Sulphuric acid leaching of Yulong oxide copper ore based on orthogonal design test

-

摘要: 为了提高西藏玉龙铜矿铜氧化矿的酸浸效率,采用正交设计法优化了酸浸过程中的各项参数,以期提高铜浸出效率,为中试及工程化生产提供理论依据.首先研究了氧化铜矿硫酸浸出的单因素最佳区间,然后针对温度、初始酸浓度、浸出时间、液固比和磨矿细度等多因素进行了正交优化.结果表明:这些因素对浸出过程均有影响,其中温度影响最大.通过参数优化,最终确定搅拌浸出最优工艺条件为:温度30 ℃、初始酸浓度100 g/L、浸矿时间2 h、液固比(指质量比)2:1、磨矿细度为粒径≤74 μm的物粒占65 %.此时,铜氧化矿中铜浸出率可以达到79.45 %.Abstract: In order to improve the sulphuric acid leaching rate of Yulong oxide copper ore orthogonal experimental design is applied to optimize the parameters of the acid leaching process, which can increase the copper leaching efficiency and provide the theory basis for industrialized production. Single factor optimum interval of oxide copper ore sulphuric acid leaching is firstly analyzed and then orthogonal optimization are conducted with factors of temperature, initial acidity, leaching time, liquid-solid ratio and grinding fineness being considered. It is shown that the temperature, initial acidity, leaching time, liquid-solid ratio and grinding fineness have contributions to the copper leaching efficiency, and temperature has greatest effects on the leaching rate. When the temperature is 30 ℃, the initial acidity is 100 g/L, the leaching time is 2 h, the liquid-solid ratio is 2:1 and grinding fineness of the particle size≤74 μm with mineral powder accounting for 65 %, copper leaching efficiency can be as high as 79.45 %.

-

Keywords:

- oxide copper ore /

- orthogonal design /

- sulphuric acid leaching /

- leaching rate

-

0 引言

西藏玉龙铜矿[1]位于西藏昌都地区江达县青泥洞乡境内,其铜资源储量650万t,远景储量达1 000万t,为我国第二大铜矿,是世界60个特大型铜矿之一.矿床分氧化铜矿带、次生铜矿带和原生铜矿带3个矿体[2],其中上部氧化铜矿带铜储量27.4万t,下部硫化铜矿带铜储量380万t.由于上部氧化矿特殊的矿石性质(氧化程度高,含泥含水量大,泥质为黏土矿物)和矿山恶劣的周边环境(高寒、高海拔、缺氧、多雨雪),再加上矿区交通不便,配套基础设施缺乏,使得该矿一直未能得到大规模的开发利用.开发玉龙铜矿不仅可促进西藏地区的经济发展,而且对整个西部高海拔、高寒地区铜资源的开发有重要的借鉴意义.

玉龙铜矿属斑岩型和矽卡岩型复合矿体,铜资源储量丰富,故开展铜矿分离试验研究具有重大生产价值.玉龙氧化铜矿中的铜以氧化铜,原生硫化铜,次生硫化铜等多种形式存在,且氧化铜占多数,可采用酸浸回收矿石中的铜.根据蔡谬璐等[3]的研究,玉龙氧化铜矿中铜的存在形式以孔雀石和蓝铜矿所含自由氧化铜为主,其含量占总铜的56.2l %;其次为黄铜矿、赤铜铁矿和自然铜所含原生硫化铜,其含量占总铜的19.53 %;然后是辉铜矿和铜蓝等所含次生硫化铜,其含量占总铜的14.20 %;硅酸盐中所含包裹铜含量最少,其含量占总铜的l0.06 %.此外玉龙地处高寒高海拔地区,矿石氧化风化严重,含泥高[4](粒径≤74 μm的物粒占25 %),直接进行堆浸溶液渗透性极差,不适合采用单一的全堆浸工艺[5].因此适于采用硫酸搅拌浸出工艺处理这部分铜矿资源.

在常温常压的条件下,氧化矿中的孔雀石和蓝铜矿在硫酸的作用下可有效浸出铜:

$$ {\rm{C}}{{\rm{u}}_{\rm{2}}}{\rm{C}}{{\rm{O}}_{\rm{3}}}{({\rm{OH}})_2}{\rm{ + 2}}{{\rm{H}}_{\rm{2}}}{\rm{S}}{{\rm{O}}_{\rm{4}}} \to 2{\rm{C}}{{\rm{u}}_{\rm{2}}}{\rm{S}}{{\rm{O}}_{\rm{4}}} + {\rm{C}}{{\rm{O}}_2} + 3{{\rm{H}}_{\rm{2}}}{\rm{O}} $$ (1) $$ {\rm{C}}{{\rm{u}}_{\rm{3}}}{{\rm{(C}}{{\rm{O}}_{\rm{3}}})_2}{({\rm{OH}})_2}{\rm{ + 3}}{{\rm{H}}_{\rm{2}}}{\rm{S}}{{\rm{O}}_{\rm{4}}} \to 3{\rm{CuS}}{{\rm{O}}_{\rm{4}}} + 2{\rm{C}}{{\rm{O}}_2} + 4{{\rm{H}}_{\rm{2}}}{\rm{O}} $$ (2) 从反应式(1)、式(2)来看,孔雀石和蓝铜矿在浸出反应过程中的产物都是硫酸铜,同时放出二氧化碳气体.从物理化学的角度看,上述反应速度很快.只要溶液的pH值满足反应需要,铜的浸出就会进行下去.

本实验采用硫酸作为浸提剂,搅拌浸出在3 L的玻璃搅拌反应器中进行.通过正交设计法优化硫酸浸出的最佳参数,以期为工业生产提供理论依据.

1 矿石性质分析

本实验所用矿石样品来自于西藏玉龙铜矿Ⅱ号矿体某采矿浅井,样品充分混匀后,分成5袋,每袋40 kg,其中一袋用作湿法搅拌浸出试验,另4袋,用作浮选试验.采用XRD[6-7]及化学方法对矿石成分及含量进行了分析.矿石中的矿物组成及相对含量分析结果见表 1,化学元素分析结果见表 2,铜物相分析结果见表 3.

表 1 西藏玉龙铜矿Ⅱ号矿体矿石中的矿物组成及相对含量/%矿物组成 相含量 孔雀石 4.36 蓝铜矿 2.38 辉铜矿 0.38 斑铜矿 0.01 铜兰 0.09 黄铜矿 1.77 铜 0.01 黄铁矿 2.71 褐铁矿 47.16 黏土矿物 25.32 长石 5.68 绢云母/白云母 2.09 方解石/白云石 2.43 石英 5.63 表 2 西藏玉龙铜矿Ⅱ号矿体氧化矿原矿化学多元素分析结果/%元素名称 含量 Cu 4.85 Fe 31.51 S 2.05 Ca 1.36 Mg 0.26 Au/(g·t-1) 0.05 Ag/(g·t-1) 15.90 Zn 0.37 Pb 0.095 Al2O3 11.88 SiO2 17.50 Mo 0.002 6 N1 0.021 Co 0.027 F 0.05 表 3 西藏玉龙铜矿Ⅱ号矿体氧化矿原矿铜物相分析结果/%项目 氧化铜 原生硫化铜 次生硫化铜矿 硅酸盐中铜 总量 含量 3.814 0.612 0.365 0.059 4.85 占有率 78.65 12.62 7.52 1.21 100 由表 1知,该矿石为含铜和铁的氧化矿石,其中氧化矿物主要有褐铁矿、孔雀石、蓝铜矿等.金属矿物有黄铁矿、黄铜矿、辉铜矿、斑铜矿等.脉石矿物主要为黏土矿物和长石,含少量绢云母/白云母、石英和碳酸盐岩.由表 2知,矿样中的有益元素为铜,含量为4.85 %,品位较高.由表 1和表 3知主要铜矿物为孔雀石和蓝铜矿类型氧化铜,氧化铜占总铜的78.65 %,其次为辉铜矿等次生硫化铜矿物和黄铜矿,极少量以自然铜形式存在.该矿石整体属于较易浸取矿石.

2 硫酸搅拌浸出单因素试验及结果分析

该矿石样品含泥量高,同时铁、硫品位较高.针对该矿石的特点,主要考察了液固比、温度、磨矿细度、浸出时间和搅拌强度对铜浸出率的影响.该矿石的硫酸搅拌浸出在3 L玻璃搅拌反应器中进行,采用恒温水浴锅控制其温度.

2.1 不同液固比对铜浸出的影响

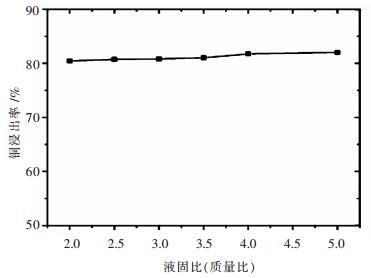

取粒径≤74 μm的物粒占82 %的矿样,在初始硫酸浓度为140 g/L,搅拌速度400 r/min的条件下,30 ℃恒温水浴浸出3 h.分别测定液固比(指质量比,下同)为2:1,2.5:1,3:1,3.5:1,4:1,5:1条件下铜的浸出率,并确定最合适的液固质量比.试验结果如图 1所示.

在硫酸搅拌浸出过程中,随着液固比的提高,铜的浸出率也随之升高,但是升高的幅度不大.这一结果说明,提高液固比对提高铜浸出率作用有限.因此,浸出过程中采用较大液固比是相对更为经济的选择.

2.2 不同浸出时间对铜浸出率的影响

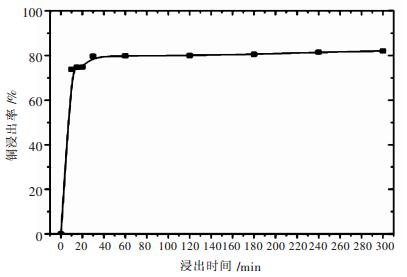

在上述优化条件下,分别取等量粒径≤74 μm的物粒占82 %的矿样5份,在初始酸浓度为140 g/L,液固比为2:1,搅拌速度400 r/min,恒温水浴浸出温度为30 ℃时,测定不同浸出时间下铜的浸出率.试验结果如图 2所示.

在硫酸浸出过程中,浸出时间在0~0.5 h范围内对铜的浸出率影响较大,期间铜浸出率快速提高,但是在0.5~5 h范围内则对铜的浸出率影响不大,铜的浸出率趋于平缓,基本保持在80 %~82 %之间.因此,继续延长浸出时间也不是有效提高铜浸出率的途径,但是考虑到运行的稳定性和可操作性,浸出时间控制在1~3 h范围内更为合理.

2.3 不同初始酸浓度对铜浸出率的影响

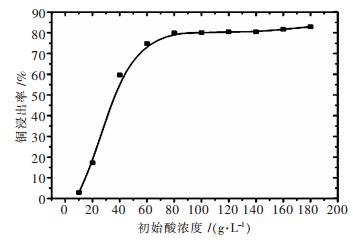

在上述优化的条件下,分别取等量粒径≤74 μm的物粒占82 %的矿样5份,在液固比为2:1,搅拌速度400 r/min,恒温水浴浸出温度为30 ℃,浸出时间3 h时,分别测定初始酸浓度为20 g/L,40 g/L,60 g/L,80 g/L,100 g/L,120 g/L条件下铜的浸出率[8].试验结果如图 3所示.

酸浸过程中初始酸浓度对铜浸出率的影响较大[9],由图 3可知,初始酸浓度在10~80 g/L之间时,铜浸出率升幅较大,在初始酸浓度大于80 g/L后铜浸出率升幅缓慢.当初始酸浓度高于80 g/L后,铜浸出率可达到79 %以上,但很难再提高.为保持较稳定的铜浸出率,初始酸浓度选择100 g/L,即200 kg/t矿较为合理.

2.4 不同磨矿细度对铜浸出率的影响

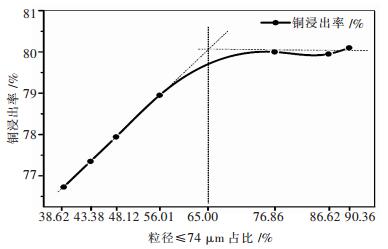

在上述优化条件下,取初始酸浓度为140 g/L,液固比为2:1,浸出时间为3 h,恒温水浴浸出温度为30 ℃时,以≤74 μm的筛孔尺寸为标准,考察不同磨矿细度下矿样的浸出率[10].试验如图 4所示.

随着磨矿细度的增大,铜浸出率升高.而当磨矿细度达到粒径≤74 μm的物粒占75 %以上时,铜浸出率略微降低.因此磨矿细度维持在粒径≤74 μm的物粒占65 %左右即可得到较好的铜浸出效果[11].

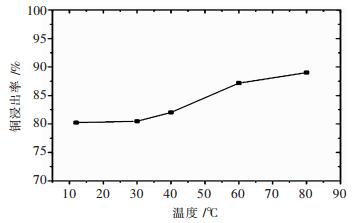

2.5 不同浸出温度对铜浸出率的影响

在上述优化条件下,取初始酸浓度为140 g/L,液固比为2:1,浸出时间为3 h,将恒温水浴浸出温度30 ℃分别换成“12 ℃,30 ℃,40 ℃,60 ℃,80 ℃”,测定不同浸出温度下铜的浸出率[12],以确定最佳的浸出温度.试验结果如图 5所示.

在硫酸搅拌浸出过程中,随着温度的升高,铜的浸出率有了较明显的提升.80 ℃的高温下浸出效果较好,铜浸出率可达89.01 %,比30 ℃时浸出率提高了约10 %.而12 ℃下铜浸出率与内地常温30 ℃时相差不大,说明氧化铜矿物的浸出对温度依赖性较小.而温度提高则有利于硫化矿物中铜的溶出.

2.6 不同搅拌强度对铜浸出率的影响

在上述优化条件下,取初始酸浓度为140 g/L,液固比为2:1,浸出时间为3 h,恒温水浴浸出温度为30 ℃,将搅拌转速分别设定为180 r/min,260 r/min,320 r/min,400 r/min,测定不同操作参数下铜的浸出率,以确定最佳的搅拌强度[13].试验结果如表 4所示.

表 4 不同搅拌速度试验结果搅拌速度/(r·min-1) 渣率/% 渣中铜品位/% 铜浸出率/% 180 88.16 1.13 79.46 260 87.14 1.12 79.88 320 87.11 1.11 80.07 400 86.12 1.10 80.48 搅拌强度对铜浸出率的影响较小.在搅拌速度从180 r/min升高到400 r/min,铜浸出率之间仍能保持在80 %左右,两者差值小于1 %.

3 硫酸搅拌浸出正交试验及结果分析

为了检测上述条件试验结果是否在交互条件下仍然保持一致,在单因子硫酸搅拌浸出试验的基础上进行了正交试验[14-16].选取了L16(54)作为正交试验设计.试验因素及水平编码表如表 5所示.

表 5 试验的因素及水平编码水平 A磨矿细度≤74 μm占比/% B液固比 C浸出时间/h D初始酸浓度/(g·L-1) E温度/℃ 1 54.16 1:1 0.5 80 15 2 64.95 2:1 1 160 30 3 73.17 3:1 2 240 45 4 83.11 4:1 3 320 60 表 6 正交试验设计及试验结果水平 A磨矿细度≤74 μm占比/% B液固比 C浸出时间/h D初始酸浓度/(g·L-1) E温度/℃ 铜浸出率/% 1 54.16 1:1 0.5 80 15 60.85 2 54.16 2:1 1 160 30 74.86 3 54.16 3:1 2 240 45 83.32 4 54.16 4:1 3 320 60 92.38 5 64.95 1:1 1 240 60 84.03 6 64.95 2:1 0.5 320 45 79.52 7 64.95 3:1 3 80 30 76.53 8 64.95 4:1 2 160 15 74.92 9 73.17 1:1 2 320 30 78.83 10 73.17 2:1 3 240 15 77.02 11 73.17 3:1 0.5 160 60 84.07 12 73.17 4:1 1 80 45 79.60 13 83.11 1:1 3 160 45 76.24 14 83.11 2:1 2 80 60 80.02 15 83.11 3:1 1 320 15 74.80 16 83.11 4:1 0.5 240 30 76.52 T1 77.852 74.987 75.240 74.250 71.898 T2 78.750 77.855 78.322 77.522 76.685 T3 79.880 79.680 79.272 80.222 79.670 T4 76.895 80.855 80.543 81.382 85.125 S 2.985 5.868 5.303 7.132 13.227 表 7 正交实验方差分析表因素 偏差平方和 自由度 F比 I临界值 显著性 磨矿细度 19.461 3 1.000 9.280 不明显 液固比 78.381 3 4.028 9.280 不明显 浸出时间 61.323 3 3.151 9.28 不明显 初始酸度 120.788 3 6.207 9.280 不明显 温度 368.200 3 18.92 9.280 明显 表 6中,T1、T2、T3、T4分别指的是相应因素下各个水平的均值,S指的是各因素的方差.均值反映了各个水平对结果的影响程度,方差反映了综合水平结果后各因素对试验结果的影响程度.通过表 6的因素比较,其影响大小顺序为E>D>B>C>A,即温度>初始酸浓度>液固比>浸出时间>磨矿细度.温度是影响铜浸出率的最为显著的因素,而相对来说,初始酸浓度、液固比、浸出时间和磨矿细度对铜浸出率的影响由于其F比值均低于F临界值,因此表现为不显著.

提高铜的浸出率[17]可以通过提高温度来实现,但是提高温度会给将来的生产工作带来较多的问题.如:①影响工艺过程和产品质量.矿石中的杂质元素溶解量加大,酸耗增加,杂质循环累积影响后续固液分离及萃取、电积效率和阴极铜产品质量;②设备材质要求更高,投资增大,高原环境下整个矿浆和溶液系统加热,设备防腐问题更难解决;③能耗加大,生产成本增加.高寒环境下加热所需能耗大大增加;④安全环保问题凸现.加热环境下,酸的挥发量加大,酸耗增加,恶化操作环境.

4 硫酸搅拌浸出优化试验及结果分析

4.1 优化实验

根据正交试验结果,选择60 ℃和30 ℃ 2个温度进行了初始酸浓度补充试验,浸出时间2 h,磨矿细度为粒径≤74 μm的物粒占65 %,液固比2:1.结果见表 8和表 9.

表 8 温度为60 ℃时不同初始酸浓度的铜浸出率结果初始酸浓度/(g·L-1) 渣中铜品位/% 铜浸出率/% 最终pH 耗酸量/(kg·t-1) 70 1.15 78.34 1.65 135.61 80 0.98 81.71 1.47 153.36 100 0.92 83.15 1.21 187.91 120 0.88 84.72 0.89 227.38 160 0.78 86.86 0.76 302.97 200 0.76 87.79 0.66 378.56 240 0.65 89.61 0.63 457.03 260 0.67 89.32 0.35 516.23 320 0.69 89.08 0.34 595.21 表 9 温度为30 ℃时不同初始酸浓度的铜浸出率结果初始酸浓度/(g·L-1) 渣中铜品位/% 铜浸出率/% 最终pH 耗酸量/(kg·t-1) 70 1.16 77.84 1.29 134.97 80 1.08 79.44 1.09 152.03 100 1.08 79.45 0.88 187.08 120 1.07 79.89 0.60 215.38 160 1.06 80.28 0.38 279.15 200 1.04 80.64 0.26 346.14 240 1.05 80.76 0.18 415.25 260 1.05 80.97 0.15 490.62 320 1.03 81.59 0.09 560.34 由表 8和表 9可知,60 ℃和30 ℃ 2个温度下,即使初始酸浓度相同,酸耗却有较大差别,且铜浸出率也有了相应的变化.在同样的初始酸浓度下,60 ℃比30 ℃的铜浸出率高出7 %到10 %,60 ℃下的实际酸耗则比30 ℃下高出5 %左右.通过优化试验的结果分析,最终确定初始酸浓度需要达到100 g/L,即200 kg/t矿可以使铜浸出率在79 %以上.

4.2 浸渣物相分析与典型浸出液成分分析

对西藏玉龙铜矿不同浸取条件下挑选了2种具有代表性的浸渣,进行了铜物相分析.

浸渣1的试验条件为:反应温度30 ℃、初始酸浓度80 g/L、液固比2:1、反应时间3 h,磨矿细度为粒径≤74 μm的物粒占82 %,搅拌速度400 r/min.

浸渣2的试验条件为:反应温度80 ℃、初始酸浓度140 g/L、液固比2:1、反应时间3 h,磨矿细度为粒径≤74 μm的物粒占82 %,搅拌速度400 r/min.

浸渣1的铜物相分析见表 10,浸渣2的铜物相分析见表 11.

表 10 浸渣1铜物相分析结果/%项目名称 氧化铜 原生硫化铜 次生硫化铜 其它铜 量 含量 0.221 0.468 0.273 0.117 1.080 占有率 20.506 43.360 25.294 10.840 100 浸出率 94.77 30.96 32.48 / 79.90 注:“/”指未测定. 表 11 浸渣2铜物相分析结果/%项目名称 氧化铜 原生硫化铜 次生硫化铜 其它铜 总量 含量 0.038 0.374 0.108 0.110 0.630 有率 6.032 59.365 17.143 17.460 100 浸出率 99.17 49.11 75.36 / 89.18 注:“/”指未测定. 试验条件表明:浸渣1为常温浸出渣,浸渣2为高温浸出渣.表 10结果表明:矿石经常温酸浸即可将94.47 %氧化铜矿物中的铜浸出,说明氧化铜矿较易被浸出,而相比较而言,硫化铜矿无论是原生硫化铜矿还是次生硫化铜矿均在常温下较难浸出.表 11结果表明:矿石经高温酸浸,除了几乎将氧化铜矿物中的铜全部浸出外,次生硫化铜矿中也有75.36 %的铜被浸出,这说明在高温条件下硫化铜矿中的次生硫化铜矿可以逐渐被浸出,而原生硫化铜矿在高温的条件下依然较难浸出.

4.3 强化浸出试验

在常规酸浸之后,考虑到浸渣中仍然有品位约为1 %铜未被浸出,因此进行加高铁[18]两段强化浸出.一段浸:磨矿细度:粒径≤74 μm的物粒占82 %,液固比2:1,初始硫酸浓度为140 g/L,浸出时间3 h,温度30 ℃.二段浸:初始硫酸浓度80 g/L,液固比2:1,浸出时间1 h,搅拌速度:400 r/min,温度30 ℃.

添加高铁的分段强化浸出结果如表 12所示.

表 12 强化浸出实验结果温度/℃ [Fe3+] /(g·L-1) 一段浸渣铜品位/% 二段强化浸渣铜品位/% 一段浸出铜浸出率/% 段浸出浸出率/% 30 5.00 1.11 1.03 80.07 81.46 30 10.00 1.11 1.01 80.07 81.76 30 12.50 1.11 0.98 80.07 82.37 80 20.00 1.11 0.67 80.07 88.16 80 0.00 1.11 0.69 80.07 88.16 由表 12可知,分步加酸或添加高铁的分段强化浸出[19],在一定程度上可促进铜的溶解,但是效果并不显著,仅能在原浸出率的基础上提高1 %~2 %.而温度是影响浸出的关键因素,温度升高到80 ℃,铜浸出率达88 %以上.而且在80 ℃的反应条件下,添加高铁几乎没有起到提高铜浸出率的效果.

5 小结与讨论

1) 通过条件试验和正交试验可得,温度、初始酸浓度、浸出时间、液固比和磨矿细度均对浸出过程有影响,且温度影响最大.但考虑到玉龙铜矿环境因素,搅拌过程加温能耗较高,操作难度大,不作主要推荐.

2) 综合试验结果推荐搅拌浸出基本工艺参数为:温度30 ℃、初始酸浓度100 g/L、浸矿时间2 h、液固比2:1、当磨矿细度为粒径≤74 μm的物粒占65 %时,在该条件下,矿样的铜浸出率可以达到79.45 %.如现场有条件采用高温搅拌浸出,推荐工艺参数为:温度60 ℃、初始酸浓度120 g/L、浸矿时间2 h、液固比2:1、磨矿细度为粒径≤74 m的物粒占65 %.在该条件下,矿样的铜浸出率可以达到84.72 %.

3) 经对试验结果的分析表明,矿样中的氧化铜矿物在常温下比较容易浸出,铜的浸出率达到了93 %以上;而硫化铜矿物则较难浸出,常温条件下难以提高其浸出率,因此铜的综合浸出率只有80 %左右,与工艺矿物学理论分析铜的浸出率的结果一致.次生硫化矿物(铜兰)对温度较敏感,提高温度可有效促进其溶解,而原生铜矿物(黄铜矿)和自然铜则很难在不加温加压的稀硫酸介质下溶解.

4) 考虑到玉龙铜矿样品中硫化铜矿物浸出困难,需要进一步探索选冶联合工艺的可行性.

-

表 1 西藏玉龙铜矿Ⅱ号矿体矿石中的矿物组成及相对含量/%

矿物组成 相含量 孔雀石 4.36 蓝铜矿 2.38 辉铜矿 0.38 斑铜矿 0.01 铜兰 0.09 黄铜矿 1.77 铜 0.01 黄铁矿 2.71 褐铁矿 47.16 黏土矿物 25.32 长石 5.68 绢云母/白云母 2.09 方解石/白云石 2.43 石英 5.63 表 2 西藏玉龙铜矿Ⅱ号矿体氧化矿原矿化学多元素分析结果/%

元素名称 含量 Cu 4.85 Fe 31.51 S 2.05 Ca 1.36 Mg 0.26 Au/(g·t-1) 0.05 Ag/(g·t-1) 15.90 Zn 0.37 Pb 0.095 Al2O3 11.88 SiO2 17.50 Mo 0.002 6 N1 0.021 Co 0.027 F 0.05 表 3 西藏玉龙铜矿Ⅱ号矿体氧化矿原矿铜物相分析结果/%

项目 氧化铜 原生硫化铜 次生硫化铜矿 硅酸盐中铜 总量 含量 3.814 0.612 0.365 0.059 4.85 占有率 78.65 12.62 7.52 1.21 100 表 4 不同搅拌速度试验结果

搅拌速度/(r·min-1) 渣率/% 渣中铜品位/% 铜浸出率/% 180 88.16 1.13 79.46 260 87.14 1.12 79.88 320 87.11 1.11 80.07 400 86.12 1.10 80.48 表 5 试验的因素及水平编码

水平 A磨矿细度≤74 μm占比/% B液固比 C浸出时间/h D初始酸浓度/(g·L-1) E温度/℃ 1 54.16 1:1 0.5 80 15 2 64.95 2:1 1 160 30 3 73.17 3:1 2 240 45 4 83.11 4:1 3 320 60 表 6 正交试验设计及试验结果

水平 A磨矿细度≤74 μm占比/% B液固比 C浸出时间/h D初始酸浓度/(g·L-1) E温度/℃ 铜浸出率/% 1 54.16 1:1 0.5 80 15 60.85 2 54.16 2:1 1 160 30 74.86 3 54.16 3:1 2 240 45 83.32 4 54.16 4:1 3 320 60 92.38 5 64.95 1:1 1 240 60 84.03 6 64.95 2:1 0.5 320 45 79.52 7 64.95 3:1 3 80 30 76.53 8 64.95 4:1 2 160 15 74.92 9 73.17 1:1 2 320 30 78.83 10 73.17 2:1 3 240 15 77.02 11 73.17 3:1 0.5 160 60 84.07 12 73.17 4:1 1 80 45 79.60 13 83.11 1:1 3 160 45 76.24 14 83.11 2:1 2 80 60 80.02 15 83.11 3:1 1 320 15 74.80 16 83.11 4:1 0.5 240 30 76.52 T1 77.852 74.987 75.240 74.250 71.898 T2 78.750 77.855 78.322 77.522 76.685 T3 79.880 79.680 79.272 80.222 79.670 T4 76.895 80.855 80.543 81.382 85.125 S 2.985 5.868 5.303 7.132 13.227 表 7 正交实验方差分析表

因素 偏差平方和 自由度 F比 I临界值 显著性 磨矿细度 19.461 3 1.000 9.280 不明显 液固比 78.381 3 4.028 9.280 不明显 浸出时间 61.323 3 3.151 9.28 不明显 初始酸度 120.788 3 6.207 9.280 不明显 温度 368.200 3 18.92 9.280 明显 表 8 温度为60 ℃时不同初始酸浓度的铜浸出率结果

初始酸浓度/(g·L-1) 渣中铜品位/% 铜浸出率/% 最终pH 耗酸量/(kg·t-1) 70 1.15 78.34 1.65 135.61 80 0.98 81.71 1.47 153.36 100 0.92 83.15 1.21 187.91 120 0.88 84.72 0.89 227.38 160 0.78 86.86 0.76 302.97 200 0.76 87.79 0.66 378.56 240 0.65 89.61 0.63 457.03 260 0.67 89.32 0.35 516.23 320 0.69 89.08 0.34 595.21 表 9 温度为30 ℃时不同初始酸浓度的铜浸出率结果

初始酸浓度/(g·L-1) 渣中铜品位/% 铜浸出率/% 最终pH 耗酸量/(kg·t-1) 70 1.16 77.84 1.29 134.97 80 1.08 79.44 1.09 152.03 100 1.08 79.45 0.88 187.08 120 1.07 79.89 0.60 215.38 160 1.06 80.28 0.38 279.15 200 1.04 80.64 0.26 346.14 240 1.05 80.76 0.18 415.25 260 1.05 80.97 0.15 490.62 320 1.03 81.59 0.09 560.34 表 10 浸渣1铜物相分析结果/%

项目名称 氧化铜 原生硫化铜 次生硫化铜 其它铜 量 含量 0.221 0.468 0.273 0.117 1.080 占有率 20.506 43.360 25.294 10.840 100 浸出率 94.77 30.96 32.48 / 79.90 注:“/”指未测定. 表 11 浸渣2铜物相分析结果/%

项目名称 氧化铜 原生硫化铜 次生硫化铜 其它铜 总量 含量 0.038 0.374 0.108 0.110 0.630 有率 6.032 59.365 17.143 17.460 100 浸出率 99.17 49.11 75.36 / 89.18 注:“/”指未测定. 表 12 强化浸出实验结果

温度/℃ [Fe3+] /(g·L-1) 一段浸渣铜品位/% 二段强化浸渣铜品位/% 一段浸出铜浸出率/% 段浸出浸出率/% 30 5.00 1.11 1.03 80.07 81.46 30 10.00 1.11 1.01 80.07 81.76 30 12.50 1.11 0.98 80.07 82.37 80 20.00 1.11 0.67 80.07 88.16 80 0.00 1.11 0.69 80.07 88.16 -

[1] 巫銮东.西藏玉龙铜矿氧化矿资源综合回收试验研究[J].采矿技术, 2011, 11(1):94-96. http://www.cnki.com.cn/Article/CJFDTOTAL-SJCK201101043.htm [2] 于宏冬.西藏玉龙氧化铜矿工艺矿物学研究[J].有色金属, 2013, 1(1):1-6. http://www.cnki.com.cn/Article/CJFDTOTAL-YSXK201301000.htm [3] 蔡谬璐, 刘爽, 李文娟, 等.玉龙铜矿V号矿体氧化矿石工艺矿物学特[J].金属矿山, 2012, 436(10):86-89. http://www.cnki.com.cn/Article/CJFDTOTAL-JSKS201210025.htm [4] 华金仓.玉龙铜矿开发思路和提铜工艺探讨[J].中国矿山, 2007, 36(3):4-6. http://www.cnki.com.cn/Article/CJFDTOTAL-YSKS200703004.htm [5] 武彪, 谢昆, 张兴勋, 等.玉龙铜矿氧化矿石合理浸出工艺研究[J].金属矿山, 2010(12):54-57. http://www.cnki.com.cn/Article/CJFDTOTAL-JSKS201012016.htm [6] 张生辉, 周亚冲, 欧雪梅, 等, FTIR和XRD研究甲酰胺在高岭石插层复合体系中的形态及其复合物的微观结构[J].光谱学与光谱分析, 2013(11):2978-2981. http://www.cnki.com.cn/Article/CJFDTOTAL-GUAN201311026.htm [7] 王翠芝, 张文媛.紫金山金铜矿明矾石的红外光谱及XRD特征[J].光谱学与光谱分析, 2013, 33(7):2978-2981. http://www.cnki.com.cn/Article/CJFDTOTAL-GUAN201307057.htm [8] 喻正军, 冯其明, 欧乐明, 等.常压下硫酸体系中钴冰铜的浸出[J].中南大学学报(自然科学版), 2006, 37(4):54-57. http://www.cnki.com.cn/Article/CJFDTOTAL-ZNGD200604009.htm [9] 伍博克.云南元江红土镍矿加压酸浸研究[D].长沙:中南大学化学化工学院, 2010. [10] 张覃, 何发钰, 卯松, 等.胶磷矿和白云石的嵌布特征及磨矿细度试验[J].化工矿物与加工, 2010, 39(12):7-11. http://www.cnki.com.cn/Article/CJFDTOTAL-HGKJ201012004.htm [11] 印万忠, 侯英, 丁亚卓, 等.破碎方式对邦铺钼铜矿石可磨性及钼浮选的影响[J].金属矿山, 2013, 2(2):86-89. http://www.cnki.com.cn/Article/CJFDTOTAL-JSKS201302022.htm [12] 刘伟锋, 刘又年, 杨天足, 等.铜阳极泥碱性加压氧化浸出渣的硫酸浸出过程[J].中南大学学报(自然科学版), 2013, 44(6):2192-2198. http://www.cnki.com.cn/Article/CJFDTOTAL-ZNGD201306002.htm [13] 石慧娴, 荣凌, 朱红光, 等.搅拌强度对全混式沼气池加温过程及加温能耗的影响[J].可再生能源, 2011, 29(1):62-71. http://www.cnki.com.cn/Article/CJFDTOTAL-NCNY201101016.htm [14] 方开泰, 马长兴.正交与均匀试验设计[M].北京:科学出版社, 2001. [15] 倪恒, 刘佑荣, 龙治国.正交设计在滑坡敏感性分析中的应用[J].岩石力学与工程学报, 2002, 21(7):989-992. http://www.cnki.com.cn/Article/CJFDTOTAL-YSLX200207011.htm [16] 张科, 秦国义, 许思勇, 等.超音速电弧喷射雾化制备AgNiCu15-5粉末工艺参数的优化[J].稀有金属材料与工程, 2013, 42(9):1965-1968. http://www.cnki.com.cn/Article/CJFDTOTAL-COSE201309043.htm [17] Ping Z, ZeYun F, Jie L, et al.Enhancement of leaching copper by electro-oxidation from metal powders of waste printed circuit board[J].Journal of Hazardous Materials, 2009, 166(2):746-750. https://www.researchgate.net/publication/23806372_Enhancement_of_leaching_copper_by_electro-oxidation_from_metal_powders_of_waste_printed_circuit_board

[18] Hiroyoshi N, Miki H, Hirajima T, et al.Enhancement of chalcopyrite leaching by ferrous ions in acidic ferric sulfate solutions[J].Hydrometallurgy, 2001, 60(3):185-197. doi: 10.1016/S0304-386X(00)00155-9

[19] 王伟之, 韩苗苗.某氧化型金矿石氰化浸出试验[J].金属矿山, 2013(1):80-82. http://www.cnki.com.cn/Article/CJFDTOTAL-JSKS201301036.htm

下载:

下载: