Stabilization of high As-contained caustic sludge by calcium-arsenic crystallization

-

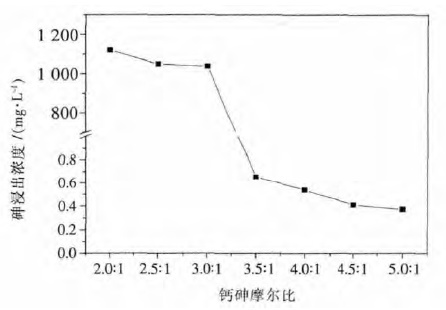

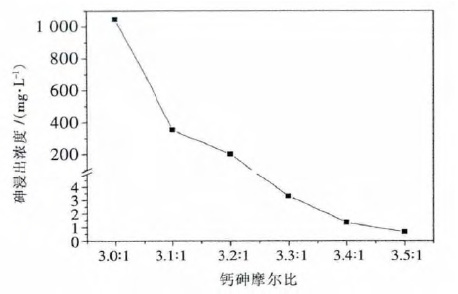

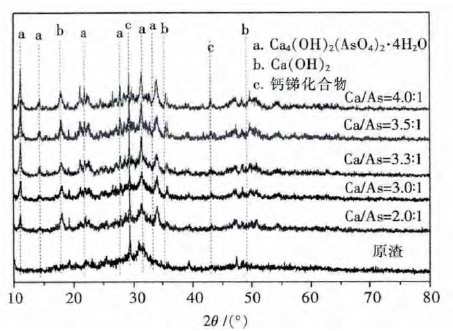

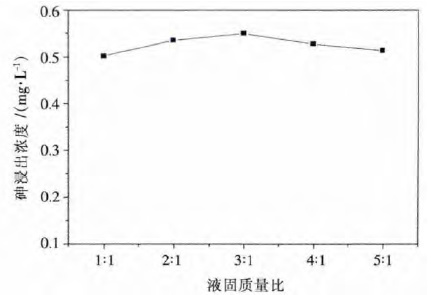

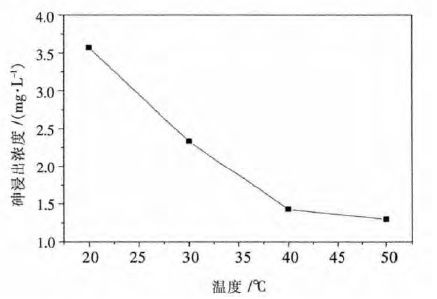

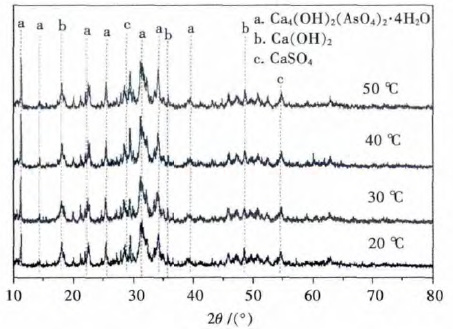

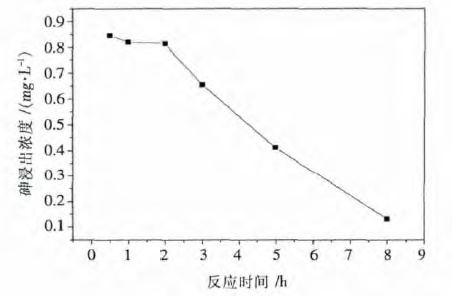

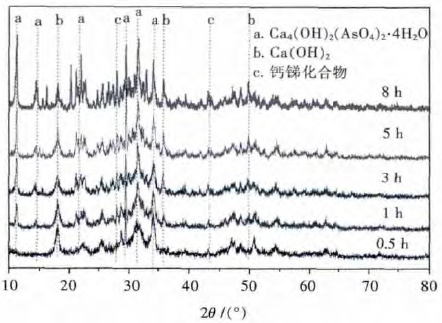

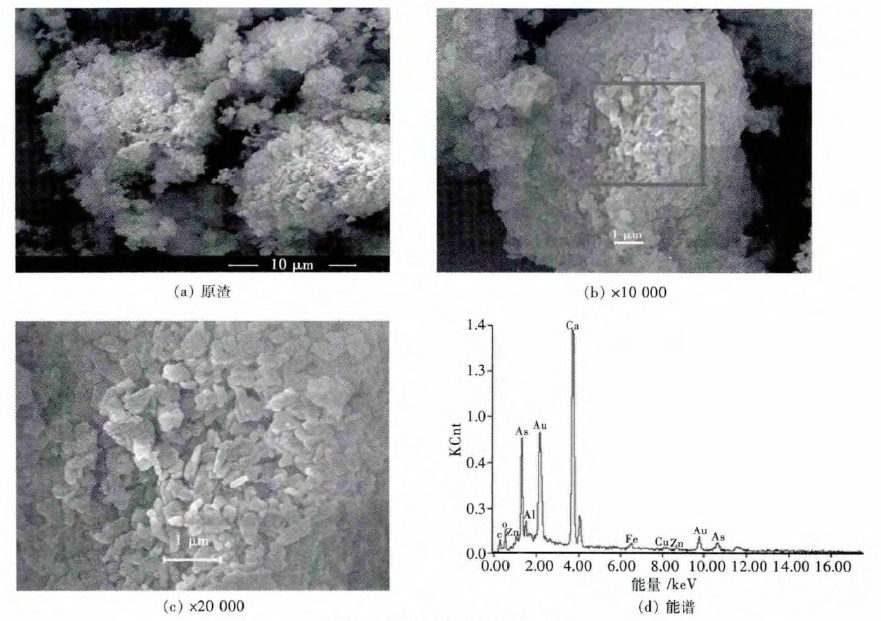

摘要: 针对湖南某锑冶炼企业的碱性高砷渣进行了钙砷晶化稳定处理的研究.考察了钙砷摩尔比 、 液固质量比 、反应温度及反应时间对钙砷晶化效果的影响 .结果表明,当钙砷摩尔比为 3.5:1,液固质量比为 3:1,反应温度为 40 ℃,反应时间为 8 h 时,砷毒性浸出浓度最低,由 1 348.67 mg/L 降低至 0.13 mg/L,优于《GB 5085.3-2007》中规定的标准值. SEM-EDS 和 XRD 分析结果表明,原渣中无定型钙砷化合物经晶化处理后,转变成为稳定的结晶良好的四水合碱式砷酸钙.Abstract: This study aimed at the stabilization of high As -contained caustic sludge taken from an antimony smelter in Hunan Province. The influences of Ca/As molar ratio, liquid/solid mass ratio, temperature and reaction time on the effects of calcium -arsenic crystallization were investigated. The results show that when the Ca/As molar ratio is 3.5 :1, the liquid/solid mass ratio is 3 :1, the temperature was 40 ℃ and the reaction time is 8 h, the As leaching concentration is the lowest descending from 1 348.67 mg/L to 0.13 mg/L which is better than standard values in GB 5085.3-2007. Besides, the XRD patterns and the SEM micrographs reveals that the amorphous Ca-As compounds in original slag transforms into stable well-crystallized calcium arsenate hyroxide hydrate (Ca4(OH)2(AsO4)2·4H2O) after crystallization .

-

Keywords:

- arsenic /

- metallurgical sludge /

- calcium arsenate /

- stabilization by crystallization

-

活性污泥法经过近百年的实践和发展,已经成为国内外应用最普遍的污水处理技术之一.然而,污水处理系统是一个多变量、非稳定、时变的复杂系统,如水质水量动态变化、反应机理复杂、存在许多干扰因素和不确定性因素等,因此,以数学模型为基础、结合污水处理工艺原理的系统仿真方法,成为对复杂的污水处理系统进行动态分析的适用方法.活性污泥数学模型的发展经历了从传统静态模型到动态模型的发展过程,如早期Eckenfelder模型、Mc Kinney模型和Lawrence-McCarty模型等静态模型,以及Andrews模型、WRc模型和ASM系列模型等动态模型.基于活性污泥系统所建立的污水处理数学模型,在污水生物处理工艺优化设计以及在工艺运行、控制方面有广泛的应用,一方面可以指导污水处理工艺的优化设计,另一方面对于现有污水处理厂的改扩建及新工艺的研发也是一种行之有效的辅助工具.

1 活性污泥静态模型

20世纪50年代,国外开始出现活性污泥数学模型的报道.其中,最具代表性的有:Eckenfelder模型、Mc Kinney模型和Lawrence-McCarty模型.早期的活性污泥数学模型将化工领域的反应器理论和微生物生长理论相结合,通过建立底物降解与微生物生长之间的关系,建立活性污泥静态模型[1].

1.1 Eckenfelder模型

Eckenfelder通过分析间歇反应器内基质浓度与微生物生长速率的关系,将微生物在培养过程中生长变化分为3个阶段[2].当反应器内微生物处于生长率上升阶段,反应器内基质浓度高,微生物的生长速率与反应器内的基质浓度无关,其表达式如下:

$$ \frac{\text{d}X}{\text{d}t}={{K}_{1}}X $$ (1) 式(1)中,X为微生物浓度,mg/L;K1为微生物增长速度常数,d-1;t为时间,s.

当反应器内微生物处于生长率下降阶段,此时反应器内基质浓度低,基质浓度成为限制微生物生长的主要因素.生长速率与基质浓度有如下表达式:

$$ \frac{\text{d}S}{\text{d}t}=-{{K}_{2}}XS $$ (2) 式(2)中,S为基质浓度,mg/L;K2为微生物减速增长速度常数d-1.

当反应器内微生物处于内源代谢状态时,微生物生长速率有如下表达式:

$$ \frac{\text{d}\left( {X}'-X \right)}{\text{d}t}=-{{K}_{3}}X $$ (3) 式(3)中,X'为生长率下降阶段末的微生物浓度,mg/L;K3为微生物衰减常数d-1.

1.2 Mc Kinney模型

McKinney模型由R.E. McKinney在1960年发表[3-4].McKinney认为微生物利用基质进行代谢过程中,基质的氧化分解、微生物生长及内源呼吸3种作用同时存在.McKinney还认为微生物浓度相对于基质浓度属于高浓度,微生物生长速率主要受基质浓度影响.当反应器内微生物处于生长率下降阶段时,其代谢过程主要与基质浓度有关,其反应过程有如下表达式:

$$ \frac{\text{d}F}{\text{d}t}=-{{K}_{\text{m}}}F $$ (4) 式(4)中,F为残存基质浓度,mg/L;Km为基质降解速率.

1.3 Lawrence-McCarty模型

Lawrence-McCarty模型将Monod方程引入废水生物处理领域,建立了微生物增殖、底物同化等方面的基本关系[5].同时该模型也强调污泥龄的作用,其基本表达式如下:

$$ \frac{\text{d}X}{\text{d}t}={{Y}_{\text{T}}}\left( \frac{\text{d}S}{\text{d}t} \right)-{{K}_{\text{d}}}X $$ (5) $$ \frac{\text{d}S}{\text{d}t}=\frac{kXS}{{{K}_{\text{S}}}+S} $$ (6) 式(5)、(6)中,YT:微生物产率系数kgVSS·[kgBOD5·d]-1;Kd:微生物衰减常数, d-1;k为单位生物量的最大底物利用率,d-1;KS:基质半饱和速率常数,mg/L.

传统的静态模型具有形式简单、参数可直接测定等优点,在污水处理工艺设计方面得到了广泛的应用[6].然而,长期应用实践表明,静态模型只考虑了稳态运行条件下微生物生长与基质浓度的关系,运用到实际复杂的非稳态活性污泥污水处理工艺系统时会出现诸多问题,如无法解释有机物去除初期阶段的快速去除的现象;不能解释当反应器内基质浓度增大时微生物生长速率相对滞后的现象[7].

2 活性污泥动态模型

活性污泥动态模型是以活性污泥动力学理论为基础,建立常微分方程(组)集总参数模型和以偏微分方程(组)分布参数模型.活性污泥法动态模型主要3种类型:Andrews模型、WRc模型和ASM系列模型.其中,ASM系列模型是目前活性污泥数学模型的研究重点.

2.1 Andrews模型

Andrews模型于20世纪80年代提出[8],该模型引入基质在活性污泥絮体内的贮存−代谢理论(图 1).该理论将基质分为溶解性基质和非溶解性基质.在基质去除过程中,微生物首先吸附非溶解性基质及部分溶解性基质,并在微生物体内以Xsto(胞内贮存物)的形式贮存,然后再被微生物利用.这一理论解释了有机物去除的初期阶段快速去除的现象[9].

2.2 WRc模型

英国水研究中心(Water Research Center)基于存活-非存活细胞代谢机理(图 2)提出WRc模型,该模型认为生物活性并不是以生物存活力为前提,细胞破裂、酶的溢出可使生物活性得到增强[7].非存活细胞的代谢作用使有机物的降解可以在不伴随微生物量增加的情况下发生,以此解释在采用Monod方程描述废水生物处理过程导致细胞浓度预测值偏高的原因[10].

Andrews模型和WRc模型用不同的机理解释了传统静态模型中无法解释的某些现象,但是这两个模型只描述了碳的去除过程并没有包括氮磷的去除过程,因而有一定局限性.

2.3 ASM系列模型

国际水协(IWA)在总结已有废水生物处理数学模型的基础上,前后推出了ASM系列模型,为污水处理工艺仿真与控制提供了重要的理论基础.国际水协于1987年正式发布活性污泥1号模型(ASM1).ASM1以矩阵的形式描述了污水处理工艺中好氧、缺氧条件下所发生有机物的水解、微生物生长及衰减等多种反应,但其主要缺陷是并未包含磷的去除过程[6].为完善模型中磷的去除过程,ASM专家组于1995年推出了活性污泥2号模型(ASM2),它同时包含有机物的厌氧、缺氧、好氧水解、聚磷菌的聚磷酸盐存储、聚磷菌的生长、硝化菌的生长及反硝化等多个反应过程[11].ASM2为综合性的污水生物处理过程动态模拟理论,其包含了化学需氧量(COD)、氮和磷等污染物质去除过程.随后,ASM课题组于1999年推出活性污泥2D号模型(ASM2D),该模型增加聚磷酸盐的缺氧贮存和聚磷菌的缺氧生长两个过程来说明聚磷菌可缺氧反硝化反应[12],从而完善了活性污泥数学模型的除磷过程.同年,ASM专家组针对ASM1应用中存在的问题进行修正,推出活性污泥3号模型(ASM3)[13].与ASM2不同的是,ASM3强调微生物细胞内部的活动过程,其不以有机物的水解作用为重点,引入有机物在微生物体内的贮藏及内源呼吸过程.ASM3和ASM1中主要过程是相同的,如都包含有机物的去除和生物脱氮.

ASM系列模型的发展是由简单到复杂的过程,所包含的组分个数、参数个数及模型机理等也不尽相同.ASM1~ASM3的模型结构信息如表 1所示..

表 1 ASM系列模型对比Table 1. Comparison of ASM series models模型 组分个数 反应个数 化学计量系数个数 动力学参数个数 模型机理及主要过程 ASM1 13 8 5 14 基于死亡-再生理论,包含有机物的去除和生物脱氮过程. ASM2 19 19 22 42 基于死亡-再生理论,包含有机物的去除、生物脱氮、生物除磷和化学除磷等过程. ASM2D 19 21 22 45 基于死亡-再生理论,包含有机物的去除、生物脱氮、生物除磷和化学除磷等过程,在ASM2的基础上增加聚磷酸盐的缺氧贮存和聚磷菌的缺氧生长两个过程 ASM3 13 12 6 21 基于内源呼吸理论,包含有机物的去除和生物脱氮过程. 3 ASM系列模型研究进展

活性污泥数学模型的研究和应用始终是国际上废水生物处理领域研究的热点之一.自国际水协发表ASM系列模型以来,在科研领域及实际工程领域当中都有相关的报道[14-16].从国内外大量的研究和应用实例中可知,ASM系列模型的研究主要分为3个方面:ASM系列模型水质组分测定研究,ASM系列模型校正研究,和ASM改进模型的应用研究.

3.1 ASM系列模型水质组分测定

ASM系列模型包含大量的水质组分,组分能否准确测定直接影响模型预测的准确程度.然而,ASM系列中COD水质组分测定目前仍然没有相关测试标准可循.测定污水COD组分的方法主要分呼吸计量法和物化法两类.

3.1.1 呼吸计量法

呼吸计量法是一种在特定条件下对微生物氧呼吸速率(OUR)进行测定和解释的方法.在活性污泥系统中,微生物的呼吸作用与废水中的污染物及微生物的生长情况有关,所以可以利用氧气平衡原理测定污水的COD组分.Hayet C等[17]利用呼吸计量法比较了传统活性污泥污水处理厂、延时曝气污水处理厂、工业污水处理厂的污水COD组分,结果表明各厂中易生物降解有机物SS分别占总COD的36%、21%和8%.Wu X等[18]利用呼吸计量法测定某焦化污水处理厂的污水COD组分,结果表明XS(易生物降解有机物)、XⅠ(惰性颗粒性有机物)、SS(易生物降解有机物)、SⅠ(惰性溶解性有机物)分别占总COD的58%、23%、12%和0.07%,利用测定结果建立ASM3模型,在预测中取得了良好的效果.

3.1.2 物化法

物化法是根据污染物粒径分布的不同,采用滤膜过滤来区分污水COD组分.Levine A D等[19]研究认为,粒径小于1.0μm近似为溶解性组分,比粒径大于1.0 μm的组分更快降解.Wu J等[20]将污水中的COD划分为4类:可沉淀COD(CSS)、不可沉COD(CNS)、胶体物质COD(CC)和溶解性物质COD(CS).原污水WR经90分钟沉淀得到沉淀后的水样为WS,WS经0.45 μm滤膜过滤得到的水样为WF.原污水经混凝沉淀后再经0.45 μm的滤膜过滤得到的水样为WFF.CSS为WR与WS之间的COD差值,CNS为WS与WF之间的差值,CC为WFF与WF之间的COD差值,CS为WFF的COD值.然而,在ASM系列模型中,COD组分是根据组分的生物转化特性(可生物降解、慢速和快速生物降解)和物化特性(可絮凝到活性污泥当中、随出水流出的溶解性不可生物降解物质)划分的,并没有严格的粒径划分.因此,在实践中物化法的应用存在一定的争议.卢培利等[21]比较了4种COD物化表征方法,分别对应0.1 μm滤膜过滤、0.45 μm滤膜过滤、絮凝和絮凝≥0.45 μm滤膜过滤,结果表明4种物化方法得到的处理液的快速生物降解物质与原污水样没有明显的差异,但是4种处理液里面包含了降解速率明显差异的物质,快速生物降解物质仅仅占35%~45%,并不能完全区分快速易生物降解物质与慢速生物降解物质.

物化法检测技术简单,且不易受外界因素的干扰,但无法完全区分COD组分,有一定局限性.呼吸计量法所需的设备仪器较为复杂,且测试周期较长,但是测试结果更符合模型组分划分的要求.在实际应用中,为取得准确的测量结果可将呼吸计量法和物化法联合使用.

3.2 ASM系列模型校正

ASM系列模型给出了不同温度条件下的模型参数的参考值.将ASM应用到一个实际的污水处理系统时,在对不同条件、不同时间、不同位置的微生物、COD、N、P等组分浓度进行计算时,需要对模型的某些参数值进行适当调整,以使模型的计算值与实际测量值相符.对模型参数的这一校核过程,称为活性污泥数学模型的校正.模型校正的主要目的是保证模型的准确性,即模型的预测计算结果与实际运行结果在误差允许范围内基本匹配.ASM系列模型的校正主要有实验校正和数学校正两种方法.

3.2.1 实验校正

活性污泥数学模型内的许多变量和参数都可以采用呼吸计量法加以测定,呼吸计量法在活性污泥数学模型校正过程中得到了普遍应用[22-23].微生物的生长与底物有着密不可分的关系,而底物中C、N的去除与氧气又相互联系.可以以OUR为中心,建立底物浓度与微生物数量的关系,分析反应的动态特性,从而求出模型中所需的参数,如利用呼吸计量法测定自养菌的最大比增长速率μmA.

已知自养菌的最大反硝化速率rN, max(mg/L·d)和其最大呼吸速率OURmA(mg/L·d)有如下关系:

$$ {{r}_{\text{N, max}}}=\frac{OU{{R}_{\text{mA}}}}{{{i}_{\text{NO}_{\text{3}}^{\text{-}}\text{-N}}}} $$ (7) 而rN, max与μmA存在如下关系:

$$ {{\mu }_{\text{mA}}}=\frac{{{r}_{\text{N, max}}}\times {{Y}_{\text{A}}}}{{{X}_{\text{B, A}}}} $$ (8) 基于式(7)及式(8)可得:

$$ {{\mu }_{\text{mA}}}=\frac{OU{{R}_{\text{mA}}}\times {{Y}_{\text{A}}}}{{{i}_{\text{NO}_{\text{3}}^{\text{-}}\text{-N}}}\times {{X}_{\text{B, A}}}} $$ (9) 式(7)、(8)、(9)中$ {{i}_{\text{NO}_{\text{3}}^{\text{-}}\text{-N}}} $为4.33gO2/gNO3--N;YA为自养菌产率系数(g细胞COD/g氧化的N);XB, A为自养菌浓度(mg/L).

因此可以利用呼吸计量法测定出OURmA,再利用式(9)求出μmA.呼吸计量法理论上可以测定ASM中的大部分参数,但是目前模型中的某些参数的测试方法尚不成熟,而且测试成本太高,从而限制了该方法的使用和推广.

3.2.2 数学校正

ASM系列模型校正的另一种方法是通过数学方法,包括专家法、过程过程法和灵敏度分析等方法.专家法是指由该领域的专业技术人员与专家的权威性经验构成专家系统,根据模型预测值与实测值的偏差,凭经验分析偏差主要是由哪些因素引起的,并进行相应参数的校核.然而,不同的专家根据其经验,可能会采用不同的参数调整措施,调整的结果也可能存在较大差异,因此专家法不易形成定论,缺乏说服力.过程工程法是对整个系统中的每一个过程进行逐步分析,找出偏差及偏差产生的原因,对相关参数进行必要的校核.从本质上讲,专家法和过程工程法都属于经验方法.利用过程工程法可使模型所需校正的参数相对较少,而且通过对参数的反复校正,一般都可以使模拟值与实测值达到最佳吻合,这使得过程工作法在模型参数校正中得到了广泛的应用[24].Veldhuizen H M V等[25]应用ASM2对某污水厂模拟时认为:针对反应区内PO43-浓度过高的问题,厌氧区末端可能是因为有过量的醋酸盐,可通过减小qfe(发酵常数)来降低,其他反应区可以增大kpp(PO43-摄取速率)来降低;缺氧区和好氧区PO43-的去除比例可以通过改变ηNO3P(聚磷菌缺氧还原系数)来调整.在模型的校核过程中,仅改变这3个参数就得到了较为理想的结果.

参数的灵敏度表示参数的变化对系统性能的影响程度,它是用来衡量参数变化对系统目标或状态产生影响程度的一个量化指标[26].灵敏度大的参数变化时对系统的状态或目标影响大,反之则影响小.对于灵敏度大的参数,不宜直接使用默认值,在模拟时须作校核;对于模型中灵敏度小的参数,在模拟时可直接使用默认值,不作校核;模型中灵敏度偏中的参数,在模拟时可视情况作或不作校核.Daelman M R J等[27]利用灵敏度分析方法对ASM1改进模型进行校正,结果显示μmaxMOB(甲烷氧化菌最大比增长速率)对系统影响最大,bMOB(甲烷氧化菌产率系数)与KCH4MOB(甲烷浓度一半时产甲烷氧化菌的生物量)影响次之.陈文亮等[28]考察了晴天、雨天、阴天等不同进水条件下ASM1模型的16个参数对BSM1(污水处理仿真基准模型)出水COD、TN、NH3-N、NO3--N灵敏度的影响.结果表明,μh(异养菌最大比增长速率)、KX(慢速可生物降解底物水解半饱和系数)、KNH(自养菌的氨半饱和系数)、bA(自养菌衰减系数)等参数的灵敏度在规定的划分范围内没有区别,而其他参数差别较为明显.灵敏度分析法可以考察模型参数的误差对模型的反应速率及组分浓度变化的影响,此外灵敏度分析也可以去除某些对模型影响不大的参数或者过程,从而简化模型.然而,灵敏度分析并不能反应每个过程的具体情况,灵敏度的大小只作为参数是否改变的依据.

3.3 ASM改进模型的应用研究

ASM系列模型是基于死亡再生或内源呼吸原理而构建的模型,主要包含有机物的去除、脱氮、除磷等过程.在实际应用中,为适应不同环境条件下运行的活性污泥系统,可对ASM系列模型进行改进以提高模型预测效果.综合国内外研究情况来看,ASM系列模型的应用改进分为模型的简化和模型过程的增加.

模型的简化是指在模型应用于某个特定的污水处理处理工艺前,在了解污水厂水质特征、工艺的水力学特性及微生物反应过程和原理的情况下,通过分析及计算变量及参数对模拟系统的敏感性,忽略不敏感因素,仅保留对整个系统影响较大的因素,从而简化模型.模型的简化目的是减少了模型的复杂程度,提高了模型的实用性.Hyunok Kim等[29-30]在ASM2的基础上,删除SI、SN2(氮气)、XI、XTSS(总悬浮固体)等不直接参与生化反应的模型组分,同时删除可以在曝气周期内维持在一定浓度的溶解氧SO2及可以在脱氮反应中得到补充的碱度SALK,建立了SLM模型.利用SLM对SBR工艺中的污染物去除过程进行模拟,结果表明模拟值与实测值非常接近,同时说明该简化模型对SBR工艺中硝化、氨化、反硝化及生物除磷等过程的模拟具有很好的预测效果.该简化模型与原ASM2模型相比,模型参数较少,模型校正较为简单,因此模拟计算时间大大缩短.S. Bahar等[31]根据ASM1和ASM3机理的不同,分别对两种原模型进行了简化.首先,在ASM1的基础上仅保留XH(异养菌生物量)、XS、SS、XP(生物衰减颗粒性产物)等4种组分,增加XVSS(挥发性悬浮固体)组分,将反应过程整合为内源衰减、水解作用、微生物增长等3个过程,构建了ASM1简化模型.其次,在ASM3的基础上仅保留XH,XS,XSTO(异养菌胞内贮存产物),XP,XVSS等5种组分,并将反应过程简化为XH内源衰减,XSTO内源衰减,基于XSTO的微生物增长等3个过程.S. Bahar将两种简化模型用于模拟污泥消化过程,结果显示ASM1简化模型的COD、VSS的模拟值与预测值的相关系数分别为0.985、0.978,ASM3简化模型的COD、VSS的模拟值与预测值的相关系数分别为0.990、0.988.

活性污泥系统是一个复杂的处理过程,虽然ASM系列模型中的反应过程已比较全面,但是在实际运用中还是会出现某些偏差.Krishna C等[32]提出ASM3模型无法体现底物浓度较高时与底物浓度下降时生长率的连续性,这是因为ASM3模型认为所有的底物需转换成储存物质,然后再同化到微生物体内,忽略了微生物直接利用易生物降解底物生长的情况.Kaelin D[33]、Gernaey K V[34]则认为ASM3、ASM1模型中忽略了亚硝酸盐在氮去除中的作用.针对实际应用中出现的偏差,可以在ASM系列模型的基础上增加某些过程,以达到更准确的模拟结果.Man Z等[35]在ASM3模型中加入SNO2(亚硝酸盐)、SNO3(硝酸盐)、XAOB(氨氧化菌)、XNOB(亚硝酸盐氧化菌)等组分,并在模型中增加了氨氧化菌及亚硝酸盐氧化菌的生长、缺氧内源呼吸、好氧内源呼吸等过程构建了ASM3扩展模型.利用扩展模型模拟实验室SBR工艺,出水浓度COD的模拟值和测量值的拟合度为97%.Ya-jing SONG等[36]则在ASM1的基础上加入SPO4(溶解性无机磷)、XPO4(颗粒性无机磷)2种组分,并将扩展模型用于Xuxi河沿程污染物质变化模拟研究,结果表明扩展模型所得数据与实测数据十分接近.

近年来,随着检测技术的提高和对活性污泥机理模型的深入研究,ASM系列模型有大量的改进应用,不同处理过程和水质指标被整合到了模型当中,见表 2.

表 2 国内外关于ASM系列改进模型的相关报道Table 2. Reports on ASM series improvement models at home and abroad文献来源 作者 改进方式 [27] Daelman M R J等 在ASM1的基础上,加入甲烷氧化菌的生长和衰减过程,构建ASM1m改进模型. [29] [30] Kim H等 在ASM2的基础上,删除SI、SN2、XI、XTSS等不直接参与生化反应的模型组分,同时删除SO2(氧气)、SALK(碱度)建立SLM模型. [31] S. Bahar等 在ASM1的基础上仅保留XH、XS、SS、XP等4种组分,增加XVSS组分,将反应过程整合为内源衰减、水解作用、微生物增长等3个过程,构建ASM1简化模型.在ASM3的基础上仅保留XH,XS,XSTO,XP,XVSS等5种组分,并将反应过程简化为XH内源衰减,XSTO内源衰减,基于XSTO的微生物增长等3个过程,构建ASM3简化模型. [35] Man Z等 在ASM3中加入SNO2,SNO3,XAOB、XNOB等组分,并在模型中增加氨氧化菌及亚硝酸盐氧化菌的生长、缺氧内源呼吸、好氧内源呼吸等过程构建ASM3扩展模型. [37] 曾维丁等 以ASM1为基础,忽略氨化反应过程,删除SALK、SO2、XI,SI等组分,建立ASM1改进模型. [38] Chen L等 在ASM3的基础上,基于微生物同时存储、同时生长的理论,加入SMP(可溶性微生物产物)过程,构建ASM3-SMP模型. [39] Janus T等 在ASM3的基础上,同时加入SMP(可溶性微生物产物)和EPS(细菌胞外多聚物)两种组分,构建CES-ASM3模型. 4 结语

活性污泥数学模型的发展是一个从片面到全面的过程,其在科研、污水处理工艺的优化设计、污水厂运行管理等方面的作用日益凸显.活性污泥数学模型未来的发展可能主要集中于以下3个方面:① 污水处理系统的不确定性分析将是今后活性污泥数学模型发展的研究重点.随着活性污泥数学模型在污水处理系统中的大量应用,模型结果可靠性要求越来越受到重视,模型模拟过程的不确定性分析,尤其是模拟结果的可靠性分析和风险水平评估显得尤为必要.② 活性污泥生物场和水力学场、温度场的耦合.传统的活性污泥数学模型只考虑了反应器内生物场的作用,但实际污水处理工艺与温度及反应池内混合液流态的影响.因此加入温度场和水力学场与传统的生物场结合将增强模型的实用性.③ 污水处理工艺管理与活性污泥数学模型的结合.活性污泥数学模型最大特点就是可以预测出水水质,如果能与在线监测设备相结合就能形成反馈调节机制.在线监测设备将信息传递给活性污泥数学模型,数学模型根据实时数据做出合理选择,调节污水厂设备的开启与闭合,实现污水厂的智能化管理.

-

表 1 碱性高砷渣的主要化学成分(质量分数,%)

Table 1 Chemical component of high-arsenic caustic sludge(massfraction,%)

-

[1] 熊如意, 宋卫峰. 环境砷污染及其治理技术发展趋势[J]. 广东化工, 2007, 34 (11):92-94. http://www.cnki.com.cn/Article/CJFDTOTAL-GDHG200711031.htm [2] 郭朝晖, 程义. 有色冶炼废渣的矿物学特征与环境活性[J]. 中南大学学报(自然科学版), 2007, 38(6):1100-1105. http://www.cnki.com.cn/Article/CJFDTOTAL-ZNGD200706016.htm [3] LeBerre J F, Gauvin R, Demopoulos G P. A study of the crystallization kinetics of scorodite via the transformation of poorly crystalline ferric arsenate in weakly acidic solution[J]. Colloids and Surfaces A: Physicochem. Eng. Aspects, 2008, 315: 117-129. doi: 10.1016/j.colsurfa.2007.07.028

[4] Krause E, Ettel. Solubilities and stabilities of ferric arsenate compounds[J]. Hydrometallurgy, 1989, 22: 311-337. doi: 10.1016/0304-386X(89)90028-5

[5] 巫瑞中. 石灰-铁盐法处理含重金属及砷工业废水[J]. 江西理工大学学报, 2006, 27(3):58-61. http://www.cnki.com.cn/Article/CJFDTOTAL-NFYX200603018.htm [6] Nishimura T, Robins R G. A Re-evaluation of the solubility and stability regions of calcium arsenites and calcium arsenates in aqueous solution at 25 ℃[J]. Mineral Proc and Extr Met Reviews, 1998, 18:283-308. doi: 10.1080/08827509808914159

[7] Nishimura T, Tozawa K. The reaction for the removal of As and As from aqueus solutions by adding calcium hydroxide[J]. J Min Met Inst Japan, 1984, 100:1085-1091.

[8] Jung W, Kim M Y, Chae J. Solidification of arsenic and heavy metal containing tailings using cement and blast furnace slag[J]. Environ Geochem Health, 2011, 33:151-158. doi: 10.1007/s10653-010-9354-2

[9] Deok H, Moon K W. Stabilization of arsenic-contaminated mine tailings using natural and calcined oyster shells[J]. Environ Earth Sci, 2011, 64:597-605. doi: 10.1007/s12665-010-0890-y

[10] Choi W H,Lee S R,Park J Y. Cement based solidification/stabilization of arsenic-contaminated mine tailings[J].Waste Management, 2009, 29: 1766-1771. doi: 10.1016/j.wasman.2008.11.008

[11] Palfy P,Vircikova E,Molnar L. Processing of arsenic waste by precipitation and solidification[J]. Waste Management, 1999, 19:55-59. doi: 10.1016/S0956-053X(99)00014-8

[12] Camacho J, Wee H Y. Arsenic stabilization on water treatment residuals by calcium addition[J]. Journal of Hazardous Materials, 2009, 165:599-603. doi: 10.1016/j.jhazmat.2008.10.038

[13] Carlo V, Veroniek D. Solidification/stabilisation of arsenic bearing fly ash from the metallurgical industry. Immobilisation mechanism of arsenic[J]. Waste Management, 2002, 22:143-146. doi: 10.1016/S0956-053X(01)00062-9

[14] Leist M, Casey R J. The management of arsenic wastes:Problems and prospects[J]. Journal of Hazardous Materials, 2000, 76:125-138. doi: 10.1016/S0304-3894(00)00188-6

[15] 朱义年, 张华. 砷酸钙化合物的溶解度及其稳定性随pH 值的变化[J]. 环境科学学报, 2005, 25: 1652-1660. http://www.cnki.com.cn/Article/CJFDTOTAL-HJXX200512015.htm [16] James V Bothe, Paul J R, Brown W. Arsenic immobilization by calcium arsenate formation[J]. Environmental Science and Techn-ology, 1999, 33: 3806-3811. doi: 10.1021/es980998m

[17] Jie C, Du Y G, A new process of continuous three-stage co-precipitation of arsenic withferrous iron and lime[J]. Hydro-metallurgy, 2014, 146: 169-174.

[18] James V B, Paul Jr, Brown W.The stabilities of calcium arsenates at 23±1 ℃[J]. Journal of Hazardous Materials, 1999, 69: 197-207. doi: 10.1016/S0304-3894(99)00105-3

[19] 雷杰, 彭兵. 用电解锰渣制备高铁硫铝酸盐水泥熟料[J]. 材料与冶金学报, 2014, 13(4):257-261. http://www.cnki.com.cn/Article/CJFDTOTAL-HUJI201404006.htm -

期刊类型引用(6)

1. 陈治池,何强,蔡然,罗华瑞,罗南,宋忱馨,程鸿. 碳中和趋势下数学模拟在污水处理系统中的发展与综合应用. 中国环境科学. 2022(06): 2587-2602 .  百度学术

百度学术

2. 吴启悦,李泓宣,张凤山,景宜,刘鸿斌. 基于GPS-X的造纸废水处理过程动态仿真研究. 中华纸业. 2021(22): 16-21 .  百度学术

百度学术

3. 赵静,张洋. ASM工艺模型的应用研究进展. 资源节约与环保. 2020(01): 133-134 .  百度学术

百度学术

4. 郑怀礼,李俊,孙强,赵瑞,李关侠,黄文璇,丁魏,肖伟龙. 城镇污水处理自动控制策略研究进展. 土木与环境工程学报(中英文). 2020(01): 126-134 .  百度学术

百度学术

5. 彭玉,王建辉,齐高相,高旭,申渝,冯东,钟诚. 活性污泥模型(ASMs)研究进展及其发展前景. 应用化工. 2020(05): 1288-1292 .  百度学术

百度学术

6. 潘东阳,刘静瑞. 基于活性污泥数学模型的污水处理工艺动态模拟. 化工设计通讯. 2019(04): 223-224 .  百度学术

百度学术

其他类型引用(14)

下载:

下载: