Effects of solid solution and aging treatment on the microstructure and properties of elastic C17510 alloy

-

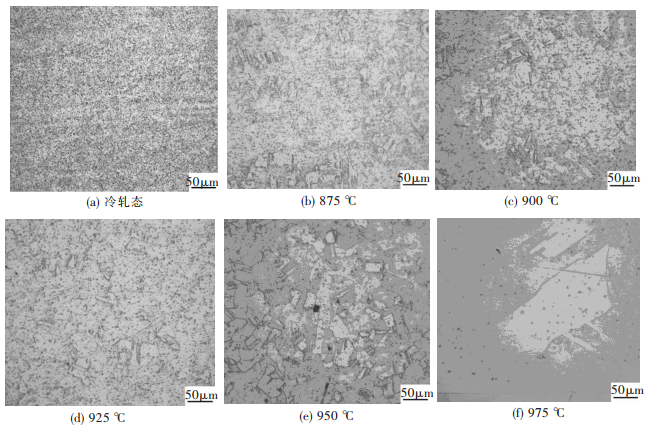

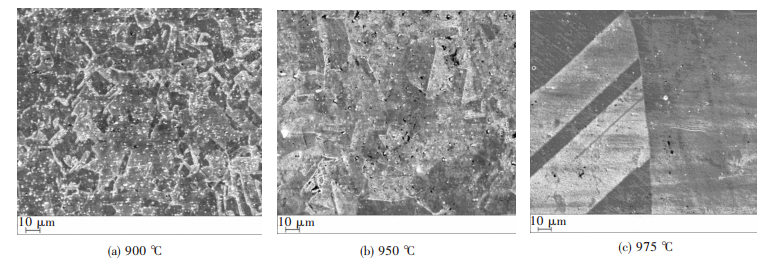

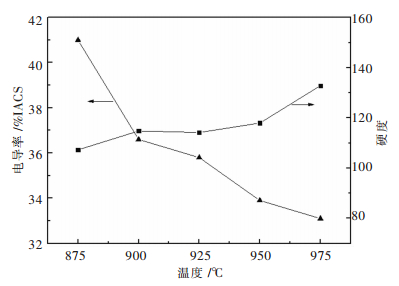

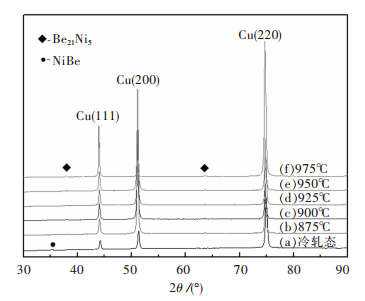

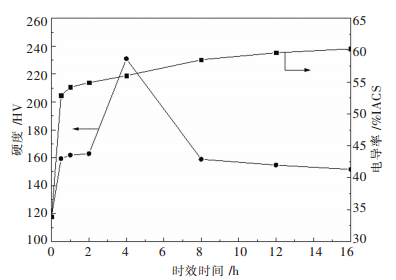

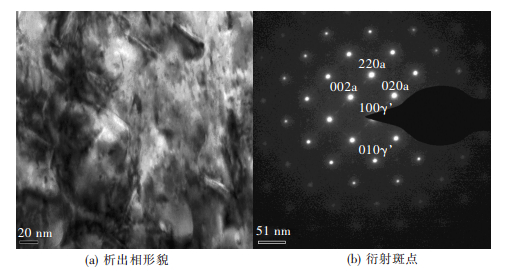

摘要: 采用OM、SEM、XRD和TEM分析手段对C17510合金的固溶时效与组织性能进行研究.结果表明,冷轧态C17510合金的合理固溶处理温度为950 ℃.时效态C17510合金的硬度与时间呈单峰型曲线,合金的电导率与时间呈先剧增,后缓慢增大,最后趋于稳定的趋势.冷轧态C17510合金经950 ℃×0.5 h固溶处理+525 ℃×4 h时效处理后,其维氏硬度为231,电导率为56%IACS.Abstract: Effects of Solid solution and aging treatment on the microstructure and properties of elastic C17510 alloy is studied by OM, SEM, XRD and TEM. The results show that the proper solid solution treatment temperature of cold-rolled C17510 alloy is 950 ℃. The hardness of specimen exhibits a single peak after aging for 4h and then continuously decreased as a result of over-aging afterwards. With the prolonged aging time, the electrical conductivity increases firstly, and then keeps stable. After the cold-rolled C17510 alloy is solution treated at 950 ℃ for 0.5 h and aged at 525 ℃ for 4 h, the Vickers hardness and electrical conductivity are 231 and 56%IACS respectively.

-

经济发展致使能源需求剧增,伴随着煤炭等不可再生能源的过度使用,能源和环境问题日益严峻,可再生能源的研发备受关注。在能源需求方面,氢能因具有能量密度高、零排放和可循环利用等特点,未来大概率会替代传统化石燃料。当前,制氢方式主要有4种:化石燃料制氢、工业副产物制氢、电解水制氢(Hydrogen Evolution Reaction, HER)、生物质制氢。HER是公认的最可持续、最环保的从水中直接产生高纯氢的方法。

对于适用于HER的催化剂而言,Pt基催化剂一直是最佳选择[1-2]。然而,成本高和稀缺性限制了Pt基催化剂在HER中大规模应用[3-4]。因此,人们一直致力于开发原料丰富、具有成本效益的高效HER催化剂[5-6]。此外,对于以金属为主要活性组分的传统固体催化剂而言,只有极少数金属活性组分在催化反应过程中起催化作用,金属的利用效率远低于理想水平。特别是对于贵金属,大剂量使用无疑增加了催化剂成本,不利于在工业化生产中应用。单原子金属催化剂(Single Atom Catalysts, SACs)的原子利用率在理论上高达100%,是一种可高效提高原子利用率和反应活性的催化剂,近来受到了广泛关注。2011年,QIAO等首次报道FeOx负载的单原子铂(Pt)催化剂可用于CO的氧化反应过程,并在此基础上提出了单原子催化(Single Atom Catalysis, SAC)的概念[7]。

SAC与纳米催化和亚纳米催化存在着明显的差异,这是因为当粒子分散度达到单原子尺寸时会出现诸多新的特性,如急剧增大的表面自由能、量子尺寸效应、不饱和配位环境和金属—载体的相互作用等[8]。正是这些显著不同的特性赋予SACs优越的性能:原子利用率高、100%的原子分散性、均匀的反应中心、优异的选择性和高稳定性等[9-10]。然而,SACs也存在不足,这是由于金属粒子减小到单原子水平时,比表面积急剧增大会导致金属表面自由能急剧增加,从而在其制备过程和处于反应状态时极易发生团聚耦合形成大的团簇,导致催化剂失活[11]。因此,稳定性和活性是SACs所面临的巨大挑战。

近年来,研究者尝试使用不同的方法制备活性与稳定性俱佳的SACs,并采用多种先进的表征分析方法,以及结合理论计算推动SAC的研究进程[12-14]。本文首先列举了SACs的常规制备方法,如热解法(高温热解、热解迁移)、沉积法(化学气相沉积法、原子层沉积法、电化学沉积)、液相合成和刻蚀法,并比较了上述制备方法的优缺点;列举了常见的SACs的表征分析方法,以及SACs在HER领域的研究进展情况;最后,指出目前SACs在应用于HER时面临的挑战,并提出了一些可能的改进方法,以期为设计廉价高效的用于HER的SACs提供有价值的参考。常用的单原子催化剂制备、表征及密度泛函计算方法如图 1所示。

1 合成方法

目前,SACs通常通过热解、沉积、液相合成和刻蚀等方法制备而成。

1.1 热解法

热解法是一种简便易行且广泛使用的SACs制备方法,但在热解过程中无法避免高能耗的问题。通常是将金属离子浸渍到载体上,然后在高温惰性气体氛围下热解成SACs[15-16]。其中,氧化石墨烯(Graphene Oxide, GO)和碳纳米管(Carbon Nanotubes, CNTs)由于含有大量可捕获和牵引金属阳离子的含氧官能团,因而成为热解法制备SACs时广泛使用的2种碳基材料。首先将贵金属或过渡金属原子分散到氮掺杂的GO或CNTs中,然后在高温退火条件下将混合物碳化,形成稳定的SACs[17]。LI等报道了单原子Ni(SA Ni)促进Pt电催化的最新研究成果,通过合成的平均长度约为300 nm、直径约为4.5 nm的富镍PtNi合金纳米线,在70 mV过电位(η),pH=14的反应条件下,质量活性可达到11.8 A/mg Pt[18]。ZHANG等报道了一种将单原子Pt从前驱体碳球表面迁移至其内部的方法,实现了孤立Pt原子在介孔碳基质(Mesoporous Carbon Matrix, PCM)中的牵引和稳定,合成了活性中心高度分散的Pt@PCM电催化剂。以0.5 mol/L H2SO4溶液为电解液,利用三电极体系对Pt@PCM的HER性能进行了测试。结果发现:Pt@PCM对HER具有很高的催化活性,其起始电位(η。)接近HER的热力学电位(即0 V vs. RHE),与商用20% Pt/C的η。相当。通过计时电流i-t曲线可知,Pt@PCM在酸性介质中5 h后的电流衰减小于起始电流的5%,表现出优异的稳定性[19]。其次,金属有机骨架化合物(Metal Organic Frameworks, MOFs)作为一类新型多孔材料[20-22],也可以作为单原子的载体,通过热解法制备SACs。如CHEN等通过将钨前驱体(WCl5)封装在MOF骨架(UiO-66-NH2)中,然后进行热解,合成了钨单原子电催化剂(W-SAC)。在0.1 mol/L KOH溶液中进行的HER性能测试表明:W-SAC与商用Pt/C几乎具有相等的活性。此外,研究人员对W-SAC进行了耐久性测试,测试结果显示,W-SAC经10 000次CV循环测试,活性并没有明显降低,这表明其具有用于实际HER的潜力[23]。MOFs作为SACs的载体有以下优点:不同种类的金属离子可以通过不同的有机前体进行桥联;掺杂的杂原子也可以通过热解固定在SACs上[24]。

通过热解过程中的原子迁移作用,同样可实现SACs的制备[25-26]。但此类方法不仅需要可移动的金属物种,而且需要一种能够捕获可移动金属物种的支撑材料[27]。通常是在惰性气氛和高于900 ℃的环境中进行,首先将贵金属纳米颗粒转变为热稳定的金属单原子;随后,辅助气体将金属单原子运送至多孔载体上[28]。QU等以有缺陷的石墨烯(Defective Graphene, DG)锚定铂单原子(Pt SAs)的方式制备了Pt SAs/DG催化剂,通过高温热解二氰胺产生的氨气促进Pt网上的Pt转变为Pt原子,Pt原子被具有丰富缺陷的DG捕捉,并在热迁移的作用下陷入DG表面的双缺陷位点中,形成Pt-C4的配位结构,实现从块体Pt到Pt SACs的一步转化。该催化剂表现出超越商用Pt/C的HER性能。电流密度为10 mA/cm2时,Pt SAs/DG的η为23 mV,低于商用Pt/C(38 mV)[29]。热解原子迁移俘获法可实现非贵金属(铜、镍和钴)一步转化为SACs。

1.2 沉积法

通过化学气相沉积法(Chemical Vapor Deposition, CVD)将金属原子沉积到选定的支撑衬底上,是常用的SACs合成方法[30]。利用气态的先驱反应物,通过原子、分子间化学反应,使得气态前驱体中的某些成分分解,并在基体上形成薄膜。QIU等报道了通过CVD法合成用于HER的单原子镍掺杂纳米多孔石墨烯催化剂,该催化剂的塔菲尔(Tafel)斜率约为45 mV/dec,说明镍的掺杂极大地改变了石墨烯的化学活性。在运行120 h后,催化活性保持约90%,证实了单原子镍掺杂纳米多孔石墨烯催化剂具有高稳定性[31]。HAN等提出了一种利用一步CVD法在1T-WS2单分子层上实现高度分散的单原子钒催化剂(V SACs@1T-WS2)制备的方法。以0.5 mol/L H2SO4溶液为电解液,通过三电极装置进行了HER性能测试,线性伏安扫描表明其在10 mA/cm2的电流密度下,η为185 mV, 而钒的负载仅为1.8~6.5 μg/cm2。在100 mV时,塔菲尔斜率为61 mV/dec,对应的周转频率(Turnover Frequency, TOF)值为3.01 s-1,显示出良好的催化性能[32]。尽管CVD法是制备杂原子掺杂石墨烯的有效方法,但低产量的石墨烯极大地限制了其实际应用。此外,无论是预沉积的金属膜,还是预抛光的金属箔,都可能导致金属残留,从而污染SACs。

原子层沉积法(Atomic Layer Deposition, ALD)是一种通过将气相前驱体脉冲交替地通入反应器并在沉积基体上通过化学反应吸附而形成沉积膜的方法[33-35]。FANG等利用ALD法将Pt原子孤立地分散在掺氮的碳(Nitrogen-Carbon, N-C)载体中,形成高度均一的Pt1/N-C,电化学测试证实其具有优异的HER性能。在1.0 mol/L KOH和0.5 mol/L H2SO4溶液中,Pt1/N-C的η均低于商用Pt/C催化剂,分别达到了极低的46 mV和19 mV,TOF更是超过Pt/C一个数量级。并且,Pt1/N-C还表现出极佳的稳定性,在20 h稳定性测试后,其活性几乎没有衰减[36]。ZHANG等通过ALD法将Pt单原子负载至氮掺杂CNTs上,随着载体中的类吡咯氮位点增加,Pt催化剂的HER活性随之提高。与商用Pt/C催化剂相比,具有更高类吡咯类氮含量的CNTs负载Pt单原子形成的催化剂表现出更高的HER性能,其质量活性比商用Pt/C高47倍[37]。ALD可以精确地控制沉积参数,使得金属原子在载体表面均匀沉积且重复性好,而且ALD亦可精确控制不同材料以原子层的方式生长,形成具有不同形貌的复合物。然而,ALD技术面临着2个主要挑战,即低金属负载量和金属位点的不均匀性。同时,ALD还受到产量低、设备成本高和前驱体的限制,这些都不利于ALD的大规模应用[38-40]。

电化学沉积法是在一定电压下,原子从阳极溶解,再沉积到阴极上的方法。该方法具有操作简单、条件温和、成本低和精确可控等特点,因此被广泛应用于纳米材料的制备和电镀等工业生产中[41-44]。ZHANG等报道了一种利用电化学沉积制备SACs的普适性方法。阴极沉积的Ir1Co0.8Fe0.2Se2/C在1 mol/L KOH中进行HER测试,仅需8 mV的过电位即可达到10 mA/cm2的电流密度,远低于商用Pt/C[45]。ZHANG等通过电化学的方法将Pt单原子固定在由CoP的纳米管(Nanotube, NT)阵列支撑泡沫Ni(Nifoam, NF)形成的载体上,合成了Pt-NT-NF催化剂。在中性介质中进行HER测试,10 mA/cm2的电流密度下,表现出24 mV的超低η,塔菲尔斜率仅为30 mV/dec。在η=50 mV时,Pt的质量活性为70 A/mg,大约是商用Pt/C的4倍,其电催化稳定性也优于商用Pt/C;由计时电流曲线可知, 其高活性保持了24 h[46]。然而,这种常规的电沉积工艺不可避免地会形成覆盖率不均匀的多层体相结构。为了克服这一困难,有研究者采用表面限制的欠电势沉积技术(Underpotential Deposition, UPD)制备单层金属结构[47]。如SHI等制备得到Pt SAs/MoS2催化剂,在酸性介质中进行HER测试,相比于纯MoS2基底,Pt SAs/MoS2表现出优异的HER电催化活性,10 mA/cm2的电流密度对应的η为59 mV,质量活性是商用Pt/C的114倍。在η为100 mV条件下,Pt SAs/MoS2的塔菲尔斜率低至31 mV/dec,TOF值高达47.3 s-1,高于绝大多数的SACs。此外,该催化剂电催化稳定性良好[48]。该方法可在常温常压下实现可控、快速地合成原子分散的金属催化剂,并且具有一定的普适性[49-51]。然而,这种电沉积工艺也有缺点,如电镀不均匀。

1.3 液相合成法

SACs也可以在液相中通过各种相互作用合成,如共价键、p-p堆积、静电吸引或螯合反应等[52-54]。CHENG等报道了Pt/TiO2-OVs催化剂,在η为50 mV时,该催化剂具有较优的质量活性(62.34 A/mg)和最高TOF(56.1 s-1),比商用Pt/C高18.7倍和5.56倍[55]。WANG等首先采用限域法合成了单层WO3·H2O(ML-WO3·H2O)纳米片,然后将Pt单原子(Pt-SA)固定在单层WO3(ML-WO3)纳米片,成功构建了Pt-SA/ML-WO3。实验结果显示,Pt-SA/ML-WO3具有优异的电催化性能,仅需22 mV的过电位即可实现10 mA/cm2的电流密度,塔菲尔斜率低至27 mV/dec,同时在η为50 mV时,具有87 s-1的超高TOF,以及高稳定性。特别值得注意的是,Pt-SA/ML-WO3在η为50 mV条件下具有87 A/mg的超高质量活性,是最先进的商用Pt/C(0.54 A/mg)的160倍[56]。液相法适用大多数载体,且操作简单,这为相应SACs的大规模生产提供了机会[57-60]。但是,包含在前体材料中的孤立金属原子因高表面能而具有强烈的聚集趋势,所以这种方法并不能制备高负载量的SACs[61]。

1.4 刻蚀法

组装/刻蚀法是一种提高电催化剂析氢性能的常用方法,通过刻蚀可改变材料的形貌及结构,增大材料的比表面积并暴露更多的活性位点,随后负载活性物质,从而制备高负载量的SACs[62-64]。QI等成功制备了一种新型界面催化剂,这一催化剂由MoS2纳米片与金属单原子钴(SA Co)通过共价结合组成(SA Co-D 1T MoS2)。组装过程中,由于Co与MoS2之间的晶格失配和Co-S之间形成强共价键,作为单原子催化剂载体的MoS2会发生由2H向扭曲的1T相的转变,该现象进一步阐释了Co单原子与载体之间的相互作用关系。在酸性电解液中,其具有类商用Pt的HER活性,且具有优异的稳定性。HER测试中,钴负载量为3.54%的SA Co-D 1T MoS2表现出极小η。(42 mV),远小于其他非贵金属催化剂,甚至与Pt/C(Pt负载量10%)的η。相当[65]。尽管组装/刻蚀法制备的电催化剂具有负载量高和性能好的优点,但仍有许多问题。首先,由于刻蚀会暴露了大量的金属原子,催化剂处于热力学亚稳态,容易氧化,导致其失去活性。其次,目前主流的刻蚀溶液仍具有高毒性和污染性。

用于HER的SACs的性能比较分析如表 1所列。

表 1 单原子催化剂的性能比较分析Table 1. Comparison and analysis of the performance of single atom catalysts

从表 1可知:通过不同方法制备而成的SACs具有不同的η。

电解水反应包括阴极还原反应(即HER)和阳极氧化反应(即析氧反应(Oxygen Evolution Reaction, OER))。OER和HER分别如式(1)和式(2)所示,总的水分解反应如式(3)所示。

(1)

(2)

(3) 因此,理论上水分解产生氢气的电位是0 V。实际上,不同制备方法会产生不同类型的单原子位点,这些单原子位点具有不同的配位构型和电子特征,最终影响SACs的结构—催化关系,从而导致不同方法制备的SACs具有不同的η。因此,有必要在原子尺度上识别SACs的活性位点,了解SACs的结构—催化关系。

2 表征分析和密度泛函计算

2.1 SACs表征技术

为了探索SACs的结构—催化关系和实现高性能催化剂的合理设计,在原子尺度上识别活性中心并监测其配位环境是非常必要的。许多先进的表征和分析方法已被用于深入研究SACs的结构—催化关系,包括扫描隧道显微镜(Scanning Tunneling Microscope, STM)、高角环形暗场像—扫描透射电子像(High-Angle Annular Dark-Field Imaging-Scanning Tunneling Microscope, HAADF-STEM)、X射线光电子能谱(X-ray Photoelectron Spectroscopy, XPS)、X射线吸收光谱(X-ray absorption spectroscopy, XAS)等[66-68]。

STM可以直接揭示SACs的形貌、电子特征,避免了从光谱或化学测量中间接分析化学信息的主观性。STM以波长极短的电子束作为照明源,用电磁透镜聚焦成像。WANG等通过STM对单层ML-WO3纳米片进行了结构分析,STM图像表明Pt-SA/ML-WO3具有不规则片状形态。从ML-WO3到Pt-SA/ML-WO3,没有出现严重的烧结现象[56]。传统的SEM或TEM(Transmission Electron Microscope, TEM)技术的分辨率有限,无法观察单原子的具体形态;具有球面像差校正的HAADF-STEM可直观观测到单原子在载体上的分散情况,极大地推动了SACs的研究进程。QI等通过HAADF-STEM对原子Co与扭曲的1T MoS2纳米片共价结合组成的界面催化剂SA Co-D 1T MoS2进行分析,HAADF-STEM图像证实了结合界面处MoS2从2H转变为D-1T相,且SA Co-D 1T MoS2和2H MoS2之间存在明显界面,Co是位于Mo原子的上方,而不是替代Mo[65]。TIAO等成功合成了N掺杂空心多孔碳(Nitrogen-Doped Hollow Porous Carbon, HC)负载的Co单原子(SA Co/HC), 通过HAADF-STEM图像可以观察到高密度的亮点,显示了原子级Co位点的分散情况[69]。与SEM或TEM对比,HAADF-STEM能获得更清晰的SACs形貌和组分信息,但其电子束很难约束,球差校正难度更大。

XPS技术可提供SACs表面的化学信息,如元素组成、元素含量及其价态。XPS技术通过用X射线(1 000~1 500 eV)照射样品,SACs的价电子或内壳层电子可以被激发。同时,测量从SACs表面逃逸的电子的数量和动能,测得的发射电子的数量和动能分别反映了表面元素的含量和化学状态信息。ZHANG等通过XPS对Pt@PCM的结构进行了分析,PCM的N1s光谱证明基质中存在石墨、吡啶和吡咯类氮物种,与上述物种对应的特征峰分别在结合能为401.6、400.6、398.6 eV处出现。吡啶中存在的N可以作为Pt原子的固定点,Pt原子的改性增加了N1s的平均结合能,同时,吡啶中N的比例也得到了提高。上述结果证明了孤立的Pt原子和碳基体之间存在相互作用,以及孤立的Pt中心和配位的N原子之间的电子转移。此外,在Pt@PCM中Pt 4f的XPS谱中可以观察到2个峰,分别出现在结合能为71.28 eV和74.53 eV处,这表明在Pt原子和吡啶中C/N之间形成了配位键,而在70.89 eV和74.23 eV处不存在与Pt-Pt键相对应的峰,证实没有形成Pt团簇粒子[19]。XPS分析所得到的信号只能确定元素有无以及大致位置,并且X射线的穿透深度有限,得不到更准确的元素化学态和分子结构信息等。

与XPS技术对比,XAS技术具有亚原子分辨率和超高电子结构敏感度,其X射线(0.1~100 keV)能将特定原子轨道上的电子激发到自由态或未占据的能级,因而XAS技术能更准确表征SACs的化学状态和几何结构。XAS又可分为2种模式:扩展的X射线吸收精细结构(Extended X-ray Absorption Fine Structure, EXAFS)和X射线吸收近边缘结构(X-ray Absorption Near Edge Structure, XANES)。SACs的局部结构信息可以由EXAFS确定,例如原子间距、配位数、邻近原子的数量和类型等。XANES数据分析可提供中心金属原子的化学状态和几何信息,例如确定价态、表征d-带特性、测定配位电荷、提供包括轨道杂化、配位数和对称性等。通常选定SACs中需要测试的某种元素,用特定的X射线光子能量扫描,将内壳电子激发到未占据的能级,从而导致某些能量(吸收边)急剧上升。每个吸收边与SACs中存在的特定原子有关,并因为周边原子的能量散射形成一系列振荡结构。以X射线光子能量作为变量,测定SACs的X射线吸收系数。其中,硬X射线(能量较高的X射线,波长在0.01~0.1 nm之间)具有研究原位电化学反应动态过程的能力,有利于建立更精确的结构—催化关系。FANG等利用ALD在金属有机骨架(MOF)衍生的N-C骨架上合成了原子分散的Pt催化剂,将其应用于HER过程时,通过XAFS技术在原子水平上确定了单个原子向近自由状态的演化过程。通过XANES光谱中的白线峰的吸收边能量和面积积分,计算定量确定铂的价态和d带空穴数,从而获得电子结构演化的定量信息。测试显示,在+0.5~+0.15 V和-0.07 V的电势下,Pt的平均价态分别从+1.89降低到+1.17和+1.12,这意味着Pt的价态向金属态降低,直到接近零价,验证了在工作状态下Pt和基底之间存在弱相互作用。EXAFS进一步确定了单原子Pt配位构型的演化。在相应的外加电位下,Pt1/N-C的EXAFS谱都在约0.16 nm处呈现一个单一的主峰,这可归因于Pt原子与C/N/O原子之间的配位。然而,当施加的电位分别从+0.5 V负移至+0.15 V和-0.07 V时,傅里叶变换峰的强度衰减了13%和35%,这表明在工作条件下Pt位点的局部几何结构有明显的变化。振荡峰的强度随着电势的增加而降低,证实了Pt原子周围的动态无序结构。值得强调的是,EXAFS和XANES分析是从相同的SACs中获得的,对配位环境和几何/电子结构有不同的表现形式,但也由此检测出SACs的结构和化学信息应一致,可以相互验证[36]。XAS技术有助于理解SACs的结构—催化关系,但XAS技术的实验装置和条件很难控制,特别是在软X射线(能量较低的X射线,波长在0.1~10 nm之间)范围内,这仍然是一个很大的挑战。

2.2 SACs电子特性的密度泛函计算

密度泛函理论(Density Functional Theory, DFT)作为处理多粒子体系的近似方法在物理、材料、化学和环境等领域广泛应用[70]。DFT通过多种近似方法,将难以解决的包含电子—电子相互作用的问题简化成无相互作用的问题,将所有误差单独放进一项中,再对这个误差进行分析。DFT可从原子或者分子尺度理解并且调控物质的性质。首先假设催化剂的结构,然后模拟不同表面原子间的相互作用,探究纳米表面的催化活性,预测出催化剂的种类以及活性位点。基于DFT的科学计算模拟方法不仅可以研究现有SACs的催化性能,而且可以预测并设计新的SACs。WANG等为了进一步阐明Pt-SA/ML-WO3的催化活性,利用DFT计算了催化剂模型的氢吸附自由能(∆GH*)。通常,接近热中性的∆GH*值(∆GH*≈0 V)对应于高活性,计算结果显示WO3、WO3-VO/W、Pt/WO3-VW和Pt/WO3-VO(VO为氧空位数量)的∆GH*值为0.55 eV、0.38 eV、-0.17 eV和0.10 eV,表明O/W空位的存在和Pt原子的掺入都可以增强SACs对氢的吸附能力。特别是,Pt原子取代W原子使得Pt/WO3-VW的∆GH*非常接近理想金属Pt(111)(-0.09 eV),DFT计算表明,Pt和载体ML-WO3之间存在很强的相互作用,这极大地调整了催化剂的电子结构,赋予其很强的导电性和合适的∆GH*值,并产生优异的电催化活性[56]。LI等通过使用负载在N掺杂碳纳米片(N-doped Carbon Nanosheets, NCNS)上的Pt单原子作为催化剂(Pt1/NCNS),利用原子层沉积(ALD)技术合成了Co SAC。DFT计算表明,Pt原子作为催化剂调节Co原子在ALD中的吸附行为,促进Co(Cp)2的解离,CoCp与吡咯N4位点结合形成Co单原子,而不是纳米粒子。这种合成策略也可以扩展到合成FePt/NCNS和NiPt/NCNS。在电化学测试中,NiPt/NCNS比Fe和Co的SACs表现出更好的催化活性,这与DFT预测一致[71]。ULLAH等使用密度泛函理论方法设计和研究了石墨炔(Graphyne, GY)表面负载过渡金属(Fe、Co、Ni、Cu和Zn)的SACs。不同SACs的∆GH*表明,锚定在GY载体上的Ni/GY具有最高的热力学稳定性和最好的HER催化活性[72]。DFT方法是通过将电子的密度分布函数作为描述体系所有性质的唯一变量来计算粒子体系的各种性质,具有计算量小的优点,但是也会受到简化处理的制约,必然会出现误差。在近似的基础上修正也许能够接近实际的数值,但是理论基础依然还是在同一个维度上。DFT适用范围相对有限,模拟效果仍需实验结果佐证。

通过多种表征方法和理论计算不仅有利于指导SACs的设计,更有助于揭示SACs在复杂催化环境中的化学反应机制。

3 结束语

对用于HER的SACs的研究进展进行了综述,首先对SACs的制备方法进行总结,重点介绍SACs的热解、沉积、液相合成和刻蚀4种制备策略;然后对SACs的表征技术进行了总结,包括扫描隧道显微镜、高角环形暗场像—扫描透射电子像、X射线光电子光谱、X射线吸收光谱,并介绍了密度泛函计算在解析SACs电子特性方面的应用。

尽管SACs在HER的研究取得了一定的进展,但目前还停留在实验室小试阶段,达不到工业化标准。有关SACs的下一步研究应集中在以下6个方面:①在确保材料稳定的基础上提高其电催化活性,发展最佳改良技术;②复合材料中考虑引入二维材料为助催化剂,降低单原子巨大的表面能和迁移能力,防止在制备过程和处于反应状态时发生团聚耦合形成趋于稳定的纳米颗粒,导致催化剂失活;③开发新的、更高效的支撑材料,提升基底材料与金属之间的相互作用以及稳定性,从而促进催化性能;④利用过渡金属和非贵金属制备高效、稳定、低成本的SACs;⑤利用新的表征手段和理论模拟运算技术,从微观和瞬态两个方面阐明电催化机理,特别是结合实验结果和密度泛函计算在分子尺度上探究HER机理;⑥明确单原子电催化剂的结构和电解水制氢活性之间的构效关系,为高效电催化剂和电催化体系的设计提供必要的理论指导。

-

[1] 陈乐平, 周全. 铍铜合金的研究进展及应用[J]. 材料热处理技术, 2009, 38(22): 14-18. http://www.cnki.com.cn/Article/CJFDTOTAL-SJGY200922005.htm [2] 潘奇汉. 铍铜合金性能与其元件生产[J]. 电子元件与材料, 2004, 23(2): 44-45. http://www.cnki.com.cn/Article/CJFDTOTAL-DZAL200402015.htm [3] 董超群, 易均平. 铍铜合金市场与应用前景展望[J]. 稀有金属, 2005, 29(3): 350-356. http://www.cnki.com.cn/Article/CJFDTOTAL-ZXJS200503018.htm [4] 阎永, 汪治军, 董超群. 我国铍铜产业科技进步回顾与展望[J]. 稀有金属, 2003, 27(1): 66-68. http://www.cnki.com.cn/Article/CJFDTOTAL-ZXJS200301012.htm [5] 刘楚明, 刘娜, 曾祥亮, 等. 形变时效工艺对低铍Cu-Ni-Be合金力学性能和电导率的影响[J]. 中南大学学报(自然科学版), 2010, 41(2): 508-513. http://www.cnki.com.cn/Article/CJFDTOTAL-ZNGD201002024.htm [6] Bonfield W, Edwardsb C. Precipitation hardening in Cu-1.8wt%Be-0.28wt%Co[J]. Journal of Material Science, 1974, 9(3): 398-408. doi: 10.1007/BF00737839

[7] Masamichi M, Yoshikiyo O. Effect of Quenching temperature on the intragranular and cellular precipitations in Cu-1.5%Be Binary alloy[J]. Material Transactions, JIM, 1995, 36(9): 1118-1123. doi: 10.2320/matertrans1989.36.1118

[8] Donoso E, Varschavsky A. Microcalorimetric evaluation of precipitation in Cu-2Be-0.2Mg[J]. Journal of Thermal Analysis and Calorimetry, 2001,63(1): 249-266. http://cn.bing.com/academic/profile?id=1709840468&encoded=0&v=paper_preview&mkt=zh-cn

[9] Chihiro W, Toshiro S, Ryoichi M. Misfit strains of precipitations phase and dimensional changes in Cu-Be alloys[J]. Philosophical Magazine, 2008, 88(9): 1401-1410. doi: 10.1080/14786430802178087

[10] Ryoichi M, Tsutomu S, Toshiro S, et al. Precipitation processes in Cu-0.9mass%Be single Crystal[J]. Material Transactions, JIM, 2006,47(12): 2925-2934. doi: 10.2320/matertrans.47.2925

[11] Peng L J, Xiong B Q, Xie G L, et al. Precipitation process and its effects on properties of aging Cu-Ni-Be alloy[J]. Rare Metals, 2013, 32(4): 332-337. doi: 10.1007/s12598-013-0074-5

[12] Rioja R J, Laughlin D E. The sequence of precipitation in Cu-2wt%Be Alloys[J]. Acta Metallurgica, 1980, 28(8): 1301-1313. http://cn.bing.com/academic/profile?id=2055824053&encoded=0&v=paper_preview&mkt=zh-cn

[13] Chihiro W, Ryoichi M. Precipitation process in a Cu-Ni-Be alloy[J].Solid State Phenomena, 2011, 172/173/174: 432-426. http://cn.bing.com/academic/profile?id=2079828595&encoded=0&v=paper_preview&mkt=zh-cn

[14] Satoshi O, Naokuni M, Kazumasa S, et al. Mechanical and Electrical proprieties and microstructure in Cu-Ni-Be alloys[J]. Journal of the Society of Material Science, 2007, 56(6): 531-536. doi: 10.2472/jsms.56.531

[15] Guha A. Development of a high strength high conductivity Cu-Ni-Be alloy[J]. High Conductivity copper and Aluminum Alloys, 1984, 26: 133-145.

-

期刊类型引用(8)

1. 邓越,王婷婷,孙清鹏,孙金峰,张少飞. 三维阵列CoO_x/CeO_2双功能催化剂的制备及其电解水性能研究. 铜业工程. 2025(01): 95-103 .  百度学术

百度学术

2. 薛天雨,黄仲,谷昊辉,张海军. 高熵合金纳米电催化剂的合成. 稀有金属. 2024(01): 90-104 .  百度学术

百度学术

3. 裴启飞,郭孟伟,邵伟春,王恩泽,高明远,张启波. 锌电积体系Zn-MnO_2同槽电解电化学分析. 有色金属科学与工程. 2024(03): 322-331 .  本站查看

本站查看

4. 于巧玲,刘成宝,曹一达,郑磊之,陈丰,钱君超,邱永斌,孟宪荣,陈志刚. SnO_2QDs-g-C_3N_4/C的合成及其光催化降解四环素研究. 稀有金属. 2024(08): 1144-1153 .  百度学术

百度学术

5. 朱得智,徐京城. FeS@NiMoO_4异质结构筑及电催化析氢性能研究. 有色金属材料与工程. 2024(06): 60-67+74 .  百度学术

百度学术

6. 侯振宇,苑慧萍,刘彧儒,沈浩,李志念,蒋利军. 化学计量比对钇-镍基储氢合金结构和储氢性能的影响. 稀有金属. 2024(12): 1671-1680 .  百度学术

百度学术

7. 余德和,左川,高勇,周世平,卢军,刘锋. 电解水析氢贵金属电催化剂的研究进展. 稀有金属. 2023(11): 1573-1586 .  百度学术

百度学术

8. 王诗雯,鲁杨帆,丁朝,李建波,陈玉安,谭军. Ti基催化剂改性Mg基储氢材料的研究进展. 稀有金属. 2023(12): 1642-1656 .  百度学术

百度学术

其他类型引用(2)

下载:

下载: