Investigation on pulverization phenomena of coke formed by lump coal pyrolysis in melter gasifier

-

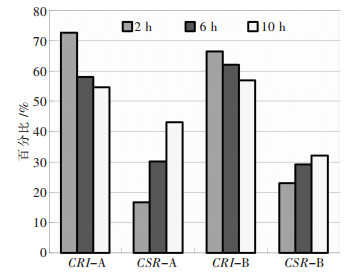

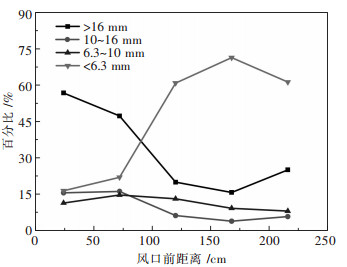

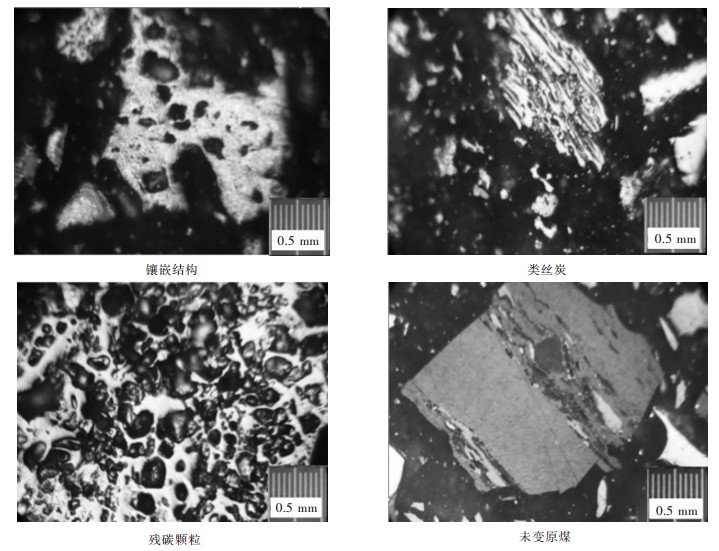

摘要: 采用200 kg级炼焦炉对熔融气化炉主要使用的2种块煤进行了不同时间的半焦裂解试验,比较了2种块煤成焦后的粒度分布和强度变化,发现B煤在炼焦炉内粉化严重,随结焦时间的延长其粒度降解度一直在升高,而A煤降解度在达到最大值后开始下降.对比了2种块煤生成半焦的矿相微观结构,A煤生成的半焦主要以镶嵌结构和各向同性结构为主,而B煤生成的半焦主要以类丝炭和各向同性结构为主;2种半焦均含有未成焦煤.通过分析熔融气化炉内取出的风口试样中不同粒度的含碳物质其矿相微观结构,认为在炉缸内 < 6.3 mm的颗粒由2两种块煤裂解成焦后的粉化现象所引起,且B煤的粉化是主要因素.Abstract: Through the different pyrolysis time tests in 200 kg coke oven of lump coal mainly used in melter gasifier, namely A coal and B coal, the size distribution and strength change of the two coals after coking was compared. Results showed that the pulverization of B coal in coke oven was severe, which size degradation rate (DR) was always increasing with the coking time prolonging. On the contrary, the DR of A coal was decreasing once reached the maximum value. The mineral microstructure of semi coke formed by the two coal pyrolysis in coke oven was also compared. It was found that semi coke formed by A coal was mainly mosaic and isotropy stucture, and the other semi coke formed by B coal was mainly fusain and isotropy structure. There was still some coal residue in both semi cokes. Through the mineral microstructure analysis of different particle size of carbon-containing materials in tuyere samples taken out from melter gasifier, it was found that the particles less than 6.3 mm in hearth were caused by the semi coke pulverization. Moreover, the pulverization of semi coke was mainly form B coal.

-

我国钢铁行业每年产生大量粉尘,一般为钢产量的8%~12%,具体包括烧结尘泥、球团尘泥、高炉尘泥、转炉污泥、电炉除尘灰、转炉除尘灰、轧钢污泥、轧钢氧化铁鳞、出铁场集尘、钢管石墨污泥和含油铁屑等。含锌粉尘主要为高炉粉尘(20~30 kg/t铁)、转炉粉尘(8~20 kg/t钢)和电炉粉尘(10~20 kg/t钢)。含锌粉尘不仅锌的含量高,还往往含有较高的铁,是非常重要的二次资源[1-3]。然而,含锌粉尘直接返回高炉使用时,因粒度过小会直接影响烧结生产,易挥发的锌在高炉中循环富集会恶化高炉冶炼[4-5]。目前大量含锌粉尘被弃用,不但对自然环境造成严重威胁,也造成大量有价元素的浪费。因此对含锌冶金粉尘进行资源化利用,可以缓解资源日益枯竭和环境污染的双重压力,具有重要意义[6-9]。

在处理含锌冶金粉尘及其固体废弃物时,湿法工艺在冶金行业中的重要性日益提高。在这方面已经进行了大量工作,例如酸浸和碱浸[10-11]。酸浸主要采用无机酸(HCl、H2SO4),在增温加压条件下可提高锌浸出率,但也导致了铁及其他杂质元素的大量溶解[12]。这会增加酸耗,腐蚀设备,也引起后续净化、过滤和萃取等过程的复杂化。碱法采用碱溶液(如NaOH、NH4HCO3或NH4OH)做浸出剂。与酸浸对比,碱浸对设备腐蚀较小,具有较好的锌选择性,但浸出率较低[13-14],目前碱浸法提锌的工业化应用较少[15]。

近年来,有机酸因具有可生物降解性和环境友好性在浸出方面受到了较多关注,但有机酸为弱酸,如何提高有机酸浸出率是普遍关注的研究重点。有机酸可通过有机物的生物降解产生,例如废水中存在的有机污染物。这些有机酸包括柠檬酸、草酸和乙酸,且其中部分酸的有效性已经被证明[16-18]。有报道称,有机酸对金属的浸出能力与它们的酸性及络合特性有关,其中强酸通常具有更高的浸出效率,而络合作用可促进金属离子的溶解[19]。然而,通过有机酸选择性浸出处理转炉粉尘中锌方面的信息是非常有限的。本研究采用草酸、柠檬酸、乙酸、丙酸、丁酸和戊酸6种有机酸对含锌冶金粉尘中的锌和铁进行选择性浸出实验,对不同有机酸浸出物进行鉴定以探究不同酸浸机理。初步研究发现丁酸具有较好的浸出效果,因此进一步对丁酸浸出工艺条件进行了优化,并设计了未来丁酸工业化浸出工艺流程。该研究结果对我国含锌冶金粉尘的绿色资源化利用具有一定的指导意义。

1 实验原料及性质

实验原料为某钢铁厂转炉炼钢除尘工序收集到的转炉粉尘滤饼,经干燥破碎筛分后得到300~500 μm粉末样品。通过X射线荧光光谱仪(XRF)分析其化学组成如表 1所示。结果表明,其金属组分中铁、锌、钙的含量最高,其他金属含量均低于2%。粉尘中锌的含量高达6.5%,铁的含量更是达到了56.4%。

表 1 转炉粉尘主要化学成分XRF分析结果Table 1. Chemical compositions of the BOS dust

图 1所示为原料的X射线衍射(XRD)图谱。结果显示锌的存在形式主要为氧化锌(ZnO)和铁酸锌(ZnFe2O4),铁主要由以金属铁(Fe)、方铁矿(FeO)、和磁铁矿(Fe3O4)组成。另外,样品还含有CaCO3和石墨C。金属Fe和FeO有最明显的突出峰,Fe3O4次之。浸出法提取锌所面临的最大问题是ZnFe2O4性质十分稳定,很难被单独的酸或碱溶解[20-22]。金属氧化物之间形成的固溶体使得锌在矿相中更加稳定,进一步增大了浸出锌的难度。

图 2所示分别为170倍和1 000倍放大倍数下样品颗粒的扫描电子显微镜(SEM)图像。在高倍(×1 000)的图像中能够清晰地观察到,样品是由多种形状各异、大小不一的微小颗粒组成的,其中大型颗粒是亚微米级颗粒的团聚体且具有多孔结构。

对粉末样品进行切片、装片处理后用扫描电子显微镜/X射线能谱仪(SEM/EDS)进行观察,得到背散射图像见图 3。从图 3中可以清晰地观察到,样品包含一个由锌、铁、氧、钙、镁等元素组成的富锌区域。由图 3的SEM图像中可知,粉尘颗粒主要由粒径小于1 μm的氧化铁颗粒组成,其中大于1 μm的颗粒较少。富锌区域的孔隙较少,而中心富锌区域的周边以及部分点状分布的低锌区域有较多孔隙。EDS分析显示锌均匀地分布在氧化铁颗粒表面,这使得锌很难被浸出。

综合上述结果可以推断:样品中的锌主要以ZnFe2O4、ZnO、铁氧化物固溶体的形式存在。锌和铁均匀分布在样品内部,增加了浸出难度。

2 实验方法及原理

实验所用草酸(pKa1: 1.25;pKa2: 4.14),柠檬酸(pKa1: 3.13;pKa2: 4.76; pKa3: 6.39),乙酸(pKa: 4.76),丙酸(pKa: 4.88),丁酸(pKa: 4.82)和戊酸(pKa: 4.84)均为分析纯,购自Sigma Aldrich,经去离子水稀释得到所需实验浓度。已知有机酸的pKa值与其酸度的变化顺序相反,且随着烷酸中碳链数的增加,其溶解度降低,戊酸的溶解度仅为49.7 g/L。

将一定浓度100 mL酸溶液置于250 mL锥形瓶中,添加一定量的粉尘于室温下浸出10 h,摇床转速为120 r/min。反应结束,滤液抽滤量取体积,粉尘浸出渣干燥并称重至恒重。使用电感耦合等离子发射光谱仪(ICP/AES)分析液相及渣相锌铁含量,用XRD分析粉尘和浸出渣的物相。

浸出率计算如下:

(1) 其中M代表锌或铁。

浸出反应的步骤如下所示:

(2)

(3)

(4)

(5)

(6) 3 结果与讨论

3.1 不同有机酸的浸出结果

图 4比较了多种有机酸在1.0 mol/L、液固化学计量比70%、室温下120 r/min浸出10 h的锌和铁浸出率。结果表明,不同种类有机酸对锌和铁的浸出效果显著不同。草酸对锌和铁的浸出率均低于1.5%,可见对2种元素均无明显的浸出效果。柠檬酸对锌的浸出率最高(71.1%),但对铁的浸出率也是最高(52.4%),因此不适合作为样品的选择浸出剂。乙酸和丙酸对锌的浸出率分别为57.3%和52.8%,但铁的浸出率也很高,分别达到40.3%和33.6%。戊酸在浸出锌和铁时有一定的选择性,锌和铁的浸出率分别为40.3%和21.0%,但与上述其他烷基酸相比效率低。通过对比发现丁酸是最有效的选择浸出剂,锌的浸出率高达49.7%,且铁的浸出率只有2.5%,该条件下的锌与铁的选择性比为19.9。

3.2 浸出渣的特征及浸出机理

3.2.1 浸出渣的特征

图 5所示为上述浸出条件下浸出渣的XRD图谱。由图 5可知,所有XRD图谱中都没有CaCO3、C和ZnO的峰。其中CaCO3和ZnO在浸出过程中与酸发生反应,石墨峰的消失是由于石墨被酸性分子吸附经过滤进入溶液造成的。所有酸浸渣的含铁相均与原粉尘的相同,但Fe和FeO的相对含量存在显著差异。因为粉尘样品主要物相就是含铁相,所以对于主要浸出产物是锌的丁酸浸出渣而言XRD图谱变化不明显。柠檬酸、乙酸、丙酸和戊酸浸出残渣中Fe和FeO的主峰变得极弱,一些副峰甚至消失。铁在上述这4种酸中的高浸出率印证了这一结果。而草酸浸出渣分为2种:大部分为粉尘浸出渣(主浸出物),还有静置放置后底部有一层非常细的颗粒物,称为副浸出渣(掉落浸出物)。草酸掉落浸出物只含草酸铁;草酸主浸出物主要含草酸铁,同时还有一定量的FeO和Fe3O4,金属铁峰的消失表明金属铁已经完全转化为草酸铁。由于化合物含量低,XRD分析草酸浸出物中未发现草酸锌。

为了进一步解释不同有机酸的浸出机理,使用SEM对所有浸出残渣的形态结构进行观察。如图 6所示,颗粒表面都形成了一些沉积物,可能是由于金属与酸根离子发生反应而形成的金属盐。图 6(a)中附着在草酸浸出物上的密集沉淀物是草酸铁,这与其XRD结果一致。柠檬酸浸出渣(图 6(b))的表面沉积物较少并存在一些裂纹,因为粉尘样品具有多孔结构,其可浸出部分几乎被全部浸出。乙酸(图 6(c))和丙酸(图 6(d))表面的大量沉积物证明了可溶性物质的浸出,丁酸浸出物(图 6(e))表面颗粒较大且孔隙度较大,而固液分离时戊酸浸出物(图 6(f))黏性较大,可能是由于过多不溶解的戊酸造成的。

3.2.2 浸出机理

在6种酸中,草酸的初始pH值最低为0.5,酸性最强,且草酸具有污染小、还原性强、络合特性好等特点,因此被广泛应用于铁氧化物的浸出。本研究中草酸溶液的最终pH值仅增加到0.58,而且ICP-OES分析液相中的铁和锌显示浸出率很低,这表明XRD分析粉尘和草酸溶液间反应生成的沉淀物抑制了粉尘浸出(见图 5)。由于室温下草酸锌(ZnC2O4·2H2O)和草酸铁(FeC2O4·2H2O)溶解度较低,2种浸出产物极易形成沉淀。

本次研究的几种酸中,柠檬酸对锌和铁的浸出能力最强,这与它的强酸性(初始pH值1.2)和优秀的络合能力有关。柠檬酸的分解分为以下3个阶段:

(7)

(8)

(9) 第一阶段解离后的酸度介于草酸和乙酸之间,第二阶段解离后的酸度与乙酸相当。柠檬酸与锌、铁离子的配位作用增加了样品的溶解度,这与IRANNAJAD等的研究结果一致[23]。第二和第三阶段解离进一步提高了柠檬酸的络合能力,从而提高了锌的浸出率。

乙酸、丙酸、丁酸、戊酸的酸度相似(初始pH值4.76~4.88),但浸出效果受多种因素影响。乙酸和丙酸的浸出效果相近,可能是由于它们的pKa、初始和最终pH(约5.2)相似。随着酸分子中碳原子数目的增加烷基链长增加,锌和铁的浸出率降低,这主要是由于酸中-CH2-结构差异造成的。酸度减小有利于锌的选择性浸出,但只适用至丁酸(最终pH值3.9)。从戊酸开始碳链增加会使铁的浸出率增加导致选择性变差,这是由于戊酸在水中溶解度较低,虽然戊酸添加量为1.0 mol/L,但实际溶液中溶解的戊酸量不足0.5 mol/L(最终pH值4.2)。丁酸对锌与铁的选择性比高达19.9,而以往报道的传统无机酸在室温下对铁的溶解性较高,对锌的选择性较低。例如,LANGOVÁ和MATÝSEK得到0.3 mol/L H2SO4在260 ℃对电弧炉粉尘浸出100 min后锌与铁的选择性比为9[24]。KELEBEK等在使用pH约为2的H2SO4时对大粒径和小粒径的转氧炉粉尘分别进行浸出,得到的锌与铁的选择性比分别为4.5和15.8[25]。相比之下,丁酸很有潜力用作冶金领域样品中选择性提取锌的浸出剂。

3.3 丁酸的酸浸条件优化及其在钢铁含锌粉尘中的应用

3.3.1 丁酸浸出条件的初步优化

鉴于初步研究中丁酸对锌和铁浸出的较强选择性,进一步对丁酸浓度和液固化学计量比进行优化研究,其余浸出条件为室温、120 r/min浸出10 h,结果见图 7所示。

由图 7可知,转炉粉尘中锌的浸出率在低酸浓度条件下(0.1~0.5 mol/L)随液固化学计量比的增加显著增长,但浓度超过1.5 mol/L之后液固化学计量比对浸出率几乎无影响。另一方面,铁的浸出率在低酸浓度下(0.1~0.5 mol/L)也随液固化学计量比的增加而增加,但在0.5 mol/L酸浓度、70%和90%液固化学计量比条件下相差不大;当酸浓度增加至1.0 mol/L,铁浸出率低于5%,与液固化学计量比无明显关联。因此铁的浸出率可直接由酸浓度控制,在1.0 mol/L酸浓度时选取较高液固化学计量比可获得较高的锌浸出率。综合考虑最终选择1.5 mol/L酸浓度和70%液固化学计量比为较优条件,此时锌和铁的浸出率分别为51.2%和0.5%,锌与铁的选择性比极高,浸出液中锌与铁的质量比为12.6。该条件下的浸出渣经干燥至恒重,质量为原粉尘样品的93.1%。经ICP/AES分析,其中铁含量增加到60.4%,而锌含量也降低到了3.4%。

3.3.2 丁酸在钢铁含锌粉尘中的应用展望

鉴于初步研究中丁酸对锌和铁浸出的较强选择性,本研究拟设计一个浸出系统(见图 8)用于从含锌冶金粉尘中选择性除锌,以用于未来工业实施。

1)将丁酸泵入搅拌槽反应器,通过传送带添加粉尘。

2)在第一个反应器中浸出一定时间后,滤液进入渗滤液收集器并进行酸再生回收。

3)分离得到的粉尘浸出物经干燥后收集待进一步后续处理。

4 结论

1)通过对原始粉尘样品的表征,发现锌和铁均匀分布在样品中,所以很难实现选择性浸出锌。锌以氧化锌和铁酸锌的形式存在,而铁则由金属铁,方铁矿和磁铁矿组成。

2)在草酸、柠檬酸、乙酸、丙酸、丁酸和戊酸中,丁酸从粉尘中选择性浸出锌的效果较优。

3)不同有机酸对粉尘的浸出机理不同。草酸易生成沉淀物抑制浸出,柠檬酸的螯合性很强,能促进浸出,但锌的浸出选择性差,烷基酸对锌的选择性随碳链增长而增大,到丁酸达到最佳,而戊酸在室温下溶解度较低无法达到设定酸浓度进行对比。

4)通过XRD和SEM对浸出残留物的观察,有机酸先腐蚀了样品表面,然后渗透到样品中。在浸出残渣的表面上形成一些沉积物,这进一步抑制了锌的反应。

5)对丁酸进行初步优化,在1.5 mol/L酸浓度和70%液固化学计量比条件下锌浸出率达到51.2%,铁浸出率仅为0.5%,浸出液中锌与铁的质量比为12.6。

6)丁酸因其高效选择性具有较好应用前景,本文设计了一个丁酸浸出工艺流程图用于未来钢铁冶金行业含锌冶金粉尘的处理。

-

表 1 试验用煤的工业分析和粘结性指数

煤种 挥发分 灰分 固定碳 水分 GR, I A 37.47 8.25 52.28 2.00 66.60 B 32.65 8.65 55.45 3.25 0.00 表 2 试验用煤的元素分析/%

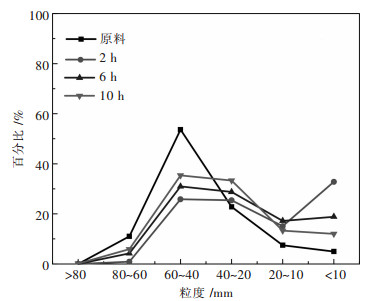

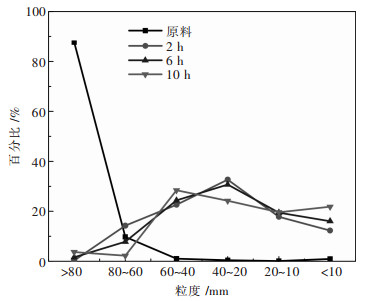

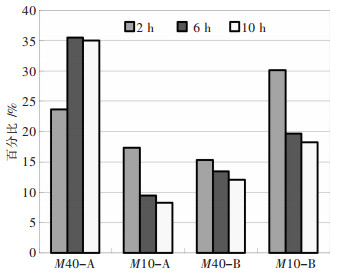

煤种 Cd Hd Nd Od Sd A 78.91 5.31 1.05 14.17 0.56 B 80.22 5.49 1.15 12.34 0.80 表 3 块煤在不同炼焦时间下的平均粒度和降解度

煤种 炼焦时间 MPS/mm DR/% A煤 0h 43.04 0.00 A煤 2 h 26.70 37.95 A煤 6 h 31.53 26.74 A煤 10 h 35.01 18.66 B煤 0h 77.77 0.00 B煤 2 h 37.67 51.57 B煤 6 h 33.55 56.86 B煤 10 h 31.56 59.42 表 4 炼焦炉内条件下形成半焦的微观矿相结构/%

编号 焦炭结构 未成焦煤 矿物及杂质 类丝炭 各向异性 各向同性 微粒镶嵌结构 中粒镶嵌结构 粗粒镶嵌结构 残碳颗粒 变形颗粒 灰渣 铁质 半透明矿渣 A-2 0 2.90 16.22 0 1.16 0 2.03 75.66 0 2.03 0 0 A-6 0.33 18.01 44.36 5.65 3.31 10.14 13.34 0.34 0 4.17 0 0.33 A-10 0.90 9.14 69.90 2.91 3.24 1.29 11.33 0 0 1.29 0 0 B-2 32.14 3.91 21.75 0 0 0 5.84 0 27.92 8.44 0 0 B-6 25.65 5.52 59.06 0 0 0 8.47 0 0 1.30 0 0 B-10 26.84 10.13 44.05 0 1.47 0 11.14 0 3.29 2.78 0.30 0 注:A-2表示在小焦炉被2 h的A种煤,B-2表示2 h的B种煤,以此类推. 表 5 熔融气化炉内大于6.3 mm风口焦试样的微观矿相结构

编号 焦炭结构 未成焦煤 矿物及杂质 类丝炭 各向异性 各向同性 微粒镶嵌结构 中粒镶嵌结构 粗粒镶嵌结构 残碳颗粒 未变原煤 灰渣 铁质 半透明矿渣 > 16mm 0 4.49 5.44 12.18 6.73 1.30 17.3 0 51.92 0.64 0 10~16 mm-1# 2.41 3.78 16.52 5.50 26.03 8.60 20.79 0.90 15.48 0 0 10~16 mm-2# 0 3.24 4.21 6.47 0.65 2.59 13.59 0.11 60.84 1.83 6.47 6.3~10 mm-1# 9.38 7.82 3.91 22.26 8.16 0.78 11.72 16.03 19.16 0.78 0 6.3~10 mm-2# 4.51 5.06 1.84 14.58 27.54 4.01 15.05 9.81 13.72 0.26 3.62 6.3~10 mm-3# 0.64 10.81 3.84 10.25 8.24 0.98 10.46 0.12 48.09 1.06 5.51 表 6 熔融气化炉内 < 6.3 mm风口焦试样的微观矿相结构

编号 焦炭结构 未成焦煤 矿物及杂质 类丝炭 各向异性 各向同性 微粒镶嵌结构 中粒镶嵌结构 粗粒镶嵌结构 残碳颗粒 未变原煤 灰渣 铁质 半透明矿渣 1~6.3 mm-1# 21.97 5.22 0 7.41 9.39 0 14.28 8.71 27.07 2.45 3.50 1~6.3 mm-2# 20.62 6.53 1.02 2.01 8.33 5.49 19.78 5.91 24.90 3.26 2.15 0.6-1 mm-1# 25.84 1.05 2.23 1.58 3.46 0.61 10.55 2.19 42.52 6.46 3.51 0.6~1 mm-2# 23.97 3.39 0.68 4.21 3.05 0 9.08 4.71 42.16 5.72 3.03 -

[1] 周渝生, 钱晖, 张友平, 等.现有主要炼铁工艺的优缺点和研发方向[J].钢铁, 2009, 44(2): 1-10. http://cpfd.cnki.com.cn/Article/CPFDTOTAL-ZGJS200804001014.htm [2] Kurunov I. F. The direct production of iron and alternatives to the blast furnace in iron metallurgy for the 21st century[J]. Metallurgist, 2010, 54(6): 27-32. https://www.researchgate.net/publication/225468675_The_direct_production_of_iron_and_alternatives_to_the_blast_furnace_in_iron_metallurgy_for_the_21st_century

[3] 赵晨熙, 张群, 徐金梧, 等. COREX冷煤气成分预测的二步建模方法[J].北京科技大学学报, 2012, 34(10): 1184-1189. http://www.cnki.com.cn/Article/CJFDTOTAL-BJKD201210013.htm [4] 李维国. COREX-3000生产现状和存在问题的分析[J].宝钢技术, 2008(6): 11-18. http://www.cnki.com.cn/Article/CJFDTOTAL-BGJS200806004.htm [5] 湛文龙, 吴铿, 徐万仁, 等. COREX熔融气化炉中块煤裂化现象[J].钢铁, 2013, 48(1): 20-23. http://www.cnki.com.cn/Article/CJFDTOTAL-GANT201301006.htm [6] Kumar P P, Gupta P K, Ranjan, M. Operating experiences with corex and blast furnace at JSW steel Ltd[J]. Ironmaking and Steelmaking, 2008, 35(4): 260-263. doi: 10.1179/174328108X301679

[7] Kumar P. P., Raju B. S. L., Ranjan, M. Characteristics of coal required for superior performance of Corex ironmaking [J]. Ironmaking and Steelmaking, 2011, 38(6): 412-416. doi: 10.1179/1743281211Y.0000000008

[8] 王玉明.块煤粒径与COREX-3000生产指标的关系[J].宝钢技术, 2012 (2): 15-18. http://www.cnki.com.cn/Article/CJFDTOTAL-BGJS201202006.htm [9] 朱丰, 张生富, 彭海军, 等. COREX炼铁工艺用煤的热解特性及气体生成规律[J].煤炭学报, 2013, 38(1): 211-216. http://www.cnki.com.cn/Article/CJFDTOTAL-MTXB2013S1036.htm [10] 王文泽, 湛文龙, 刘肖, 等.高炉入炉焦炭高温反应特性的研究[J].有色金属科学与工程, 2014(1): 9-13. http://ysjskx.paperopen.com/oa/DArticle.aspx?type=view&id=201312008 [11] 刘殊远, 汪印, 武荣成, 等.热态半焦和冷态半焦催化裂解煤焦油研究[J].燃料化学学报, 2013, 41(9): 1041-1049 http://www.cnki.com.cn/Article/CJFDTOTAL-RLHX201309003.htm [12] Kumar P P, Raju B S L, Ranjan M. Characteristics of coal required for superior performance of COREX ironmaking[J]. Ironmaking and Steelmaking, 2011, 38(6): 412-416. doi: 10.1179/1743281211Y.0000000008

[13] Kumar P P, Barman S C, Reddy B M, et al. Raw materials for COREX and their influence on furnace performance[J]. Ironmak-ing and Steelmaking, 2009, 36(2): 87-90. doi: 10.1179/174328108X378152

[14] 李强, 张玉栋, 张丽娟. COREX竖炉布料规律的数学模型[J].东北大学学报:自然科学版, 2011, 32(11): 1592-1594. http://www.cnki.com.cn/Article/CJFDTOTAL-DBDX201111017.htm [15] Pal S, Lahiri A K. Mathematical model of COREX melter gasifier: part I. steady state model[J]. Metallurgical and Materials Transactions: B, 2003, 34(2): 103-114. https://www.researchgate.net/publication/225583823_Mathematical_model_of_COREX_melter_gasifier_Part_I_Steady-state_model

[16] 郭艳玲, 徐万仁, 李肇毅. COREX熔融气化炉煤焦混合料柱特性研究[J].宝钢技术, 2010 (5): 24-27. http://www.cnki.com.cn/Article/CJFDTOTAL-BGJS201005011.htm

下载:

下载: