Process parameters of laser cladding iron-based coating iron-based coating

-

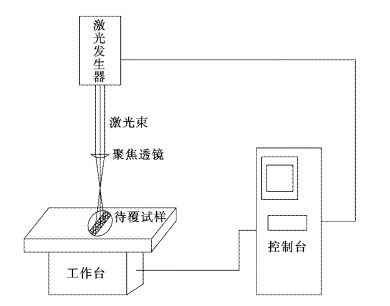

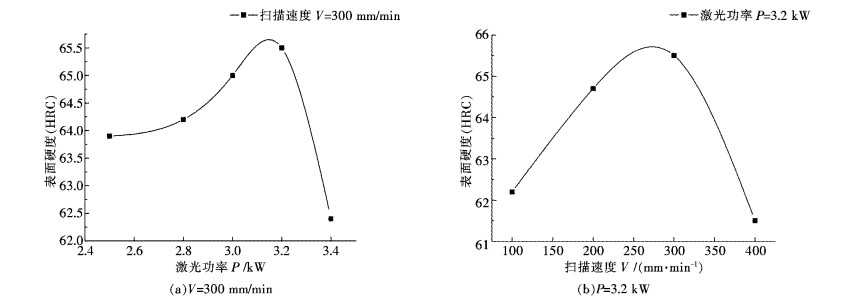

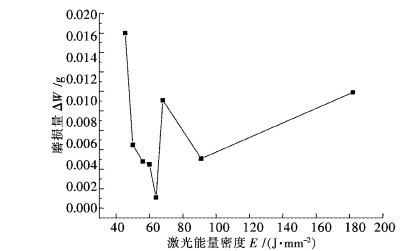

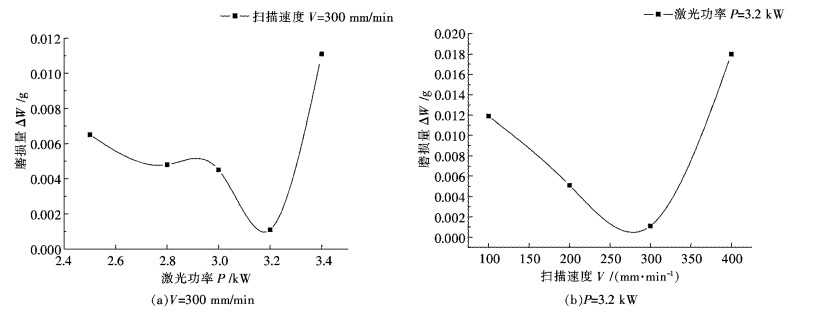

摘要: 以激光熔覆铁基涂层为研究对象,在MM-P2屏显式摩擦磨损试验机上进行摩擦磨损对比实验,分析了不同工艺参数下熔覆层形貌及熔覆涂层后磨损量的变化关系.结果表明:熔覆涂层后的表面硬度均在62HRC以上,远高于基体的硬度;熔覆层的形貌和质量主要影响因素是扫描速度,激光功率次之,并在此基础上采用能量密度进行表征,能量密度为60 J/mm2左右时的耐磨性最好,其最佳组合工艺参数为激光功率3.2 kW左右、扫描速度300 mm/min左右.激光功率过高,扫描速度过快都会导致熔覆层耐磨性能下降.Abstract: Comparative experiments of friction and wear were performed on MM-P2-screen friction and wear tester using laser cladding iron-based coating as the object of study. The morphology of cladding layer under different process parameters were studied by analyzing the changes of wear amount and cladding coating. The results show that the surface hardness are above 62 HRC after cladding coating, far higher than the hardness of substrate. Scanning speed and laser power are the most important factors affecting the morphology and quality of cladding layer. Energy density characterization results show the best abrasion resistance occurs when the energy density is around 60 J/mm2. The scope of the optimal process parameters are: laser power approximately 3.2 kW, the scanning speed around 300 mm/min. The results show that too high laser power and scanning speed also decrease the abrasion resistance of cladding layer.

-

Keywords:

- laser cladding /

- cladding layer /

- process parameters /

- wear resistance

-

在矿山设计中,最为关键的是生产规模论证以及采矿设计方案的优选,其中采矿设计方案主要包括采矿方法以及矿山开拓运输方案的确定,这两者均依赖于矿床地质资源条件以及开采技术条件,其优选结果如何直接影响到矿山今后生产的技术经济效益,因此,对矿山企业来说具有非常重要的意义.目前,国内外众多矿山工作者已经做了大量的研究与实践[1-4],但研究方法一般较为简单,多为方案直接比选法.本文将采用多属性决策理论进行研究.

1 采矿方法优选

白象山铁矿是姑山铁矿区内的一个大型矿床.矿区内的姑山铁矿床、和睦山铁矿床、钟九铁矿床、钟山铁矿床等由马钢集团姑山矿业公司开采. 姑山矿区位于安徽省马鞍山市当涂县城南偏东10 km处,白象山铁矿床与姑山矿业公司所在地直线距离2.5km,地理坐标为东经118°31′53″,北纬31°27′34″.白象山铁矿是今后相当长一个时期姑山矿业公司的主力矿山,能否按期建成白象山铁矿,关系到姑山矿的长治久安[5].

1.1 矿体特征

矿床内共圈定矿体11 个,其中Ⅰ号矿体为主矿体,地质储量约占矿床总储量的98.9 %,其余小矿体占总储量的1.1 %. 白象山铁矿的矿体变化很大,勘探线1~9 线矿体的水平厚度最大达到300~400 m,倾角在9~13°;其它的在几十米,倾角在20~40°.因此,在不同的区段采场形式是不同的,基本上可分为如下两种:

(1) 特厚大矿体.主要是指勘探线1~9 线西部区段和其他水平厚度大于100 m 的厚大矿体.

(2) 一般厚度矿体.主要是矿体水平厚度50 m 以下的矿体,矿体倾角一般都稍大,在20~40°之间.对矿体水平厚度在50~100 m 之间的,倾角又适合采用脉外出矿的,采场布置也按此布置,只是采场生产能力可按特厚大矿体采场计.

1.2 采矿方法选择

采矿方法选择除了要考虑通常的基本要求外,即安全、矿石贫化率小、矿石回采率高、生产效率高、经济效益好等[6],还要满足矿山提出的地表不塌陷、井下不突水的要求,而充填采矿法则能够同时满足这两个要求[7].根据矿体的埋藏条件和矿岩的稳定性、水文地质条件,可选择的采矿方法有:机械化盘区上向分层连续倾斜进路尾砂充填采矿法(简称连续倾斜进路尾砂充填采矿法)、机械化盘区点柱式上向分层充填采矿法(简称点柱充填法);对厚大矿体或矿体中厚但倾角陡的矿体采用大直径深孔空场嗣后充填采矿法和分段空场嗣后充填采矿法技术上也是可行的[8-9].

(1) 连续倾斜进路尾砂充填采矿法.连续倾斜进路尾砂充填采矿法是典型的机械化盘区上向分层连续进路式胶结充填采矿法的变异,只是进路呈平行四边形,并且充填时不添加水泥,全部用尾砂充填(或增加水泥砂浆胶面).回采是在每一分层以进路的形式凿岩爆破出矿,一条进路采完后即进行充填,在尾砂脱水固结后,第二条进路从旁边开始回采.这种方法的优点是回采进路高度小,顶板易处理,作业安全;采用尾砂充填作业成本低;能较好地适应矿体形状的变化,矿石损失贫化率低.缺点是采场需要一条一条地充,工序相对较多,劳动生产率相对较低.由于采用尾砂充填,因此尾砂的粒径要求较粗,易于脱水,采场充填接顶要求严格.

(2) 点柱充填采矿法.点柱充填采矿法是在采场中均匀布置点柱(点柱间距15 m,点柱尺寸为4.5 m×4.5m),采场顶板靠点柱支撑,点柱作为永久损失.每分层回采时采用水平炮孔落矿(也有打上向孔的),充填可根据回采的情况分次充填.和连续进路倾斜尾砂充填采矿法相比,点柱充填采矿法的优点是凿岩爆破的效率高,采场生产能力较大,也能较好地控制采场顶板和矿体上盘围岩稳定.缺点是采场暴露面积较大,采场顶板管理要求严格,安全可靠性比采用连续进路倾斜尾砂充填采矿法相对要低.

(3) 大直径深孔空场嗣后充填采矿法和分段空场嗣后充填采矿法.该方法的优点是人员设备不需进入采场空区,回采作业安全; 采用集中凿岩集中出矿,设备利用率高;单位开采面积采矿生产能力大.缺点是采场暴露的高度大,在水文条件复杂的矿山不能及时有效地控制涌水突发事故的发生; 如矿房不采用胶结充填则需留大量的矿柱不能回收,矿石损失率大,如矿房采用胶结充填则充填成本相对较高;对矿体的形状变化适应差,因而矿石的贫化率大,矿石损失率也较大.因此,不推荐采用该采矿方法.若矿岩的稳固性较好、矿体倾角和厚度又适宜的情况下,在矿体疏干之后,可试用沿走向布置的分段空场嗣后充填采矿法,但最后空区应完全充填接顶以保护地表.

(4) 采矿方法优选.根据矿山提出的保证地表不塌陷、井下不突水等要求,结合白象山铁矿床开采技术条件,考虑到矿山生产规模的需要,认为必须采用连续倾斜进路尾砂充填采矿法和点柱充填采矿法,才能实现安全高强度回采,满足矿山年采出矿量200 万t 以上并保护地表的要求. 为适应白象山的层状缓倾斜、水平矿体厚度变化较大的情况,连续倾斜进路充填采矿法和点柱充填采矿法,均沿走向布置盘区(长100 m),特厚大矿体每个盘区按100 m×100 m 划分为若干个矿块.

2 主要开拓运输方案及其技术经济指标

2.1 主要开拓运输方案

根据矿体的赋存条件和矿床开采技术条件,矿床开拓主要以竖井开拓为主,开拓运输方案受厂址的影响,初步拟定4 个方案,分别为:

(1) 方案D1.主副井、选厂在龙尾冲方案.采用主副井开拓,主副井和选厂布置在龙尾冲的山坡上,工业场地靠近矿体(在-470 m 水平副井离矿体约660 m).

(2) 方案D2.主副井、选厂在泉水湾方案.采用主副井开拓,主副井和选厂布置在泉水湾的山坡上.

(3)方案D3.副井在钟山,主井和选厂在龙尾冲方案.采用主副井开拓,副井布置在钟山(青山河的西面),主井和选厂在龙尾冲的山坡上.井下人员和材料均从钟山副井下到井下,机修可完全利用已有的设施.副井场地应增设变电所,为副井服务,地表布置空压机房.但在主井附近需设一条进风井(即方案D1中的副井位置),进风井内设梯子间,排水管、供水管、供电电缆从进风井走.

(4) 方案D4.钟山通地表的斜坡道,主井和选厂在龙尾冲方案.采用主井和辅助斜坡道开拓,辅助斜坡道开口布置在钟山(青山河的西面),主井和选厂在龙尾冲的山坡上. 在钟山掘进斜坡道到-450 m 水平(即取代方案D3中的副井和副井石门),人员材料通过无轨设备运输到井下,从地表到井下-450 m 水平辅助斜坡道长约为3300 m.

2.2 主要技术经济指标

所提出开拓运输方案的主要技术经济指标见表 1.

表 1 主要技术经济指标

3 基于理想点法的开拓运输方案优化选择

3.1 开拓运输方案优缺点比较

各开拓运输方案的优缺点见表 2.

表 2 4 个方案优缺点比较

由表 2 可知,D1基建工程量省,基建时间相对要短,但年均经营费用较高;与D1相比,D2主副井远离矿体多460 m 左右,井下运距也多460 m(单程),此方案基建时间相对要长一些,人员上下班井下需多走约460 m;D3基建工程量大,但利用了原来的一些设施,如原有的一些住宅和土地,可减少征地的数量.但副井石门巷道长,到矿体约1800 m,且巷道需要穿过F2断层,F2断层导水性强,周围岩石不好,给施工会带来一定的难度;D4减少了井筒装备、井塔及提升设施,无轨设备上下、材料运输非常方便,但斜坡道运输紧张.直观来看,D1与D2难以取舍、D4似乎优于D3,但D1、D2与D4比较起来,较难下结论,还需要结合表 1 以及矿山治水实际情况加以权衡.

3.2 基于理想点法的开拓运输方案优化选择模型

1) 基于理想点法的多属性优化选择模型

矿山开拓运输方案的选择是一个多目标优化问题,可进行以下描述:方案集D={Di}(i=1,2,…,m);属性集X={Xj}(j=1,2,…,n),属性值为xij,属性向量为xi =(xi1,xi2,…,xin);目标集为Y={Yk} (k=1,2,…,p),目标值为yik.通过目标函数fk(x)建立Di的属性向量xi与Yk的关系,即yik=fk(xi).可得评价矩阵[10-12]:

其中F(xi )=[f1(xi),f2 (xi),…,fP (xi )]

fk(x)为评价属性的价值函数Vj(xij),则:

在优选方案目标体系中包括两大类目标,即极大型目标和极小型目标.一般来说,希望所优选的方案具有理想值.然而实际上,理想点是不太容易求出的,因此,只有在拟定备择方案中寻求相对较优.如果目标函数没有数学解析表达式,则只能由实验求得,也可以根据专家经验提出近似理想值.

近似理想点确定后,需要构建理想方案,即I*,则

其中

于是寻求Di,使其到近似理想点的距离最小.另外,如果各属性目标的重要程度不一样,那么引进权重

(1) 式(1)中αi为Di与I* 的近似程度,即近似度.

U(Di)说明选出的最优方案与I* 最接近,即αi最小.

2) 开拓运输方案评判指标体系的构建与测算

第1,构建开拓运输方案评判指标体系,见表 3.

表 3 开拓运输方案评判指标体系

第2,对表 3 中X4、X6两项指标采用百分制打分.其中X4:易为0,一般为60,较难为80,难为100;X6:一般为60,较好为80,好为100.

第3,选择标准化函数,求出标准化矩阵.设I1、I2依次为极大型、极小型指标的集合,于是可以选取如下的标准化函数:

则标准化矩阵

第4,计算各指标的权重系数.首先将评价指标按照行和列排列,形成一个正方形表格;其次,利用相对比较法对指标之间的关系进行分析,将评分值记入表格;然后,将指标评分值每行求和;最后,归一化,得到权重系数.

第5,求各个方案与理想决策方案的近似度.

理想点为I*=(V1*,V2* ,…,V6*)=(1,1,1,1,1,1).

利用式(1),取P=2,则α1=0.632,α2=0.449,α3=0.794,α4=0.773. 因此,4 个开拓运输方案的排序为D2、D1、D4、D3,设计推荐方案为D2或D1.

4 结论

根据姑山矿提出的保证地表不塌陷、井下不突水等要求,结合白象山铁矿床开采技术条件,考虑到矿山生产规模的需要,得出必须采用连续倾斜进路尾砂充填采矿法和点柱充填采矿法,才能实现安全高强度回采,满足矿山年采出矿200 万t 以上并保护地表的要求.根据白象山铁矿床矿体的赋存条件和矿床开采技术条件,拟定了4 个开拓运输方案,建立了开拓运输方案评判指标体系,利用理想点法对4 个方案进行比较优选,结果表明:D2、D1依次为较优推荐方案.上述研究成果已经被马钢集团姑山矿业有限公司采纳,目前正在应用中,长期社会与经济效益预期良好.因此,利用理想点法进行矿山开拓运输方案的优化选择具有较好的可靠性以及实用与推广价值.

-

表 1 铁基合金粉末的化学成分

Table 1 Chemical composition of iron base alloy powder

元素 C Si Cr Mo Mn V W Fe 含量/% 1.0 0.3 4.0 5.0 0.3 2.0 6.2 余量 表 2 不同激光功率对熔覆层形貌及耐磨性的影响

Table 2 Effects of laser power on morphology and wear resistance of cladding layers

标准样编号 激光功率

P/(kW)扫描速度

V/(mm·min-1)熔覆层形貌 表面硬度测得值

(HRC)硬度均值

(HRC)磨损前测得值

W0/g磨损后测得值

Wt/g磨损量

ΔW/gA1 2.5 300

63.8

64.3

63.663.9 9.6293

9.6291

9.62929.6228

9.6226

9.62270.0065 A2 2.8 300

64.8

63.6

64.264.2 9.5674

9.5673

9.56729.5627

9.5623

9.56250.0048 A3 3.0 300

64.6

65.5

64.965.0 9.6302

9.6301

9.63039.6258

9.6256

9.62570.0045 A4 3.2 300

65.6

64.7

66.265.5 9.5781

9.5782

9.57809.5768

9.5772

9.57700.0011 A5 3.4 300

61.6

63.3

62.362.4 9.5431

9.5433

9.54359.5323

9.5321

9.53190.0111 表 3 不同扫描速度对熔覆层形貌及耐磨性的影响

Table 3 Effects of scanning speed on morphology and wear resistance of cladding layers

标准样编号 激光功率

P/(kW)扫描速度

V/(mm·min-1)熔覆层形貌 表面硬度

(HRC)硬度均值

(HRC)磨损前测得值

W0/g磨损后测得值

Wt/g磨损量

ΔW/gB1 3.2 100

61.6

62.5

62.362.2 9.5741

9.5743

9.57459.5626

9.5624

9.56220.0119 B2 3.2 200

64.5

64.9

64.764.7 9.6564

9.6563

9.65629.5613

9.5612

9.56110.0051 A4 3.2 300

65.6

64.7

66.265.5 9.5781

9.5782

9.57809.5768

9.5772

9.57700.0011 B4 3.2 400

61.6

62.3

60.661.5 9.4861

9.4863

9.48659.4683

9.4681

9.46850.0180 表 4 不同工艺参数配比下的激光能量密度

Table 4 Different process parameters ratio of laser energy density

试样编号 A1 A2 A3 A4 A5 B1 B2 B4 激光能量密度

/(J·mm-2)50 56 60 64 68 182 91 45.5 -

[1] 张勤俭, 赵路明, 刘敏之, 等.刀具涂层技术的研究现状和发展趋势[J].有色金属科学与工程, 2014, 5(2):20-25. http://ysjskx.paperopen.com/oa/DArticle.aspx?type=view&id=201402004 [2] Qiu X W, Li G, Qiu L. The latest development and prospects of laser cladding technology[J]. Rare Metals and Cemented Carbides, 2008, 36(3): 54-57.

[3] 黄瑞芬, 罗建民, 王春琴.激光熔覆技术的应用及其发展[J].兵器材料科学与工程, 2005, 28(4): 57-59. http://www.cnki.com.cn/Article/CJFDTOTAL-BCKG200504018.htm [4] Aghasibeig M, Fredriksson H. Laser cladding of a featureless iron-based alloy[J]. Surface and Coatings Technology, 2012, 209(8): 32-37. http://www.docin.com/p-788505586.html

[5] 赵文强, 苗鸿宾, 游小红.矿用液压支柱的激光熔覆强化技术研究[J].矿山机械, 2011, 39(12): 18-20. http://www.cnki.com.cn/Article/CJFDTOTAL-KSJX201112007.htm [6] 余菊美, 卢洵, 晁明举, 等.铁基合金激光熔覆层组织分布及开裂敏感性研究[J].应用激光, 2006, 26(3):175-177. http://www.cnki.com.cn/Article/CJFDTOTAL-YYJG200603009.htm [7] 马运哲, 董世运, 徐滨士, 等.铁基合金激光熔覆技术工艺优化研究[J].中国表面工程, 2006, 19(5):154-160. http://www.cnki.com.cn/Article/CJFDTOTAL-BMGC2006S1041.htm [8] 李宝灵, 温宗胤, 刘旭红, 等.激光熔覆技术应用于轴类零件表面修复的实验研究[J].应用激光, 2007, 27(4): 290-294. http://www.cnki.com.cn/Article/CJFDTOTAL-YYJG200704006.htm [9] Yu Y S, Ni H J, Wen J L. A study on laser cladding of iron-based alloy[J]. China Surface Engineering, 2004(4): 24-31.

[10] Komvopoulos K, Nagarathnam K. Processing and characterization of laser-cladded coating materials[J]. Journal of Engineering Materials and Technology, 1990, 112(2): 131-143. doi: 10.1115/1.2903299

[11] Emamian A, Corbin S F, Khajepour A. Effect of laser cladding process parameters on clad quality and in-situ formed microstructure of Fe-TiC composite coatings[J]. Surface and Coatings Technology, 2010, 205(7): 2007-2015. doi: 10.1016/j.surfcoat.2010.08.087

[12] 吴钢, 刘宝, 宋光明.激光工艺参数对表面硬度影响规律的研究[J].机械工人, 2005, 26(1):59-61. http://www.cnki.com.cn/Article/CJFDTOTAL-JXRG20050100S.htm [13] 李养良, 潘东, 杜大明, 等.激光工艺参数对45#钢表面熔覆层组织及硬度的影响[J].应用激光, 2009, 29(5):398-401. http://www.cnki.com.cn/Article/CJFDTOTAL-YYJG200905009.htm [14] 朱刚贤, 张安峰, 李涤尘.激光熔覆工艺参数对熔覆层表面平整度的影响[J].中国激光, 2010, 37(1):296-301. http://www.cnki.com.cn/Article/CJFDTOTAL-JJZZ201001056.htm [15] Bo X, Wei T. The geometrical features of single laser cladding for the green remanufacturing[J]. Applied Laser, 2010(4):2. http://en.cnki.com.cn/Article_en/CJFDTOTAL-YYJG201004002.htm

下载:

下载: