Anti-burning loss of CuCrZr alloys melted under non-vacuum conditions

-

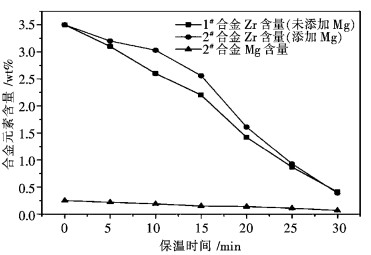

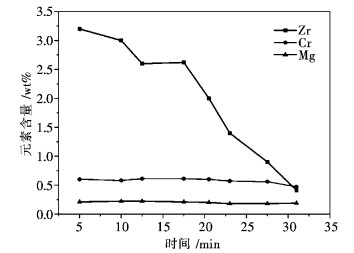

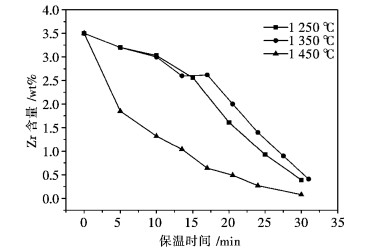

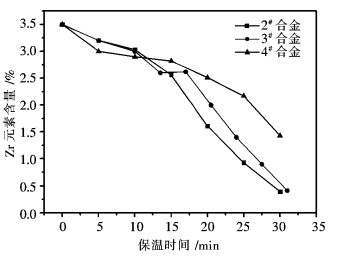

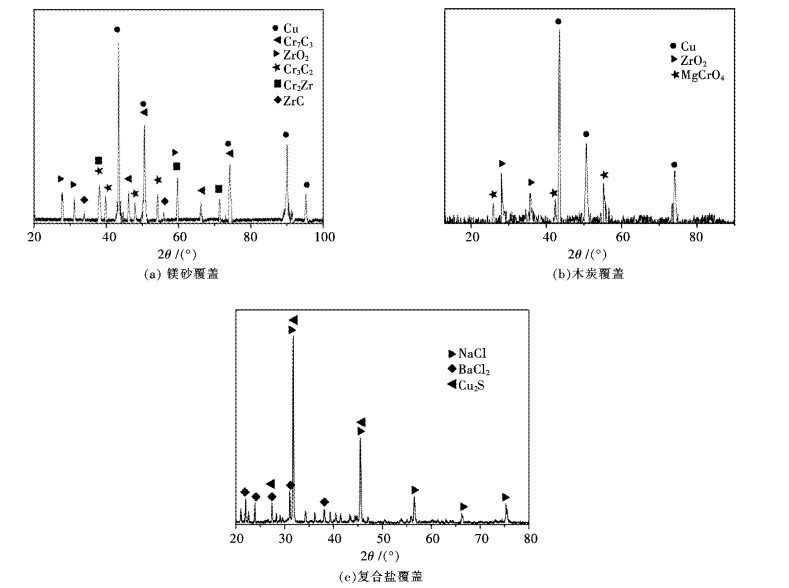

摘要: 高强高导CuCrZr合金在非真空熔铸过程中合金元素的氧化烧损是限制其工业化连续化生产的关键因素之一.为减缓合金元素的烧损,研究脱氧剂和覆盖材料对CuCrZr合金的非真空熔铸抗烧损效果的影响.结果表明,Mg元素的添加在熔炼初期能有效减缓Zr的烧损,且温度应当低于1 350 ℃,熔炼30 min后Zr的收得率在同一水平;当熔炼温度高于1 350 ℃时,合金中Zr元素烧损非常严重,Mg元素的保护作用大大减弱.采用复合盐覆盖能够显著提高Zr的收得率,熔炼30 min后其收得率仍达40.86 %.对合金炉渣进行XRD分析的结果表明:复合盐覆盖时,其炉渣相对木炭和氧化镁覆盖时更干净,炉渣中只含盐类.Abstract: Oxidation is one of the key factors of high strength high conductivity CuCrZr alloys melted in the non-vacuum condition which limits its industrialized continuous cast. This paper investigates the effects of anti-oxidation and coverage materials on the non-vacuum melting process in order to slow the mass loss of Zr. The results indicate that Mg addition can effectively slow the mass loss of Zr at the initial stage of melting process below 1 350 ℃. After melting for 30 min, Zr residual keeps the same level; the mass loss of Zr is very marked because the Mg protection is greatly weakened when the melting temperature reaches 1 350 ℃. Composite salt can effectively improve the residual of Zr with 40.86 % of residual of Zr after melting for 30 min. The XRD patterns of slag show that no any other reactants but salts exist in the slag when covered by composite salt.

-

Keywords:

- CuCrZr /

- non-vacuum melting /

- oxidation burning loss /

- covering materials

-

数字高程模型(Digital Elevation Model简称DEM)从20世纪50年代后期被引入以来,得到极大关注和广泛应用。随着地理信息系统应用的普及,DEM作为数字地形模拟的重要成果已经成为国家空间数据基础设施(NSDI)的基本内容之一,并被纳入数字化空间数据框架(DGDF)进行规模化生产[1]。本次研究采用江西德兴铜矿区DEM数据,分析自20世纪80年代矿山开发之初到如今人类活动对地表形态变迁造成的影响。

1 研究区概况

德兴铜矿是世界上已探明铜储量在800万t以上的特大型斑岩铜矿之一,也是中国最大的露天有色金属矿。矿区位于江西省东北部德兴市境内,与临近的大茅山同属怀玉山脉。其范围东至铁罗山,南至富家坞,西至张家畈,北至乐安河,主体沿大坞河两岸分布,东西长约12km,南北约8km,面积近100km2。矿区属中低山丘陵区,山体走向近乎南北,地势东南高、西北低,矿区现有两处废石堆(祝家、西源沟)、三座尾矿库,已储尾矿2.2亿t[2]。

2 数字高程模型应用

数字高程模型由数字地面模型(Digital Terrain Model,简称DTM)引申而来。DTM是描述地面特性的空间分布的有序数值阵列,这种地面特性可以是地价、土地权属、土壤类型、地貌特征、岩层深度及土地利用等与地形有关的信息。当这种地面特性由高程或海拔高程来表示时,这样的DTM就称为DEM。DEM是一种表达三维空间信息的数据结构,属于立体空间信息的范畴。

为了了解铜矿地区的今昔地形变化,首先需要建立不同时相的DEM,模拟出该地区过去和现在的地形状况。

1986年DEM生成:对1986年测绘部门手工绘制的1: 10万地形图的等高线进行扫描矢量化处理并赋予高程值,然后在GIS软件平台下生成DEM,从而建立过去的地形模拟数据。它以灰度图像形式表示,实质是把覆盖区域划分成大小和形状都相同的规则网格,用相应矩阵的行列号来对地面网格点的二维地理空间定位,而矩阵元素(图像灰度)则记录对应点的高程[3]。

2000年DEM生成:获取2000年10月17日接收的ASTER卫星遥感数据[2]。利用ASTER在近红外波段提供15m分辨率的径向立体像对(Band 3N和3B)这一特点,在遥感图像处理平台下自动生成DEM。

2.1 三维矿山地形动态演示

三维地理信息系统可定义为在三维方式下用于采集、存储、管理、处理、检索、分析和表达地理空间数据的计算机系统,而三维地形动态演示隶属于地理空间数据表达的研究范畴[4]。将地球表面地形与地物的三维空间属性采用数字高程模型这种数据结构合理地表达出来,然后逼真地再现于计算机屏幕上,达到直观真实地给决策者以视觉感受的需要,可以克服非专业人士难以解读地质图的障碍。

在这一问题上,国内外诸多遥感和三维GIS软件都提供了三维可视化工具。其中ERDAS IMAGIN E的虚拟地理信息系统(VirtualGIS)模块便能出色的完成上述工作,为用户建立一种对大型多源数据库进行实时漫游操作的途径[5]。

2.1.1 研究区选择及数据准备

(1)研究区。选择该矿区及周围约214.65km2的地区作为实验区,可以囊括全部铜矿开采区、尾矿堆放区及附近居民区。

(2)DEM。由2000年ASTER-Band3立体像对生成,img格式,格网间距为1000m,投影为Transverse Mercator,椭球为Krasovsky,基准面为Pulkovo1942,中央经线为东经117°。

(3)影像。由2000年ASTER-RGB:732彩色合成,为源影像的镶嵌数据,img格式,分辨率为15 m,投影为Transverse Mercator,椭球为Krasovsky,基准面为Pulkovo1942,中央经线为东经117°。

2.1.2 三维矿山地形演示

在Virtual GIS模块下的Virtual GIS Viewer视窗中同时将两幅具有相同投影方式、坐标范围、大地水准面等参数的DEM和ASTER彩色合成影像打开,可将其叠合在一起,得到的三维矿山虚拟视景(如图 1)既包含了高程信息,又具备了卫星影像的光谱特征,为各项遥感调查提供了直观可靠的理论基础。图中偏南部的品红色区域为大型铜矿露天采场,采场东北部的蓝色凹陷地带为4号尾矿库所在地,堆积了大量尾矿和废水。采场正北方有两个较小的蓝色区域,分别是1号和2号尾矿库。

另外,在该模块下还可制作三维虚拟矿山飞行动画。首先建立飞行路径,然后对飞行路径中各节点的高程(AGL&ASL)、速度(Speed)、焦点(Focal point)、视场角度(FOA)、俯视角度(Pitch)、方位角度(Azimuth)和旋转角度(Roll)调整到最佳,并对飞行过程的连续性和飞行角度反复对各点进行调整。最后,通过三维动画工具(Create Movie)在实时的三维飞行或漫游操作过程中直接记录画面生成三维动画(如图 2)。

2.2 剖面分析

2.2.1 研究区选择及介绍

随着铜矿开采活动的日益激烈,尾矿废渣堆积的日益增多,矿山周围原始地形发生了极大变化。自80年代中期以来,地形变化较明显的区域主要分布在各尾矿库所在地,其中以4号尾矿库区域变化尤为显著,可针对这一区域不同时相的剖面做动态变化对比分析。

4号尾矿库位于大山选矿厂下西源沟,1986年9月开工建设,1987年11月竣工。初期坝高42m,坝顶标高110m,设计最终堆积标高285m,有效库容8亿m3[2]。1986年至2000年期间,4号尾矿库的建立和使用使该区域地形发生了巨大变化。

2.2.2 基于DEM的剖面分析

传统方法采用手工绘制剖面图,精度往往难以保证;若需任意选取剖面线观察剖面,传统方法效率也非常低下。而利用DEM数据,在ERDAS等遥感图像处理平台下,可以准确而高效地绘制多类型、多角度剖面图,从而进行不同形式的剖面对比分析,使用户更加深入地掌握研究区的动态变化情况。

2.2.2.1 三维空间剖面

三维空间剖面是在DEM数据基础上建立的立体剖面,可以显示任一空间数据集的高低起伏状况。以ERDAS软件平台的Viewer模块为例,通过设定剖面位置,X、Y、Z轴长度及表示意义后,对该地区的4号尾矿库中同一区域范围的DEM提取三维空间剖面,所做的1986年与2000年的三维空间剖面对比情况如图 3和图 4所示。其中X、Y轴均表示图像中的像元值(距离),1986年的DEM基础上建立的剖面中Z轴表示绝对高程,2000年的DEM基础上建立的剖面中Z轴表示相对高程,在此仅对二剖面做定性变化对比分析。

2.2.2.2 空间剖面曲线

空间剖面曲线是以曲线的形式反映沿用户定义曲线上DEM所表现出的地表在空间上的高低起伏状况。在Viewer模块中分别装入1986年和2000年的DEM数据,调整X、Y、Z轴的长度、表示意义和单位后,将剖面线分别建立在1986年和2000年数据的4号尾矿库同一位置,即可生成相应的空间剖面曲线(如图 5、图 6)。其中X轴表示剖面线所代表的实际距离,基于1986年DEM的剖面曲线图中Y轴表示绝对高程,基于2000年DEM的剖面曲线中Y轴表示相对高程,在此仅对二剖面曲线做定性变化对比分析。

2.2.3 剖面分析总结

通过对同一地貌单元以上述两种形式进行的地形今昔形态对比分析中不难看出,1986年的4号尾矿库区域地形高低起伏,地表面曲线蜿蜒曲折,属于典型的山岭沟谷地貌;至2000年,低谷已抬升,地表面相对高程趋于一致,成为水平面。由此说明,经历了十余年的矿山挖掘和填埋过程,4号尾矿库所在的沟谷被尾矿砂和废水堆积,曾经沟壑起伏的山谷地形已被改造成如今的矿渣水库。剖面图形数据直观地表明,铜矿尾矿的堆积造成了地形的变迁,改变了原始的地形地貌。

2.3 体积量算

在德兴地区的矿山开采过程中,排放出大量的固体废料、废弃物(如尾矿、矸石等)需要与邻近矿区储矿量相匹配的容积适当的尾矿库来堆置。这些用于堆积尾矿砂的尾矿库不但改变了原始的地形,矿石、废渣中的重金属元素以及废石堆浸喷淋造成的酸性水体、尾矿堆放和选矿废水造成的碱性水体和混合污染水体都严重影响着当地的土壤肥力和植被长势。因此,调查量算尾矿库的体积和表面积等统计数据对于决策部门作出合理妥善的规划决策和制定改善污染的有效措施具有重大意义,对于后期的尾矿再利用以及扩容工程也提供了量的依据。在这一问题上,以建设较早的2号尾矿库为例做体积量算。

2号尾矿库位于铜埠,1980年开工,1984年12月竣工投入使用。采用“上游法”堆坝工艺,设计最终堆积标高250m,有效库容1亿m3。库首建有堆石坝,坝底标高45.7m,坝顶标高70m[2]。

目前,许多三维地理信息系统软件都提供了体积量算的功能,一改往日传统测绘和手工统计方法的繁琐。由于DEM已具备了矿山三维形态的数据信息,因此只需将其导入地理信息系统软件的相关模块,提供必要的空间参数,即可迅速完成体积量算,得出有效容积和表面积等统计结果。在ArcGIS家族的ArcScene模块下导入2号尾矿库的DEM(如图 7),该系统采用基于像元的微小柱体法(即将量算地区的DEM视为一个由许多以像元大小为底面、以像元反射值为高的立柱体组合而成的空间体,这个空间体的体积即所有立柱体体积之和),利用DEM这种特殊的表面数据计算出尾矿库的有效容积和库底面积。位于尾矿库中部的拦水坝高55m,可近似于库深提供给系统做统计。通过量算,2号尾矿库的表面积为1885539.46m2,合185.54hm2,与规划面积183.5hm2基本吻合。其最大有效库容为1.00亿m3与初期设计库容1亿m3也基本一致。

3 结论与讨论

(1)将DEM叠加以表面纹理影像数据,在遥感图像处理平台下做三维视景建立以及动态飞行模拟,将矿山立体全貌搬上荧幕,使用户可以畅游在仿真模拟的三维矿山中。然而随着真三维的矿山实体和矿山生产空间模拟成为需求,构建空间实体的大量基础数据的采集及处理问题亟待解决。

(2)利用地理信息系统空间分析工具对目标区域的DEM所作的地形空间剖面和剖面曲线,为测绘工作者和政府决策人员提供了科学的理论根据。同时,打破了以往旧的工作模式,解除了相关工作人员手绘剖面图的繁琐。加以不同时相的剖面对比分析,可为决策者实时监测矿山开发状况和地形改造提供动态依据。

(3)利用DEM对矿山以及尾矿库和废水池等具有空间体积的矿山附带设施做体积量算,有助于调查尾矿库的有效库容和尾矿堆积状况,为评估和预测矿山储量变化和尾矿库堆积能力提供数字依据。在体积计算的精度方面,由于作者所获数据精度的限制,以及所采用软件中提供的模型算法尚存在局限性,有待于进一步探索。

-

表 1 试验合金成分及部分熔炼参数

Table 1 Alloys components and metting parameters

合金编号 合金成分/ wt% 熔炼温度/ ℃ 坩埚材质 覆盖材料 Cr Zr Mg Cu 1# 0.8 3.5 0 余量 1 250 氧化镁 氧化镁 2# 0.8 3.5 0.25 余量 1 250 氧化镁 氧化镁 3# 0.6 3.5 0.25 余量 1 350 石墨 木炭 4# 0.6 3.5 0.25 余量 1 250 氧化镁 复合盐 5# 0.6 3.5 0.25 余量 1 450 镁砂 镁砂 -

[1] 田荣璋, 王祝堂.铜合金及其加工手册[M].长沙:中南大学出版社, 2002: 27-304. [2] Kalinin G., Barabash V, Cardella A, et al.Assessment and selection of materials for ITER in-vessel components[J].Journal of Nuclear Materials, 2000, 283/284/285/286/287: 10-19. https://www.researchgate.net/publication/223013800_Assessment_and_selection_of_materials_for_ITER_in-vessel_components

[3] 小林正男.高强高传导性引线框架用铜合金OMCL-1[J].铜加工, 1989, 33(1): 71-74.(陈汝团译自日本金属学会会报, 1988, 27(4): 284-286. [4] 杨斌.适用于高速电气化铁路的铜合金接触线[J].铁道机车车辆, 2005, 25(1): 68-70. http://www.cnki.com.cn/Article/CJFDTOTAL-TDJC20050100J.htm [5] Sun L X, Tao N R, Lu K.A high strength and high electrical conductivity bulk CuCrZr alloy with nanotwins[J].Scripta Materialia, 2015, 99(1): 73-76. https://www.researchgate.net/publication/271080918_A_high_strength_and_high_electrical_conductivity_bulk_CuCrZr_alloy_with_nanotwins

[6] Feng H, Jiang H, Yan D, et al.Effect of continuous extrusion on the microstructure and mechanical properties of a CuCrZr alloy[J].Materials Science and Engineering: A, 2013, 582: 219-224. doi: 10.1016/j.msea.2013.06.031

[7] Liu X, Lian Y, Chen L, et al.Tungsten joining with copper alloy and its high heat load performance[J].Journal of Nuclear Materials, 2014, 455(1): 382-386. http://adsabs.harvard.edu/abs/2014JNuM..455..382L

[8] Edwards D J, Singh B N, Bilde-SØrensen J B.Initiation and propagation of cleared channels in neutron-irradiated pure copper and a precipitation hardened CuCrZr alloy[J].Journal of Nuclear Materials, 2005, 342(1): 164-178. https://www.researchgate.net/publication/229164569_Initiation_and_propagation_of_cleared_channels_in_neutron-irradiated_pure_copper_and_a_precipitation_hardened_CuCrZr_alloy

[9] Edwards D J, Singh B N, Tähtinen S.Effect of heat treatments on precipitate microstructure and mechanical properties of a CuCrZr alloy[J].Journal of Nuclear Materials, 2007, 367: 904-909. https://www.researchgate.net/publication/239342509_Effect_of_heat_treatments_on_precipitate_microstructure_and_mechanical_properties_of_a_CuCrZr_alloy

[10] Holzwarth U, Stamm H, Pisoni M, et al.The recovery of tensile properties of CuCrZr alloy after hot isostatic pressing[J].Fusion Engineering and Design, 2000, 51(1): 111-116. https://www.researchgate.net/publication/245220634_Recovery_of_tensile_properties_of_CuCrZr_alloy_after_hot_isostatic_pressing

[11] Rotti C, Panda N, Patel H, et al.Establishing ITER-grade properties in CuCrZr: The Indian experience[J].Fusion Science and Technology, 2014, 65(2): 205-211. http://www.ans.org/store/article-35604/

[12] 贾淑果, 刘平, 宋克兴, 等.CuCrZr原位复合材料的组织与性能[J].中国有色金属学报, 2010, 20(7): 1134-1138. [13] 吴一凤, 夏承东, 汪明朴, 等.热轧工艺对Cu-Cr-Zr合金力学性能和电学性能的影响[J].中南大学学报(自然科学版), 2013, 44(3): 930-935. http://www.cnki.com.cn/Article/CJFDTOTAL-ZNGD201303013.htm [14] 郭望望.非真空熔铸Cu-Cr-Zr合金组织性能研究[D].洛阳:河南科技大学, 2011. http://cdmd.cnki.com.cn/Article/CDMD-10464-1011285123.htm [15] 慕思国, 汤玉琼, 郭富安, 等.Cu-Cr-Zr系合金非真空熔炼过程的热力学分析[J].中国有色金属学报, 2007, 17(8): 1330-1335. http://www.cnki.com.cn/Article/CJFDTOTAL-ZYXZ200708017.htm [16] 翁远辉, 陈钢, 吴渊, 等.非真空熔铸铜铬锆合金中的烧损和缺陷研究[J].铸造技术, 2013, 34(8): 1021-1023. http://www.cnki.com.cn/Article/CJFDTOTAL-ZZJS201308025.htm [17] 陶业卿.高强高导Cu-Cr-Zr合金非真空熔炼工艺及性能研究[D].洛阳:河南科技大学, 2011. http://cdmd.cnki.com.cn/Article/CDMD-10464-1011285123.htm

下载:

下载: