Numerical simulation of supporting scheme in deep soft roadway

-

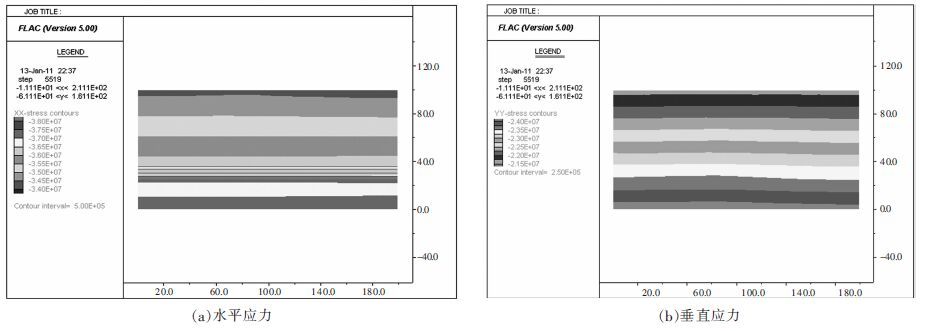

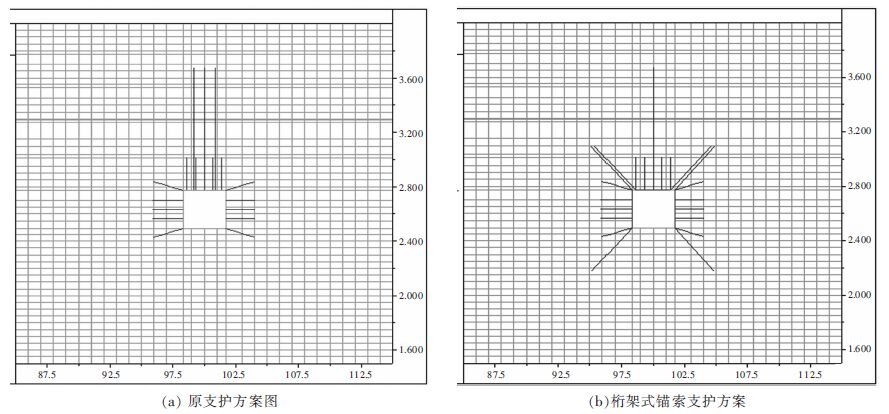

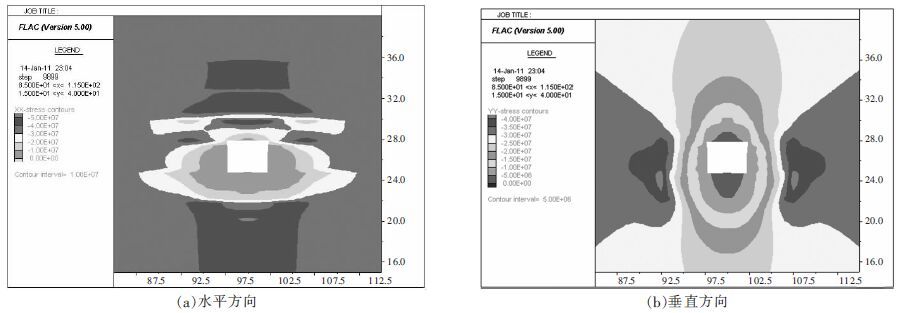

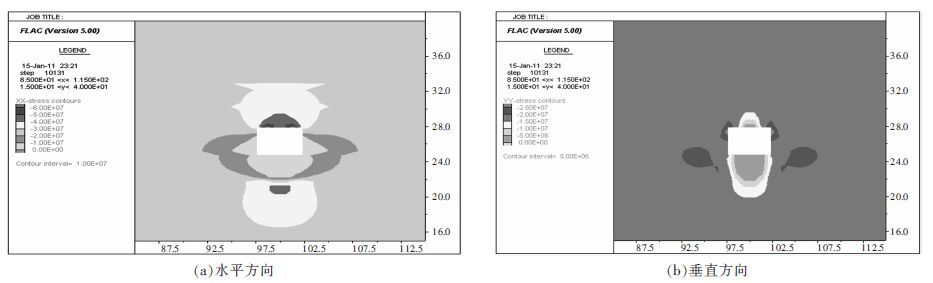

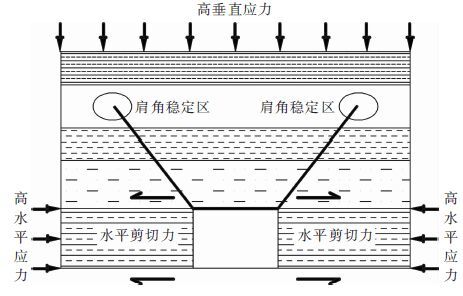

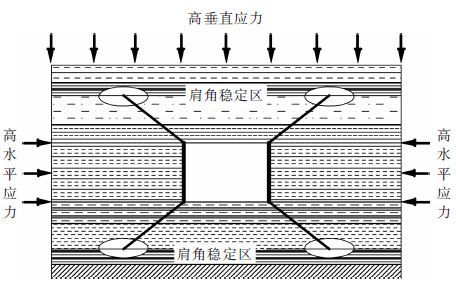

摘要: 为确定某煤矿安全生产的巷道支护方案,以其601综采工作面顺槽开挖为背景,利用FLAC2D数值软件模拟,并对比分析了有无预应力桁架两种支护方案下巷道围岩的位移.应力和塑性区分布状态. 结果表明:采用原支护方案时,巷道顶板.两肩角及两帮等多处出现应力集中,塑性区域较大,并且巷道的变形量大,两帮的变形位移高达1 m;采用预应力桁架支护时,巷道顶板应力分布状况良好,只有两肩角及两帮深处岩体出现了应力集中,但塑性区域明显减小,巷道变形有较大改善,两帮变形位移降至0.0106 m,深部软岩巷道的损伤变形降低显著,在实际应用中取得了良好的效果,为煤巷支护设计提供了一种可行的方法.Abstract: In order to determine a roadway supporting schemes of coal mine safety production, base on the background of the excavation in the mining gateway of 601 fully mechanized coal mining face in a coal mine, prestressed truss supporting scheme and non-prestressed truss supporting scheme of surrounding rock of roadway displacement, stress distribution and plastic zone of surrounding rock are compared and analyzed by FLAC2D numerical simulation software of theoretical calculation. The results show that using the original support scheme, stress concentration occurs in tunnel roof , roof corners and both sides of the roadway. Plastic zone is large and roadway undergoes great deformation. Displacements on both sides of the roadway are up to 1m. When adopting prestressed truss support, the stress distribution in the tunnel roof is in good condition, but concentration of stress occurs in the roof corners and sides of the roadway rock stress. Plastic zone is distinctly smaller and the deformation of roadway improves substantially. Deformation displacements on both sides of the roadway are reduced to 0.0106m, so the deformation of deep soft roadway decreased significantly. A feasible method for the design of the mining gateway support is provided and performs well in practical application.

-

Keywords:

- deep soft roadway /

- numerical simulation /

- supporting design /

- prestressed truss

-

7075铝合金是典型的航空用铝合金,具有强度高、质量轻、耐腐蚀等多重特性,对组织和性能要求较高[1-2]。近年来,7075铝合金不断实现民用化,已经应用于制造汽车零部件[3],在代替部分汽车用高强钢方面应用潜力巨大。7075铝合金的塑性变形工艺以挤压为主,目前有关7075铝合金轧制工艺的研究还较少,有关热处理工艺[2,4]和应力腐蚀性能[5]的研究较多。因此,有必要对7075铝合金的轧制工艺开展研究,找到实现批量化生产7075铝板的较优轧制工艺,进一步提高7075铝板的生产效率,优化生产成本。异步轧制是通过加入非对称元素,在轧制变形区内形成“搓轧区”,产生较大的剪切变形量[6]。在异步轧制基础上,又发展出了水平错位等速轧制和龙形轧制[7]等非对称轧制方法。异步轧制在极薄带材轧制方面表现出较大潜力,东北大学在20世纪80年代就采用异步轧制技术用直径90 mm的工作辊轧制出0.005 mm厚度的铜箔[8]。在铝板异步轧制方面,有实验表明异步轧制对AA 5454铝板力学性能改善不明显[9],但KAZEMI-NAVAEE等[10]的实验证实异步轧制对冷轧7075铝板的屈服强度和抗拉强度有提升作用,可以作为7075铝板轧制工艺改善的探索方向。以上实验的共同特点是轧制累积变形率均不足70%,因此有必要进行更高轧制累积变形率的异步轧制实验,并与常规轧制的铝板的性能对比,为进一步开发更高效的7075铝板轧制工艺提供借鉴。

本文采用异速轧制和常规轧制2种方式,以不同轧制累积变形率(最高85%)对7075铝板进行轧制对比实验。考察了异速比对单道次异速轧制轧板弯曲程度的影响;采用相同道次分配和异速比,在不同轧制累积变形率的情况下,对比研究了异速轧制和常规轧制对7075铝板变形情况、晶粒组织、断口形貌和力学性能的影响。

1 实验部分

本文所用轧制板坯为7075铝合金T6态成品板,经锯切和铣面后获得板坯尺寸为300 mm × 100 mm × 20 mm(长 × 宽 × 厚)。实验所用轧机为二辊轧机,可在线调整异速比。坯料加热采用台车式电阻炉,加热工艺为440 ℃保温6 h。

实验分2步进行:第1步进行异速比对轧板弯曲情况影响的轧制实验;第2步进行异速轧制和常规轧制的多道次轧制实验。第1步实验采用的异速比分别为1.02、1.06、1.12和1.16,每个异速比单道次轧制1块铝板,道次压下量设为4 mm、变形率20%,轧后立即水淬,再进行轧板弯曲程度测量。第2步进行多道次轧制实验,分2组进行,第1组为常规轧制,第2组为异速轧制,道次分配相同,如表1所列,异速轧制下轧辊转速快于上轧辊。每组实验轧制4块板,分别轧3、4、5、6道次,设计累积变形率分别为60%、75%、85%、95%。轧后铝板立即水淬,再进行T6热处理,工艺为460 ℃固溶1 h,再在120 ℃进行24 h时效处理。

表 1 道次分配参数和设计累积变形率Table 1. Pass allocation parameters and design cumulative deformation rates轧制道次 设计道次变形量/mm 设计累积变形率/% 1 4 20 2 4 40 3 4 60 4 3 75 5 2 85 6 2 95 金相试样经磨抛后,采用4% HF + 6% HCl + 10% HNO3 + 80% H2O溶液侵蚀,在Observer 3 m ZEISS光学显微镜下观察金相组织。断口扫描电镜观察采用日立 SU5000热场式场发射扫描电镜, 力学性能测试采用 MTS 810 力学实验机。屈服强度和抗拉强度测量执行GB/T 228—2010《金属材料拉伸试验室温试验方法》,因为异速轧制后轧板呈现一定程度的弯曲,尽管只在较平直的位置截取拉伸试样,仍无法实现试样完全平直,因此,本文中异速轧制轧板的屈服强度和抗拉强度仅供对比参照。

2 轧板弯曲情况

因为轧辊转速不同,轧板与轧辊接触的表面金属流动速度也不同,造成异速轧制轧板向慢速辊方向弯曲,所以对异速轧制轧板弯曲程度的表征和分析十分重要,也是改进工艺、克服弯曲所建立的数学模型的重要基础。为尝试建立轧板弯曲程度与异速比的数学关系,将轧板水平放置,使其开口朝向水平底面,轧板弯曲内面形成一个圆弧,测量该圆弧最高点距离水平底面距离y,以及圆弧即轧板弯曲内面与水平底面的两接触点距离x,用y/x值描述轧板弯曲程度[11],测量方法如图1(a)所示。

所得y/x值随异速比变化的情况见图1(b),异速轧制轧板y/x值随着异速比增大而先升高后降低,在异速比1.12时达到最高0.222 18,之后在异速比1.16时降至0.191 14。JIANG等[12]对异步轧制厚钢板进行了有限元模拟(压下率12.8%),当异速比达到1.15时,轧板弯曲程度最大。由于轧机能力所限,本研究未能进行更大异速比的轧制,因此无法直接判断随着异速比进一步增大,轧板弯曲程度是否会持续减弱甚至消失。但是,采用其他工艺方法能够减弱甚至消除异速轧制轧板弯曲已被证实。例如龙形轧制[13],亦称蛇形轧制,是一种非对称轧制,在异步轧制的基础上,将转速不同的两辊在水平方向上前后偏移,对板材增加一个弯矩以抵消可能的弯曲,通过调节异速比、错位量、压下量等参数,可以实现无弯曲的轧制[14]。郑细昭等[15]采用非线性回归得到了龙形轧制中轧板弯曲控制的最佳错位量的数学模型。

目前,轧板弯曲程度多采用弯曲曲率表征。FU等[16]建立了龙形轧制轧板曲率预测的解析模型,针对轧板曲率变化进行了大量计算。相比于曲率法,采用y/x值表征轧板弯曲程度的操作相对简便,可以较快地建立弯曲程度与异速比的数学关系。与用轧板的弯曲曲率表征轧板弯曲程度相同,采用y/x值表征轧板的弯曲程度同样是将轧板弯曲的弧线设想为一个标准圆形的其中一段,使得计算简化。但是,对于轧板实际弯曲的弧线形状以及适用的数学表达,目前还无具体研究结果。

结合第1步实验的结果,异速比1.02对轧板的影响较小,不足以反映异速轧制的特征;异速比1.12导致轧板弯曲太大,进行多道次轧制存在咬入困难,并且可能损坏设备;异速比1.16已经达到设备可调的上限。因此,为顺利进行实验和保护设备安全,选择异速比1.06进行第2步实验。第2步实验中异速轧制铝板的表面形貌如图2所示。

3 轧制对比实验

3.1 实际轧制变形率

为对比异速轧制和常规轧制后轧板的实际累积变形率是否存在差异,异速轧制和常规轧制采用了相同的道次分配方案。由于轧机存在一定的弹跳现象以及轧制能力有限,导致轧板的实际累积变形率达不到设计累积变形率。因此,本研究中每道次轧制的设计累积变形率偏大,以求达到预想的实际累积变形率,每道次轧制的设计累积变形率和实际累积变形率如图3所示。

由图3可见,常规轧制轧板的实际累积变形率与设计累积变形率相差8%~10%,这个数值在第3道次至第6道次都比较稳定。异速轧制轧板的实际累积变形率在第3道次至第5道次与设计累积变形率相差6%~8%,第6道次时相差10%。异速轧制和常规轧制轧板每道次的实际累积变形率相差不大,在1%~2%之间。

在相同设计累积变形率的情况下,异速轧制与常规轧制所得的实际累积变形率不同的结果此前还未见报道。在同样存在异速轧制的情况下,雷军义等[17]在对龙形轧制的研究中提出辊缝补偿量的概念,即龙形轧制与常规轧制的实际变形量存在差异,并认为该辊缝补偿量与异速轧制无关。本研究中异速轧制与常规轧制所得的实际累积变形率相差不大,所以后续实验仍将同道次的两种轧板进行比较。

3.2 晶粒组织

异速轧制和常规轧制的轧板经T6热处理后,沿厚度方向在轧板中心部切取平行于轧向的侧面观察晶粒组织。如图4所示,异速轧制和常规轧制在第3道次时的T6板中心部以变形组织为主,此时实际累积压下率约为51%,原始板坯中的晶粒组织被破坏,只能看到垂直于轧制方向的条带状的变形组织。对比图4(a)和图4(e)可知,3道次异速轧制的T6板中心部变形更严重,组织变形更明显,变形条带更清晰、密集,但未观察到文献[10]中描述的剪切变形带。因为累积的变形储能有限,异速轧制和常规轧制3道次的轧板都无法在T6热处理过程中实现充分完全的再结晶,在T6热处理后仍存在明显的变形组织。这种以变形组织为主的特征在4道次轧制的T6板中没有明显改变。

![]() 图 4 T6板晶粒组织(图中箭头所示为轧制方向):(a)常规轧制3道次;(b)常规轧制4道次;(c)常规轧制5道次;(d)常规轧制6道次;(e)异速轧制3道次;(f)异速轧制4道次;(g)异速轧制5道次;(h)异速轧制6道次(b)symmetrical rolling 4 passes; (c)symmetrical rolling 5 passes; (d)symmetrical rolling 6 passes; (e)asymmetrical rollingFigure 4. Microstructure of T6 plates(the arrows in the figures show the rolling direction):(a)symmetrical rolling 3 passes;3 passes; (f)asymmetrical rolling 4 passes; (g)asymmetrical rolling 5 passes; (h)asymmetrical rolling 6 passes

图 4 T6板晶粒组织(图中箭头所示为轧制方向):(a)常规轧制3道次;(b)常规轧制4道次;(c)常规轧制5道次;(d)常规轧制6道次;(e)异速轧制3道次;(f)异速轧制4道次;(g)异速轧制5道次;(h)异速轧制6道次(b)symmetrical rolling 4 passes; (c)symmetrical rolling 5 passes; (d)symmetrical rolling 6 passes; (e)asymmetrical rollingFigure 4. Microstructure of T6 plates(the arrows in the figures show the rolling direction):(a)symmetrical rolling 3 passes;3 passes; (f)asymmetrical rolling 4 passes; (g)asymmetrical rolling 5 passes; (h)asymmetrical rolling 6 passesTAJALLY等[18]的研究表明,当冷轧变形量达到71%时,在265 ℃保温条件下仅需70 min即可完成再结晶。在图4(c)和图4(g)中,异速轧制和常规轧制在第5道次的T6板中心部已经可以看到变形组织减少,再结晶晶粒开始增加。经过6道次异速轧制和常规轧制的轧板,实际累积变形率分别达到83%和85%,轧制变形严重,累积了较充分的变形储能,而变形储能是再结晶的动力,因此在T6热处理过程中发生了较充分的静态再结晶。在图4(d)和图4(h)中,异速轧制和常规轧制的轧板经过6道次轧制和T6热处理后,中心部变形组织已经基本消除,转变为长条状的晶粒组织,尽管仍有垂直于轧制方向伸长的特征,但已可见比较清晰的晶粒和晶界。7075是Al-Zn-Mg-Cu合金,其主要强化模型为沉淀强化,细晶强化即晶界强化的效果较弱[19]。

3.3 断口形貌

图5所示为异速轧制和常规轧制第3道次和第6道次轧板T6热处理后的拉伸断口的SEM形貌。在7075铝合金固溶过程中,部分第二相(如Al7Cu2Fe)不会溶解,随着保温时间延长,Mg2Si会逐渐粗化长大[20]。结合图4可知,异速轧制和常规轧制的轧板第3道次的T6板中因为主要是变形组织,所以图5(a)和图5(d)中都有垂直于轧制方向的大量撕裂棱,局部可见由于大尺寸第二相颗粒造成的孔洞。由图5(b)和图5(e)可见,垂直于轧制方向的撕裂棱明显减少,以大小不一的韧窝断口和沿晶断口为主,是未溶相粒子和时效过程中弥散析出的第二相粒子共同存在的结果;虽然也可见第二相颗粒造成的孔洞,但相比图5(a)和图5(d)中都明显减少,是变形破碎大尺寸第二相颗粒的结果。对比可见,图5(e)中韧窝更多,大小韧窝相套,韧窝尺寸和深度的分布比图5(b)中更均匀。

![]() 图 5 T6板断口SEM形貌:(a)常规轧制3道次;(b)常规轧制6道次;(c)常规轧制6道次,局部高倍形貌, 箭头所示为第二相粒子;(d)异速轧制3道次;(e)异速轧制6道次;(f)异速轧制6道次,局部高倍形貌, 箭头所示为第二相粒子Figure 5. Fracture SEM morphology of T6 plates: (a)symmetrical rolling 3 passes; (b)symmetrical rolling 6 passes; (c)symmetrical rolling 6 passes, partial high magnification, the arrows show the second phase particles;(d)asymmetrical rolling 3 passes;(e)asymmetrical rolling 6 passes;(f)asymmetrical rolling 6 passes, partial high magnification, the arrows show the second phase particles

图 5 T6板断口SEM形貌:(a)常规轧制3道次;(b)常规轧制6道次;(c)常规轧制6道次,局部高倍形貌, 箭头所示为第二相粒子;(d)异速轧制3道次;(e)异速轧制6道次;(f)异速轧制6道次,局部高倍形貌, 箭头所示为第二相粒子Figure 5. Fracture SEM morphology of T6 plates: (a)symmetrical rolling 3 passes; (b)symmetrical rolling 6 passes; (c)symmetrical rolling 6 passes, partial high magnification, the arrows show the second phase particles;(d)asymmetrical rolling 3 passes;(e)asymmetrical rolling 6 passes;(f)asymmetrical rolling 6 passes, partial high magnification, the arrows show the second phase particles图5(c)为图5(b)局部的高倍形貌,图5(f)为图5(e)局部的高倍形貌,图5(c)和图5(f)中均可见大量尺寸小于 1 μm 的韧窝,并且在韧窝底部出现弥散析出的尺寸小于 100 nm 的微小第二相粒子,图5(f)中的韧窝尺寸较图5(c)中更小。

3.4 屈服强度和抗拉强度

异速轧制和常规轧制的轧板经T6热处理后的屈服强度和抗拉强度如图6所示,异速轧制轧板T6热处理后的屈服强度和抗拉强度均高于常规轧制的轧板,但提高幅度不大。此结果与KRANER等[21]的铝板异步轧制实验结果相似,但对纯铝板进行的异步轧制实验发现,异步轧制轧板的强度明显高于对称轧制[22]。

同时,常规轧制第4道次的轧板T6热处理后的强度最高,第5道次和第6道次轧制的轧板T6热处理后的强度不再上升,而异速轧制的轧板T6热处理后的强度随轧制道次增加,轧制累积变形率持续升高。据文献[23]报道,7075铝合金轧板在常规轧制累积变形率达到80%时,强度不再升高反而降低。本研究中常规轧制第4道次时累积变形率为67%,此后随累积变形率升高,T6热处理后的轧板强度不再明显变化。结合文献[23]与本研究中常规轧制的结果可知,7075铝合金轧板在常规轧制达到一定变形量时会出现强度峰值,出现峰值的变形量可能因板坯状态、均热条件和道次分配等的差异而在不同的实验中存在差异。但是,异速轧制的7075铝板T6热处理后的强度随轧制累积变形率升高而持续增大,未出现强度达到峰值后不再升高的情况(如图6所示)。

4 结论

本文采用4个不同的轧制累积变形率,最高轧制累积变形率达到80%以上,对比研究了异速轧制和常规轧制对7075铝板变形情况、晶粒组织、断口形貌和力学性能的影响,得到以下结论:

1)当轧制异速比从1.02升至1.12时,y/x值达到最高0.222 18,此时轧板弯曲程度最大,之后在异速比1.16时y/x值降至0.191 14,即轧板弯曲程度较异速比1.12时减弱。

2)异速轧制和常规轧制采用了相同的设计累计变形率,但轧板实际累计变形率相差1%~2%。

3)异速轧制和常规轧制的7075铝板在累积实际变形率分别达到67%和69%时,T6热处理后的晶粒组织以变形组织为主;在累积实际变形率达到约76%时,随着累积实际变形率增加,再结晶更加充分,T6热处理后的7075铝板中以伸长的条状晶粒为主。

4)经过6道次异速轧制和常规轧制的7075铝板,T6热处理后,在断口中可见大量尺寸小于1 μm的韧窝,并且在韧窝底部出现弥散析出的尺寸小于100 nm的微小第二相粒子,异速轧制7075铝板中韧窝尺寸较常规轧制7075铝板中更细小。

5)与常规轧制相比,采用异速轧制的7075铝板的强度高,但提高幅度不大;7075铝合金轧板在常规轧制达到一定变形量时会出现强度峰值,而异速轧制的7075铝板的强度随轧制累积变形率升高而持续提高。

-

表 1 煤层顶底板情况表

顶板名称 岩石名称 厚度/m 岩性特征 老顶 粉、细砂岩互层 2.0~4.0 灰黑色、薄层状粉砂岩与细砂岩互层 直接顶 粉砂岩 8.0~10.0 黑色、薄层状、水平层理,产少量植物化石,夹煤线 伪顶 炭质泥岩 0.1~0.3 黑色、鳞片状、染手 伪底 泥岩 0.1~0.3 灰黑色鳞片状泥岩 直接底 泥岩 2.0 褐色、团块状泥岩、产植物化石,遇水膨胀 老底 粉砂岩 12.0 灰黑色,致密,产少量植物化石及菱铁结核 表 2 模型中各岩体等效参数

围岩 平均岩层厚度/m 容重/(g.cm-3) 单轴抗压强度/MPa 单轴抗拉强度/MPa 粘聚力/MPa 内摩擦角/(°) 弹性模量/GPa 泊松比 粉砂岩与细矿岩 3 2.64 40 1.80 4.25 37 11.65 0.21 粉砂岩(夹镜煤煤线) 10 2.5 18 1.81 2.70 36 11.05 0.22 B4煤 2.8 1.6 12 1.43 1.50 18 0.45 0.42 炭泥岩 3 2.32 14 1.12 0.52 30 4.38 0.32 粉砂岩 20 2.5 18 1.81 2.70 36 11.05 0.22 表 3 支护方案参数

方案 位置 支护结构 间排距/(m×m) 长度/m 直径/m 预紧力/kN 锚固力/kN 原方案 顶板 锚杆 0.750×0.800 2.600 0.022 30 120 锚索 1.250×0.850 9.000 0.022 ~ 120 两帮 锚杆 0.700×0.800 2.600 0.022 20 80 新方案 顶板 锚杆 0.750×0.800 2.600 0.022 30 120 锚索 1.250×0.850 9.000 0.022 ~ 120 桁架锚索 2.500×1.600 6.300 0.01524 60 120 两帮 锚杆 0.700×0.800 2.600 0.022 20 80 桁架锚索 2.500×1.600 6.300 0.01524 60 120 表 4 支护结构物理参数

支护结构 弹性模量E/GPa 抗拉强度Ft/kN 横截面积A/(10-4·m2) 锚固粘结力cg/(kN·m-1) 摩擦角φg/(°) 锚固刚度kg/GPa 外圈周长Pg/m 锚索 200 300 3.8 1000 32 10 0.08796 锚杆 200 300 3.8 1000 32 10 0.08796 桁架锚索 200 250 1.8 800 32 10 0.08796 表 5 两方案巷道围岩位移量对比

支护方案 顶板下沉量 底鼓量 帮部位移量 原方案 0.074m 0.24m 1m 新方案 0.012m 0.101m 0.0106m 新方案占旧方案比例 16.2% 42.1% 1.1% -

[1] 马蓓蓓,鲁春霞,张雷. 中国煤炭资源开发的潜力评价与开发战略[J]. 资源科学,2009,31(2):224-230. http://www.cnki.com.cn/Article/CJFDTOTAL-ZRZY200902008.htm [2] 马其华,王宜泰. 深井沿空巷道小煤柱护巷机理及支护技术[J]. 采矿与安全工程学报,2009,26(4):520-523. http://www.cnki.com.cn/Article/CJFDTOTAL-KSYL200904029.htm [3] 饶运章,钟健,桂旺华,等. 龙门山矿区套孔应力解除法测定原岩应力[J]. 有色金属科学与工程,2013(3):68-72. http://ysjskx.paperopen.com/oa/DArticle.aspx?type=view&id=201303022 [4] 王新军,翟加文. 论深部软岩巷道支护技术系统工程方法[J]. 矿业安全与环保,2012,39(5):77-80. http://www.cnki.com.cn/Article/CJFDTOTAL-ENER201205025.htm [5] 陈荣德,张荪铭,胡立国,等. 高强度高预应力耦合支护技术在深井软岩巷道中的应用[J]. 煤矿开采,2008,13(1):46-48. http://www.cnki.com.cn/Article/CJFDTOTAL-MKKC200801018.htm [6] 司文,张念超,张慧君,等. 高地压软岩巷道围岩强化控制技术[J]. 煤矿安全,2012,43(8):85-88. http://www.cnki.com.cn/Article/CJFDTOTAL-MKAQ201208027.htm [7] 张炜,张东升,王旭锋,等. 大断面回采巷道锚梁网索联合支护效果分析[J]. 煤炭工程,2008(7):64-66. http://www.cnki.com.cn/Article/CJFDTOTAL-MKSJ200807034.htm [8] 陈蓥,张宏伟,张哲,等. 护巷煤柱宽度与回采巷道支护的数值模拟研究[J]. 矿业安全与环保,2011,38(5):4-7. http://www.cnki.com.cn/Article/CJFDTOTAL-ENER201105003.htm [9] 赵奎,邵海,徐峰,等. 某铜矿不同采矿进路布置开采稳定性数值模拟[J]. 有色金属科学与工程,2013(2):46-50. http://ysjskx.paperopen.com/oa/DArticle.aspx?type=view&id=201211015 [10] 罗立强,王卫军,余伟健,等. 高应力软岩巷道预应力桁架锚索支护技术[J]. 湖南科技大学学报:自然科学版,2012,27(1):17-22. http://www.cnki.com.cn/Article/CJFDTOTAL-XTKY201201005.htm [11] 彭剑文,赵奎,曹宗权,等. FLAC和神经网络在隧道位移反分析中的应用[J]. 有色金属科学与工程,2011(6):79-82. http://ysjskx.paperopen.com/oa/DArticle.aspx?type=view&id=201110010 [12] 余伟健,王卫军,文国华,等. 深井复合顶板煤巷变形机理及控制对策[J]. 岩土工程学报,2012(8):1501-1508. http://www.cnki.com.cn/Article/CJFDTOTAL-YTGC201208026.htm [13] 王连国,缪协兴,董健涛,等. 深部软岩巷道锚注支护数值模拟研究[J]. 岩土力学,2005,26(6):983-985. http://www.cnki.com.cn/Article/CJFDTOTAL-YTLX200506035.htm [14] 王春波,杨万斌. 基于数值模拟分析的巷道支护设计[J]. 煤炭工程,2009(5):60-63. http://www.cnki.com.cn/Article/CJFDTOTAL-MKSJ200905031.htm [15] 饶运章,徐灵彬. 某铜矿逆断层对围岩稳定性影响数值分析[J]. 有色金属科学与工程,2012(6):55-60. http://ysjskx.paperopen.com/oa/DArticle.aspx?type=view&id=201210001 [16] 李桂臣,张农,刘召辉,等. 煤巷预应力桁架锚杆支护技术[J]. 采矿与安全工程学报,2007(2):150-154. http://www.cnki.com.cn/Article/CJFDTOTAL-KSYL200702005.htm

下载:

下载: