Influence of lead-zinc tailings on cement properties and mineral composition

-

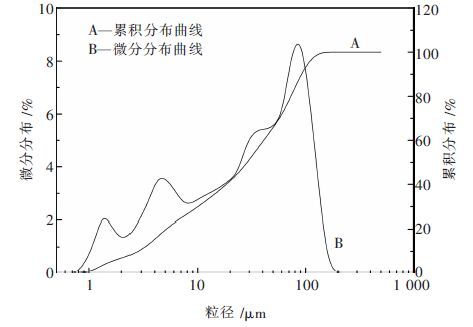

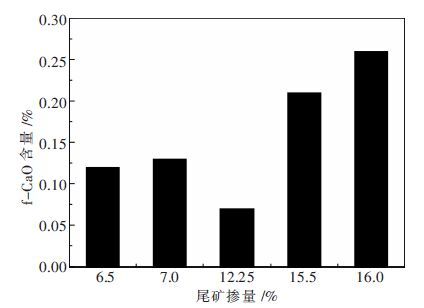

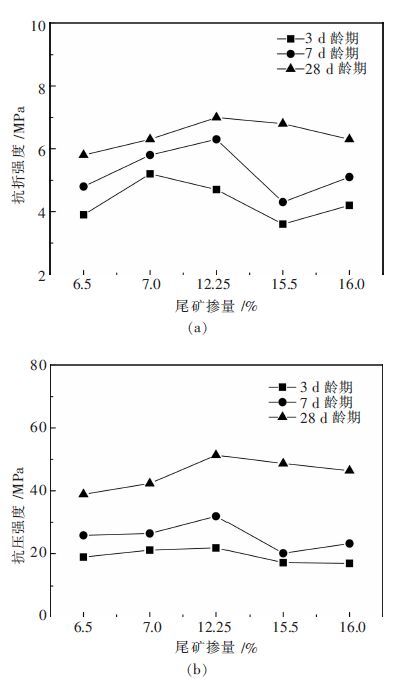

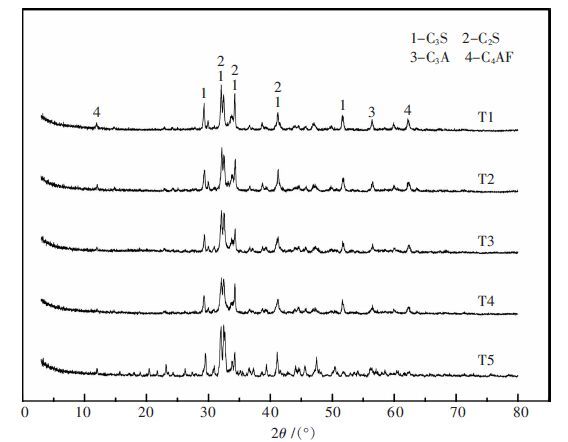

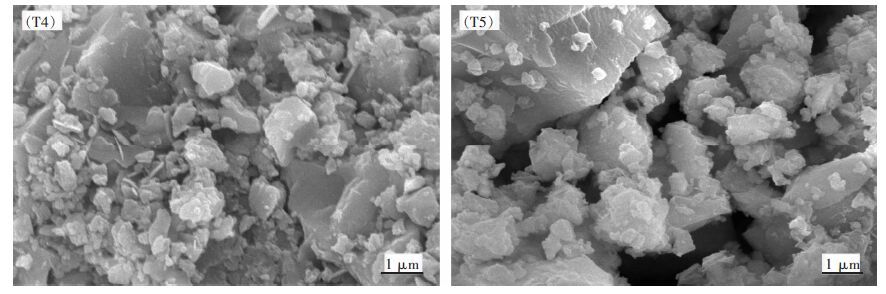

摘要: 研究以铅锌尾矿为水泥原料,设计不同尾矿掺量的配方分别在1350OC下般烧制备硅酸盐水泥熟料.采用甘油酒精法分析生料的易烧性,根据《水泥胶砂强度检l方法(ISO法nl量水泥各龄期的抗压、抗斤强度,用XRD研究了熟料的矿物组成,用SEM分析了矿物的晶体形貌.试验结果表明:当铅锌尾矿掺量为12.25%时,熟料中f-CaO含量最低,为0.07%.当铅锌尾矿掺量为12.25%-16%时,水泥各龄期强度均超过GB175-2007中规定的42.5标准水泥,其中铅锌尾矿掺量为12.25%时,3d、28d抗压强度分别为21.8MPa、51.3MPa.掺铅锌尾矿,熟矿物为C3S,矿物形成良好.Abstract: The paper mainly studies the Portland cement clinker prepared by using lead-zinc tailings as raw material, under the condition of different tailings dosages and the same temperature at 1 350 OC . The f -CaO content is tested by the glycerol alcohol method and the compressive strength and flexural strength are measured according to cement mortar strength detection method (ISO). Phase composition, chemical composition and microstructure of clinkers are characterized by using XRD and SEM. The results show that the f-CaO content is at its lowest of 0.07 % when the dosage of lead-zinc tailings is 12.25 %. The cement strength at various ages exceed the requirement of 42.5 standard cement in accordance with GB175 -2007 when the content of lead -zinc tailings is between 12.25 % and 16 % . And when the content of lead -zinc tailings is 12.25 % , the compressive strengths at 3 days and 28 days are 21.8 MPa and 51.3 MPa, respectively. After mixing proper content of lead-zinc tailings, the main clinker mineral is C3S with silicate crystals well formed.

-

Keywords:

- lead-zinc tailings /

- cement /

- burnability /

- C3S /

- compressive strength

-

震动是爆破的主要危害之一[1-3],是一个涉及爆源、传播介质、受震物体,受爆破参数、地质地层、结构响应等因素影响的复杂过程[4-5].在地下矿山,频繁爆破产生的震动对采空区、巷道、井筒、支护体、地表构筑物和尾矿库坝体的稳定性造成了极大的危害,信号的获取和分析研究是矿山爆破研究的重要内容[6-7].小波包技术具有多分辨分析特性,适合处理爆破震动等非平稳信号,针对小波技术只对低频部分持续分解, 造成高频部分频率分辨率差,小波包技术对信号高频部分同样细化分解,提高了信号高频部分的分辨率,是一种更加精细的信号分析方法[8-10]. 为此,借助小波包技术对某矿爆破震动信号进行分析.

1 矿山与测试

1.1 矿山概况

该矿位于地表侵蚀面之上,是急倾斜中厚矿体,矿石、夹石和顶底板围岩稳固性好;矿区含水层少,岩组富水性较弱,水文地质情况较好.采用水平扇形深孔阶段矿房法开采矿体(图 1),矿房沿走向布置,长度56 m,宽度12.7 m,阶段高度50 m,顶柱5 m,间柱6 m.炮孔由YT一28 型钻机钻进,孔径62~65 mm,孔深5~20 m,崩矿时采用导爆管雷管孔内微差起爆,水平扇形炮孔由下往上逐排爆破,矿石靠自重下放到底部结构.

1.2 仪器与测点

现场测试分5 组(A、B、C、D、E)实验,见图 1,爆源集中在该矿79 线的+372 m 分段的采矿进路和切割巷道,测点(1、2、3、4、5)布置在+384 m 分段的放顶巷道.

测试仪器为BlastmateⅢ 爆破测震仪[11],当质点速度超过0.1 mm 时,传感器自动触发,采样持续时间6 s,D、E 组采样率2 048 ,A、B、C 组采样率4 096,为方便分析,对其进行抽稀,变成2048.

1.3 测试结果

表 1是测震仪记录数据,图 2是B 组实验测试2号点的原始波形图,噪声充满整个时间采样坐标,波形出现只有正值部分的异常现象,信号分辨率差,分析前须进行去噪处理.

表 1 原始数据

2 小波包去躁

小波包去噪通常采用阔值法去噪,其基本步骤有[12-14]: ① 选定合适的小波基,对原始信号进行一定层次的分解; ② 确定阔值并对最底层小波包高频系数进行阔值量化; ③ 重构最底层小波包低频系数和经过量化处理的高频系数,得到真实信号.

爆破震动信号衰减迅速,常采用db 和sym 两类小波基进行分析[15],图 3是采用db8 小波基对原始波形进行3 层小波包分解去噪后的波形.去噪后,信 号的质点峰值速度(PPV) 由0.l52 0 cm/s 变成0.l53 0 cm/s,噪声强度达到0.0l6 5 cm/s.

3 小波包分解

奈奎斯特频率为采样率的一半[16],故信号的频率范围为0-l 024 Hz,选定db8 小波基对去噪后获取的真实信号进行4 层分解,则可获取24个频段长度为64 Hz 的分信号,其对应的频率范围分别为0~64 Hz、64~l28 Hz、… 、960~1 024 Hz.0~64 Hz、64~128Hz、64~192 Hz、192~256 Hz 这4 个频段( 图 4)的分信号,幅值较大,有明显的衰减,为信号分布的主要频率区域. 大于256 Hz 频段的分信号幅值很小,是信号的微弱部分,而爆破震动信号频率通常是在200 Hz 以下的区域,这也反证了小波包去噪的有效性.

4 实验分析

测振仪记录的数据变化复杂,规律性差.在相同爆破条件下,1、2、5 号测点的速度和频段分速度大致呈随距离增大而变小的规律.而3、4 号与1、2、5 号测点相比,总速度和频段分速度幅值大,其原因是1、2、5 号测点与爆源中间隔有一条放顶巷道,震动波传播实际距离比理论值更远,3、4 号测点与爆源同侧,震动波理论传播距离即为实际传播距离.

噪声呈随机、多变特性,与测试环境、传播介质等因素有关,但常与真实信号混叠,造成信号波形淹没,使PPV 增大或减小,降低原始信号的准确性与可靠性.

总体而言, 爆破震动速度在各频段均匀分布,没有明显集中现象,见表 2.但在一次爆破中,1、2 测点频段4 的分速度相对频段1、频段2 大,由于高频振动波在传播过程中容易被吸收,5 测点频段2 的分速度相对频段4 大,也即随着传播距离的增大,速度有向低频集中的趋势.实际工程中,在井筒、地表等地,距离爆源较远,爆破震动波频率易接近于构筑物的固有频率,产生共振效应,加大爆破震动危害.

表 2 频段分信号

为得出速度V、药量Q和距离R的关系,将国内外普遍采用的萨道夫斯基公式$V=k{{\left( \sqrt[3]{Q}/R \right)}^{a}}k\rho \left( k \right)$是与爆破条件有关的系数、a是与传播地层和介质有关的衰减指数、ρ是药量Q与距离R的组合值称为比列药量)引人,对去噪后的数据进行线性拟合,见图 5,得出a=1.459 5、k=10.657 0,也即该矿爆破震动速度的经验公式为$V=10.657{{\left( \sqrt[3]{Q}/R \right)}^{1.4595}}$.

5 结论

1) 噪声易与真实信号混叠,造成信号波形被淹没,使PPV 增大或减小,降低原始信号的准确性与可靠性.

2) 真实信号在0-256 Hz 均有分布,各频段未见明显集中现象,但在同一爆破中,随着传播距离的增加,速度有向低频集中的趋势.

3) 通过线性回归,得出该矿的萨道夫斯基公式衰减系数a=1.459 5、k=10.657 0,从而确定了爆破震动波衰减的经验公式,为矿山爆破设计提供了一定依据.

-

表 1 原料的化学成分 /%

原料 Ca0 SiO2 A12O3 Fe2O3 烧失量 石灰石 49.50 6.25 1.30 0.50 40.00 有色金属灰渣 12.62 30.77 15.04 33.54 0.00 石英采矿废石 0.30 94.00 1.00 0.24 0.80 粉煤灰 3.60 57.60 25.50 3.25 5.90 铅锌尾矿 14.57 49.18 11.60 11.90 4.10 表 2 水泥生料化学成分和率值

样品 尾矿掺量/% KH p SiO2 Al2O3 Fe2O3 Ca0 Mg0 烧失量 T1 6.5 0.880 1.950 1.570 13.87 4.34 2.77 42.31 1.39 33.51 T2 7.0 0.902 1.781 1.217 13.55 4.18 3.43 42.32 1.47 33.21 T3 12.25 0.921 2.300 1.590 13.85 3.81 2.40 42.86 1.38 33.77 T4 15.5 0.892 2.230 1.270 14.30 3.59 2.82 42.61 1.46 33.15 T5 16.0 0.921 2.430 1.440 14.15 3.44 2.39 42.99 1.41 33.57 -

[1] 高国龙, 张望, 周连碧, 等. 桥口铅锌尾矿库重金属迁移转化规律研究[J]. 有色金属工程, 2013, 3(3): 41-44. http://www.cnki.com.cn/Article/CJFDTOTAL-YOUS201303016.htm [2] 吴振清, 周进军, 唐声飞, 等. 利用铅锌尾矿代替粘土和铁粉配料生产水泥熟料的研究[J]. 新世纪水泥导报, 2006, 12(3): 31-32. http://www.cnki.com.cn/Article/CJFDTOTAL-SNDB200603011.htm [3] 刘振肖, 陈建宏. 基于模糊综合评判的尾矿库土地复垦效益评价[J]. 矿业研究与开发, 2010, 30(4): 97-100. http://www.cnki.com.cn/Article/CJFDTOTAL-KYYK201004032.htm [4] 黄光耀, 冯其明, 欧乐明, 等. 利用微泡浮选柱从浮选尾矿中回收微细粒级自钨矿[J]. 中南大学学报 : 自然科学版, 2009, 40(2):263-267. http://www.cnki.com.cn/Article/CJFDTOTAL-ZNGD200902004.htm [5] 张平, 甘国娟, 廖柏寒, 等. 铅锌矿区重金属复合污染对土壤酶活性的影响[J]. 安全与环境学报, 2013, 13: 147-150. http://www.cnki.com.cn/Article/CJFDTOTAL-AQHJ201303034.htm [6] Choi W H, Lee S R, Park J Y. Cement based solidification/stabi- lization of arsenic-contaminated mine tailings[J]. Waste manage- ment, 2009, 29(5): 1766-1771. doi: 10.1016/j.wasman.2008.11.008

[7] Kohfahl C, Graupner T, Fetzer C, et al. The impact of cemented layers and hardpans on oxygen diffusivity in mining waste heaps a field study of the Halsbrücke lead-zinc mine tailings (Germany)[J]. Science of the Total Environment, 2010, 408(23): 5932-5939. doi: 10.1016/j.scitotenv.2010.08.034

[8] Kesimal A, Yilmaz E, Ercikdi B. Evaluation of paste backfill mixtures consisting of sulphide-rich mill tailings and varying ce- ment contents[J]. Cement and concrete research, 2004, 34(10): 1817-1822. doi: 10.1016/j.cemconres.2004.01.018

[9] 卢红. 国内铅锌尾矿回收为建筑材料应用概况[J]. 福建建材, 2013(9): 19-20. http://www.cnki.com.cn/Article/CJFDTOTAL-FJJC201309009.htm [10] 沈雪飞, 薛群虎, 徐亮, 等. 利用铅锌尾矿制备天然水硬性石灰可行性研究[J]. 硅酸盐通报, 2013, 32(10): 1973-1978. http://www.cnki.com.cn/Article/CJFDTOTAL-GSYT201310009.htm [11] 施正伦, 骆仲泱, 林细光, 等. 尾矿作水泥矿化剂和铁质原料的试验研究[J]. 浙江大学学报:工学版, 2008, 42(3): 506-510. http://www.cnki.com.cn/Article/CJFDTOTAL-ZDZC200803028.htm [12] 何哲祥, 周喜艳, 肖祈春 . 尾矿应用于水泥原料的研究进展 [J].资源环境与工程, 2013, 27(5): 724-727. http://www.cnki.com.cn/Article/CJFDTOTAL-HBDK201305031.htm [13] 苏达根, 周新涛. 钨尾矿作环保型水泥熟料矿化剂研究 [J]. 中国钨业, 2007, 22(2): 31-33. http://www.cnki.com.cn/Article/CJFDTOTAL-ZGWU200702007.htm [14] 田吉宁, 崔工伟, 余鑫, 等. 铅锌尾矿作矿化剂应用探讨[J]. 广西节能, 2001 (1): 21-22. [15] 宣庆庆, 李东旭, 罗治敏. 铅锌尾矿用于中热水泥的制备[J]. 材料科学与工程学报, 2009, 27(2): 266-270. http://www.cnki.com.cn/Article/CJFDTOTAL-CLKX200902032.htm [16] 宣庆庆, 朱建平, 李东旭, 等. 用铅锌尾矿制备中热水泥熟料的研究[J]. 硅酸盐通报, 2007(10): 930-934. http://www.cnki.com.cn/Article/CJFDTOTAL-GSYT200705018.htm [17] 张献伟. 铅锌尾矿渣代替硫酸渣烧石英尾矿代替粘土生产水泥熟料[J]. 河南建材, 2004(2): 18-30. http://www.cnki.com.cn/Article/CJFDTOTAL-HNJC200402006.htm [18] 张晶晶, 齐砚勇, 温馨. 煅烧温度对水泥熟料主要矿物形成的影响[J]. 硅酸盐通报, 2013, 23(9): 1756-1762. http://www.cnki.com.cn/Article/CJFDTOTAL-GSYT201309012.htm

下载:

下载: