Mineral processing technology of a high iron-Cu-S ore

-

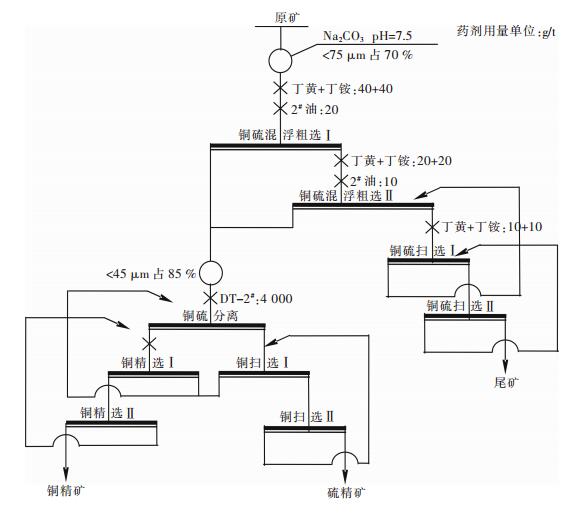

摘要: 针对某高铁铜硫矿石的性质,将原矿磨至细度为≤74 μm占70 %、以碳酸钠为pH调整剂、丁基黄药+丁铵黑药为组合捕收剂混合浮选铜硫,铜硫粗精矿再磨至≤45 μm占85 %后,主要以新型无机抑制剂DT-2#(次氯酸钙为有效成分)为黄铁矿抑制剂进行铜硫分离,浮选尾矿进行磁选选铁.试验结果表明,采用“铜硫混浮-粗精矿再磨-铜硫分离-浮选尾矿磁选”流程,在原矿含铜0.52 %、硫2.31 %、铁49.26 %的条件下,可获得含铜22.36 %、回收率为87.29 %的铜精矿,含硫38.43 %、回收率为62.88 %的硫精矿,含铁66.98 %,回收率为91.34 %的铁精矿.所用工艺流程简单,选矿指标较佳.Abstract: In light of the characteristics of a high iron Cu-S ore, under the condition of < 75μm grinding fineness being 70 %, using sodium carbonate as pH adjusting agent, with butyl xanthate and ammonium butyl as the combination collector of copper sulfide mixed flotation, iron is recovered from magnetic flotation tailings after the copper sulfide crude concentrate is regrinded to < 45 μm which accounts for 85 %, with DT-2# [The active ingredient is Ca (ClO)2]as the new inorganic inhibitor of pyrite to separate copper and sulfide. The test results show that using the process of "copper sulfide mixed flotation-crude concentrate regrinding-copper sulfide separation-magnetic flotation tailings", copper concentrate, sulfur concentrate and iron concentrate can be obtained containing 22.36 % of Cu with copper recovery rate of 87.29 %, 38.43 % of S with sulfur recovery rate of 62.88 %, and 66.98 % of Fe and iron recovery rate of 91.34 % respectively from a feed ore containing 0.52 % Cu, 2.31 % S and 49.26 % Fe. The process is simple to use with a good beneficiation index.

-

Keywords:

- mixed flotation /

- copper sulfide separation /

- DT-2# /

- magnetic separation

-

我国是铜硫矿物资源与生产大国,但由于长时间的不断开采和地质变化原因,这使得铜硫矿石的组分越来越复杂,品位越来越低,矿物间致密共生,镶嵌关系复杂多变.因此,铜硫矿物的选矿已成为硫化矿分选中较为典型的难题.温子龙等[1]对西宁某原生铜矿石进行了选矿试验研究,运用异丙基黄药和丁铵黑药组合捕收剂,获得铜精矿品位为18.16 %、回收率为86.21 %,硫精矿品位为30.12 %、回收率为82.07 %的选矿工艺指标.胡海祥等[2]通过对某铜硫铁复杂多金属矿分选新工艺试验研究,获得铜精矿品位19.53 %,回收率38.58 %;硫精矿品位43.27 %,回收率91.90 %;铁精矿品位64.72 %,回收率56.60 %的选矿指标.叶雪均等[3]针对安徽某铁矿磁选尾矿中铜矿物粗细不均,次生硫化铜含量较高,且部分黄铜矿被黄铁矿包裹等特点,在原铜硫混浮-铜硫分离工艺前进行了增设快速浮铜工艺环节的研究,并对混精再磨、分离工艺进行了优化研究.采用试验确定的半优先浮铜闭路试验流程处理该试样,可获得铜品位21. 48 %、回收率达82. 85 %的铜精矿,以及硫品位为48. 34 %、回收率为84. 43 %的硫精矿.

试验根据某矿石含铁49.26 %、铜0.52 %、硫2.31 %,为高铁铜硫矿,针对矿石特点,研究了采用“铜硫混浮-粗精矿再磨-铜硫分离-浮选尾矿磁选”流程,回收多金属,试验结果表明该矿石中有价元素得到了有效分离回收,选别指标较佳,所用工艺流程简单,可为开发同类矿石提供借鉴.

1 矿石性质

1.1 矿石多元素及物相分析

该矿主要有价组分是铁、铜、硫,主要元素铁、铜、硫均以独立矿物存在,原矿含铁、铜品位较高,有较大回收价值,主要金属矿物为磁铁矿,黄铜矿和黄铁矿,次为磁赤铁矿、褐铁矿、赤铁矿、菱铁矿以及微量的闪锌矿和方铅矿等金属矿物.非金属矿物主要为石英,次为磷灰石、黑云母、碳酸盐矿物、斜长石、普通角闪石及少量的白云母、绿泥石和绢云母.

表 1 原矿多元素分析结果/%元素 Cu S Pb Zn Fe P SiO2 Al2O3 CaO MgO Au* Ag* 含量 0.52 2.31 0.02 0.03 49.26 0.90 8.12 1.39 0.54 0.53 0.21 4.78 注:标有*的单位为g/t. 表 2 铜物相分析结果/%相别 原生硫化铜 次生硫化铜 自由氧化铜 结合氧化铜 总铜 含量 0.274 0.142 0.051 0.047 0.514 占有率 53.31 27.63 9.92 9.14 100.00 1.2 矿物单体解离度分析

黄铜矿单体解离分析,如表 3所示.

表 3 黄铜矿单体解离分析结果/%粒级/mm 产率 单体 连生体 1/4 2/4 3/4 0.45~2 63.45 46.51 27.9 18.6 6.98 0.125~0.45 20.68 84.1 2.7 4.31 8.89 0.076~0.125 4.35 85.4 1.86 2.88 3.71 0.045~0.076 5.68 94.94 1.22 1.83 1.37 < 0.045 5.84 97.61 0.1 1.36 0.87 合计 100.00 60.75 18.95 13.31 6.57 通过在显微镜下分析发现,在黄铜矿单体解离度总样为60.75 %的情况下,≥0.45 mm粒度级单体解离较差仅为46.51 %.但≥0.076 mm粒级达到85.40 %,<0.045 mm仍未达到完全解离.但总体上来看,黄铜矿解离甚好.

2 试验矿样及方案的确定

2.1 试验矿样

根据原矿物质组成研究和试验的需要,将大块原矿分别经破碎、筛分到<2 mm,最后通过环锥法堆4次混匀,缩分取样装袋,以下所述“原矿”均为<2 mm选矿试验样.

2.2 试验方案的确定

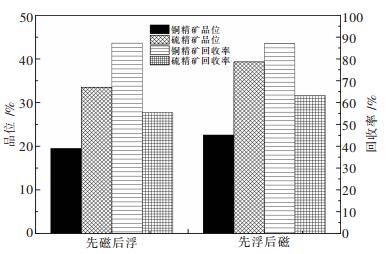

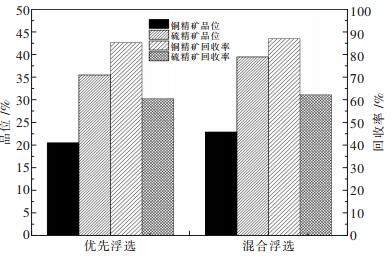

对于含铁铜硫矿石,常用的原则流程有“先磁后浮”和“先浮后磁”2种[4].采用“先磁后浮”原则流程,则在浮选之前需对磁选尾矿进行浓缩,增加了成本,而且采用“先磁后浮”获得的磁选铁精矿的含硫量相对“先浮后磁”较高,在本研究探索试验亦得到印证.因此,铜硫铁矿石矿一般采用“先浮后磁”原则流程进行选矿[5-6].对于硫化铜矿物,目前常用的工艺流程有:优先浮选、混合浮选、等可浮、部分优先、部分混合浮选等[7-9].

针对矿石特点,对该矿石进行了大量的探索试验,试验结果如图 1、图 2所示.

根据上述试验结果,最终确定采用“先浮后磁”原则流程,对铜硫矿物进行混合浮选,浮选尾矿进行磁选回收铁.

3 结果与分析

3.1 磨矿细度对铜硫混浮指标的影响试验

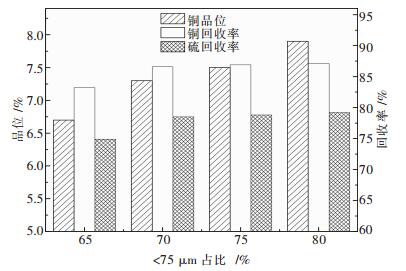

欲达到较好的选别指标,合适的磨矿细度是关键,磨矿过细容易造成过粉碎,影响有用矿物的回收,太粗则有用矿物单体解离不够[10-12].以碳酸钠调整矿浆pH,丁基黄药+Mac(30+30)g/t为捕收剂,改变磨矿细度,进行铜硫混浮粗选磨矿细度试验,试验结果见图 3.

由图 3可知,随着磨矿细度的增加,铜硫混合粗精矿中铜品位、铜回收率、硫回收率均逐渐升高,当磨矿细度增加至<75 μm占70 %时,铜硫混合粗精矿中铜品位、铜回收率、硫回收率已基本趋于最大值,此后,增加趋势很小,故为了节约磨矿成本,磨矿细度定为<75 μm占70 %.

3.2 捕收剂种类对铜硫混浮指标的影响试验

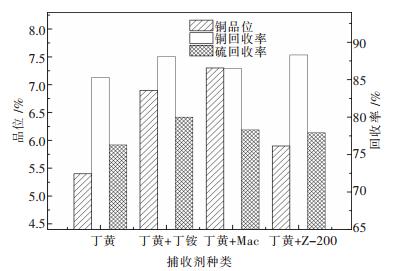

对于铜硫混合浮选,选用捕收能力强的捕收剂至关重要,试验对丁基黄药、丁基黄药+丁铵黑药、丁基黄药+Mac、丁基黄药+Z-200#等若干组捕收剂对矿石铜硫混合浮选粗选的影响进行了考查,其中磨矿细度为<75 μm占70 %,捕收剂固定用量为60 g/t、组合药剂配比为1:1,试验结果见图 4.

由图 4可知,单独使用丁基黄药为捕收剂时,混合粗精矿中铜品位、铜回收率及硫回收率均最低,选别指标最差;使用丁基黄药+Z-200#组合捕收剂时,混合粗精矿中铜回收率最高,但回收硫效果不理想;使用丁基黄药+Mac组合捕收剂时,铜品位最高;以丁基黄药+丁铵黑药为捕收剂时,硫回收指标最高,且铜品位及回收率较好,因此,选用丁基黄药+丁铵黑药为铜硫混浮粗选时的捕收剂.

3.3 捕收剂用量对铜硫混浮指标的影响试验

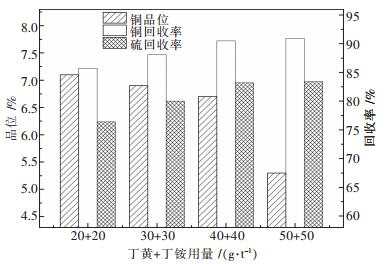

在确定丁基黄药+丁铵黑药为铜硫混合浮选粗选捕收剂基础上,以<75 μm占70 %为磨矿细度,丁基黄药+丁铵黑药为捕收剂,考查了不同用量捕收剂对铜硫混浮指标的影响,试验结果见图 5.

由图 5可知,随着组合捕收剂用量的增加,混合粗精矿中铜品位逐渐降低,而铜回收率及硫回收率均逐渐升高,综合考虑铜品位以及铜硫回收率,选用(40+40)g/t为丁基黄药+丁铵黑药的用量.

3.4 再磨细度对铜硫分离指标的影响试验

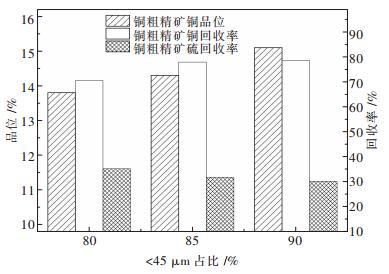

探索试验表明,由于粒度过粗,铜、硫矿物未得到充分解离,当铜硫混合粗精矿直接加抑制剂进行分离时,铜硫互含严重,分离效果不佳,因此考虑进行铜硫混合粗精矿再磨,并考查磨矿细度对分离指标的影响.固定铜硫混浮粗选各条件:铜硫粗选磨矿细度为<75 μm占70 %,丁基黄药+丁铵黑药为(40+40)g/t,铜硫分离抑制剂选用石灰5 000 g/t,改变铜硫混合粗精矿的磨矿细度,试验结果见图 6.

由图 6可知,随着磨矿细度的增加,铜粗精矿中铜品位及铜回收率均逐渐升高,且铜粗精矿中含硫量逐渐减少,但磨矿细度超过<45 μm占85 %后,指标已基本稳定.考虑节约磨矿成本,因此铜硫混合粗精矿再磨细度定为<45 μm占85 %.

3.5 抑制剂种类对铜硫分离指标的影响试验

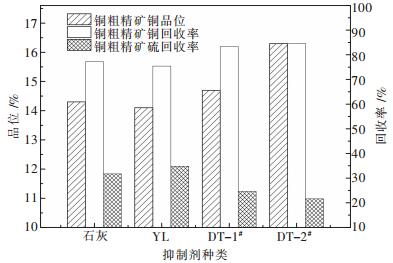

选用合适的黄铁矿抑制剂可有效改善铜硫分离效果,以获得合格的铜、硫精矿.在探索试验及有关文献资料[13-15]的基础上,主要考查石灰、YL、DT-1#及DT-2#等4种黄铁矿抑制剂对铜硫分离的效果.固定铜硫粗选磨矿细度为<75 μm占70 %,丁基黄药+丁铵黑药为(40+40)g/t,铜硫混合粗精矿再磨细度为<45 μm占85 %,固定抑制剂用量为5 000 g/t,改变抑制剂种类,试验结果见图 7.

由图 7可知,4种抑制剂中,DT-1#及DT-2#效果较好,而以新型高效无机抑制剂DT-2#(次氯酸钙为有效成分)为铜硫分离抑制剂时,选别指标最佳,此时铜粗精矿中铜品位及铜回收率最高,且铜精矿中含硫最少.因此,选用新型高效无机抑制剂DT-2#(次氯酸钙为有效成分)为铜硫分离时黄铁矿的抑制剂.

3.6 新型无机抑制剂DT-2#的用量对铜硫分离指标的影响试验

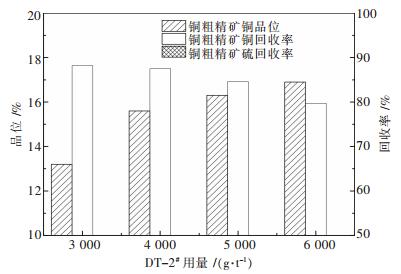

试验固定铜硫粗选磨矿细度为<75 μm占70 %,丁基黄药+丁铵黑药为(40+40)g/t,铜硫混合粗精矿再磨细度为<45 μm占85 %,固定抑制剂为DT-2#,改变DT-2#用量,试验结果见图 8.

由图 8可知,随着DT-2#用量的增加,铜粗精矿铜品位逐渐升高,铜回收率及铜粗精矿中含硫量逐渐减少,综合考虑各项指标,DT-2#用量定为4 000 g/t.此时,铜粗精矿铜品位为15.60 %,铜回收率为87.50 %,铜粗精矿中含硫为25.40 %的技术指标.

3.7 浮选闭路试验

在条件试验及开路试验的基础上,进行了实验室闭路试验.试验流程见图 9,试验结果见表 4.

表 4 闭路试验结果/%产品名称 产率 品位 回收率 Cu S Cu S 铜精矿 2.03 22.36 23.21 87.29 20.40 硫精矿 3.78 0.48 38.43 3.49 62.88 尾矿 94.19 0.05 0.41 9.22 16.72 原矿 100.00 0.52 2.31 100.00 100.00 由表 4可知,在原矿含铜0.52 %、硫2.31 %的情况下,采用磨矿细度<75 μm占70 %、碳酸钠为pH调整剂、丁基黄药+丁铵黑药为组合捕收剂混合浮选铜硫,铜硫粗精矿再磨至<45 μm占85 %后,以DT-2#为抑制剂进行铜硫分离的“铜硫混浮-精矿再磨-铜硫分离”的工艺流程,可获得含铜22.36 %、回收率为87.29 %的铜精矿,含硫38.43 %、回收率为62.88 %的硫精矿.

3.8 尾矿磁选试验

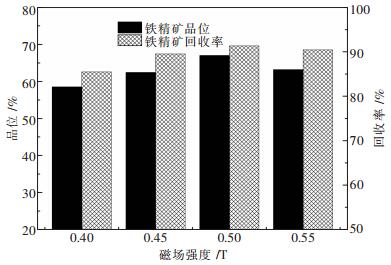

通过对浮选尾矿进行磁选条件探索试验,试验结果如图 10所示.

从图 10可以看出,上SLon高梯度强磁选时,当磁场强度为0.5 T,对铜硫浮选尾矿采用一粗一扫的磁选流程回收磁铁矿,可以获得含铁66.98 %,回收率为91.34 %的铁精矿,选铁指标较好.

4 结束语

1) 本试验矿样主要金属矿物有磁铁矿,黄铜矿和黄铁矿,其次为磁赤铁矿、褐铁矿、赤铁矿、菱铁矿.非金属矿物有石英,其次为磷灰石、黑云母、碳酸盐矿物、斜长石、普通角闪石及少量的白云母、绿泥石和绢云母.

2) 本试验以“浮选-磁选”为原则流程,采用“铜硫混浮-粗精矿再磨-铜硫分离-浮选尾矿磁选”的工艺流程,在磨矿细度为<74 μm占70 %条件下,以碳酸钠为pH调整剂,丁基黄药+丁铵黑药为组合捕收剂,进行铜硫混合浮选,铜硫粗精矿再磨至细度为<45 μm占85 %,以新型高效无机抑制剂DT-2#(次氯酸钙为有效成分)为黄铁矿抑制剂进行铜硫分离,浮选尾矿采用一粗一扫流程磁选回收磁铁矿.在原矿含铜0.52 %、硫2.31 %、铁49.26 %的情况下,最终可获得含铜22.36 %、回收率为87.29 %的铜精矿,含硫38.43 %、回收率为62.88 %的硫精矿,含铁66.98 %,回收率为91.34 %的铁精矿

3) 本试验采用自制研发的新型高效无机抑制剂DT-2#(次氯酸钙为有效成分)代替传统的高碱石灰抑制剂,在低碱调条件下成功实现铜硫分离,大大减少了抑制剂的用量,较大地节约了选矿成本,给矿山企业创造了良好的经济效益.

-

表 1 原矿多元素分析结果/%

元素 Cu S Pb Zn Fe P SiO2 Al2O3 CaO MgO Au* Ag* 含量 0.52 2.31 0.02 0.03 49.26 0.90 8.12 1.39 0.54 0.53 0.21 4.78 注:标有*的单位为g/t. 表 2 铜物相分析结果/%

相别 原生硫化铜 次生硫化铜 自由氧化铜 结合氧化铜 总铜 含量 0.274 0.142 0.051 0.047 0.514 占有率 53.31 27.63 9.92 9.14 100.00 表 3 黄铜矿单体解离分析结果/%

粒级/mm 产率 单体 连生体 1/4 2/4 3/4 0.45~2 63.45 46.51 27.9 18.6 6.98 0.125~0.45 20.68 84.1 2.7 4.31 8.89 0.076~0.125 4.35 85.4 1.86 2.88 3.71 0.045~0.076 5.68 94.94 1.22 1.83 1.37 < 0.045 5.84 97.61 0.1 1.36 0.87 合计 100.00 60.75 18.95 13.31 6.57 表 4 闭路试验结果/%

产品名称 产率 品位 回收率 Cu S Cu S 铜精矿 2.03 22.36 23.21 87.29 20.40 硫精矿 3.78 0.48 38.43 3.49 62.88 尾矿 94.19 0.05 0.41 9.22 16.72 原矿 100.00 0.52 2.31 100.00 100.00 -

[1] 温子龙, 林海, 董颖博, 等.西宁某低品位铜矿选矿试验研究[J].有色金属(选矿部分), 2013(1):12-16. http://www.cnki.com.cn/Article/CJFDTOTAL-YSXK201301002.htm [2] 胡海祥, 李广, 刘俊, 等.某铜硫铁复杂多金属矿分选新工艺试验研究[J].矿山机械, 2012, 40(9):87-91. http://www.cnki.com.cn/Article/CJFDTOTAL-KSJX201209028.htm [3] 叶雪均, 熊立.安徽某铁尾矿中铜硫的选矿回收研究[J].金属矿山, 2012(7):155-157. http://www.cnki.com.cn/Article/CJFDTOTAL-JSKS201207043.htm [4] 王立刚, 陈金中.澳大利亚Cairn Hill磁铁矿选矿试验研究[J].有色金属(选矿部分), 2008(3):20-24. http://www.cnki.com.cn/Article/CJFDTOTAL-YSXK200803006.htm [5] 李俊宁, 肖春莲.某铁硫铜复杂多金属矿选矿工艺研究[J].金属矿山, 2008(12):58-63. http://www.cnki.com.cn/Article/CJFDTOTAL-JSKS200812019.htm [6] 普仓凤.铜铁共采矿石选矿工艺流程试验研究[J].云南冶金, 2008, 37(4):21-22. http://www.cnki.com.cn/Article/CJFDTOTAL-YNYJ200804007.htm [7] 朱继生.冬瓜山铜矿选矿技术攻关[J].中国钼业, 2006, 30(5):24-27. http://www.cnki.com.cn/Article/CJFDTOTAL-ZGMY200605009.htm [8] 阮华东, 彭屹.武山铜矿提高选矿指标实践[J].矿业快报, 2004(7):32-34. http://www.cnki.com.cn/Article/CJFDTOTAL-KYKB200407018.htm [9] 吴熙群, 李世伦, 谢珉.西藏玉龙铜矿硫化矿选矿工艺流程的研究[J].矿冶, 2000, 9(4):32-37. http://www.cnki.com.cn/Article/CJFDTOTAL-KYZZ200004007.htm [10] 胡熙庚.有色金属硫化矿选矿[M].北京:冶金工业出版社, 1987. [11] 钱鑫, 张文彬, 邓彤, 等.铜的选矿[M].北京:冶金工业出版社, 1978. [12] 胡为柏.浮选[M].北京:冶金工业出版社, 1983. [13] 王勇, 叶雪均, 艾光华.某铜银多金属矿石低碱度铜硫浮选分离试验[J].金属矿山, 2010(6):105-108. http://www.cnki.com.cn/Article/CJFDTOTAL-JSKS201006031.htm [14] 汤玉和, 汪泰.铜硫浮选分离药剂的研究现状[J].材料研究与应用, 2012, 6(2):100-102. http://www.cnki.com.cn/Article/CJFDTOTAL-GDYS201202007.htm [15] 李崇德, 孙传尧.铜硫浮选分离的进展[J].国外金属矿选矿, 2000(8):2-7.

下载:

下载: