子水时,渗透系数随温度升高而略有增大,当试验溶液为CaCl2溶液时,渗透系数随温度升高而增大。

温度效应的机理大致可分为3种:结合水变化、流体黏滞度变化和土体凝胶态蒙脱石数量。温度升高时,强结合水会脱离土颗粒的吸附,强结合水转变为弱结合水和自由水;在CaCl2溶液作用下,Ca2+吸附在土体颗粒上,使强结合水显著降低,最终导致渗流通道扩大,使渗透系数增大。对于凝胶态蒙脱石,黏土体中一个或多个黏土片形成细小颗粒,其变化不易被直接观察到,但能从膨胀指数试验间接呈现,温度升高时,原有的颗粒状膨润土发生分解,随着溶液渗流,凝胶态蒙脱石增多,渗透系数可能会减小。

YE等通过新型研制的膨胀试验装置对GMZ01膨润土进行了不同温度下的膨胀压力试验与饱和渗透试验。结果表明,渗透系数随温度升高而增大,温度变化路径对饱和渗透系数没有影响,这种温度效应可以用水的黏滞性变化解释[44]。

CHO等研究了不同压实度饱和钙基膨润土在20~80 ℃之间的渗透性能,膨润土在80 ℃的渗透系数约是20 ℃的3倍[45]。在只考虑水的黏滞性的情况下,参考图 8中温度对水黏度的影响,随温度升高,水的黏度变化影响水的渗透性能。

VILLAR等在20~80 ℃之间考察了压实膨润土的流体力学性能变化,根据水运动黏度的热变化,渗透性能随温度的变化低于所预测的结果;温度升高引起土骨料中吸附水向骨料间自由水转移[46]。

CHEN等进行一系列使用温度控制的三轴单元渗透试验,得出在80 ℃的渗透系数是常温(23 ℃)下的渗透系数的2.4倍。在加热冷却循环过程中,渗透系数随温度的变化是可逆的[47]。

万敏研究了温度对GMZ01膨润土微观结构的影响,在约束条件下,饱和膨润土的土体结构不会随温度变化而发生较大的改变,因此对其孔隙率、渗透系数等物理特性影响不大[48]。

王媛等开展了不同温度(5、15、25、35、45 ℃)下室内变水头渗透试验,得到不同温度下的渗透系数[49]。随温度升高,3种试样的渗透系数呈线性增长。分析认为,温度效应影响黏土渗透性的作用机理主要是水的黏滞性变化、土颗粒双电子层厚度变化、土骨架细观结构的变化等。温度对黏土渗透性影响与黏土中有机质含量有关,当有机质存在时,形成黏土-有机质团聚体,增加黏性土渗透性,但不会改变渗透系数随温度而改变的变化率。

白冰等研究了温度对黏性土介质渗透特性的影响[50]。研究表明,随着温度升高,渗透系数增大,认为这是水的黏滞度变化导致的。

邵玉娴等研究了温度效应对渗透特性的影响[51]。随着流体温度升高,膨胀性和渗透性均增大,认为其原因是与吸附结合水量有关。通过容量法测量吸附结合水量,由此分析吸附结合水量与温度的关系,随温度升高呈近似线性降低。从微观角度分析,温度升高导致分子运动剧烈,使部分结合水转变为自由水,从而使吸附结合水量减少,结合水减少时,可以看作土体颗粒上所存在水膜的变化,这个过程可能产生相互作用力的变化,最终导致宏观上渗透系数的改变。

综上可知,流体温度对土体渗透特性的影响主要体现在流体自身黏度变化、土体中结合水的转化、双电层厚度变化以及土骨架细观结构的变化等。随着温度升高,水的黏滞性会降低,从而导致渗透系数增大。随着温度升高,土颗粒中的强结合水也会转化为弱结合水和自由水,使土颗粒的离子水化半径减小,导致渗透性增大。

6 结束语与展望

本文聚焦流体的理化特性对于渗流规律的影响,综述了流体的化学组成、浓度、pH值和温度对土体渗透特性的影响,分析了相关作用机理。研究表明,流体主要通过改变土体微细观结构、双电层厚度、结合水含量、产生化学势等方式影响土体的渗流规律。基于上述结果,笔者认为下面的问题值得进一步研究:①从流体-土体耦合作用方面深入研究,分析渗流过程的多场耦合作用机理,进而构建多场耦合作用下的渗流模型;②开展多尺度的渗流研究,在细观与微观层面上分析流体与土体的相关作用,以验证宏观渗流规律的合理性;③室内试验得到的规律并不能完全符合复杂的工程实际,进一步开展复杂状况下渗流数值模拟研究,应用软件的计算、模拟功能,得到更多有用的信息。

-

表 1 罗逊-莱蒙勒尔粒度特性参数值

Table 1 Parameters of R Rosin-E Rammler characteristics

磨矿浓度/% 参数b 参数n 一段磨 二段磨 一段磨 二段磨 60 6.82 18.64 0.87 1.53 65 7.43 16.67 0.91 1.47 70 7.62 16.53 0.90 1.45 75 8.01 16.24 0.92 1.45 80 8.60 15.29 0.94 1.40 平均值 7.70 16.67 0.91 1.46 表 2 磨矿产品中合格粒级的产率和平均粒度

Table 2 Qualified productivity and average particle size in grinding production

磨矿浓度/% 一段磨 二段磨 γ100~10μm/% γ-10μm/% D/μm γ100~10μm/% γ-10μm/% D/μm 60 47.07 11.52 48.29 39.84 4.92 61.17 65 46.36 12.08 48.37 39.94 5.21 62.98 70 47.07 11.35 48.30 40.29 5.46 62.91 75 46.86 11.66 48.53 39.81 5.50 62.49 80 47.20 11.82 48.24 40.06 5.90 61.83 平均值 46.91 11.69 48.35 39.99 5.40 62.28 表 3 不同磨矿浓度的磨矿效率统计表/%

Table 3 Statistics of grinding efficiency of different grinding concentrations /%

磨矿浓度/% E技 E过 E总 η 一段磨 二段磨 一段磨 二段磨 一段磨 二段磨 一段磨 二段磨 60 26.40 25.47 5.70 3.57 32.10 29.04 82.24 87.71 65 26.38 26.33 5.49 3.41 31.87 29.74 82.77 88.53 70 26.71 25.98 5.50 3.51 32.21 29.49 82.92 88.10 75 26.79 25.40 5.44 3.72 32.23 29.12 83.12 87.23 80 26.59 25.71 6.01 3.43 32.60 29.14 81.56 88.23 平均值 26.57 25.78 5.63 3.53 32.20 29.31 82.53 87.96 表 4 工业试验前后磨矿产品特性对比结果/%

Table 4 Grinding characteristics comparison results of Industrial test of the before and after /%

磨矿分级机组别 γ100~10 μm γ-10 μm D100-10μm/μm E技 η 一段磨 实验组 37.69 12.03 49.09 25.20 75.04 对比组 35.46 12.91 47.96 22.41 70.65 实验组﹣对比组 +2.23 -0.88 +1.13 +2.79 +4.39 二段磨 实验组 59.99 10.35 57.87 36.36 84.79 对比组 56.02 11.70 54.07 31.50 78.67 实验组﹣对比组 +3.96 -1.35 +3.80 +4.86 +6.12 注:“+”代表提高幅度,“﹣”代表降低幅度。 表 5 二段分级溢流产品质量的对比/%

Table 5 Quality contrast of secondary classification overflow /%

组别 γ100~10 μm γ-1 0μm D100-10μm/μm β溢流 实验组 83.44 9.54 41.5 0.40 对照组 82.72 16.30 40.1 0.39 实验组﹣对照组 +0.72 -6.76 +1.4 +0.01 注:“+”代表提高幅度,“﹣”代表降低幅度。 -

[1] NAOYA K, MITSUYUKI K, SHINICHI K, et al. Influence of dry and wet grinding conditions on fineness and shape of particle size distribution of product in a ball mill[J]. Advanced powder technology, 2011(22): 86-92. http://cn.bing.com/academic/profile?id=2091104110&encoded=0&v=paper_preview&mkt=zh-cn

[2] 石贵明, 吴彩斌, 肖良, 等.柿竹园钨多金属矿优化磨矿系统实验室研究[J].有色金属科学与工程, 2013, 4(5):79-84. http://ysjskx.paperopen.com/oa/DArticle.aspx?type=view&id=2013050016 [3] 肖庆飞, 段希祥.磨矿过程中应注意的问题分析及对策研讨[J].矿产综合利用, 2006(4):30-33. http://www.cnki.com.cn/Article/CJFDTOTAL-KCZL200604008.htm [4] YEKELER M, OZKAN A, AUSTIN L G. Kinetics of fine wet grinding in a laboratory ball mill[J]. Powder Technology, 2001(114): 221-228. http://cn.bing.com/academic/profile?id=2021984080&encoded=0&v=paper_preview&mkt=zh-cn

[5] TEKE E, YEKELER M, ULUSOY U, et al. Kinetics of dry grinding of industrial minerals:calcite and barite[J]. International Journal of Miner Process, 2002 (67): 29-42. http://cn.bing.com/academic/profile?id=2083666649&encoded=0&v=paper_preview&mkt=zh-cn

[6] GUPTA V K, HODOUIN D, EVERELL M D. An analysis of wet grinding operation using a linearized population balance model for a pilot scale grate-discharge ball mill[J]. Powder Technology, 1982(32): 233-244. http://cn.bing.com/academic/profile?id=1990199597&encoded=0&v=paper_preview&mkt=zh-cn

[7] 曾春水.浅谈磨矿浓度对磨矿效果的影响[J].中国钨业, 1998(2):25-27. http://www.cnki.com.cn/Article/CJFDTOTAL-ZGWU199802009.htm [8] 鄢发明, 艾光华, 吴彩斌, 等.钨矿石磨矿动力学研究[J].有色金属科学与工程, 2015, 6(4):81-85. http://ysjskx.paperopen.com/oa/DArticle.aspx?type=view&id=201504017 [9] 中国科学技术协会.颗粒学学科发展报告2009-2010[M].北京:中国科学技术出版社, 2010. [10] 曾凡, 胡永平.矿物加工颗粒学[M].徐州:中国矿业大学出版社, 1995. [11] 李启衡.粉碎理论概要[M].北京:冶金工业出版社, 1993. [12] 肖庆飞, 罗春梅.碎矿与磨矿技术问答[M].北京:冶金工业出版, 2010. [13] FUERSTENAU D W, M ABOUZEID A Z. The energy efficiency of ball milling in comminution[J]. In ternational Journal of Miner Process, 2002(67):161-185. https://www.researchgate.net/publication/222151626_The_energy_efficiency_of_ball_milling_in_comminution

[14] 段希祥.碎矿与磨矿[M]. 3版.北京:冶金工业出版社, 2012. [15] 明平田, 吴国民, 李飞, 等.磨矿分级工艺考察及分析研究[J].有色金属(选矿部分), 2012(6):45-48. http://www.cnki.com.cn/Article/CJFDTOTAL-YSXK201206011.htm [16] 侯英, 印万忠, 丁亚卓, 等.不同破碎方式下产品磨矿特性的对比研究[J].有色金属, 2014(1):5-8. http://www.cnki.com.cn/Article/CJFDTOTAL-YSXK201401002.htm -

期刊类型引用(2)

1. 安厚睿,彭陈亮,林福明,王观石,龙平,肖霞. 考虑离子尺寸效应的蒙脱石双电层中阳离子和电势分布研究. 有色金属科学与工程. 2024(06): 952-962 .  本站查看

本站查看

2. 郭钟群,周可凡,周尖荣,刘凌峰,唐韬,王晓军. 溶浸液对离子型稀土饱和-非饱和渗透特性的影响. 有色金属工程. 2023(04): 66-77 .  百度学术

百度学术

其他类型引用(3)

下载:

下载: