Abnormal mechanical behaviors of deformed Zn-Cu-Ti alloy

-

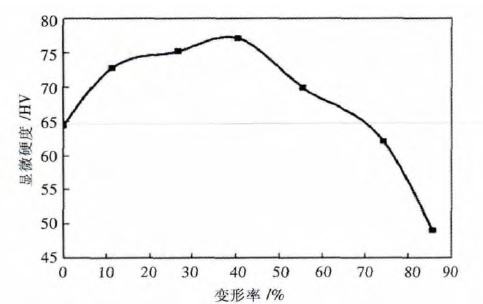

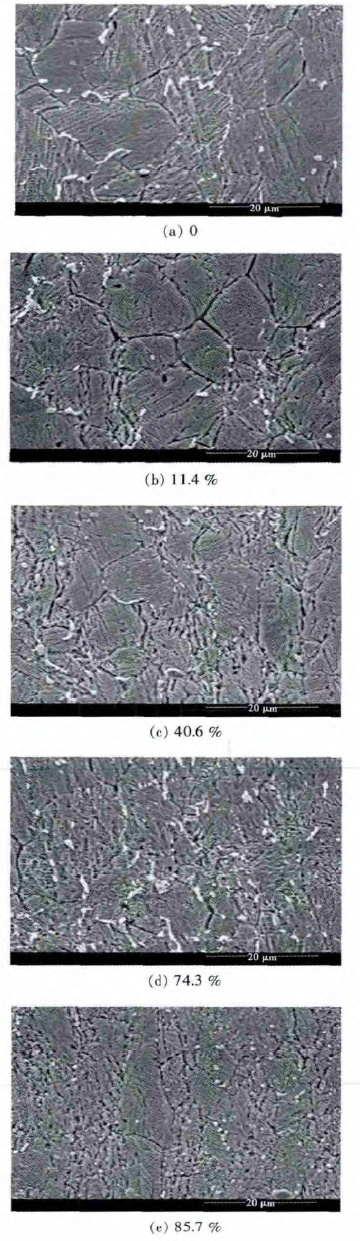

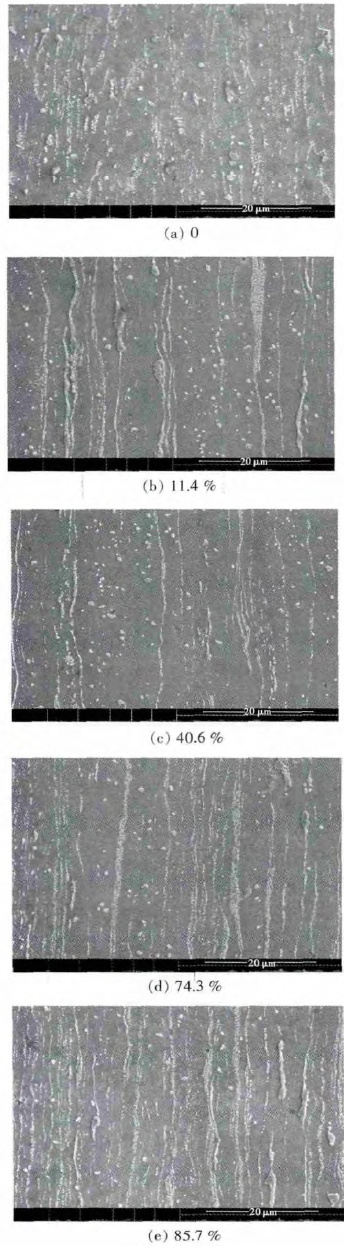

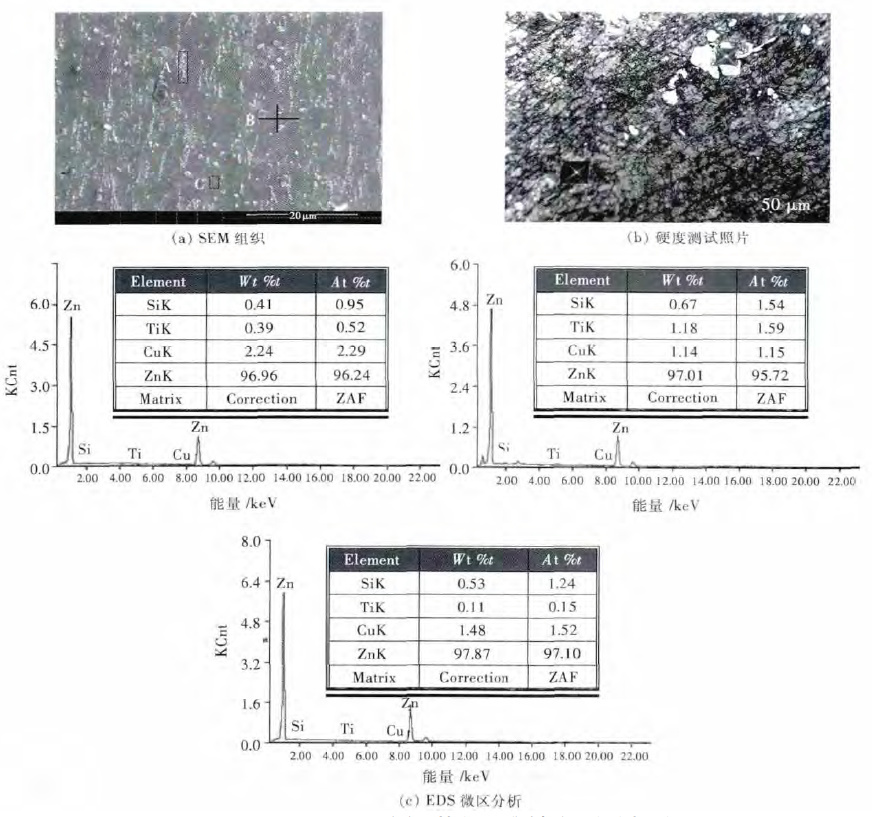

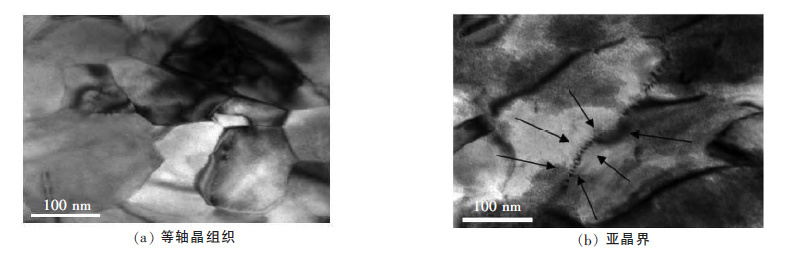

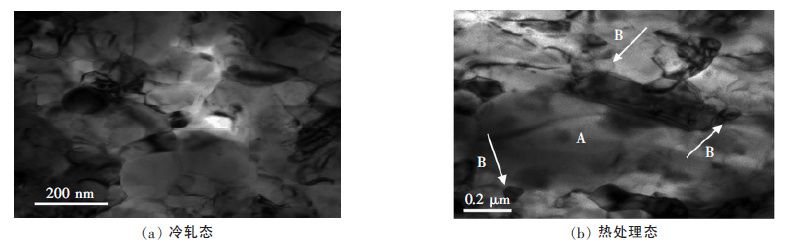

摘要: 发现了 Zn-Cu-Ti 合金具有“加工软化”和“退火硬化”等异常力学行为. 采用 SEM、TEM、EDS 等手段对合金冷轧和热处理态显微组织进行观察和分析. 结果显示,该合金冷轧初始阶段(0 %~40.6 %), 硬度略微升高,而继续提高变形率到 40.6 %~85.7 %,合金硬度明显下降,表现出剧烈的 “加工软化 ” 行为. 冷轧变形时,应变诱发动态再结晶,第二相析出增多,固溶 Cu、Ti 原子减少,固溶强化显著减弱,是引起合金“加工软化”的主要原因. 对经过 85.7 %冷轧变形的带材在 195 ℃和 215 ℃下退火,带材强度显著升高,表现出明显的“退火硬化”,且 215 ℃退火比 195 ℃退火同样时间的强度高. 退火时第二相分解,Cu、Ti 原子固溶于基体,固溶强化效应高于第二相强化,使合金表现出“退火硬化”行为.

-

关键词:

- Zn-Cu-Ti 合金 /

- 加工软化 /

- 退火硬化 /

- 固溶强化 /

- 第二相强化

Abstract: The abnormal mechanical behaviors of Zn-Cu-Ti alloy were discovered, such as working softening and anneal hardening. Microstructures of cold-rolled and annealed strips were observed and analyzed by SEM、 TEM and EDS. The results show that vickers hardness of the strips increases slightly as cold rolling deformation rate raising from 0 % to 40.6 %, and decreases significantly as cold rolling proceeding (40.6 %~85.7 %), the alloy exhibits a remarkable working softening. The facilitated precipitation induced by cold strain which weakens solid solution strengthening by reducing Cu and Ti solute atoms, along with dynamic recrystallization, resulting in working softening. Strength of the strips (cold deformation rate of 85.7 % ) increase significantly after being annealed at 195 ℃ or 215 ℃ , the alloy exhibits a remarkable anneal hardening. Strength of the strips soaking at 215 ℃ is higher than that at 195 ℃ for the same time period. The decomposition of second phase, the dissolution of Cu and Ti atoms during annealing and the effect of solid solution strengthening surpassing second phase strengthening result in anneal hardening of the alloy. -

0 引言

在现代工业生产及居民生活中,水泵应用范围极为广泛。实际供水系统中用户的用水量始终处于不停的变化状态,时大时小,而水泵不论用水量大小,始终全速运行,白白消耗掉了大量能量。自从通用变频器问世以来,变频调速技术在各个领域得到了广泛的应用。变频恒压供水设备以其节能、安全、高品质的供水质量等优点,在实际应用中得到了很大的发展。

笔者对公司的工业用水系统进行了变频恒压供水改造,取得了一些经验。同时,对变频恒压供水系统的改造提出了一些观点(节能方面)与大家共同探讨分析。

1 水泵变频调速系统改造方案

淄博铁鹰钢铁有限公司现有320m3高炉两座,60万t球团线一条,36m2带烧两条,供水系统主要用于生产用水,见图 1。

整个系统有两个供水池,正常情况下由主供水池向各用水单位供水,特殊情况下采用备用水池。主供水池有两台水泵(其中一台备用),水泵、电机型号完全一致。各用水单位用水情况主要分为两类:第一类用水单位均有自备水池,根据消耗情况定时补水,每天集中补10h左右即可。如:铸铁机、冲渣泵房、原料泵房、中心泵房;第二类用水单位要求24h水不能间断,如:冷却用水(供水管路附近风机的冷却用水)、生活洗刷、浴池用水等。那么这套系统进行变频改造节能效果如何呢,下面进行理论分析。

由水泵中的轴功率比例定律可知,水泵的输出功率与转速的3次方成正比。但上述理论是水泵运行于全相似工况下得出的结论,而我公司供水系统中水泵的出水口和进水口之间是有高度差的,管路阻力曲线也处于不停变化状态,水泵不运行于全相似工况,因此也就不能用全相似的理论来分析变频的节能[1]。而应该在分析容入系统中的水泵性能受管路系统阻力特性等因素影响的基础上,利用离心泵的特性曲线公式来分析水泵的变频节能。实际水泵的功耗计算公式为[2]:

P=ρQH/102ηrηF

式中P:——水泵电动机的输出功率,kW;

ρ——输出介质体积质量,kg/m3;

Q——流量,m3/s;

H——扬程,m;

ηr——传动装置的效率;

ηF——水泵的效率。

图 2中F1为工频50Hz时水泵的工作曲线,a为水泵工频状态下的额定工作点。F2及F3分别为不同频率时水泵的工作曲线。R1、R2、R3分别为不同管网阻力曲线。

首先看R2曲线,当管路曲线变为R2后,水泵工作点由a移动到b后,根据前面的公式,此时水泵的能耗为:

Pb=rQbHb/102ηrηF

当管网阻力曲线发生变化后,若调整水泵的频率为F2,则水泵的工作点为a2,此时水泵的能耗为:

Pa2=rQa2Ha/102ηrηF

两者之差为:

ΔP1=Pb-Pa2

从中可以明显的看出:Hb>Ha2,Qb>Qa2,ΔP1>0,ΔP1就是采用变频调速后节约的电能[3]。

当管路曲线变为R3后,水泵工作点由b点移动到c点,此时水泵的能耗为PC,若调整水泵的工作曲线为F3,则水泵的工作点为a3,此时节能效果更为明显。

通过以上分析不难看出,水泵工频状态的工作点及管网阻力曲线是决定变频是否节能的关键,笔者认为:

(1)若管网阻力曲线变化不大,水泵基本工作于额定状态,如图 2中的a点,则变频调速基本不节能;若工作于b或接近于H轴的某点,变频调速虽然节能,但节能效果不明显[4]。

(2)管网阻力曲线变化频繁且幅度较大,流量不稳定,经流量偏小,如常工作于c点的水泵系统,则值得进行变频改造,且改造后节能效果明显。

经过分析论证,我们认为我公司的供水系统基本符合上述第二条的条件,因而可以进行改造。

2 变频器的调试安装及准备工作

目前市面变频器的种类繁多,经过反复比较,最终选定的变频器为ABB550系列,ABB系列变频器内置PID CTRL宏,特别适合于单台水泵的小型恒压供水系统。实际系统构成框图如图 3。

2.1 起始频率的问题

在实际工作中,应用变频调速时,当频率下降到30~35Hz以下时不出水了,这是因为水泵进出口水位存在一定的高度差,也就是水泵的净扬程,水泵的扬程只有大于净扬程也就是图 2中的H0点时才能出水。要确定好这一频率,可采用试验法逐渐测定出它的数值。同时还应注意的是,大部分水泵电机为自冷式电机,若转速过低,则电机自身热量不易散发,易烧毁电机,因此起点频率若不能保证电机的散热,要给电机加装外部冷却设施。

2.2 PID参数设定

PID参数要设置得当,尤其是P、I参数,要经过反复试验确定,否则易引起水泵的转速变化过于频繁,影响供水质量。

2.3 共振频率的确定

由于原水泵设计工作于50Hz的状态下,采用变频调速后,在一定的频率范围之内,水泵容易发生共振,在调试时可用变频器中的危险速度功能跳过这些频率。笔者就曾遇到过这样的问题,图 1中泵一、泵二为同厂家、同型号的两台水泵,改造完成后分别对它们进行了共振试验,结果是两台泵的共振频率不完全一样,泵二的共振区间明显少于泵一,这种情况应与泵的安装有关系。危险速度设定后,应隔一段时间测试一下泵的共振情况,特别是更换水泵或电机重新找正后,更需要重新设定,不能一劳永逸,以免环境变化后水泵的共振频率变化而引起设备的损坏。

2.4 变频故障的处理

若压力变送器反馈的压力信号断线,变频器要保持在继续运行状态,同时发出报警信号,避免因压力变送器引起停水事故;若水泵或变频出现故障不能继续工作时,系统应能自动启动备用泵,同时发出报警信号,防止停水事故的发生。

3 水泵变频调速系统投入运行的效果分析

系统改造后经过3个月的试用、调整,现已顺利运行一年多,实践证明,该套系统起到了以下作用:

(1)管网供水质量得到提高。各用水单位明显感觉到供水压力的稳定,特别是小用水户,不再象以前那样感觉水压时大时小。

(2)泵的噪声减少了。原系统中用水量减少后,水泵处于憋泵运行,噪声较大,采用变频调速后,随着用水量的减少,泵的转速随之降低,降低了噪声。

(3)提高了设备的使用寿命和可靠性。当检测到电机出现异常时,变频可以瞬间停止电机运转,避免电机烧毁等事故的发生。原水泵电机的轴承温度较高,轴承端盖能够达到65℃以上,影响了轴承的使用寿命,采用变频后,电机轴承温度明显降低。

(4)减少了水资源的浪费。变频调速后必然降低单位时间内的供水量,从而节约了水资源。

(5)节约了电耗。系统投运后电耗有了明显的降低,同时提高了功率因数,降低了无功电耗。

4 经济效益分析

笔者对同一台水泵使用变频前后随机抽取4d的耗电量进行对比,对比结果见表 1。

表 1 变频节电对比表 kW·h

从表 1中可以看出:使用变频每天的节电量平均为231.5kW·h,按0.5元/kW·h计算,每天节约电费115.75元,则每年节约电费40512.5元。

该套系统包括变频器、压力变送器等共计投资为61000元,系统的回收期为1.5a。若变频器的使用寿命为8a,则该套系统节约电费是相当可观的。

5 结论

此次系统改造成功之后,又对本单位其他几处供水系统进行了改造,均取得了较好的节电效果。通过对水泵变频调速的应用,笔者认为变频调速是一种应用广泛的水泵节能技术,但具有较为严格的适用条件,不能简单地应用于任何供水系统,具体采取何种节能措施,应结合实际情况区别对待。

-

表 1 Zn-Cu-Ti 合金的化学成分(质量分数,%)

Table 1 Compositions of Zn-Cu-Ti alloy(mass fraction,%)

表 2 退火态Zn-Cu-Ti 带材力学性能参数

Table 2 Mechanical properties of annealed Zn-Cu-Ti alloy strips

-

[1] 彭曙光. 锌铜钛合金及其产业前景分析[J]. 湖南有色金属, 2003, 19(2): 35-37. http://www.cnki.com.cn/Article/CJFDTOTAL-HNYJ200302011.htm [2] 郭天立, 杨如中, 陈锐. 锌合金发展现状述评[J]. 有色矿冶, 2001, 17(5): 37-40. http://www.cnki.com.cn/Article/CJFDTOTAL-YSKY200105009.htm [3] 彭大暑. 金属塑性加工原理[M]. 2版. 长沙: 中南大学出版社, 2014: 159-163. [4] 高存贞, 杨涤心, 谢敬佩, 等. 高铝锌合金研究现状及进展[J]. 热加工工艺, 2010, 39(7): 23-28. http://www.cnki.com.cn/Article/CJFDTOTAL-SJGY201007007.htm [5] 孙文声, 张锦麟. 加工量对ZA16合金组织和性能的影响[J]. 热加工工艺, 2010, 39(23): 13-15. http://www.cnki.com.cn/Article/CJFDTOTAL-SJGY201023005.htm [6] 孙文声, 张锦麟, 董乐军. 变形Zn-16Al合金退火硬化行为研究[J]. 兵器材料科学与工程, 2010, 33(6): 51-53. http://www.cnki.com.cn/Article/CJFDTOTAL-BCKG201006020.htm [7] Yang C F, Pan J H, Lee T H. Work-softening and anneal-hardening behaviors in fine-grained Zn-Al alloys[J]. Journal of Alloys and Compounds, 2009, 468: 230-236. doi: 10.1016/j.jallcom.2008.01.067

[8] 张喜民. 变形锌铜钛合金蠕变行为及其组织性能研究[D]. 长沙: 中南大学, 2010. [9] Diot M, Philippe M J, WeGria J, et al. Addition elements and texture gradients in rolled zinc alloys[J]. Scripta Materialia, 1999, 40(11): 1295-1303. doi: 10.1016/S1359-6462(99)00077-9

[10] 王艳, 肖来荣, 万磊, 等. 两种变形Zn-Cu-Ti锌合金的组织与性能[J]. 特种铸造及有色合金, 2012, 32(11): 1054-1059. http://www.cnki.com.cn/Article/CJFDTOTAL-TZZZ201211033.htm [11] Abou El-Khair M T, Daoud A, Ismail A. Effect of different Al contents on the microstructure, tensile and wear properties of Zn-based alloy[J]. Materials Letters, 2004, 58(11): 1754-1760. doi: 10.1016/j.matlet.2003.10.058

[12] 张喜民, 肖来荣, 温燕宁. 挤压Zn-Cu-Ti合金组织及其力学性能[J]. 材料科学与工程学报, 2010, 28(4): 1-7. http://www.cnki.com.cn/Article/CJFDTOTAL-CLKX201004025.htm [13] Zhu Y H, To S, Liu X M, et al. Microstructural changes inside the lamellar structures of alloy ZA27[J]. Materials Characterization, 2006, 57(4/5): 326-332. http://cn.bing.com/academic/profile?id=9435cc55ce88be38ef8da3d246eaa9af&encoded=0&v=paper_preview&mkt=zh-cn

[14] 乔艳艳, 宋克兴, 张彦敏, 等. 热处理对变形Zn-Cu-Ti合金组织和性能的影响[J]. 河南科技大学学报, 2015, 36(1): 6-12. http://www.cnki.com.cn/Article/CJFDTOTAL-LYGX201501003.htm [15] Savaskan T, Hekimoqlu A P, Purcek G. Effect of copper content on the mechanical and sliding wear properties of monotectoid-based zinc-aluminium-copper alloys[J]. Tribology International, 2004, 37(1): 45-50. doi: 10.1016/S0301-679X(03)00113-0

[16] Santos G A, de Moura Neto C, Osorio W R, et al. Design of mechanical properties of a Zn27Al alloy based on microstructure dendritic array spacing [J]. Materials and Design, 2007, 28 (9): 2425-2430. doi: 10.1016/j.matdes.2006.09.009

下载:

下载: